SO-LOW MV Series User manual

To reduce the risk of fire, electric shock or injury to persons using this freezer, read all instructions and follow

basic safety precautions before using the unit, including the following:

Do not modify the plug provided with the unit. If it will not fit the outlet,

have a proper outlet installed by a qualified electrician.

Do not position equipment so it is difficult to disconnect from the power supply.

While under warranty, do not attempt to repair or replace any part of the

freezer for servicing without first contacting the So-Low Service Department.

BEFORE CALLING THE MANUFACTURER’S TECHNICAL SUPPORT DEPARTMENT

Please have the model number of the unit, box identification number, and serial number ready as

well as the problem description. The model, serial number and box id number can be found on

the serial tag, which is located on the interior left upper wall, or back of the unit.

SAVE THESE INSTRUCTIONS

Table of Contents

1. Application Notes

1

2.Safety Instructions

2

3.Precautions in Use

4

4.Installation

4

4

.1

Installation Environment

4

4

.2

Installation Site

4

4

.3

Preparation before Use

5

4

.4

First Power-on

5

4

.5 Operation after Power Failure

5

5.Product composition and overview

6

6.Operating Instructions

7

6.1 Function Introduction

7-9

6.2 Optional function

10

7.Maintenance and Service

10

7.1 Equipment Maintenance

10

7.2

Equipment Discontinuation

11

7.3 Maintenance, Replacement, and Recovery of Rechargeable Batteries

11

8.Troubleshooting and Maintenance Services

12

9.Specifications

13

10.Packing List

13

11.Electrical Schematic Diagram

14

1

1.Application Notes

Thank you for choosing and using our products! For your safe and convenient use and reasonable

maintenance of the equipment, please read the Operation Instructions carefully before use and keep it properly

for reference

The equipment operator can copy some chapters of this operation manual, but only for internal use, for

example, to instruct the user how to deal with emergencies. These chapters are clearly marked in the catalog

of the manual.

So-Low Environmental has obligation and responsibility for any instrument damage caused by the user's failure

to use the equipment according to the instructions or the method specified by the manufacturer.

Due to the rapid improvement of our products, the functions described in the instructions may be inconsistent

with those of the products you purchased. Please refer to the physical functions.

Please carefully read the Attention and Safety Precautions (in 2. Safety Instructions).

During transportation or use, no violent vibration or collision is allowed, and the

refrigerator shall be kept away from rain. Store in a clean room with humidity of no more

than 80 %, no corrosive gas and good ventilation.

Pharmacy/Medical refrigerators (hereinafter referred to as equipment) can only be

operated by trained and authorized personnel.

Maintenance of the equipment can only be completed by us, or an agent

authorized by us.

If the operator encounters any situation not mentioned in this manual, please contact

So-Low Environmental or an agent authorized by us for the correct handling method.

If the equipment is not used according to the method specified in the specification, it

may be damaged.

Try to use the accessories provided by us. If users would

like to use other accessories, we will not be responsible for the adverse

consequences caused therefrom.

Equipment must be inspected and maintained regularly to ensure good operation of the

equipment.

Tips

Properly use protective equipment (including protective clothing, protective gloves,

goggles, etc.)

Keep good hygiene habits

Please pay attention to safety when using this product

Keep clear of obstruction all ventilation openings in the appliance enclosure or in the

structure for building-in.

Do not use mechanical devices or other means to accelerate the defrosting process, other

than those recommended by the manufacturer.

Do not damage the refrigerating circuit.

Do not use electrical appliances inside the food/ice storage compartments unless they are of

the type recommended by the manufacturer.

2.Safety Instructions

When using this product for the first time, please pay attention to the meaning of the following warning signs

and carefully read the safety precautions, so that you can use this equipment safely and correctly.

Warning! Failure to observe the

Attention!

Failure to observe the precautions

precautions may result in serious personal

may result in personal injury or equipment

injury or death.

failure and related property losses.

Protective conductor terminal

Risk of Exploration This sign indicates the

risk of explosion when using volatile and

explosive chemicals.

Do not place it obliquely

Avoid direct sunlight

Beware of electric shock.

Beware of fire

This equipment is a precision instrument

Warning: Failure to observe the precautions may result in serious personal injury or

death.

Do not touch the equipment with wet hands to avoid electric shock; Equipment shall not be grounded through

gas pipeline, water supply pipeline, telephone line or lightning rod, which may easily cause electric shock.

This equipment can only be installed by professional technicians or after-sales maintenance personnel, it

may cause electric shock or fire.

Please handle the power cord carefully to avoid short circuits or open circuits. Please turn off the power

before pulling out the power plug. Don't bundle the power cord, don't press it under furniture or heavy

objects.

After installation, the power plug must be within reach, so that the power plug can be unplugged in time in

case of emergency.

Be sure to install the equipment on solid and flat ground and take due care to prevent tipping over. If the

ground is not solid enough or the installation location is not appropriate, it may cause the equipment to

fall over and cause equipment damage or personal injury.

Do not lengthen the power cord without authorization to avoid heating or fire.

Do not use the power supply that is not specified in the equipment design, to avoid overheating, short

circuit, and other faults.

This equipment adopts a 110V/60HZ AC power supply. If the operating voltage is too low or too high, a

suitable automatic voltage stabilizer must be installed for cooperative use.

Please place the equipment stably and avoid shaking.

Do not place the equipment in a dangerous area, and do not operate the equipment near flammable items

to prevent explosion or fire accidents.

2

Do not place the equipment in areas exposed to the sun or rain, to prevent danger such as short circuit or

overheating.

Do not tilt or lay the equipment sideways, and do not impact the equipment body; Refrigeration systems are

installed in the equipment, which is easy to be damaged by tilt or impact.

Please place the equipment in a dry and dust-free environment to avoid risks such as overheating, and short circuit.

In case of unexpected sound, smell, smoke, etc. when the power is turned on, please unplug the power in

time and contact the manufacturer or supplier.

Please place the equipment in a dry and ventilated environment and ensure that the equipment vents and

instrument surfaces are not blocked or shielded by walls or other objects; Do not use it in a poorly ventilated

environment to prevent damage caused by heat released by equipment.

It is forbidden to disassemble and modify this equipment without authorization, to avoid potential safety

hazards. In this case, So-Low will not bear any responsibility for quality accidents.

It is forbidden to put flammable and explosive dangerous goods, strong corrosive acids, alkalis and other

items unsuitable for the equipment in the equipment.

When storing toxic, harmful, or radioactive materials, please use the equipment in safe areas. Improper use

may cause harm to human health or the environment.

Metal objects such as nails or iron wires shall not be inserted into any aperture and gap or any outlet of the

equipment, otherwise electric shock or injury may be caused due to accidental contact between the above

objects and moving parts.

To ensure the normal operation and ventilation and heat dissipation of the equipment,the back, left and right

sides of the cabinet shall be at least 1-2 inches away from the wall, and the air inlet and air outlet must not

be blocked by obstacles!

This equipment must be connected to a ground wire.

Note: Failure to observe the precautions may result in personal injury or equipment failure and

related property losses.

It is forbidden to store living animals, flowers, or other items with strict temperature requirements in

the equipment.

When the equipment is running, do not touch the inner surface of the cabinet without wearing protective gear.

Hold the handle and close the door to avoid pinching your fingers; When the equipment is not used for a long

time, please unplug it and pack it for storage.

When restarting the equipment after power failure or power off, please check the equipment settings first,

otherwise the stored items may be damaged due to the change of settings.

The equipment can be used for item preservation, not as production equipment!

Keep the keys in a safe location.

When handling the equipment, please be careful not to tip over the equipment, to prevent equipment

damage or personal injury.

When handling, it shall be lifted from the bottom, with the inclined plane is not greater than 45°, and it shall

be handled with care. Please use the equipment in safe areas. Improper use may cause harm to human

health or the environment.

3

3. Precautions in Use

Before putting the items into the equipment, please confirm that the temperature in the freezer storage chamber has

reached the set value first, and then put the articles in batches. Every time you put in items; they shall not exceed 1/3 of

the inner volume of the freezer storage chamber to prevent excessive temperature rise.

The equipment temperature display value is the temperature at the temperature sensor in the freezer storage chamber.

There is a certain gap between the displayed temperature and the actual temperature at the center of the equipment when

the equipment just starts running, but as the equipment enters a stable state, the displayed temperature will gradually

approach the actual temperature.

Please use a diluted neutral cleaner to clean the equipment, and do not use brushes, acid, gasoline, soap powder,

polishing agent, or hot water to clean the equipment, otherwise the painted surface and plastic rubber parts may be

damaged. Be careful not to wipe plastic rubber parts with volatile solvents such as gasoline.

When the equipment is not used for a long time, the power supply shall be cut off.

4.Product Installation

4.1 Installation Environment

Ambient temperature: 16℃~ 32℃, the most ideal temperature is 18℃~ 25℃, and the air conditioning system

shall be used when necessary.

Relative humidity: ≤80%RH.

There is no strong vibration and corrosive gas around.

Avoid the existence of a large amount of dust.

Avoid rocking or shaking the equipment.

Elevation of the working position of the equipment: less than 2000m.

Indoor use, pollution degree 2, and overvoltage category II.

Input voltage AC single-phase 110V.

There is no direct sunlight, other cold and heat sources, and strong electromagnetic interference, which

will affect the normal operation of the control system and directly damage the system in severe cases.

4.2 Installation Site

To operate the equipment normally and obtain the best performance level, the installation site

of the equipment shall meet the following requirements:

It cannot be installed in a narrow and closed space, and the door of the room shall not be

smaller or lower than this equipment, which shall at least ensure the normal access of the

equipment, to avoid the maintenance difficulties in case of equipment failure, which may

result in damage to stored items due to the failure to repair the equipment in time.

The installation floor must be solid, flat, non-combustible, and able to bear the weight of

the equipment during operation.

It shall be with good ventilation, and direct sunlight shall be avoided.

Each piece of equipment needs to use a power outlet independently.

Please ensure that the current by the power outlet shall be ≥10A, and the plug and outlet are firmly connected.

Check the working voltage before use. In areas with unstable voltage, consider using a

voltage stabilizer suitable for equipment load. The power of the voltage stabilizer is greater than

4KW to ensure that the input voltage requirements in the installation environment are met.

Equipment shall be reliably grounded. If the power cord outlet is equipped with grounding

wire, check whether the grounding is good before use. If the outlet is not equipped with

grounding wire, it must be installed by professional engineers and technicians.

Attention: Since the ambient temperature has great influence on the equipment, if the above

environmental requirements cannot be met, the equipment may not run normally. Please

improve the environment before using the equipment; The equipment is operated intermittently

4

4.3 Preparation beforeUse:

1.

Remove the outer packaging ofall products (including the protective foam in the packaging box)

2.

Inventory of accessories: Please check the accessories and materials according to the packing list.

3.

Cleaning: Clean the product once before use.

4.4 First Power-on

When using the equipment for the first time, please follow these steps:

1.

After the equipment is placed, leveled, and cleaned, it shall stand for more than 24 hours, and then power it on

to ensure the normal operation of the equipment.

2.

Under no-load condition, connect the power cord to a dedicated outlet with appropriate specifications.

3.

After plugging in, turn on the power switch of the equipment.

4.

Check whether the operating temperature of the equipment reaches the required value, observe the normal

start and stop of the equipment for 24 hours, and put a small amount of items in the freezer after confirming

the normal performance.

5.

Please store items in batches, with the items not exceeding 1/3 of the freezer volume each time.

6.

Try not to open the door during cooling, otherwise the temperature will rise.

4.5 Operation after PowerFailure

1.

The equipment has a memory function for the set value. When the power is restored after power failure, the equipment

will continue to operate before power failure.

2.

Once the equipment is powered off, it requires 5 minutes before it can be switched on again, so as to avoid

damaging the compressor.

3.

We guarantee the normal operation of this equipment under certain conditions, but we are not responsible for

any loss or damage of stored items after a power failure.

Notes:

◆

Aspecialpersonshallbe responsibleforcheckingandrecordingtherunningstatusoftheequipmenteveryday

(recordand checkonce every 2-4 hours).Incaseoffailureorshutdown,thetemperatureinthefreezer willrise.

Ifitcannot be repaired in a short time, please take out the stored items and transfer them to a place that

meets the temperature requirements for storage to avoid damage to the items.

◆

Before putting items into the equipment, it shall be confirmed in advance whether the temperature range of the

equipment meets the temperature requirement of the items, so as to avoid damage to stored items due to the

differencebetweenthe settabletemperatureoftheequipmentand therequiredtemperatureoftheitems.Please

payattentionnottoblock theair outlet and air inlet when putting items into the equipment.

◆

Dueto the refrigerationinertia, thereisa certaindifferencebetween theactualdisplaytemperature

andthe settemperature of the equipment, which is a normal phenomenon.

◆

The equipment is an item storage equipment, which cannot be used for routine production operations. It is

strictly forbiddentoputtoo manyitemswhicharerelativelyhotintotheequipmentatonetime,otherwisethe

compressorwillrun foralong time,andbe burneddueto high temperature.Itemsmust be putin batches,soas

toensurethat the freezer is cooled step by step until the temperature required for storing items isreached.

◆

Electrical appliances without production license shall not be usedinside the equipment.

◆

Donotchangethesettemperaturefrequentlyina shorttime,otherwisetheexpectedsettingeffectmaynotbe

achieved duetothelargetemperatureinertia;Ensurethatthereisacertainaircirculationspacearoundthe

cabinetwhenputtingin items, especially do not block the temperature sensor in the cabinet (for collecting

the temperature of the cabinet), otherwise itwill affectthe stability and accurate control ofthe temperature in

thefreezer body!

◆

Itemsshallnotbeplaced directlyatthebottom ofthefreezer,but onthebottomshelf, otherwisethe

refrigerationeffectofthe equipment will be affected.

◆

When putting in items, if the moisture content of the items is too much or too little, it will affect the humidity

change in thecabinet, so it is best to keep the items sealed; The humidity of the working environment will affect

thechangeofhumidity in the cabinet, especially if the door is opened too frequently and the door is not closed

properly

5

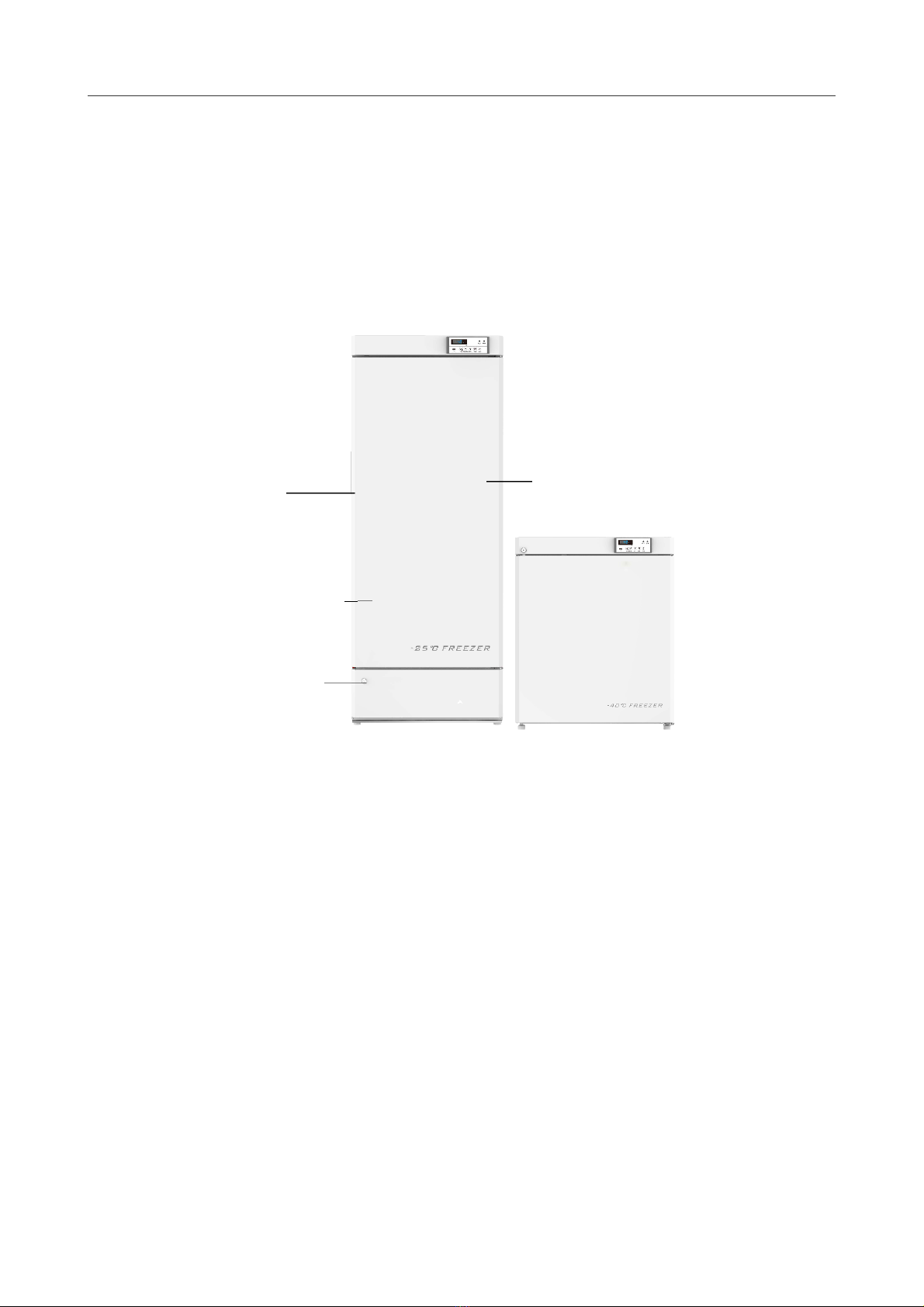

5. Component Composition

Display control panel

Door handle Foam door

Cabinet

Door lock

Leveling foot

DHK25-10SD/DHK40-10SD MV30-4UCF/MV40-4UCF

* Due to the improvement of products and model diffierences, the actual products may be different from the diagram.

Please refer to the actual products! The diagram is only used for functional parts description.

* Structure and composition The product consists of freezer body, door (glass door structure or foam door structure),

refrigeration system and control system.

Intended use:

* Scope of application: It is suitable for storing items in hospitals, pharmacies, epidemic prevention stations, research

institutions, biopharmaceuticals and other units.

* The storage temperature inside the box can be adjusted through the temperature button on the control panel, which is

convenient to use and reliable in performance.

* The freezer comes with drawers, each of which can hold 40 pounds.

6

6. Operating Instructions

6.1 Function Introduction

a

b

c

h

g

f

e

d

Type A control panel

Function description of Type A control panel(Applicable to MV40-4UCF,MV30-4UCF,DHK25-10SD,DHK40-10SD)

1.Control board introduction:

a. -25 is display window for temperature. Under normal operating conditions, the average

temperature of the freezer compartment in the cabinet is displayed in units of °C; Different running

status can be displayed in the setup state (see below for details).

b. Door opening indicator : when the door is opened, the indicator light will be on. when the

door is opened more than 1 minute, the indicator lighting with buzzer alarm, display "do".

c. Fault indicator: The indicator is off when the product is operating normally; the indicator is on

when the product is operating abnormally.

d.“PRINT”: The system can retain 7 days of data for printing. Press the Print key to print

the temperature for the set period of time.

e. In parameter setting mode, move to the previous parameter or decrease the value of

the parameter. For example, when adjust the set temperature, press this button to reduce the

set temperature. When adjust the parameter value, long press the key to quickly decrease the

parameter.

f. In parameter setting mode, you can move to the next parameter or increase the value of

the parameter. For example, when adjust the set temperature, press this button to increase the

set temperature value. When adjust the parameter value, press and hold the up button for a

long time and the parameter will increase rapidly. Under normal conditions, press and hold the

key for 3 seconds to import the U disk for 12 months.

g. is the button for set/mute, when there is no alarm state and the key is not unlocked, press

,Displaying ambient temperature for 5 seconds and then restores normal display;

In the unlockedstate, press for 3 seconds, can enter the user menu. When buzzer alarm

(including high temperature alarm, door open alarm, sensor fault alarm, etc.), in the locked state,

first time press , Buzzer stops tweeting, 5 seconds after showing ambient temperature, resume

normal display (The key mute is only to turn off the buzzer of this abnormal state alarm. If the fault

is not eliminated, the buzzer will continue to alarm when the next exception occurs),

press again, buzzer alarms, After the ambient temperature is displayed for 5 seconds, the

cabinet temperature and alarm status are restored. When the press is under unlocked state,

can be used as a set button.

In the unlock state, in the parameter setting mode, press this key to display the value and

the parameter name. If the pressed time is longer than 3 seconds, the setting will be saved and

returned to normal interface. 7

h. USB data ;

Automatic export: when the U disk is connected to the USB interface, the recorder buzzer will chirp

once and display "on". PDF files of data that not currently exported will be generated in the U disk.

After data transmission, the buzzer will chirp once again and display "End".After 6s, it will return to

normal display.

Note: when the data is very little, the digital tube will not display "on" and "End".

Manually export: If the button is under locked state, after connecting U disk well and buzzer alarm

for one time, press upper button for 3 seconds, digital tube display “d01”, Press the up button

or down button to adjust “d00~d12”, press , The U disk internally generates a PDF file that

generates this file (d00) or generates the data recorded in the previous month (1-12).

2.Function settings

a.Power on, open the power switch on the back of the cabient, the machine can enter the

working state;

b.User parameter settings:

Unlock: In the normal running state, press the key and for 3 seconds at the same

time, the digital tube will display the parameter code "0000", and input the password

"0005" (enter the user menu password, enter "0099" to restore the key lock password to the

default "0005"), Unlock at this time. Press the key for 3 seconds after unlocking, the

digital tube displays the parameter code

"PS1" and enters the setting adjustment.

c.Use the up or down key to scroll through the parameters. The display order is b1-b2-Set-H-L-

n-y-r-S-F-Pt-tH1-P1-PS1.

Press the key to confirm the category. The first parameter name of this type of parameter

will be displayed.

1. Press or to scroll through the values

2. Press the to display the corresponding value

3. Press or to increase or decrease the value

4. Press the to temporarily store the modified value of the lock and return to the

display parameter.

5. If you need to modify other parameters, repeat steps 1-4.

6. Press the for more than 3 seconds to store the modified parameter and return to

the display parameter category.

d. Press the for more than 3 seconds, or if there is no button within 60 seconds, exit the

parameter setting program.

8

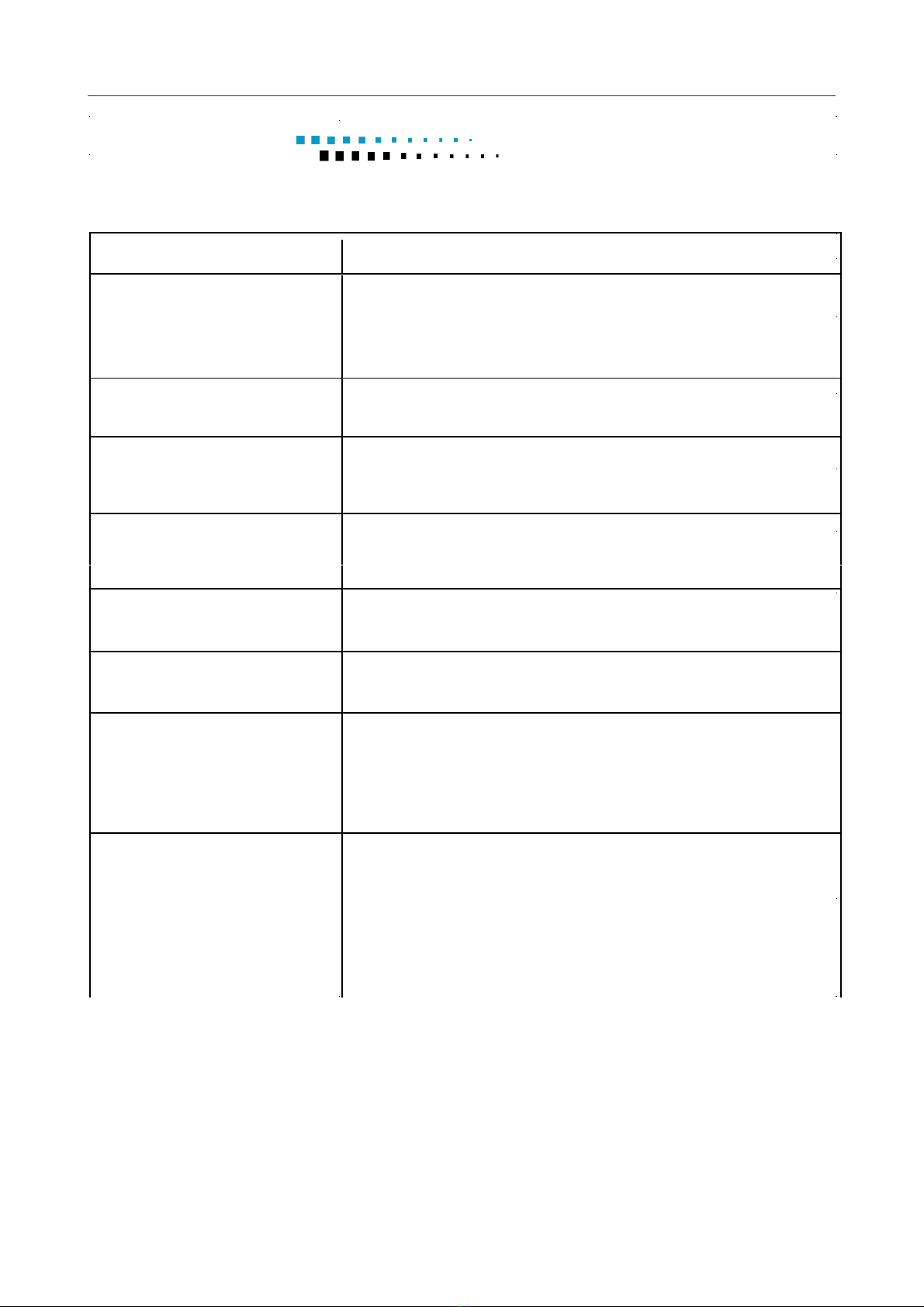

4.Parameter display

NO.

Menu item

Parameter Range

Suggested settings

Remarks

1

b1

V1.0-9.9

1.0

Hardware version

2

b2

V1.0-9.9

1.1

Software version

3

Set

-10~-25

-25

Temperature setting

Set value of high temperature alarm set+H;

4

H

0.0~10.0

5.0

When H=0, the alarm is deactivated; When the

temperature is higher than the high temp alarm

set temperature alarm displays H1

Set value of low temperature alarm set-L;

5

L

0.0~10.0

5.0

When L=0, the alarm is deactivated; When the

temperature is lower than low temp set the

low temperature alarm displays L1

6

Pt

0~240min

20

Print interval

7

tH1

20.0~50.0℃

40.0

Upper limit of ambient temperature alarm

8

PS1

0000~9999

0005

User menu password settings

9

MAX

-

-

The highest temperature since last clearance

10

NIN

-

-

The lowest temperature since last clearance

11

CLR

-

-

Clearance of the Max and Min temperature

records

Quick setting of time after power on

After the power-on self-test on the display board is completed, the quick setting menu is displayed.

Menu item

Menu

Menu description

Set range

Default

Unit

n

Set logger module time - year

10~50

/

y

Set logger module time - month

1~12

--

/

Quick

r

Set logger module time - day

01~31

--

/

S

Set logger module time - hour

00~23

--

/

Settings

F

Set logger module time - minute

00~59

--

/

menu

Pt

Print interval

0~240

20

min

SCY

Temperature data recording period

0~240

10

min

0: shielded

recorder

If there is no operation for 60 seconds under the quick setting menu, it will automatically exit the quick setting menu and return

to normal display.

5.Alarm display

Alarm Code

Fault description

H1

High temperature alarm

L1

Low temperature alarm

H2

High ambient temperature alarm

door

Door open alarm

PF

Power failure alarm

bL

Low battery alarm

Er

Data Logging not connected

LoF

Data Logging not started

EE

Communication error

9

6.2 Functional fittings

1.Printer

Automatic printing:

When the printing interval Pt is not 0, the printer prints the current data every Pt minutes.

Note: When the printing interval Pt is less than the recording interval SCy, it is printed according to

the recording interval; the remaining printing intervals are printed as an integral multiple of the

recording interval Scy, that is: the printing interval Pt should be set as an integral multiple of the

recording interval.

Manual printing:

When the key is unlocked and the working voltage is normal, press the print key to display "P01" by

the digital tube, press the up key or down key to adjust "P00~P07." Press the set/mute multiplexing

key or print key, and the printer will cancel the manual printing (P00) or print the data recorded in

the previous days (1 ~ 7), with the data interval same as the automatic printing interval. Printing

paper installation:

The printing paper has been installed at the factory. When the paper is used up after a long time,

you may purchase the same paper for installation. The installation steps are as follows:

①Click the cylindrical button on the printer to open the cover of the printer;

②Put the printing paper into the printer box and pull the paper head of the roll so that the paper

slightly exposes from the upper port of the box cover after the box cover of the printer is closed.

③Close the box cover.

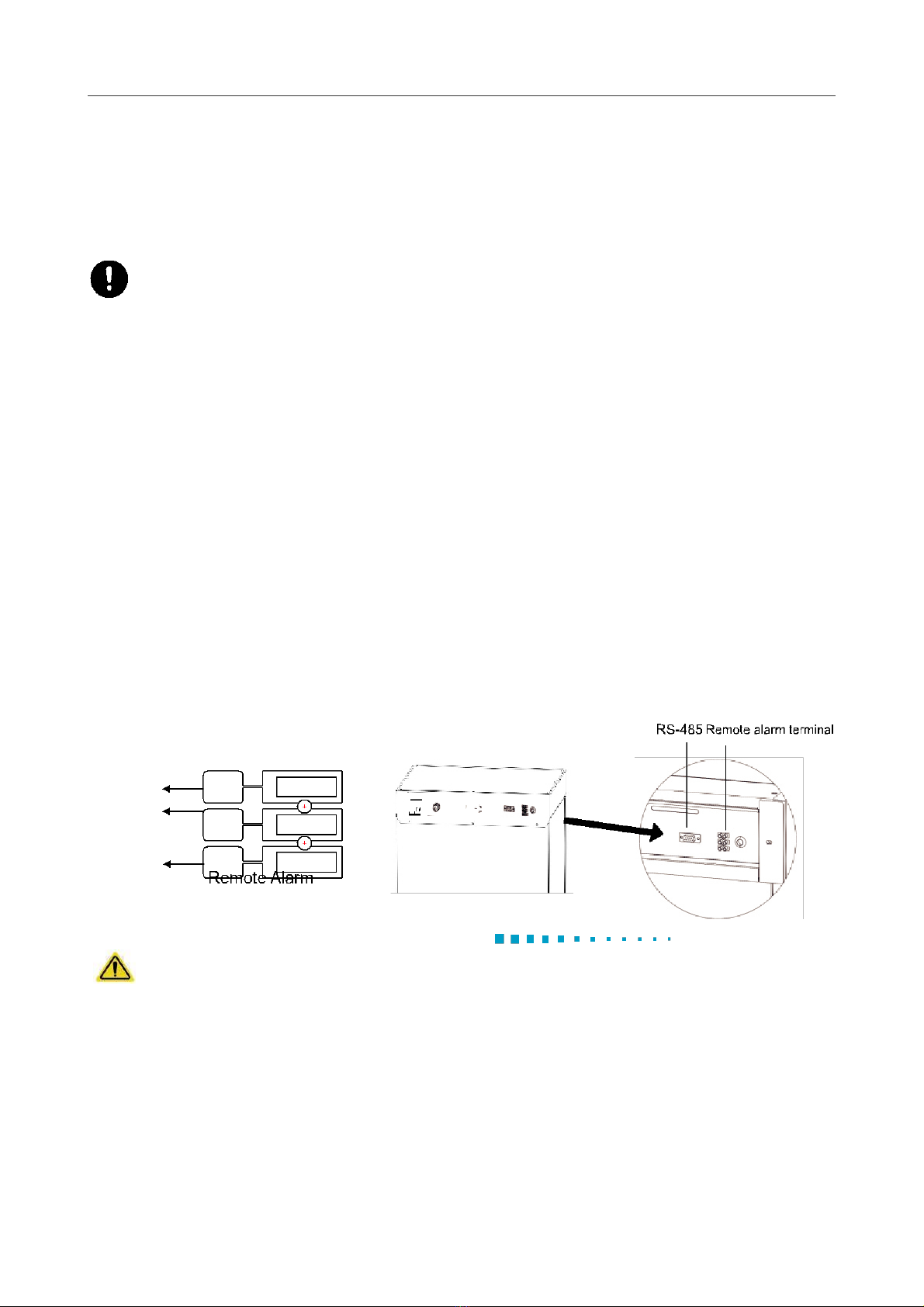

2.Remote alarm terminal and RS485 interface

The remote alarm terminal is installed in the back of refrigerator and the alarm signal is output by the terminal.

The terminal bearing capacity is SELV DC 30V, 2A.

Normally

open N.O.

Common COM

Normally

closed N.C.

Max DC30V 2A

7.Defrost,Discontinuation and Maintenance

Warning:

In order to prevent people from getting electric shock or injury, please cut off the power supply

of the equipment before any repairs and maintenance

Make sure you don't inhale drugs or suspended particles around it when maintaining

the equipment, otherwise it will harm your health

7.1. Equipment Maintenance

Defrosting: The equipment will automatically defrost during the working process for the convenience of

use. Cleaning and maintenance: The equipment should be cleaned and maintained regularly (for safety,

please remove the power plug), and the inner and outer surfaces of the freezer should be wiped with a

warm, damp soft cloth.

10

Notes:

Do not use sharp metal appliances during defrosting to avoid damage to the freezer.

Do not position the equipment so that it is difficult to operate the disconnecting device of separable

plug.

Protection impairment if used in a manner not specified by the manufacturer.

The power relay switch on the back of the case can not only contact and open the power circuit, but

also provide immediate protection in the event of short-circuit faults, severe loads and undervoltage in

the power circuit, and it can also be used to start the compressor infrequently to protect the equipment.

7.2. Equipment Discontinuation

Deactivation: If the equipment is stored in an unsupervised area for a long time and not used, the power

supply should be cut off and the inner and outer surfaces of the freezer should be cleaned with a warm,

damp soft cloth, aired and sealed. The equipment must be locked to ensure that children cannot open the

freezer door.

Scrapping: When the equipment reaches the end of its service life, it should be scrapped and must be

handed over to a qualified professional recycling agency for disposal per local regulations. Non-

professionals are not allowed to disassemble and break down the equipment without authorization. The

scrapped equipment should be placed in a designated area inaccessible to children to avoid danger.

7.3 Maintenance, Replacement, and Recovery of Rechargeable Batteries

Battery installation position: top of the freezer body and bottom inside the electrical

box. 1. Battery maintenance

①In order to prolong the service life of the battery and avoid the product being left unused for a long

time, the product must be operated for more than 24 hours every month to facilitate charging.

②When the equipment is not used for a long time, it should be connected to the working power regularly

(generally once a month), and the power lock switch should be turned on so that the equipment can run

for a period of time to complete charging, and each charging time should be no less than 24 hours;

③When the working power supply is interrupted, the power lock switch of the equipment shall be turned

off in time, otherwise it will cause power loss in battery and even permanent damage to the battery in

severe cases;

④The main power switch must be turned off during a long-term power outage or during transportation,

otherwise long-term discharge causes power loss in battery and even permanent damage to the

battery, and the display is abnormal after re-energizing;

⑤The battery is a consumable, with a service life of about 2-3 years. If the battery is used improperly,

such as power loss or reaching the end of battery life, it will cause a low battery alarm (refrigeration is

not affected, but there is an alarm failure and influence to the use function of the printer, please contact

our local distributor after-sales staff for replacement).

2. Battery replacement and recovery

①Turn off the power switch and pull out the power plug from the outlet;

②Remove the screws on the electrical box with a screwdriver. (Note: There are high-voltage electrical

components in the electrical box, therefore before opening, turn off the power supply, unplug the power

plug and turn off the power lock switch of the freezer, and the electrical box can only be opened by

qualified engineers or maintenance personnel).

③Pull out the battery connecting cable; (Before unplugging the battery fixing cable, pay attention to the

cathode/anode of the battery and the sequence of the connecting cables, so as to prevent burning down

the control system due to installation of the new battery with cathode/anode reversed. Generally, the red

wire is connected to the cathode, and the black wire is connected to the anode.

④Use a screwdriver to remove the fastening screws on the battery fixing plate and take out the

battery; ⑤The battery model is BT-12M4.0AC(12V4.0AH);

⑥For a replaced battery that can be recycled, please contact the local battery recycling agency.

Tips: In order to effectively ensure that the battery replacement meets the requirements of the control

system and avoid the influence of improper operation on the system, please contact our after-sales

personnel for replacement or guidance.

11

8.After-sales service

Any product may fail. Please observe the operation of equipment while in use.

Fan motor replacement time: about 6 years; Service life of the product: 10 years.

Problems

Causes and solutions

Please make sure that the outlet is energized.

Equipment does not work

Please make sure power plug is plugged in,not loose.

Please make sure the power fuse is not disconnected.

Please make sure the supply voltage is appropriate,not too low or

too high.

Compressor is not running

Please make sure that the temperature is set correctly.

Please check whether the temperature inside the cabinet is too low.

The temperature does not

Please make sure that the door is closed tightly and don't open it

too many times during a short time.

reach the set value

Please don't put too many items in at one time.

Please make sure that the ambinet temperature is not too high.

High noise

Please make sure that the freezer body is placed on a flat ground.

Please make sure that the freezer body does not contact the wall.

Condensation on freezer body

In rainy and humid seasons, door condensation is

surface

normal, and it shall be wiped off with a dry cloth.

Undesirable odor

Equipment needs to be cleaned. Items

with heavy smell are not packed.

After the equipment is used for a period of time, the door seal

The door is not closed properly,

becomes hard and deformed.

Maintenance method: Blow the deformed part of the hot seal

and the cool air leaks

with a blower to soften it, and then close and compress it after

the door seal becomes soft.

If the items were just put in,it will be automatically eliminated

after

running for a period of time when the temperature is stable .

The alarm lamp flashes and

Please check if it is because the door is not locked.

Please check if it is because of the low battery,which will be

the buzzer is triggered

automatically eliminated after a period of running.

Please make sure the temperature is not exceeding the

standard.

12

The following conditions are not faults:

①When the compressor starts and stops, the equipment parts will make a slight impact sound

②When overheated items are put in after the door is opened, high temperature alarm and high humidity

alarm will be triggered in the control system (if this function is available, please refer to the alarm display

table);

Solution: Put the items into the equipment after they are naturally cooled. Put the items in small quantities

in batches, and do not put too much at a time. After the system runs stably, the high temperature alarm

and high humidity alarm will be released automatically.

③Slight sound of running water caused by refrigerant flowing in the pipeline.

Notes:

The equipment can only be repaired, maintained or improved by the engineers certified by us,

so as to ensure the normal operation of the equipment and the compliance with corresponding

safety standards.

Please clean and disinfect the equipment before notifying the maintenance engineer; During the

warranty period of the equipment, the Company will not undertake the warranty obligation if the

fault or damage is caused by improper use of the user.

Ambient temperature for storage: -40°C-+55°C, relative humidity: 10% ~ 90%.

9. Specification

Ambient

Rated

Rated

Temp

Effective

Model

Refrigerant

voltage

frequency

Range

temperature

volume (L)

(v~)

(Hz)

(°C)

MV30-4UCF

16~32℃

R600a

110

60

-10~-25℃

90

MV40-4UCF

16~32℃

R290

110

60

-20~-40℃

90

DHK25-10SD

16~32℃

R600a

110

60

-10~-25℃

270

DHK40-10SD

16~32℃

R290

110

60

-20~-40℃

270

*The foaming material of this product is cyclopentane.

10.Accessories

Name

Operation Manual

Key

Defrosting shovel

Number

1

2

1

* The specific packing list shall be subject to the physical objects received.

13

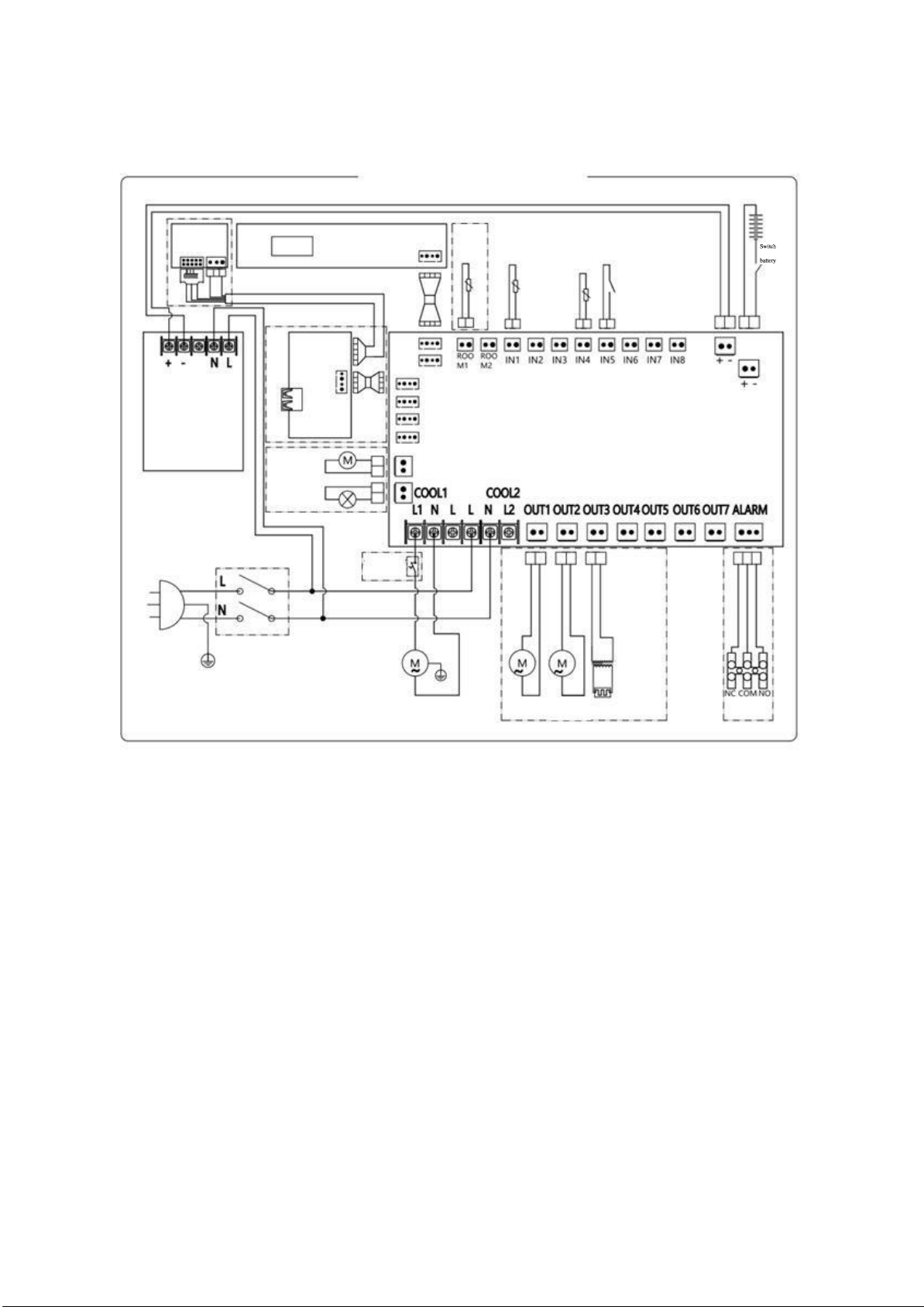

Circuit diagram

Battery

Printer

Display PCB

Sensor

Sensor

for

for control

room

Sensor

for

ambient

TEMP

Sensor

for

door

for

SPS

USB

Control PCB

Fan for

evaporator

LED Light

Power plug Power switch

Controller

set

Transformer

Note: some models don't have the optional parts within the Compressor set

dotted line, the detailed is subject to the available

Fan for

condenser

Fan for

Heater

evaporator for door

Alarm

Other manuals for MV Series

1

This manual suits for next models

5

Table of contents

Other SO-LOW Freezer manuals