SO-LOW FDC nCOMPASS User manual

INSTRUCTIONS: SINGLE STAGE FREEZER

1.1 RANGE OF ENVIRONMENTAL CONDITIONS FOR WHICH

THIS EQUIPMENT IS DESIGNED

1. Indoor use.

2. Altitude up to 2000m.

3. Temperatures 15°C to 30°C ( 60°F TO 85°F )

4. Recommended humidity range of 30% to 90%.

5. Mains supply fluctuations up to -5% to +10% of the nominal voltage.

6. Transient overvoltages typically present on the mains supply (overvoltage category II). Pollution

degree 1.

CAUTION! THIS FREEZER IS PROVIDED WITH AN INPUT CIRCUIT

PROTECTIVE DEVICE WHICH SHALL BE MAINTAINED AND SERVICED

BY QUALIFIED PERSONNEL ONLY.

FUSES OR BREAKERS USED INSIDE PROTECTIVE DEVICE

15A OR 20A 250V TIME DELAY

WARNING! UPLUG FREEZER BEFORE ANY TECHNICAL SERVICE IS

PREFORMED ON THE UNIT!

CAUTION! DO NOT POSITION EQUIPMENT SO IT IS DIFFICULT TO

DISCONNECT FROM THE POWER SUPPLY.

1.2 STARTING INSTRUCTIONS

1. Plug the freezer into the proper outlet with an adequate power supply.

2. Confirm the freezer has at least 6” of air space on each side, for air circulation.

3. Turn the refrigeration switch (located in back of unit) to the ON position (if applicable).

4. The compressor(s) will start to operate and pull down to the set point on the

temperature control.

5. When the freezer reaches the set point, the compressor(s) will cycle on and off to

maintain the set point desired by the user on the temperature control.

1.3 CLEANING PROCEDURE

1. Wipe down the exterior of the freezer with a soft cloth and spray type polish.

2. If frost builds up in the chamber, a bucket and ice-scraper can be used to remove the ice.

If excessive ice builds up, the unit can be defrosted (see below).

1.4 DEFROST PROCEDURE

1. Remove any product in the freezer and store it in a back-up freezer or elsewhere.

2. Unplug the freezer, and open the freezer front door / lid.

For upright units, use a cloth to protect the control from dripping water.

3. Air out the freezer for at least 12 hours, allowing the unit to reach room temperature.

4. Take a rag and wipe up all the excess water in the unit (melted frost).

5. Plug the unit in and set your temperature to the desired setpoint

6. Once the desired temperature is reached, add product back into the unit.

NOTE: It is recommended to slowly re-add your product into the freezer to prevent

an extreme load on the compressors, which could shorten freezer life expectancy.

1.5 AUTOMATIC STARTING SYSTEM

The automatic starting system is provided on all freezer systems in case of power failure.

If there is an electrical power interruption to the unit and power is not restored

immediately, the unit will automatically start up whenever power is returned.

ATTENTION: Always leave the refrigeration switch in ON position, as this will

automatically activate the automatic starting system.

Single Stage

After power restoration, the single stage will start to operate and begin to pull down to

setpoint temperature.

CAUTION! COVER SCREEN ON BACK OF FREEZER TO BE REMOVED BY

AUTHORIZED PERSONNEL ONLY. FOR CONNECTIONS TO THE

EXTERNAL ALARM COVER SCREEN MUST BE REPLACED BEFORE

PUTTING FREEZER INTO SERVICE. FAILURE TO REINSTALL COVER

COULD RESULT IN HAZARD.

1.7 WARNING SYMBOLS

BLACK WITH YELLOW

BACKGROUND

LIGHTNING

BOLT

CAUTION: RISK OF

ELECTRICAL

SHOCK

BLACK WITH YELLOW

BACKGROUND

EXCLIMATION

POINT

CAUTION: REFER TO

ACCOMPANYING

DOCUMENTS

1.8ALARM SYSTEM

MODEL

OPERATION INSTRUCTIONS

FDC nCOMPASS

Alarm will automatically activate when freezer is connected to a

power source.

FDC 4000

Alarm will automatically activate when the freezer reaches set point

or 8 hours after the unit has been first plugged in.

FDC 4100

Manually activate the alarm by moving the toggle switch to the on

position once the freezer reaches setpoint.

PARTLOW 1160

Manually activate the alarm by moving the toggle switch to the on

position once the freezer reaches setpoint.

The alarm will not sound again until the temperature varies 12°C (20°F) from the

temperature control set point. Please note that the alarm will sound if there is a power

outage to the freezer.

Alarm system should be tested every 30 days.

Non-rechargeable batteries should be changed approximately every two years.

Rechargeable batteries should be changed approximately every three years with

lead acid rechargeable 12 Amp per hour, model PS-12120F2 or equivalent.

1.9 ALARM BATTERY TESTING

If applicable, the alarm switch has a test position that can be used anytime to see if the

battery is charged or if the buzzer is working properly.

OPTIONAL EQUIPMENT –DRY CONTACT ALARM RELAY

Located on the back of the freezer is a terminal strip marked ALARM RELAY CONTACTS.

Rating of this connection:

ALARM RELAY CONTACTS CONNECTION RATING

PARTLOW 1160

FDC 4100

FDC 4000

FDC nCOMPASS

10A 250VAC

10A 250VAC

2A 125 VAC

2A 250 VAC

10A 30VDC

10A 30VDC

2A 30 VDC

2A 30 VDC

RED –NORMALLY CLOSED

WHITE –COMMON

BLUE –NORMALLY OPEN

CAUTION! IF IT IS NECESSARY TO REMOVE METAL COVER SCREEN ON

BACK OF FREEZER TO MAKE CONNECTIONS TO ALARM RELAY, COVER

MUST BE REPLACED BEFORE FREEZER IS PUT INTO OPERATION

2.0 TEMPERATURE CONTROL

This freezer includes a digital temperature control which displays the setpoint and actual

temperature of the unit on the display screen.

The temperature control is manually adjustable to the desired temperature in 1° C

increments within the limits of the control range.

WARNING

Unauthorized entry into this control will void warranty.

SO-LOW CONTROL MODELS

PARTLOW 1160

FDC 4100

FDC 4000

FDC nCOMPASS

PARTLOW 1160

FDC 4100

SO-LOW

T

S

FDC 4000

“”””””””””

“””””””””

“””””””””””

“”””””””””

FDC

nCOMPASS

FDC nCompass

VERSION 6.1.17

Notes, cautions and warnings appear throughout this book to draw your attention to important

operational and safety information.

A “NOTE” marks a short message to alert you to an important detail.

A “CAUTION” safety alert appears with information that is important for protecting your

equipment and performance.

A “WARNING” safety alert appears with information that is important for protecting you, others and

equipment from damage. Pay very close attention to all warnings that apply to your application.

This symbol (an exclamation point in a triangle) precedes a general CAUTION or WARNING

statement.

This symbol (a lightning bolt in a lightning bolt in a triangle) precedes an electric shock hazard

CAUTION or WARNING safety statement.

Future Design Controls, Inc.

7524 West 98th Place

Bridgeview, IL 60455

Tel: (888) 751-5444

Fax: (888) 307-8014

FDC nCompass

VERSION 6.1.17

The nCompass display is split into two sections; the upper icon bar and bottom main display area.

The basic functions and settings for the upper Icon Bar are listed below:

The menu icon will open the main menu for navigating to the different control and

monitoring screens. Menu items will dynamically appear providing available options

based on the system area the user is in, i.e., security, data logging, setup, etc.

The information (help) icon will display text based help associated with the current

screen. Help is available in three languages, English, Spanish and French based on

the user selection in the offline setup of section of nCompass.

The home icon will return the user to the main view from anywhere in the nCompass

application. The main view is set by the OEM in the nCompass configuration and can

be the single or dual loop, trend, alarm, alarm history, event or digital IO view.

The alarm icon will appear and flash when a new system alarm occurs. Pressing the

alarm icon will take the user directly to the alarm monitor screen in order to view and

/or reset the active alarm condition.

The speaker icon will open the volume control menu, which controls the audible level

of temperature and condition alarms. The volume setting of “100”is the factory default

setting. Moving the volume dial to the “0”will disable the audible alarm.

IMPORTANT: Do not use any sharp or metal objects on the touch screen as they may damage the

surface. Also be sure that hands and fingers are free from oils or chemicals which may

mar the surface of the touch screen

Attention: Loading time between menu screens or parameter selection screens may vary.

Some menu screens may require several seconds to load before the information is displayed.

Pushing the display several times while a menu or parameter is loading may result in menus

being opened, or parameters being changed unintentionally.

Icon Bar

Main Display

FDC nCompass

VERSION 6.1.17

The nCompass display is split into two sections; the upper icon bar and bottom main display area.

The basic functions and settings for the bottom Display Area are listed below:

LOCATION

FUNCTION

ICON

DESCRIPTION

A

Temperature

Scale

This display shows the temperature scale of the freezer (°C or °F).

Pressing this display allows you to reset the historical maximum and minimum

temperature (see location C for additional information).

B

Setpoint

Temperature

This number display shows the setpoint temperature of the unit.

Press and release the red numbers to change the setpoint temperature. Input the

new setpoint temperature with number pad and press and release the done key.

C

Actual

Temperature

This number display shows the actual temperature inside the unit.

Pressing this display will show the historical maximum and minimum temperatures.

The historical record can be set by pressing the Temperature Scale button.

D

Snowflake

This display shows when the refrigeration system compressors are cycled on.

There is no additional functionality of this icon.

E

Alarm Test

This display shows if the alarm test is active. Pressing this display will move the

slider to the ON position, and sound the audible alarm as a test. Note that if the

volume is set to “0”, no alarm will sound. Press the icon again to reset it to OFF.

F

Power

Connection

This display shows the current power connection for the control. If the control is on

AC power, a green plug icon will appear. If the control is on backup battery power, a

red battery icon will appear. There is no additional functionality of this icon.

Note: When changing unit setpoint temperature, the unit must have active power from an

electrical grid for at least 5 minutes after the setpoint temperature is changed, for the new

setpoint to become permanent.

If electrical power to the control is lost before the 5 minute setpoint adjustment period,

the unit will restore itself to the last saved setpoint temperature on power start-up.

C

E

B

D

A

F

FDC nCompass

VERSION 6.1.17

In the case of power failure, the nCompass temperature control switches from AC power to a backup

battery located inside the electrical panel of the freezer. This battery is the 6 volt rechargeable type, and

is designed to last approximately 24-48 hours during power failure. It is recommended to test the battery

on a regular basis and replace the battery when needed (approximately 3-5 years).

ATTENTION: The battery backup system only powers the control during power failure.

It does not power the refrigeration system, and the freezer will not run during power failure.

When unplugging the freezer to put it into storage, the power failure alarm will sound. To disable this

power failure alarm, you will need to disconnect the battery; which is located in the electrical panel.

To do this, complete the following procedure:

1. Locate the electrical panel on the side of the freezer.

2. Remove the screws with a Phillips screwdriver, and remove the panel.

3. Locate the battery (which is clearly marked) in the lower right hand corner.

4. Disconnect one lead from the battery by removing the connector on the battery.

5. When returning the unit to service, complete steps 1-4, but reconnect the unplugged battery in

step 4. Then plug the freezer into the outlet to restore power.

It is recommended to keep the freezer plugged in and running when possible. Leaving the unit

unplugged for long periods of time may shorten the life expectancy of the freezer.

SIDE OF FREEZER

ELECTRICAL PANEL BOX

CAUTION

RISK OF ELECTRICAL SHOCK

USE CAUTION NEAR ELECTRICAL CONNECTIONS

FDC nCompass

VERSION 6.1.17

The nCOMPASS controller plate located on the front of the chamber can be vertical or horizontal

depending on the orientation of your unit. Upright freezer models use the horizontal format (shown in

the picture below to the left). Chest freezer models use the vertical format (shown in the picture below to

the right).

UPRIGHT STYLE CHEST STYLE

STEP

DESCRIPTION

ICON

INSTRUCTIONS

1

Insert USB

Insert your USB Drive / Flash Drive into the USB port located on the front of

the control.

2

Home Menu

Press the menu icon, at the top of the display area.

This will open the Home menu.

3

Data Menu

Press the Data button, located in the Home menu.

This will open the Data panel. This menu controls how data is transfer to

your USB device.

4

Specify name

of Data File

(Optional) Enter the requested information into the File Name field. If no file

name is entered, the control will automatically generate a file name for you.

5

Save Data

Press the Save button, located in the Data menu.

6

Home

Press the home key, to return to the home screen.

7

Remove USB

Remove your USB Drive / Flash Drive from USB port located on the front of

the control.

nCOMPASS

SO-LOW

ENVIRONMENTAL

nCOMPASS

SO-LOW

ENVIRONMENTAL

USB PORT

FDC nCompass

VERSION 6.1.17

On the bottom of the freezer ( located either next to the electrical panel, or on the back of the unit ), is an

RJ45 ethernet connection port. This connection port can be used to connect the nCompass control to

your local computer network. When connected to your computer network the nCompass control has

access to the following functionality:

•VNC access for remote connection, for local network users.

When your local computer network also has internet access, the nCompass control has access to the

following functionality:

•Email (and text) alerts to a specified email address (or phone).

•Upload temperature data to an FTP server

EMAIL / TEXT ALARMS MAY NOT OPERATE DURING POWER FAILURE

IF YOUR NETWORK IS NOT PROPERLY CONFIGURED

The battery backup system on the freezer only powers the control during power failure. It does

not power any additional network systems which may be required for your internet to operate.

It is recommended to have your local network router, and modem, connected to a battery

backup, so the freezer’s internet connection will continue to operate during power failure.

Follow the below procedure for adjustments which require the DATA setting to be turned OFF.

Follow the below procedure for adjustments which require the DATA setting to be turned ON.

ATTENTION: While the DATA setting is turned OFF, temperature data will not be recorded.

1

Home Menu

Press the menu icon, at the top of the display area.

This will open the Home menu.

2

Data Menu

Press the Data button, located in the Main menu.

This will open the Data panel.

3

DATA

Press the Data button on the right hand side to turn the data light off/on.

A BRIGHT green light indicates the data is turned on.

A DARK green light indicates the data is turned off.

4

Home

Press the home key, to return to the home screen.

FDC nCompass

VERSION 6.1.17

The nCOMPASS temperature controller has an adjustable temperature scale ( Celsius of Fahrenheit ).

Note: Once the temperature scale has been changed, all past and future temperature data will

be converted into the selected temperature scale.

STEP

DESCRIPTION

ICON

INSTRUCTIONS

1

DATA OFF

Follow the steps in the DATA SETTINGS ADJUSTMENTS

to turn the data OFF.

2

Home Menu

Press the menu icon, at the top of the display area.

This will open the Home menu.

3

Settings

Press the settings button, located in the Home menu.

This will open the Settings panel.

4

Settings Menu

Press the menu icon, at the top of the display area.

This will open the settings menu.

5

Offline Mode

Press the offline button, located in the Settings Menu.

Press YES when prompted to open the control in offline mode.

This will open the Offline mode panel.

6

Offline Menu

Press the menu icon, at the top of the display area.

This will open the offline menu.

7

Units

Press the units button, located in the Offline menu.

This will open the units panel.

8

Select Scale

Select the temperature scale (Celsius of Fahrenheit) you wish to display.

A BRIGHT yellow icon indicates the scale has been selected.

A DARK yellow icon indicates the scale has not been selected.

9

Home

Press the Home button when completed, to return to the home screen.

10

DATA ON

Follow the steps in the DATA SETTINGS ADJUSTMENTS

to turn the data ON.

FDC nCompass

VERSION 6.1.17

The nCOMPASS temperature controller has an adjustable offset to calibrate the temperature control.

Note: Adjustments made to the temperature offset will calibrate the control. Adjusting this

setting improperly can cause inaccuracies and fluctuations in the temperature of the freezer.

STEP

DESCRIPTION

ICON

INSTRUCTIONS

1

DATA OFF

Follow the steps in the DATA SETTINGS ADJUSTMENTS

to turn the data OFF.

2

Home Menu

Press the menu icon, at the top of the display area.

This will open the Home menu.

3

Settings

Press the settings button, located in the Home menu.

This will open the Settings panel.

4

Settings Menu

Press the menu icon, at the top of the display area.

This will open the settings menu.

5

Offline Mode

Press the offline button, located in the Settings Menu.

Press YES when prompted to open the control in offline mode.

This will open the Offline mode panel.

6

Offline Menu

Press the menu icon, at the top of the display area.

This will open the offline menu.

7

Calibrate

Press the calibrate icon, located in the Offline menu.

This will open the calibration menu.

8

User Calibration

Press “Perform User Calibration Offset”

This will open the user calibration menu.

9

Low Point Offset

Enter the desired offset in the Low Point Offset Field.

10

Done

Press “Done”when completed.

11

Home

Press the Home button when completed, to return to the home screen.

12

DATA ON

Follow the steps in the DATA SETTINGS ADJUSTMENTS

to turn the data ON.

FDC nCompass

VERSION 6.1.17

The nCOMPASS temperature controller has an adjustable alarm differential, to set when the freezer

goes into alarm state.

Note: Improper adjustments to the Alarm Differential could result in the alarm not operating as

designed. The factory configuration for the Alarm Differential is 12.

It is not recommended to set the Deviation Band to a value less than 10, as this may

result in the alarm sounding during the freezers normal temperature cycle.

STEP

DESCRIPTION

ICON

INSTRUCTIONS

1

Home Menu

Press the menu icon, at the top of the display area.

This will open the Home menu.

2

Settings

Press the settings button, located in the Home menu.

This will open the Settings panel.

3

Settings Menu

Press the menu icon, at the top of the display area.

This will open the settings menu.

4

Alarm

Press the alarm button, located in the Settings menu.

This will open the Alarm panel.

5

Deviation Band

Set the Deviation Band value to the desired Alarm Differential.

Note: Alarm #1, and Alarm #2 can be set for different values for

different alarm states.

6

Home

Press the Home button when completed, to return to the home screen.

The nCompass Control uses a custom Windows CE based software stored on an internal hard drive

inside the device. Future Design Controls Windows CE based nCompass display and Control Module

(Idec PLC) software (listed as “SOFTWARE” in this document) is protected by copyright laws and

international copyright treaties, as well as other intellectual property laws and treaties. All ownership and

rights remain with Future Design Controls. The nCompass Control does not receive software updates

though the internet, or other means.

DO NOT ATTEMPT TO REMOVE THE HARD DRIVE FROM THE DEVICE.

DO NOT ATTEMPT TO REMOVE THE SD CARD FROM THE DEVICE.

To remove user data from the SD Card, please contact Future Design Controls, Inc. (888-751-5444)

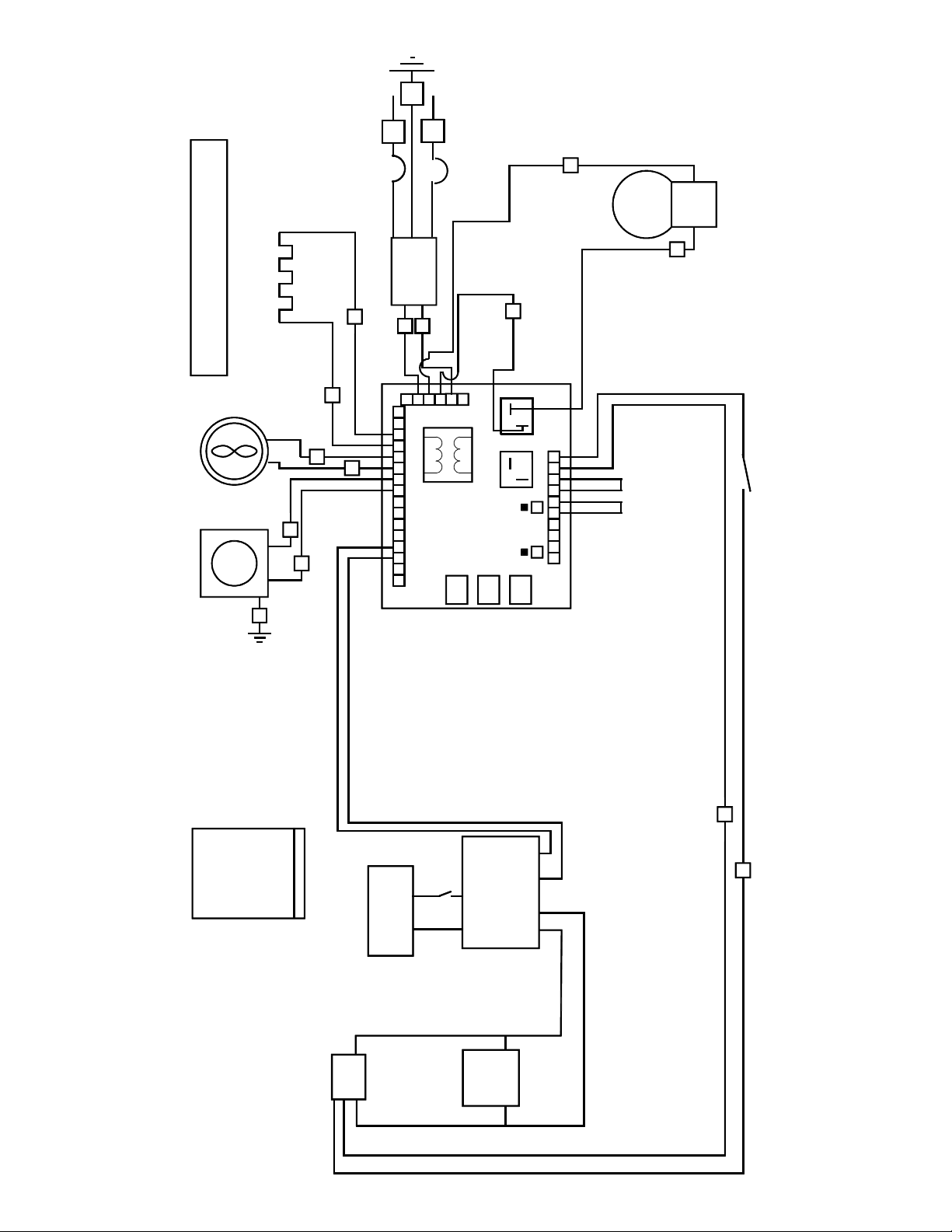

COLOR CODE CHART

YELLOW = Y

ORANGE = O

BLUE = B

RED = R

WHITE = W

BLACK = BK

COND. FAN(S)

TRANSFORMER

(IF APPLICABLE)

TEMP. REC.

(IF APPLICABLE)

COMPRESSOR

HEATER(S)

B

R

B

B

R

R

ELECTRICAL DIAGRAM

NOTE: ACCESSORIES ARE CONNECTED TO AC TERMINAL STRIP

W

BK

GREEN/YELLOW = GY

GY

BK

W

GREEN = G

G

CIRCUIT BREAKER

TC INPUT

BK

230 VOLTS, 50/60 HERTZ, 1 PHASE

UPS

+-

CONTROLER

B 42

BLACK

BLACK

RED

BLACK

BATTERY

KEY SWITCH

+-

5-23-2017

BLACK

NC230 UPS SINGLE STAGE

(IF APPLICABLE)

REFRIGERATION SWITCH

(IF APPLICABLE)

BK

BK

BK

BK

EVAPORATOR

HEAT EXCHANGER

CAPILLARY TUBE

DRIER

COMPRESSOR

OIL SEPARATOR

(IF APPLICABLE)

REFRIGERANT FLOW CHART

FLSS

LOW SIDE VALVE

HIGH SIDE VALVE (IF APPLICABLE)

AIR COOLED CONDENSER

TO ENSURE YOU ARE PROVIDED THE CORRECT PARTS,

THE MODEL AND SERIAL NUMBER OF YOUR UNIT

MUST BE PROVIDED WHEN ORDERING.

COMPRESSOR MODEL

HP

VOLTAGE

HERTZ

PHASE

SO-LOW PART #

TECUMSEH AJB2433ZXA

1

115

50/60

1

AJB24-115

TECUMSEH AJB2433ZXD

1

208/220/230

50/60

1

AJB24-208

EMBRACO FFI12HBX

1/3

115

50/60

1

FF12-115

DANFOSS SC15FTX

1/3

115

50/60

1

SC15-115

DANFOSS SC18FTX

1/2

208/220/230

50/60

1

SC15-208

TEMPERATURE CONTROL PARTS

SO-LOW PART #

FDC 4100

4100

FDC 4000

4000

FDC nCOMPASS

nCOMPASS

CASCADE ELECTRICAL PARTS

SO-LOW PART #

Heater Harness No. H-200

217-VOLTAGE

Refrigeration Switch No. 2X464

TOGGLE

Condenser Fan Motor No. GE-5411 - 115/60/1

500-115

Condenser Fan Motor No. GE-5421 - 230/50-60/1

500-VOLTAGE

Electrical Cord No. 8-3 (Please Specify Voltage)

PWRCRD-VOLTAGE

Control Board No. CECB2TUV (Please Specify Voltage)

231-VOLTAGE

REFRIGERATION PARTS

SO-LOW PART #

Air Cooled Condenser No. 3CZ0602B

254

Heat Exchanger, No. HE-502

HX-SS

Drier No. C-052-S

256L

Capillary Tube No. CT-502

SSC-23

Oil Separator, Temprite Series 900 (If Applicable)

900

HARDWARE PARTS

SO-LOW PART #

Latch No. METL-L1-99

REX37L1-3

Chest Hinge

59-928M

Upright Hinge No. Polar 109-LH

59-928U

Cabinet Gasket

NX504B1

Lid or Door Gasket

PSOS

Grill No. 650H

356F, 356S

Sub-Lids (Must have Model Number)

SL-MODEL NUMBER

Inner Door (Must have Model & Serial Number)

357-MODEL NUMBER-SERIAL NUMBER

Clips & Rollers for Inner Doors (Quantity 10 minimum)

405

Shelves for Freezer (Must have Model Number)

4015-MODEL NUMBER

SS REFRIGERATION & HARDWARE PARTS LIST

This manual suits for next models

3

Table of contents

Other SO-LOW Freezer manuals