SO-LOW PV85 Series User manual

ULTRA LOW FREEZER

U85 / C85 / PH85 / PV85 SERIES

INSTRUCTIONS

USER MANUAL

WARNING: READ BEFORE CONTINUING

To reduce the risk of fire, electric shock or injury to persons using this freezer, read all

instructions and follow basic safety precautions before using the unit, including the following:

Do not modify the plug provided with the freezer. If it will not fit the outlet,

have a proper outlet installed by a qualified electrician.

Do not position equipment so it is difficult to disconnect from the power supply.

freezer must be at least 6” away from any wall or object on any side.

While under warranty, do not attempt to repair or replace any part of the

freezer for servicing without first contacting the So-Low Service Department.

SAVE THESE INSTRUCTIONS

So-Low Environmental Equipment Company

10310 Spartan Drive

Cincinnati, OH 45215-1221

Tel: 513-772-9410

http://www.so-low.com

For customer service:

Email: sales@so-low.com

For parts replacement:

Email: parts@so-low.com

For technical support:

Email: service@so-low.com

CONTENTS

♦SYMBOLS AND STARTING INSTRUCTIONS………………………..

1

● MEANING OF ILLUSTRATED SYMBOLS…………………………………...

1

● STARTING INSTRUCTIONS…………………………………………………..

1

♦UNIT REQUIREMENTS………………………………………………….

2

●

PRE-INSTALLATION INFORMATION………………………………………...

2

♦PREVENTATIVE MAINTENANCE…..………………………………….

3

● FREEZER STORAGE PROCEDURE……………………………………..….

3

● ALARM BATTERY REPLACEMENT…...……………………………………..

4

● CLEANING PROCEDURE……………………………………………………..

5

● DEFROSTING PROCEDURE………………………………………………….

5

● CLEANING AIR CONDENSER………………………………………………... 6

♦UNIT OPERATION………………………………………………………..

7

● CHANGING SETPOINT / OPERATION TEMPERATURE………….………

7

♦ALARM OPERATION…………………………………………………….

8

● ALARM SYSTEM……………………………………………………………….. 8

● DRY CONTACT RELAY………………………………………………………..

8

♦CONTROL PROGRAMMING……………………………………………

9

● CONTROL KEYS & DISPLAYS………………………………………………..

9

● CONTROL DISPLAY VALUES………………………………………………... 10

● USER PARAMETER MODE…………………………………………………...

10

● PROGRAM PARAMETER MODE…………………………………………….

11

● CALIBRATION PROCEDURE………………………………………………...

12

♦FREQUENTLY ASKED QUESTIONS…………………………………..

13

♦REPLACEMENT PARTS LIST…………………………………………..

14

♦TECHNICAL SUPPORT………….………………………………………

15

♦MAINTENANCE CHECKLIST….………………………………………..

16

Explanation

SYMBOLS AND STARTING INSTRUCTIONS

ILLUSTRATED SYMBOLS

Various symbols are used in this safety manual in order to use the unit without

danger of injury and damage of the unit. Be sure that you understand the

warnings and cautions in this manual before operating the unit.

CAUTION

BLACK WITH YELLOW BACKGROUND

LIGHTNING BOLT

CAUTION, RISK OF ELECTRICAL SHOCK

WARNING

BLACK WITH YELLOW BACKGROUND

EXCLAMATION POINT

CAUTION, REFER TO ACCOMPANYING DOCUMENTS

1. Move the freezer to an indoor location, and plug the freezer into an appropriate

outlet with an adequate power supply. Consult your maintenance department for

additional information on the proper electrical configuration for this unit.

2. Once plugged in, the compressor(s) will start to operate and pull down to the

setpoint on the temperature control. The freezers default setpoint is -85°C for

cascade units, and -40°C for single stage units.

3. Allow the freezer to reach the setpoint temperature. Depending on the size of the

unit, this may take up to 12 hours.

4. Product can now be loaded into the freezer for storage.

To prevent overloading the cooling system, product should be

loaded gradually, in batches. Allow the temperature to recover to

setpoint before the next batch of product is loaded into the unit.

1

Unit Information

MEANING OF ILLUSTRATED SYMBOLS

UNIT REQUIREMENTS

STARTING INSTRUCTIONS

RANGE OF ENVIRONMENTAL CONDITIONS

FOR WHICH THIS EQUIPMENT IS DESIGNED

1. Indoor use.

2. Altitude up to 2000m.

3. Ambient temperatures 15°C to 30°C ( 60°F TO 85°F )

4. Recommended humidity range of 30% to 90%.

5. Mains supply fluctuations up to -5% to +10% of the nominal voltage.

6. Transient over-voltages typically present on the mains supply

(overvoltage category II). Pollution degree 1.

WARNING

DURING OPERATION THIS UNIT MUST REMAIN IN UPRIGHT

POSITION. DURING TRANSPORATION UNIT MUST NOT BE

TIPPED MORE THAN 45° FROM UPRIGHT POSITION.

CAUTION

UNPLUG UNIT AND SWITCH OFF ELECTRICAL BREAKER

BEFORE ANY TECHNICAL SERVICE IS PERFORMED.

CAUTION

COVERS ON BACK / SIDE OF FREEZER MAY ONLY BE

REMOVED BY AUTHORIZED PERSONNEL. FAILURE TO

RE-INSTALL COVER COULD RESULT IN HAZARD.

CAUTION

UNIT MUST BE OPERATED ON A DEDICATED ELECTRICAL

LINE. USING A NON-DEDICATED LINE MAY RESULT IN UNIT

STARTUP FAILURE.

CAUTION

ONLY PLUG THIS UNIT INTO THE PROPER OUTLET. DO

NOT ATTEMPT TO MODIFY PLUG IN ANY WAY. IMPROPER

USE OF THE ELECTRICAL PLUG WILL VOID WARRANTY.

WARNING

DO NOT POSITION EQUIPMENT SO IT IS DIFFICULT TO

DISCONNECT FROM THE POWER SUPPLY.

2

PRE-INSTALLATION INFORMATION

PREVENTATIVE MAINTENANCE

FREEZER STORAGE PROCEDURE

The unit can be turned off for storage by unplugging the unit from the wall

outlet and/or switching off the electrical breaker in the electrical box.

ATTENTION

RISK OF ELECTRICAL SHOCK

USE CAUTION NEAR ELECTRICAL CONNECTIONS

Once the unit is unplugged, the freezer will go into “Power Failure” alarm.

To disable the Power Failure alarm;

1. Locate the electrical panel on the side of the freezer.

2. Remove the screws with a Phillips screwdriver, and remove the panel.

3. Locate the battery (which is clearly marked) in the lower right hand corner.

4. Disconnect one lead from the battery by removing the connector on the battery.

5. When returning the unit to service, complete steps 1-4, but reconnect the

unplugged battery in step 4. Then plug the unit into the outlet to restore power.

NOTICE

SEE STARTING INSTRUCTIONS ON PAGE 1

WHEN PUTTING UNIT BACK INTO SERVICE.

3

PREVENTATIVE MAINTENANCE

ALARM BATTERY REPLACEMENT

NOTICE

THE LO-BAT (LOW BATTERY ALARM) IS NOT ABLE TO BE

SILENCED OR DISABLED.

TO REDUCE THE VOLUME OF THE ALARM UNTIL A

REPLACEMENT CAN BE INSTALLED, A PIECE OF TAPE CAN

BE PLACED OVER THE BUZZER HOLE ON THE CONTROL

To reduce the risk of fire, electric shock or injury to persons using this

freezer, read all instructions and follow basic safety precautions.

CAUTION

DISCONNECT THIS UNIT FROM THE POWER SUPPLY

BEFORE PERFORMING MAINTENANCE ON THE UNIT.

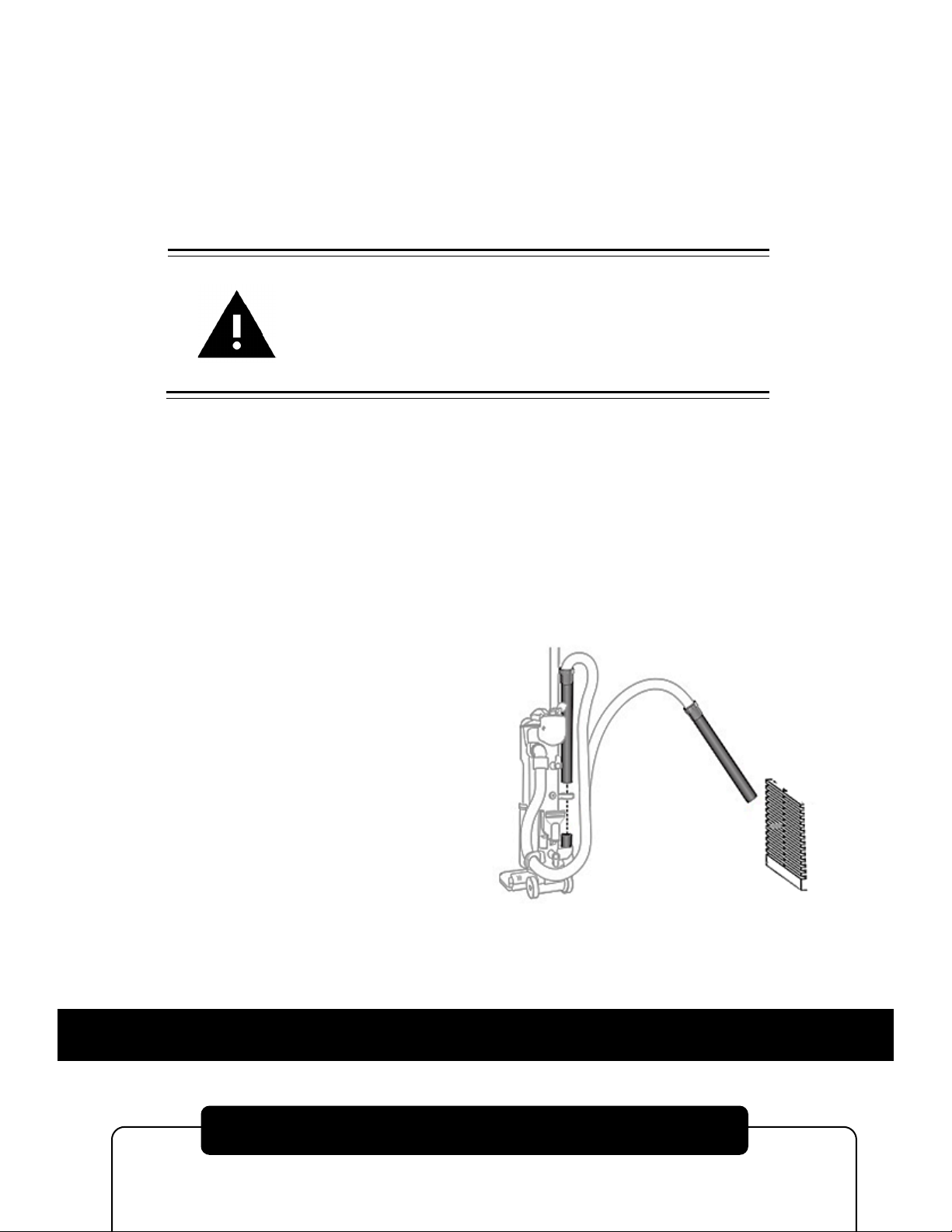

1. Unplug freezer from power supply.

2. Remove cover marked electrical panel located on side of cabinet.

3. Disconnect wires from battery terminals – Note which color wires were

connected to positive/negative. Colors vary depending on when unit was

made. Older models used black wire as positive and white as negative. Newer

models use red wire as positive and black as negative. See picture for battery

location.

4. Remove strap holding

battery in place.

5. Replace battery and

reconnect wires (see #3)

6. Test alarm.

7. Reinstall battery strap and

electrical box cover.

8. Plug freezer back into

power supply, and allow

up to 24 hours for the new

battery to fully charge.

4

CLEANING PROCEDURE

PREVENTATIVE MAINTENANCE

Wipe down the exterior of the freezer with a soft cloth and/or general spray

type polish. Do not use corrosive cleaners/chemicals on the exterior.

If frost builds up in the chamber, a bucket and ice-scraper can be used to

remove ice. If excessive ice builds up, the unit can be defrosted (see below).

1. Remove any product in the freezer, and temporarily store it in a

back-up freezer or elsewhere.

2. Unplug the freezer, and fully open the freezer front door / lid.

ATTENTION

FOR UPRIGHT UNITS, IT IS IMPORTANT TO PROTECT THE

CONTROL FROM DRIPPING WATER. PLACE A CLOTH OR

TOWEL ON THE LEADING EDGE OF THE COOLING

CHAMBER ABOVE THE CONTROL TO DEFLECT / ABSORB

WATER THAT COULD DRAIN ONTO THE CONTROL.

3. Air out the freezer, allowing the unit to reach room temperature for at

least 12 hours. Using fans to blow air into the unit is recommended.

4. Take a rag and wipe up all the excess water in the unit (melted frost).

5. Close the unit, and plug the unit in to activate the start-up process.

PLEASE CONSULT THE START-UP INSTRUCTIONS ON PAGE 1 FOR UNIT STARTUP

6. Once the desired temperature is reached, you may slowly begin to add

your product back into the unit.

ATTENTION

IT IS RECOMMENDED TO SLOWLY RE-ADD YOUR

PRODUCT INTO THE FREEZER TO PREVENT AN

EXTREME LOAD ON THE COMPRESSORS, WHICH

COULD SHORTEN FREEZER LIFE EXPECTANCY.

5

DEFROST PROCEDURE

CLEANING AIR CONDENSER

PREVENTATIVE MAINTENANCE

Large amounts of dust build-up on the air-cooled condenser can cause

excess stress for the refrigeration system. This excess stress may increase

the chance of a refrigeration issue and reduce the life expectancy of the

refrigeration system.

ATTENTION

IT IS RECOMMENDED TO CLEAN THE

CONDENSER AT LEAST ONCE EVERY

90 DAYS TO PREVENT DUST BUILDUP.

1. Using a Philips Head screwdriver, remove the screws for grill located on

front of unit. Once the screws are removed, the front grill can be removed

allowing easy access to the air cooled condenser.

Note: It is recommended to keep the screws in a safe location, so they can

be used to re-attach the grill once cleaning is completed.

2. Use a vacuum cleaner to pull up any dust built up on the condenser fins.

The most efficient method of doing this is using a furniture cleaning

attachment (if available).

Note: Cans of compressed air can also

be used to blow away dust, however

this is not the most recommended way

to clean the condenser; as the dust

may float through the air and

eventually return to clog up the

condenser.

3. Once clean, re-align the front grill and attach it using a screwdriver.

6

CHANGING SETPOINT TEMPERATURE

UNIT OPERATION

The temperature control is manually adjustable to the desired temperature in 1° C

increments within the limits of the control range.

TEMPERATURE SET POINT

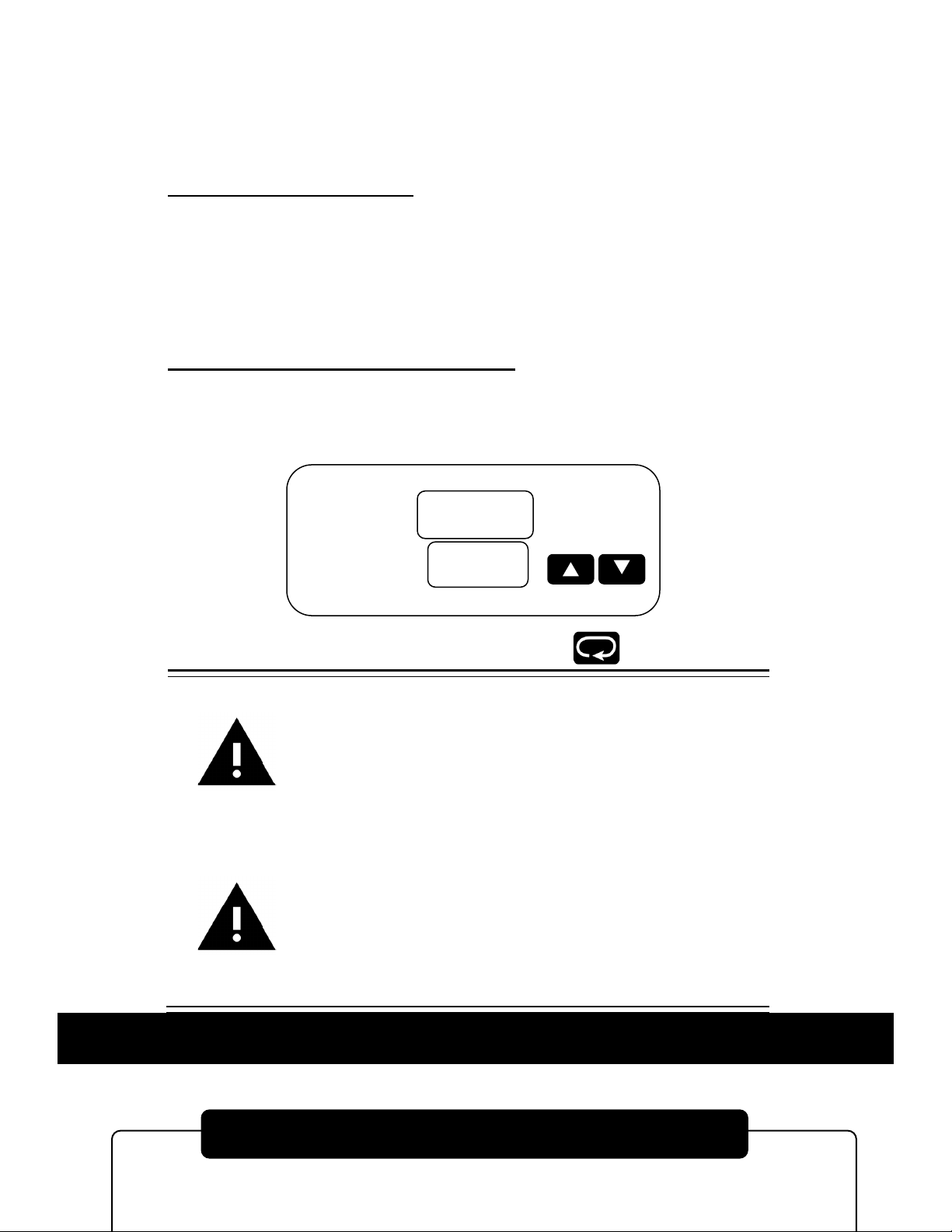

The control has two displays;

1) The upper display ( TEMP ) is the current actual unit temperature.

2) The lower display ( SET ) is the temperature set point.

The temperature set point has been pre-set at the factory. See page 1 for additional

information on factory default setpoint.

CHANGING TEMPERATURE SETPOINT

The temperature set point can be changed by simply pressing the “up” arrow to

raise or the “down” arrow to lower the temperature set point.

WARNING

CHANGING THE CONTROL PARAMETERS OUTSIDE OF

THE MANUFACTURE RECOMMENDED RANGE, COULD

SHORTEN THE LIFE-SPAN OF YOUR EQUIPMENT; OR

CAUSE ISSUES RESULTING IN MECHANICAL FAILURE.

WARNING

USE ONLY THE “UP” AND “DOWN” KEYS WHEN MAKING

CHANGES ON THIS CONTROL. WARRANTY WILL BE VOID

IF USED IN ANY OTHER WAY.

CONTACT FACTORY FOR ALL OTHER ADJUSTMENTS IN

SETTINGS.

7

TEMP

SET

-888

-888

ALARM SYSTEM

ALARM / RELAY OPERATION

When operating the unit for the first time, the alarm will be disabled until the

unit reaches set point, or 8 hours after the unit has been first plugged in.

The alarm will not sound again until the unit goes out of temperature range.

THE FACTORY DEFAULT ALARM RANGE IS ±12°C (20°F) FROM SETPOINT.

Note: The freezer contains a back-up battery, which will power the alarm

system for approximately 48 hours during a power outage.

ALARM SYSTEM BATTERY REPLACEMENT

•Rechargeable batteries should be changed approximately every three years

with lead acid rechargeable 1.2 Ah min, model PS-640F1 or equivalent.

Battery should be tested every 30 days.

ATTENTION

THE BATTERY DOES NOT POWER THE COOLING SYSTEM.

The dry contact relay is a terminal strip located on the back of the freezer.

RATING OF THIS CONNECTION:

2A 125 VAC

2A 30 VDC

RED – NORMALLY CLOSED

WHITE – COMMON

BLUE – NORMALLY OPEN

WARNING

IF IT IS NECESSARY TO REMOVE METAL COVER SCREEN

ON BACK OF FREEZER TO MAKE CONNECTIONS TO

ALARM RELAY, COVER MUST BE REPLACED BEFORE

FREEZER IS PUT INTO OPERATION

8

CONTROL KEYS & DISPLAYS

CONTROL PROGRAMMING

DRY CONTACT RELAY

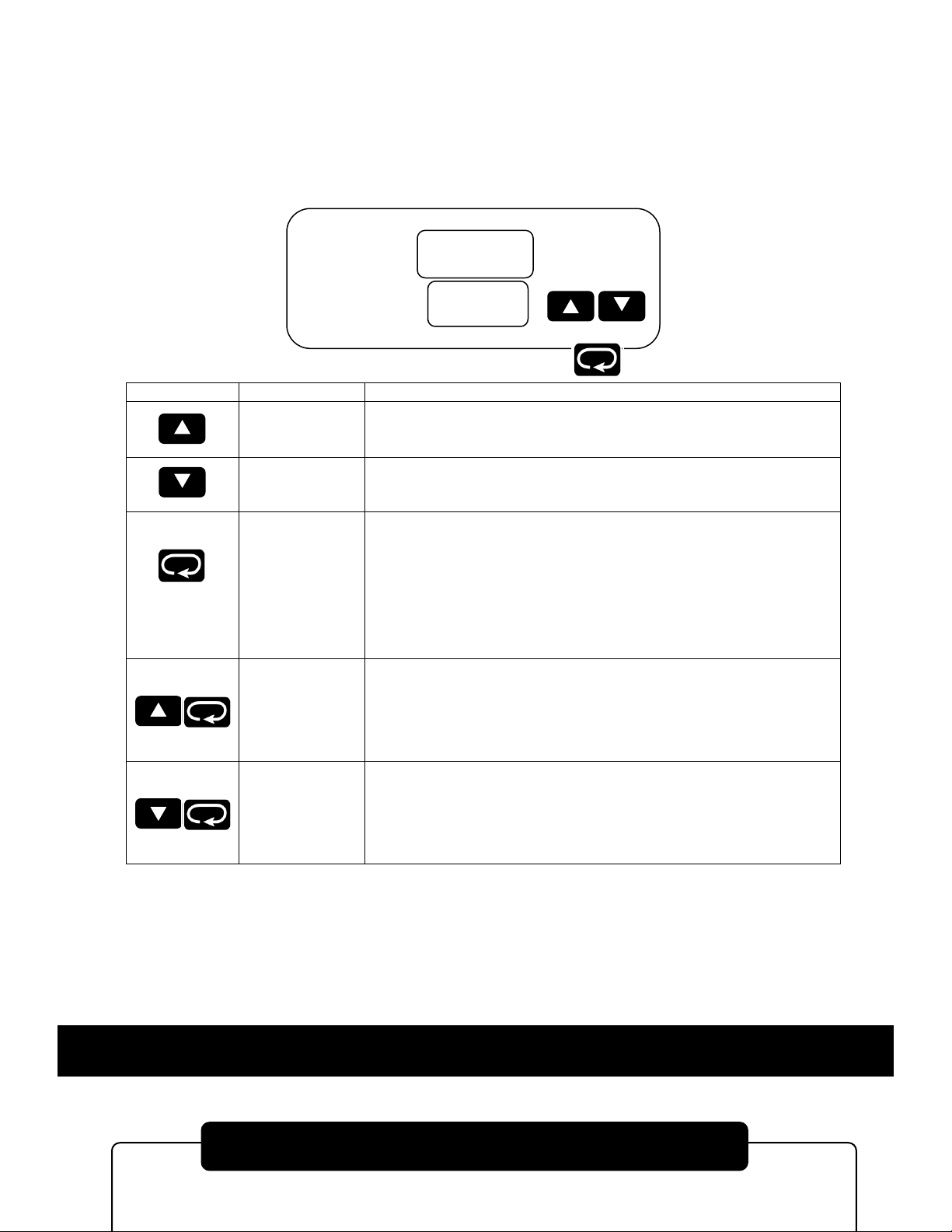

The FDC-4000 controller is programmed by using three keys on the front

panel. The available key functions are listed in following table. Note: Only use

the tip of your finger to depress the keys. Using a rigid object such as a pen,

screwdriver or even your finger-nail may permanently damage the keypad.

TOUCH KEYS

FUNCTION

DESCRIPTION

Up Key

Press and release to increase the control set-point (while in normal control

mode) or to change lower display program parameter (while in User Menu or

Factory Mode). Press and hold to accelerate increment speed.

Down Key

Press and release to decrease the control set-point (while in normal control

mode) or to change lower display program parameter (while in User Menu or

Factory Mode). Press and hold to accelerate decrement speed.

Pressing

key while in

normal control

mode

Scroll Key

Press and hold for at least 2 seconds and release (while in normal control

mode) to access operator level parameters. Press and release to cycle

through all user parameters. Press and hold for 2 seconds and release to

silence audible alarm under normal power or on battery power. While unit is in

an alarm condition, the external alarm relay contacts will remain energized

until the alarm condition no longer exists. Press and hold to display chamber

temperature while the controller is on battery power. Chamber temperature will

be displayed until key is released. Alarm contact will remain energized while

operating on battery power.

Press both keys

simultaneously

Current Power

Reading

Displays current AC power (i.e. 110VAC) as long as keys are pressed. If

power is 110VAC or 220VAC, unit will display 110. Mode is only active during

normal control mode (when top display = PV, Lower display = SP). N/A on

battery power.

Press both keys

simultaneously

Alarm Test

Energize audible alarm and alarm relay output as long as keys are pressed.

Mode is only active during normal control mode (when top display = PV,

Lower display = SP). N/A on battery power.

Note: When the controller is displaying temperature in normal control mode,

press/release or press/hold the up/down keys to change the set-point value.

This set-point mode does not apply to power off modes.

9

TEMP

SET

-888

-888

CONTROL DISPLAY VALUES

CONTROL PROGRAMMING

A

A

E

E

I

I

N

n

S

S

X

B

b

F

F

J

J

O

o

T

t

Y

y

C

C

G

G

K

Y

P

P

U

u

Z

C

c

H

H

L

L

Q

V

u

?

?

D

d

h

h

M

N

R

r

W

=

=

:Confused Character

The upper display is used to show the process value or menu prompt. The

lower display is used to show the set-point value or menu value. Both displays

are blank while on battery power unless the button is pressed to

display the process value. Note: When operating on battery power, the battery

status LED (labeled “BAT” on the front panel) will be lit.

To enter the USER parameter mode, hold the scroll key for 2 seconds and

release.

To enter the user parameter mode, hold the Scroll Button

for 2 seconds and release.

To make changes in the user parameter mode, press the up or

down arrows.

To exit the user parameter mode, press and release the Scroll

Button.

10

USER PARAMETER MODE

PROGRAM PARAMETER MODE

CONTROL PROGRAMMING

To enter the PROGRAM parameter mode, hold the scroll key until the screen

changes to ‘SPL’, then release. This will take approximately 15 seconds.

To page through Parameters; Press and Release the scroll key

Please read the superscript instructions (bottom of page) for

each Parameter value.

THE FOLLOWING VALUES WERE SET WHEN THIS UNIT WAS SHIPPED

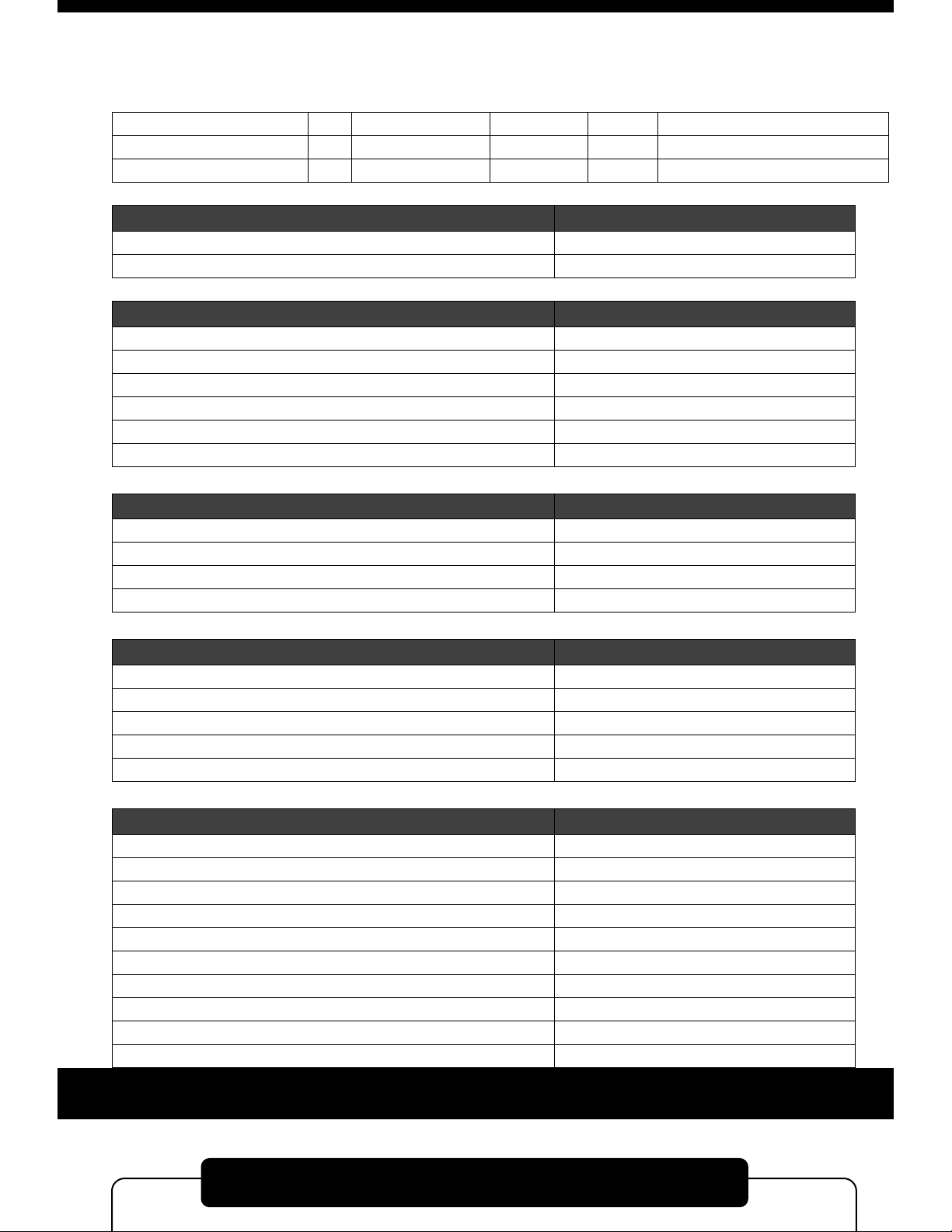

PARAMETERS

DESCRIPTION °F °C ON OFF

SPL

3

Lower Setpoint -148 -100 X

SPH

3

Upper Setpoint -40 -40 X

Al

2

Alarm X

INV

1

Temperature Scale °F °C X

SHF

1

Calibration X

ASP

1

Alarm Differential 22 12 X

AHY

3,1

Alarm Hysteresis 1.8 1.0 X

OHY

3,1

Output Hysteresis 3.6 2.0 X

RB

1

Alarm Delay in Minutes 30 X

DoR

4

Door Alarm X

SP

2

Setpoint X

IN2

4

N / A N / A

TO EXIT TAP SCROLL KEY REPEATEDLY UNTIL TEMPERATURE/SETPOINT SCREEN

APPEARS

1) This parameter has been turned “on” by pressing either arrow key and then make your changes in

“user” mode.

THE VALUES TO BE CHANGED ARE DISPLAYED IN USER MODE ONLY, except SPL and SPH.

2) No values to change, either enable or disable by pressing the or arrow buttons.

3) Any changes made here without expressed permission from the manufacturer will VOID the

warranty of the unit.

4) The parameter “DoR” and IN2 cannot be utilized at this time.

11

CALIBRATION PROCEDURE

CONTROL PROGRAMMING

To calibrate the control, the calibration parameter must be turned on.

To enter the CALIBRATION mode, hold the scroll key until the screen changes

to ‘SPL’, then release. This will take approximately 15 seconds.

Press and Release the scroll key to page through Parameters.

Once value SHF is shown, Use the or arrow keys to change

value to ON.

PARAMETERS

DESCRIPTION °F °C ON OFF

SPL

3

Lower Setpoint

SPH

3

Upper Setpoint

Al

2

Alarm

INV

1

Temperature Scale

SHF

1

Calibration X

•Hold SCROLL KEY for 2 seconds and release. SHF should

appear in the top display and the current calibration value should

appear in the bottom display.

•The value can now be changed with UP or DOWN arrow keys.

•Once finished, press and release the SCROLL KEY to return to

the main screen.

12

ONCE THE CALIBRATION PARAMETER HAS BEEN TURNED ON

FREQUENTLY ASKED QUESITONS

COMMON QUESTIONS

Q: When should I defrost my unit?

A: Units should be defrosted when ice accumulation reaches approximately

1/2 inch thick. Ice acts like an insulator and has to work harder to reach the

same temperature.

Q: Is this unit self-defrosting?

A: No, this unit is a manual defrost unit.

Q: Should I leave my freezer operating when I am not using it?

A: This unit is designed to operate continuously. Leaving the refrigeration

system in operation, (even if not in use) may extend the life of the freezer,

and reduce the chance of refrigeration issues that may occur if the freezer is

not in operation for long periods of time.

Q: What ambient conditions is this unit designed for?

A: This unit is designed for:

•Indoor use

•Altitude up to 2000m.

•Temperatures 15°C to 32°C ( 60°F TO 85°F )

•Recommended humidity range of 30% to 90%.

Q: What electrical conditions is this unit designed for?

A: This unit is designed for:

•Mains supply fluctuations up to -5% to +10% of the nominal voltage.

Consult the serial tag for nominal voltage.

•Transient overvoltage typically present on the mains supply

(overvoltage category II). Pollution degree 1.

Q: Does my unit require a dedicated electrical line?

A: Yes, this unit requires a dedicated electrical line.

Please consult the labels on your unit for specific electrical requirements.

Q: Will the backup battery keep my unit cool during power failure?

A: NO, the backup battery only powers the alarm during power failure. It will

not power the refrigeration system, and will not keep the unit cooling during

power outages.

Q: Will the freezer start up after a power outage?

A: Yes, the freezer will automatically re-start when power is restored.

The overall restart process will begin in stages to prevent system overloads;

and may take up to minutes after re-start before cooling resumes.

13

COMPRESSOR MODEL

HP

VOLTAGE

HERTZ

PHASE

PART #

TECUMSEH AJB2433ZXA

1

115

50/60

1

AJB24-115

TECUMSEH AJB2433ZXD

1

208/220/230

50/60

1

AJB24-208

EMBRACO FFI12HBX

1/

3

115

50/60

1

FF12-115

DANFOSS SC15FTX

1/3

115

50/60

1

SC15-115

DANFOSS SC18FTX

1/2

208/220/230

50/60

1

SC15-208

TEMPERATURE CONTROL PARTS

PART #

FDC 4000

4000

FDC nCOMPASS

nCOMPASS

CASCADE ELECTRICAL PARTS

PART #

Heater Harness No. H-200

217-VOLTAGE

Refrigeration Switch No. 2X464

TOGGLE

Condenser Fan Motor No. GE-5411 - 115/60/1

500-115

Condenser Fan Motor No. GE-5421 - 230/50-60/1

500-VOLTAGE

Electrical Cord No. 8-3 (Please Specify Voltage)

PWRCRD-VOLTAGE

Control Board No. CECB2TUV (Please Specify Voltage)

231-VOLTAGE

REFRIGERATION HIGH STAGE PARTS

PART #

Air Cooled Condenser No. 3CZ0602B

254

Drier No. C-053-S

256H

Capillary Tube

HS-17, HS-20

Oil Separator, Temprite Series 900 (If Applicable)

900

REFRIGERATION LOW STAGE PARTS

PART #

Pressure Control No. 20PS01-0039

259

Receiver Condenser

RCN-LS

Drier No. CO-52S-S

256L

Capillary Tube

LS-28, LS-31

Oil Separator, Temprite Series 900 (If Applicable)

900

HARDWARE PARTS

PART #

Latch No. METL-L1-99

REX37L1-3

Chest Hinge

59-928M

Upright Hinge No. Polar 109-LH

59-928U

Cabinet Gasket

NX504B1

Lid or Door Gasket

PSOS

Grill No. 650H

356F, 356S

Sub-Lids (Must have Model Number)

SL-MODEL NUMBER

Inner Door (Must have Model & Serial Number)

357-MODEL NUMBER-SERIAL NUMBER

Clips & Rollers for Inner Doors (Quantity 10 minimum)

405

Shelves for Freezer (Must have Model Number)

4015-MODEL NUMBER

14

TECHNICAL ASSISTANCE

TECHNICAL SUPPORT

IN CASE OF REQUEST FOR REPAIR

If failure occurs, stop operation of unit, and turn OFF the breaker power

switch located in the electrical panel box, and unplug the power plug.

WARNING

IF FAILURE OCCURS AND UNIT IS STILL UNDER

WARRANTY, DO NOT ATTEMPT TO MAKE ANY REPAIR

MODIFICATIONS TO THE UNIT BEFORE CONTACTING

THE SO-LOW SERVICE DEPARTMENT, AS THIS MAY

RESULT IN WARRANTY BEING VOIDED.

< CHECK FOLLOWING ITEMS BEFORE CALLING OR EMAILING >

◆Model Number of Product

______________________________________________

◆Serial Number of Product

______________________________________________

◆Issue (as detailed as possible)

______________________________________________________________________

________

______________________________________________________________________

________

______________________________________________________________________

________

______________________________________________________________________

________

So-Low Environmental Equipment Company

10310 Spartan Drive

Cincinnati, OH 45215-1221

For customer service:

Email: sales@so-low.com

For parts replacement:

Email: parts@so-low.com

For technical support:

Email: service@so-low.com

15

IT IS RECOMMENDED TO COMPLETE CHECKLIST EVERY 30 DAYS

◆MODEL NUMBER OF PRODUCT ◆SERIAL NUMBER OF PRODUCT

________________________________ ________________________________

Checked that freezer is operating at the correct setpoint temperature.

Checked operation of condenser fans, and cleaned air cooled condenser.

Confirmed unit is at least 6 inches away from walls, or obstacles, on all

sides to allow for sufficient air flow.

Confirmed ambient room temperature is within range acceptable ranges.

Recommended room temperature range is 15°C to 26°C ( 60°F TO 80°F )

◆ AMBIENT ROOM TEMPERATURE IS: _________________°

Checked operation of alarm system on unit.

Note: Alarm can be simulated by temporarily raising setpoint out of range.

Checked temperature recorders for proper operation (If applicable).

Note: If there are any deviations observed, further diagnosing may be required.

Check operation of CO2 or LN2 backup system. (If applicable)

ITEMS BELOW MUST BE CHECKED BY YOUR IN-HOUSE TECHNICAL PROFESSIONAL

USE CAUTION WHEN WORKING AROUND ELECTRICAL CIRCUITS

Checked AMP draw of unit when compressors stabilize.

Checked incoming voltage and voltage drop when compressors start up.

◆NOTES

______________________________________________________________________

________

______________________________________________________________________

________

◆COMPLETED BY ◆COMPLETED DATE

__________________________________ __________________________________

MAINTENANCE CHECKLIST

TECHNICAL SUPPORT

This manual suits for next models

3

Table of contents

Other SO-LOW Freezer manuals