SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

Email: sales@soilmoisture.com - Website: http://www.soilmoisture.com

SOILMOISTURE

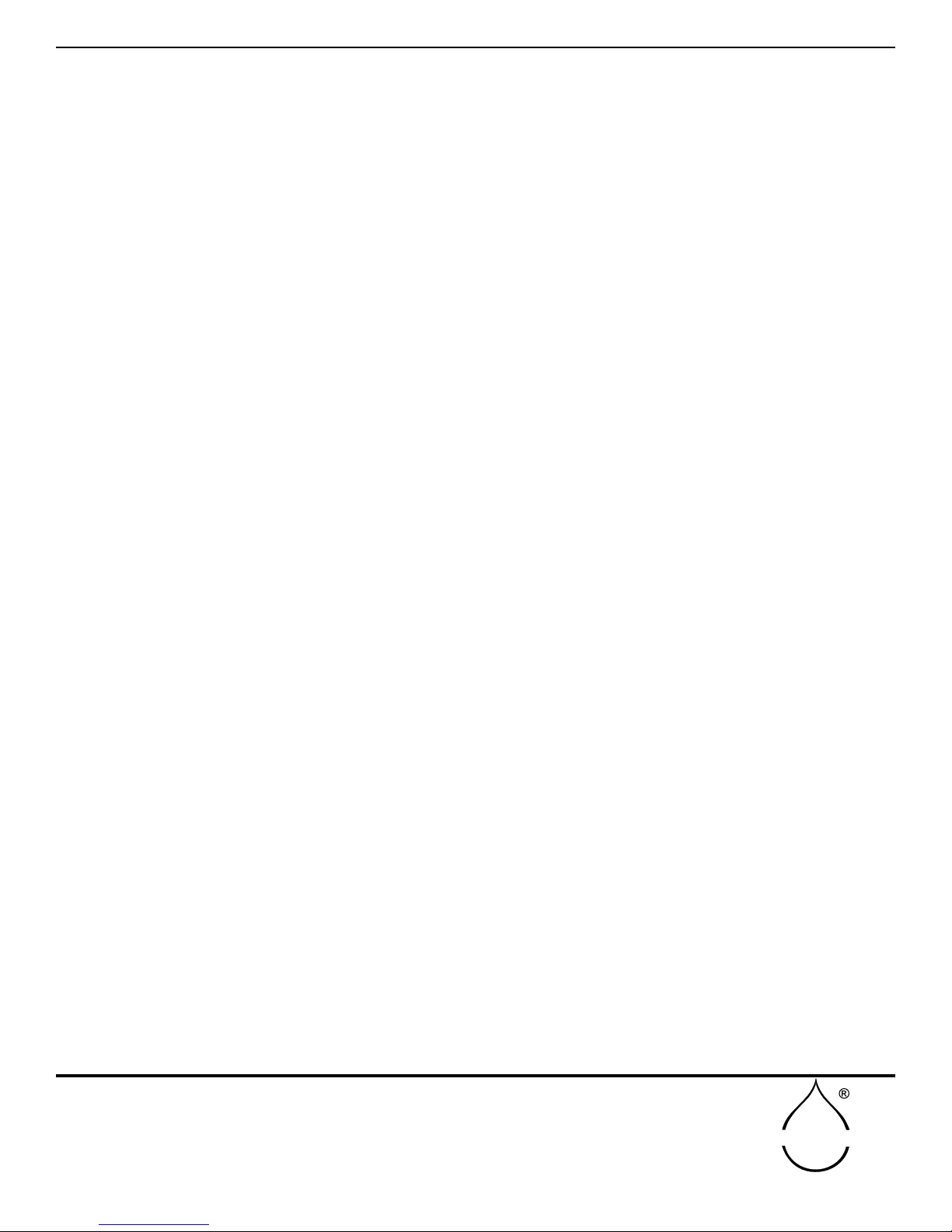

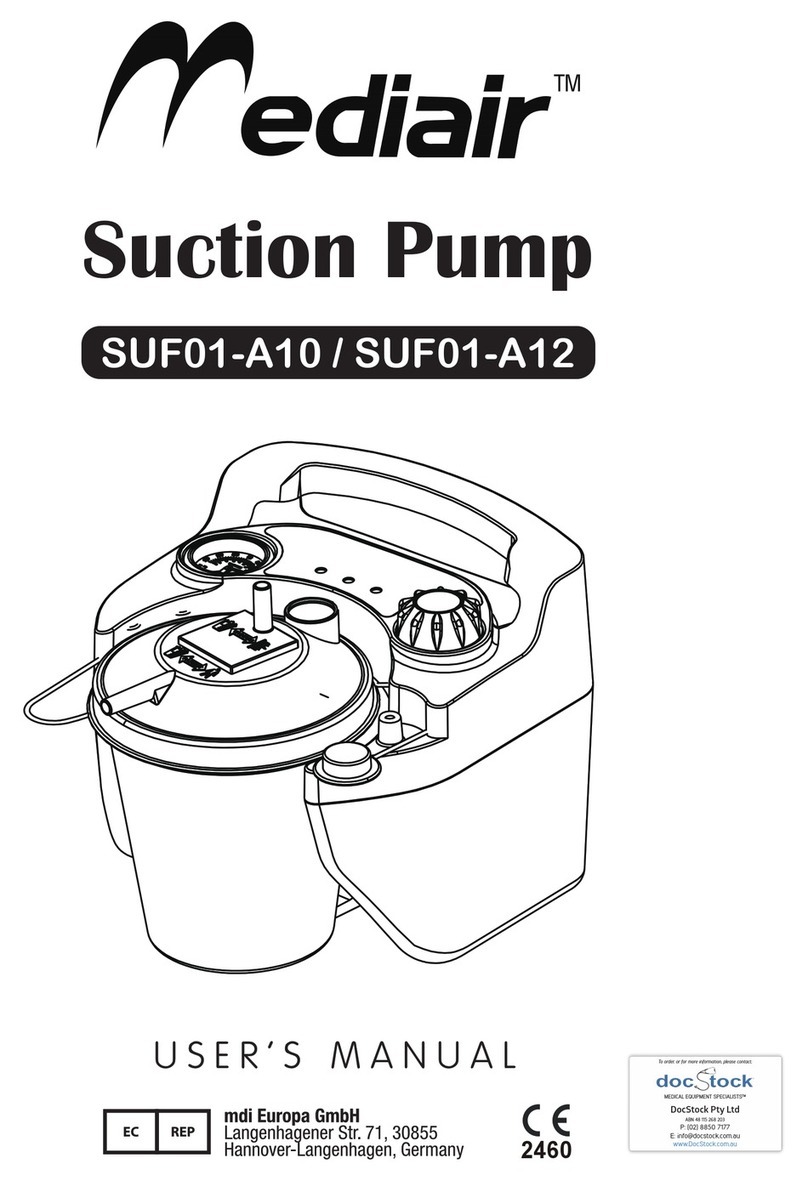

On the Model No. 1920 Pressure-Vacuum Soil Water

Sampler, the pinch clamp on the discharge access tube

is closed and the vacuum tting of the Pressure-Vacu-

um Hand Pump is connected to the pressure-vacuum

access tube, Fig. 9. The pump is then stroked until a

vacuum of about 60 centibars (18” of mercury) is cre-

ated within the sampler, as read on the vacuum dial

gauge connected to the pump. The pinch clamp on the

pressure vacuum access tube is then closed securely

to seal the sampler under vacuum. The hand pump

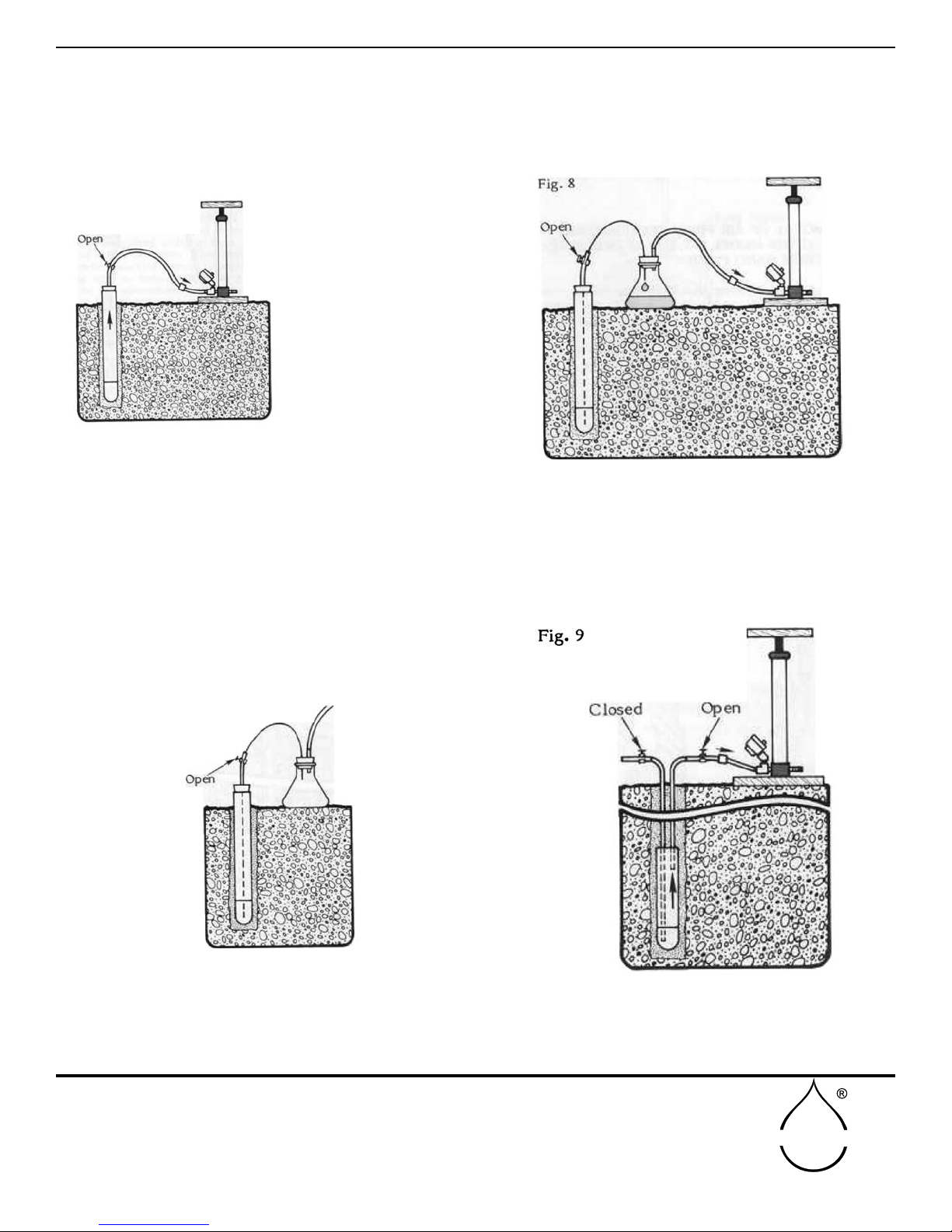

can now be disconnected for other uses. To remove the

collected soil water sample from the Model No. 1920

Pressure Vacuum Soil Water Sampler, attach the

pressure-vacuum access tube to the pressure tting

of the Pressure-Vacuum Hand Pump, Fig. 10. Place

the discharge access tube in a small collection bottle

and open both pinch clamps. Apply a few strokes on

the hand pump to develop enough pressure within

the sampler to force the collected sample out of the

sampler and into the collection bottle.

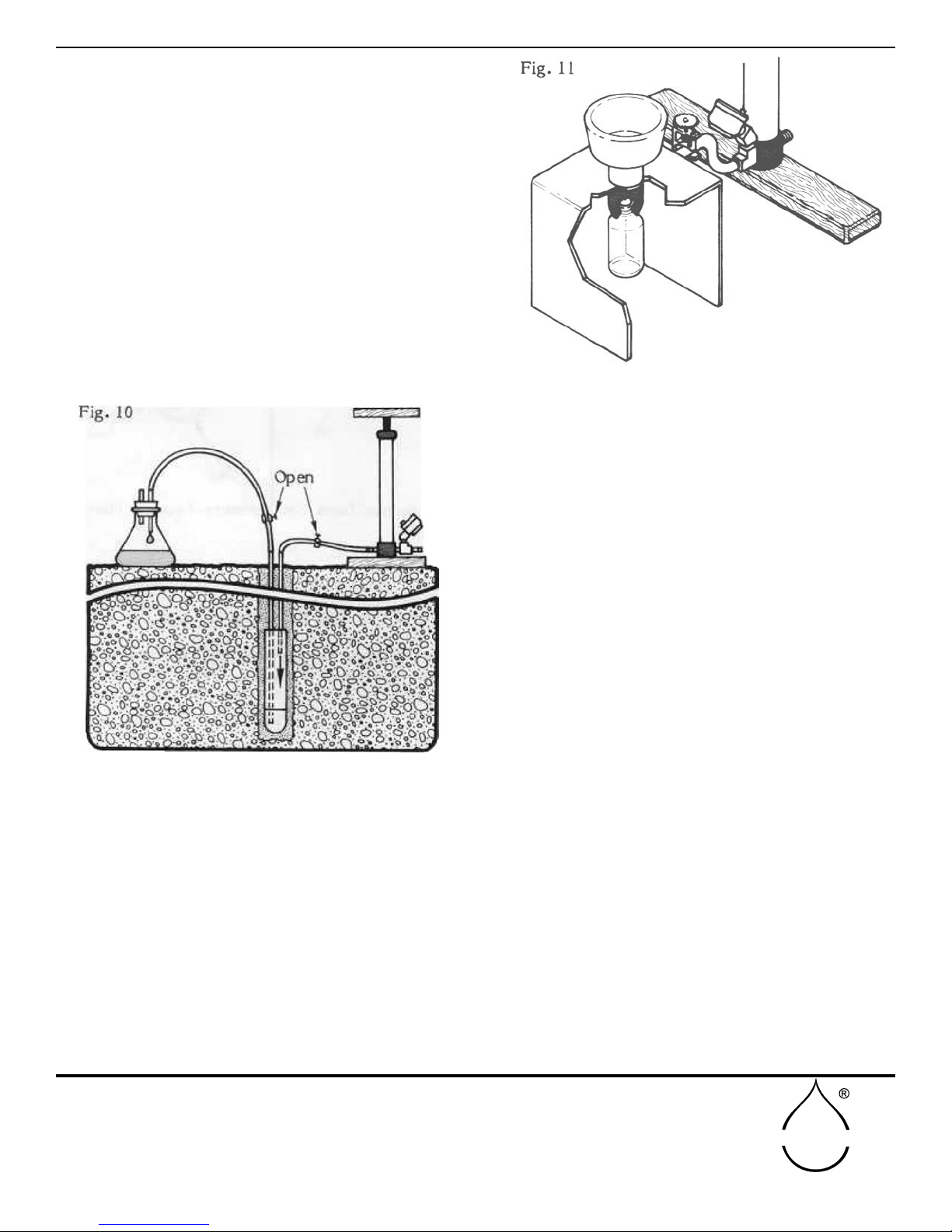

USING THE 2006G2 PRESSUREVACUUM

HAND PUMP AS A VACUUM SOURCE FOR

PORTABLE EXTRACTORS

Connect a length of 3/16” I.D. rubber hose to the

connection tting of the portable extractor and the

vacuum tting of the pump, Fig. 11. A pinch clamp

is placed on the rubber tube and left open. A vacuum

of 80 to 90 centibars is then pulled, using the pump,

within the extractor as read on the vacuum dial

gauge. After the vacuum is pulled, the pinch clamp is

closed, and the pump can be removed for other uses.

The vacuum created within the extractor will cause

the soil water sample to move from the funnel into

the collection bottle.

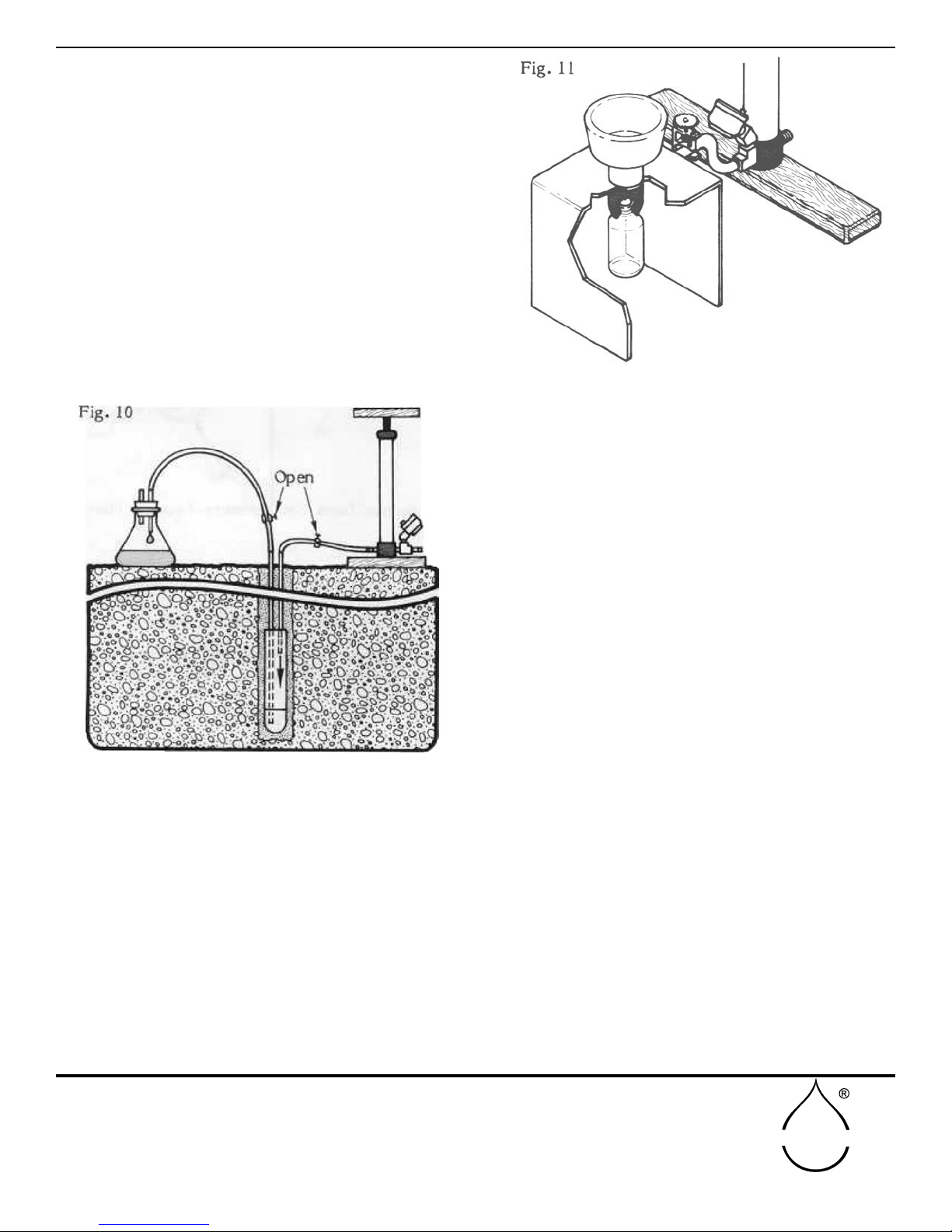

USING THE PRESSURE/VACUUM HAND

PUMP TO CHECK THE CALIBRATION OF

TENSIOMETER DIAL GAUGES

The adapter tting on the end of the rubber hose is

inserted into the ller end of the tensiometer body

and held tightly against the “0” ring seal to make

a vacuum-tight seal, as explained previously. As a

vacuum is pulled within the tensiometer, the reading

of the vacuum dial gauge on the tensiometer can be

compared with the reading of the vacuum dial gauge

on the pump, which is used as the reference gauge.

In checking the calibration of the vacuum dial gauge,

it is always desirable to lightly tap the gauge case to

relieve the internal friction of the gauge mechanism

to obtain the most accurate reading.

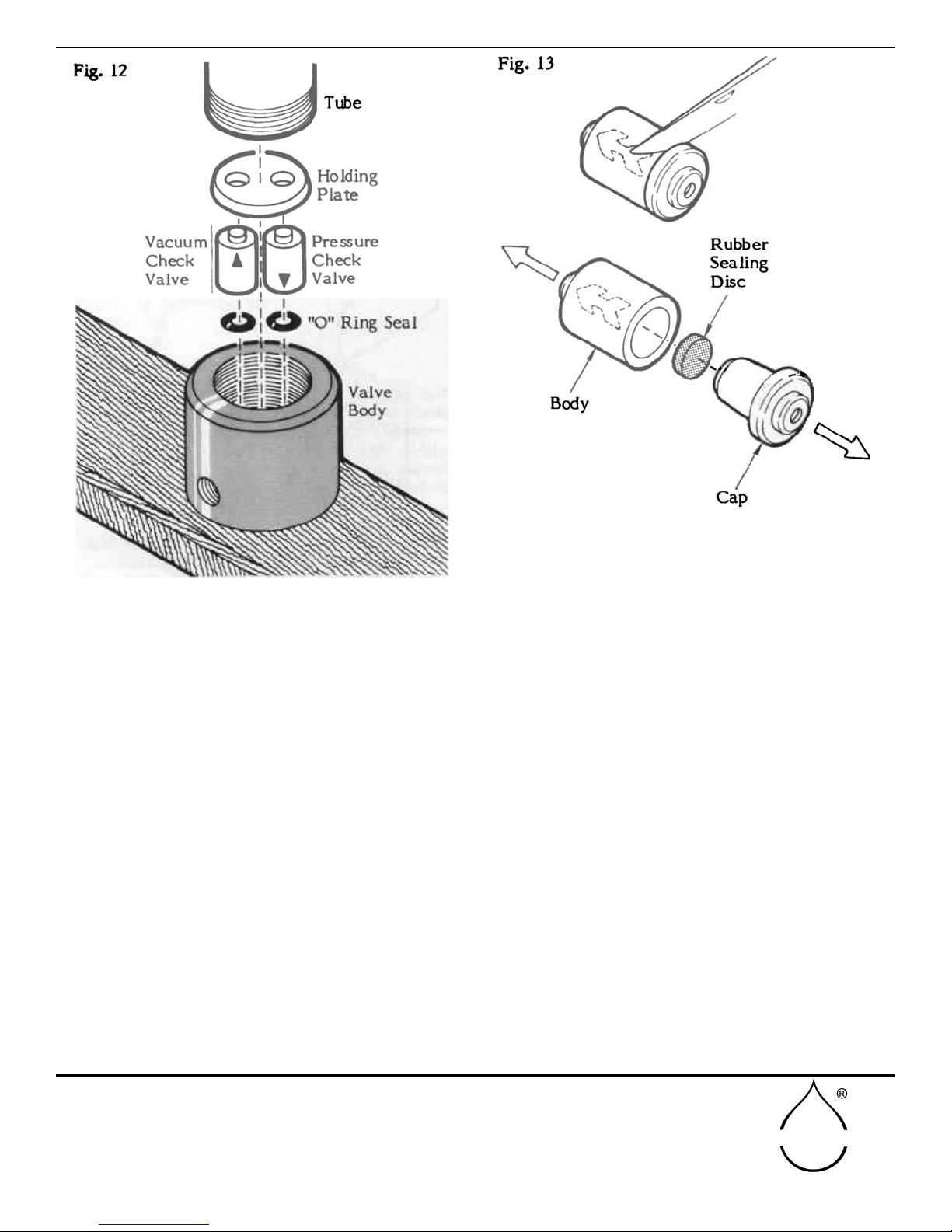

GENERAL CARE AND MAINTENANCE

When the 2006G2 Pressure-Vacuum Hand Pumps are

used for air removal or pulling a vacuum, very little

maintenance of the unit is required. If, however, the

pump will not hold a vacuum or has a pressure leak,

the check valves of the pump could be leaking due

to accumulation of debris. The check valves can be

removed to be ushed and cleaned of particles which

may interfere with their proper sealing action. To

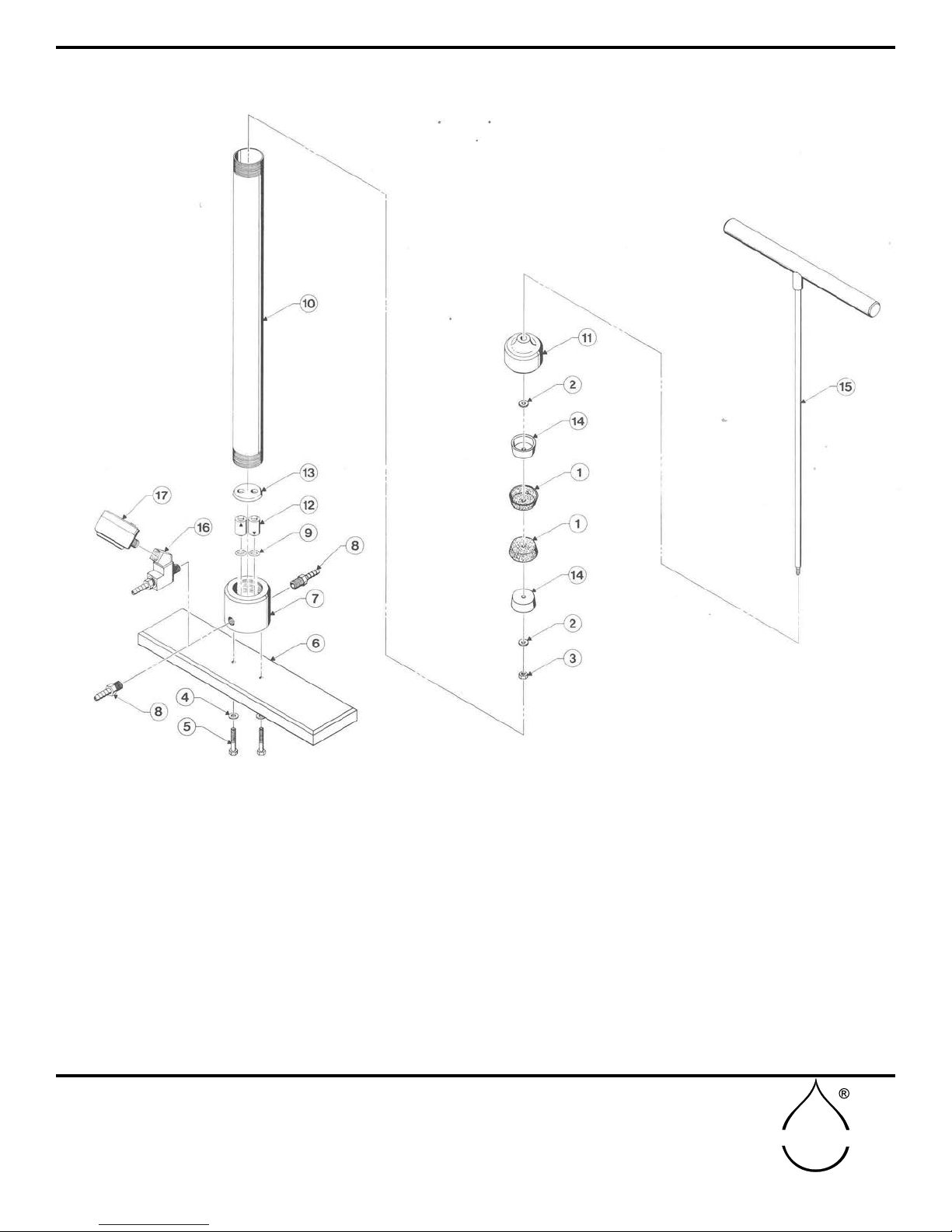

remove the check valves, unscrew the tube from the