Sojet ELFIN ID User manual

Edition: E1D20150415

High Resolution Inkjet Printer

User Manual

XiaMen Sojet Electronics Co.,Ltd.

IMPORTANT

To ensure the best printing quality, we recommend using only our specified cartridges and

the corresponding accessories. Any malfunction or poor printing quality caused by improper

use of other kinds of inks or accessories will be not be guarranteed.

Safety Precautions

There is high voltage inside the machine when it is live. Maintenance or disassembly by

unqualified or unauthorized person is strictly prohibited, so as not to cause any accident.

Machine must be reliably grounded by connecting the grounding wire for the machine during

equipment setup. Unreliable grounding will result in machine failure that the machine cannot

work normally.

Do not expose ink to direct sunlight or high temperature (35℃above). The heat of direct sun-

light or high temperature will affect ink’s storage life and print quality.

If you get ink spill on the eyes or skin during use, please clean your eyes or skin by clean

water.

Ink leakage inside printer can result in burnout damage to the machine. Switch off the

machine and unplug it from power outlet when there’s ink leakage inside printer. Contact

qualified service technician for test and repair.

Warning Signs

Caution: The sign “ ” indicates information for caution of possible damage to hardware

of inkjet printer or data loss.

Attention: The sign “” indicates important notes helpful for your trouble-free operation

of the machine.

Content

Introduction

06 Chapter One: Important Precautions for Using

06 1.1 Important Setup Precautions

6 1.2 Important Operation Precautions

7 Chapter Two: Setup and Installation Instructions

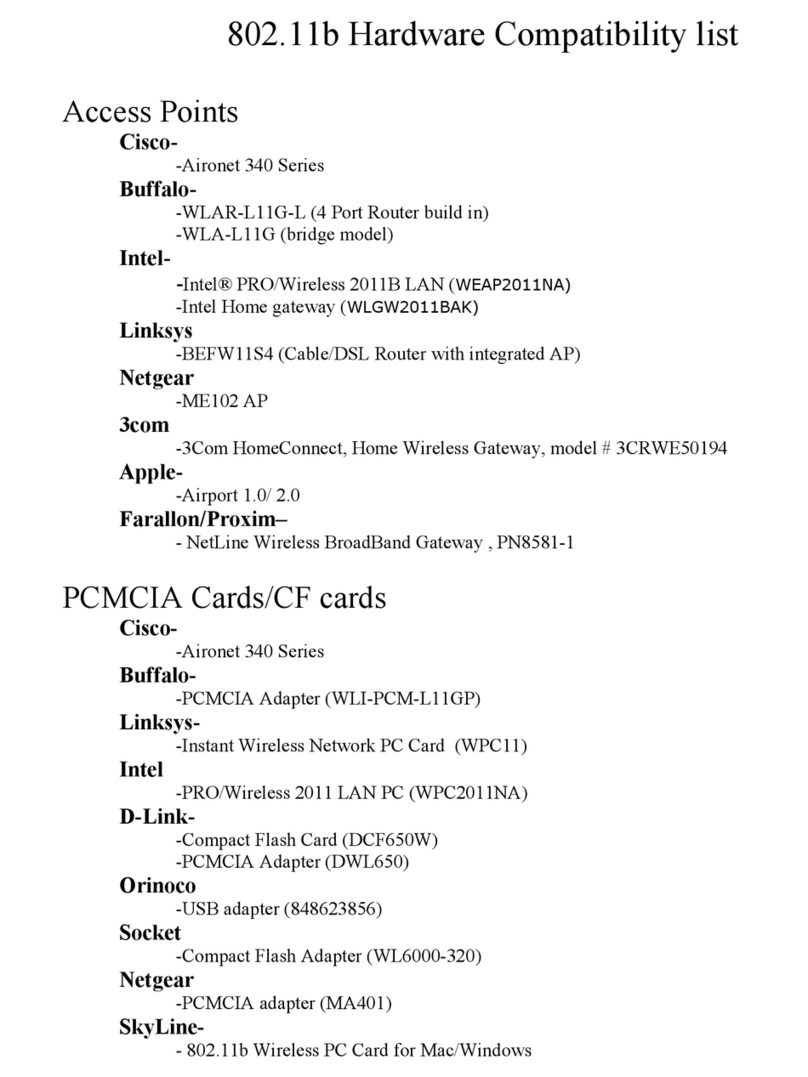

8 2.1 Parts List

9 2.2 Deviceinstallation

09 2.2.1 Side printing installation

9 2.2.2 Down printinginstallation

10 2.2.3 Springback mechanism installation(optional)

11 Chapter Three: DeviceIntroduction

11 3.1 Controller Introduction

11 3.2 Printer head Introduction

12 3.3 Technical Specifications

13 Chapter Four: How to Use the Printer and the Check Work before/afterUse

13 4.1 How to Use the Printer

13 4.2 Check Work before Use

13 4.3 Check Work afterUse

14 Chapter Five: Printer Operation Instructions

14 5.1 Main Interface

15 5.2 Printing Management

15 5.2.1 Find/Preview Data

15 5.2.2 Start Printing / Printing Report

15 5.2.3 Printing Delay

16 5.2.4 Print Initial Values

16 5.2.5 Stop Printing

17 5.3 New/Edit Data

17 5.3.1 New/Edit Data

18 5.3.2 Add TextObject

18 5.3.3 Add Production Date Object

18 5.3.4 Add Expiration DateObject

19 5.3.5 Add Image LogoObject

19 5.3.6 Add Counter Object

19 5.3.7 Add Shift CodeObject

20 5.3.8 Add BarcodeObject

21 5.3.9 Delete Data or Object

22 5.4 System Management

22 5.4.1 System Setting

23 5.4.2 Edit Options

24 5.4.3 Printing Options

26 5.4.4 Special Features

27 5.4.5 Screen TouchCorrection

28 5.5 Tools Management

28 5.5.1 Image Management

28 5.5.2 System Upgrade

29 5.5.3 System Backup

29 5.5.4 System Record

29 5.5.5 AboutEquipment

30 5.5.6 System Reset

31 5.6 Edit Input Method Options

32 5.7 Status Bar

33 Chapter Six: Care and Maintenance

33 6.1 Printer Care and Maintenance

33 6.2 Ink Cartridge Care and Maintenance

34 Chapter Seven:Troubleshooting

34 7.1 Troubleshooting for InkCartridge

35 7.2 Troubleshooting for Printer

36 Appendix 1: Terms and Definitions

Please read this manual carefully before you use thisequipment.

Introduction

Thank you for your purchase of this high resolution printer. We want you to get helpful information

for your work with this equipment; therefore we would like to explain a little bit about how to use this

machine by this user manual by the following content:

Important precautions for use of themachine

Introduction of printer: Parts and components of themachine

Setup and Installation Instructions: Instructions for Equipment Setup and Cartridge Installation.

How to use the printer and the check work before/after use of the printer: explanations of general

operation and startup/shutdown.

Operation instructions: explanations on how to new/edit data for printing, and how to adjust

printer settings.

Care and Maintenance: Care and maintenance for printer andcartridge

Troubleshooting: Common failures occurred andsolutions

Appendix 1 - Terms and Definitions: Definitions for terms used in thisdocument.

Please read this user manual carefully before first use of the printer for full understanding and atten-

tion of important information so that you will get maximum use from your new equipment. This will

also help you have a quick reference to related sections when you have any problems during use.

Note 1: If you cannot solve the problem encountered during use, please contact us for assistance.

Note 2:The information contained herein is subject tochange without notice.The amended informa-

tion will be updated in user manual by newedition.

Note 3: Any machine failure or damage caused by user’s negligence in following this manual will not

be covered by the warranty.

ChapterOne:ImportantPrecautionsforUsing

Welcome to use this printer. In order to protect your personal safety and user rights, ensure correct

installation and operation, and full play of the machine, it is important that you read the precautions

carefully.

1.1 Important Setup Precautions

1.1.1 Use exclusive power supply for the equipment. Do not share same power supply with other

equipment. Besides, Installation of an additional UPS isrecommended.

1.1.2 Mount the support in sound and stable place. Do not choose the location that will be easily

affected by shock or sway.

1.1.3 Choose well-working conveyor belt for high printquality.

1.1.4 Add deflector to the printer for production line setup in order to prevent any printing object

hitting the nozzle plate to causedamage.

1.1.5 Make sure the printer is wellgrounded.

1.1.6 Maintain the distance between deflector and printing object at 0.5-2.5mm as recommended.

1.1.7 Make sure to insert and remove the ink cartridge by an angle of 15 degree so as not tocause

damage to the cartridge.

1.1.8 Make sure the setup environment is tidy and clean. Clean the dust on printer from time to time

when dusty environment isunavoidable.

1.2 Important Operation Precautions

1.2.1 Do not poke or impact the touch screen sharply.

1.2.2 Do not cover up the built-in photocell. Otherwise the printer doesn’tprint.

1.2.3 Use Non-woven to wipe the nozzle plate when the print is not clear or dots are missing.

1.2.4 Set print delay value for best print result when print position changes (see Section5.2.3).

1.2.5 Do not insert or remove ink cartridge while the machine is in printing process so asnot to cause

damage to the cartridge.

1.2.6 Do not use compressed air for cleaning the touch screen. High pressure of the compressed air

will damage the touch screen.

1.2.7 Do not use compressed air for direct or indirect cleaning of the ink cartridge. High pressureof

the compressed air will damage the nozzleplate.

1.2.8 Read Chapter Seven for troubleshooting when there’s failure occurs. If you cannot solve the

problem encountered, contact your local dealer or our after-saleservice.

Note: Depending on properties, some ink cartridge may require to be removed from printer after

use. Turn off the machine and remove the cartridge from printer.Wipe the printhead clean with Non-

woven; cap the printhead with the designed cap for prevention of the nozzles from clogging.

(Contact our after-sale service for information of inkproperties.)

ChapterTwo:InstallationandSetupInstructions

This chapter will illustrate how to set up the equipment and how to install an ink cartridge. Firstly

please check the machine parts by looking at the packing picture and parts list.

Packing Picture

2.1 Parts List

Once you have unpacked your machine, check to make sure that you have all the parts shownhere.

1、Controller 2、Printer head 3、USB

4、power line 5、power supply adapter 6、printer head

connection line

7、ground line 8、round bar fixer X 2 9、round bar

10、bi-directionbracket 11、bi-pass clamp x 2 12、A. M8*16 SCREW: 11PCS

B. M4*8 SCREW: 2PCS

13、inner hexagon spanner 14、Springback holder and

anti shock groups (selectable)

2.2 Device installation

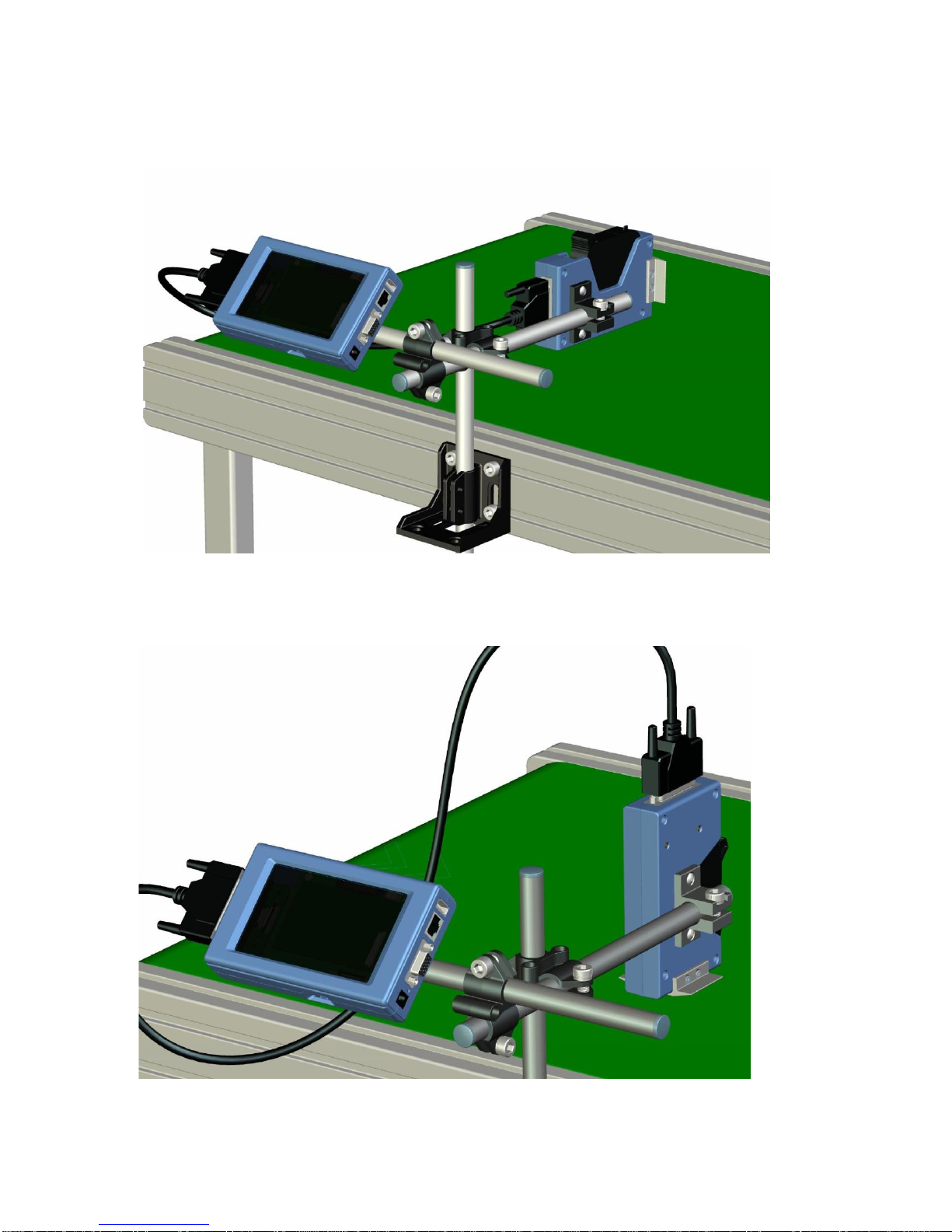

2.2.1 Side printing installation

2.2.2 Down printing installation

2.2.3 Springback mechanism installation (optional)

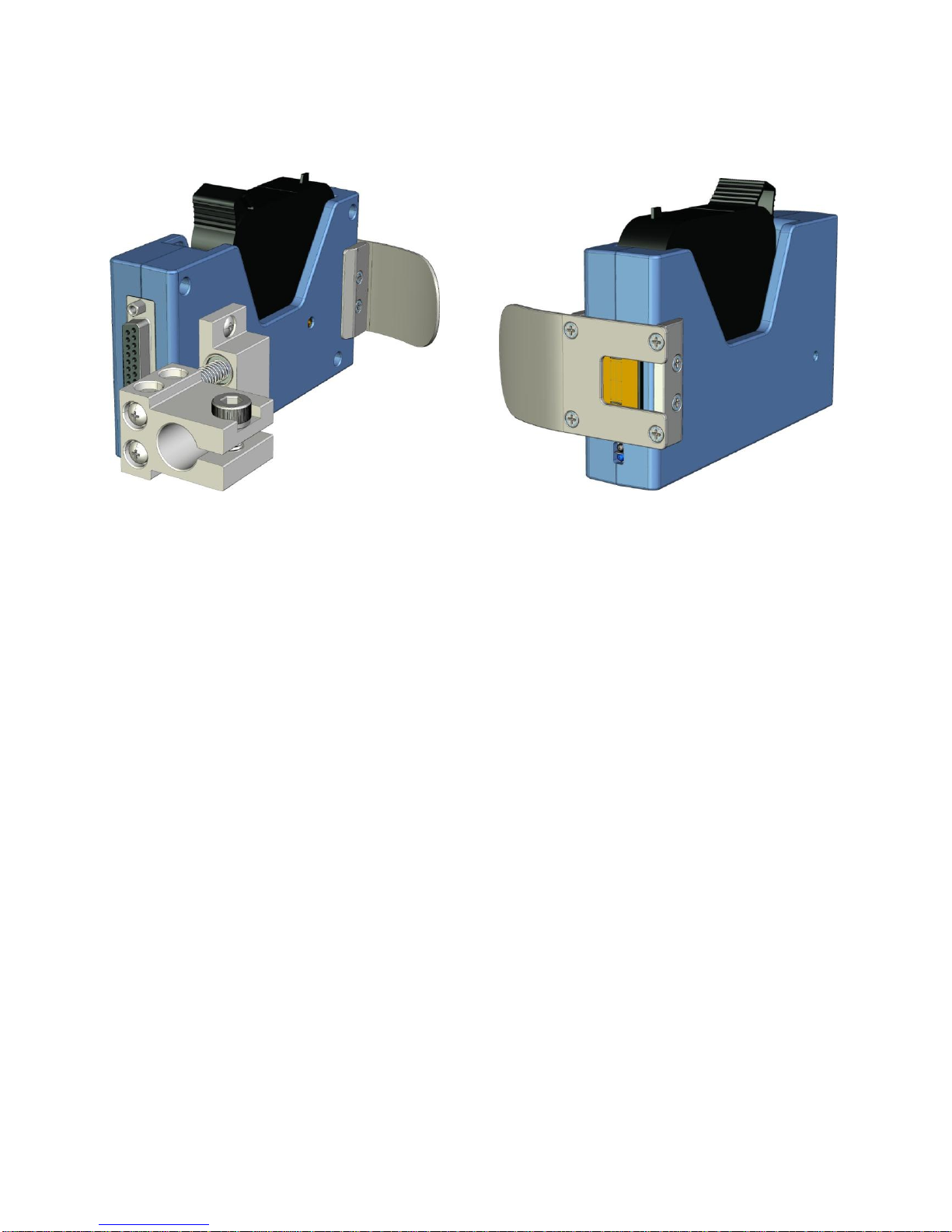

Springback mechanism installation Anti-shock plate installation

Chapter three:Device Introduction

3.1 Controller Introduction

Touch screen

Power port

DB15 port

Ethernet port

USB 接口

DB25 port

Power switch

3.2 Printer head Introduction

Anti-shock plate

Ground connection screw

DB25 port

3.3Technical Specifications

A. Performance Values

Item

Specifications

Note

Technical source

HP TIJ 2.5 Thermal Ink Jettechnology

Dimension

Controller(H*W*D):142*65*98mm

Printer head(H*W*D):145*80*60mm

support size

Two steel tubes:

Φ16mm*350mm, and Φ16mm*280mm.

Clamp and bracket

not included

Power supply

Input: AC 90V-240V/50-60HZ,60W;

With power adapter

Output: 12V DC / 5A;

Power cord length: 1.8m;

Power adapter cord length: 1.2m

Print heights

1-12.7mm

Print speed and

resolution

horizontal resolution

(DPI)

Maximum speed (m/min)

600

30.4

400

45.7

300

60.9

150

121.9

Print application

Barcode, alphabetic, numeric, image logos,

date/time, expiration date, shift code, counter, lot-box

code

Connection Ports

1.Ethernet port;

2.USB2.0 port;

3.DB15 port.

4.DB25 port.

Interface

5inch full-color large LCD touch screen with

resolution 800*480.

Ink management

1.Automatically recognizes ink types, and identifies

optimum printing parameters for each inktype;

2. Guarantees the using of genuine original HPink;

3. Automatic measuring system for the usage ofink.

Mounting

Standard side, downward and anti-shocksupport.

Product Certification

CE, FCC.

Environment

requirement

1. Working environment: -10°C~ +55°C; 10%-85%RH;

2. Storage environment: -25°C~ +80°C; 10%-90%RH.

B. Features:

Item

Specifications

Note

Languages

Chinese, English, Japanese, French, German,

Spanish, Portuguese andRussian.

Font

Default font is Arial; allow users to load fonts they

need.

Barcode

UPCA, UPCE, EAN13, EAN8, INT25, CODE39,

CODE128, EAN128, PDF417, DATAMATRIX, QR.

Date format

Variety of date formats available

Counter

Flexible setting for common counter, lot-Box code

counters.

Print speed

Print speed can be set, automatically tested, or set

and tested by externalencoder.

Built-in photocell

Good for simple print, no external photocellneeded.

Multi-management

Multi-level password protection (Operator, Technician

and administrator).

C. Ink Solutions:

1. Support 42ml, 370ml, 350ml cartridges of HP TIJ2.5technology;

2. Support ink of various colors: black, red, green, yellow andblue;

3. Support porous, semi-porous and non-poroussubstrates.

Chapter Four: How to Use the Printer and

the Check Work before/after Use

In this Chapter, you will learn how to use the printer, including check work before and afteruse.

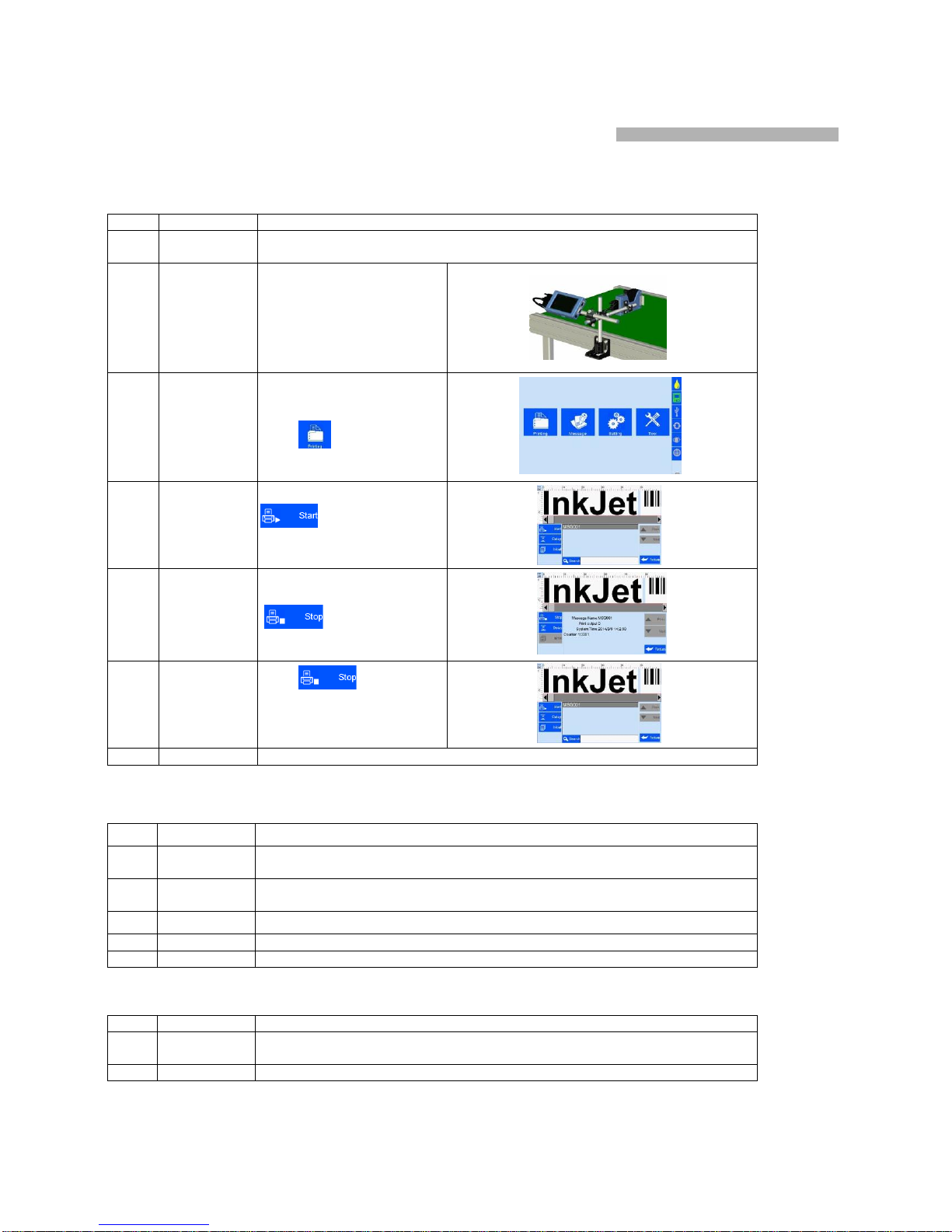

4.1 How to Use the Printer

Sq #

Procedure

Instructions

1

cartridge

Installation

Insert cartridge into the printer stall by an angle of 15 degree, close cartridge clip

to secure. (see 2.3 CartridgeInstallation)

Connect poweradapter

2

Turn on

printer

to printer power input,

switch on power,printer

entersinitialization

startup.

After initialization startup,

3

Main

Interface -

Printing

Management

“main interface” appears

(see Section 5.1).

Click to enter

“Printing Management” (see

Section 5.2).

4

Select data -

Start printing

Select a file on data list,click

to Start printing.

5

Printing

report

When printing starts, the

button change to the icon

for stop printing,

meanwhile a printing report

appears.

6

Stop printing

Click to stop

printing, printing report exits,

and the button returns to

“Start printing” status.

7

Switch off

Exit printing, and switch off power.

4.2 Check Work before Use

Sq #

Item

Check Work

1

Printer

support

Is the support securelymounted?

2

Printer

position

Is the printer orientation correct? Is the nozzle plate parallel to printing object? Is

the throw distance controlled within 0.5-2.5mm?

3

cartridge

Is the cartridge wiped clean? Has the cartridge been installed to printer?

4

Power input

Is the printer input voltagenormal?

5

Printer status

Check status bar, is the equipment statusnormal?

4.3 Check Work after Use

Sq #

Item

Check Work

1

Printer

PowerStatus

Is the printer power switched off?

2

cartridge

Is the cartridge removed from printer and wiped clean and printheadcapped?

Chapter Five: Printer Operation Instructions

This chapter explains how to operate printer interface, including Printing Management, Data Man-

agement, System Management, Tools Management, and Status Bar.

5.1 Main Interface

Switch on power,

Settin

g

Management

Printin

g

Management

Data

Management

Tools

Management

Status bar

(Figure 1)

printer starts

initialization

startup. After

initialization

startup, “main

interface” appears

(see Figure 1).

Printing

Management

Tofind and preview data, start/stop printing, set printing delay value, andset

printing initial values (see Section5.2).

Data

Managemen

ToFind/Preview, File-new, Edit, Delete data (see Section5.3).

System

Management

Tomanage system setting, editing options, printing options, user authority,and

screen correction setting (see Section 5.4).

Tools

Management

Tomanage image logo, system upgrade, system backup, system record, equip-

ment default restoring, system resetting (see Section 5.5).

Status bar

Display information of ink, equipment, USB, encoder, external photocell, and

Ethernet status (see Section 5.7).

5.2 Printing Management

Click on maininterface

Preview

Page up

Page

Down

Return

(Figure 2)

to enter printing management

interface

(see Figure 2)

Scroll bar

Start

printing

Printing

File name

delay

Search

Keywords enteringbar

5.2.1 Find/Preview Data (see Figure 2)

A. Find data

Find by Pageup/Pagedown/keywords.

B. Preview data

Preview data by locating or selecting a file of data to display on preview interface;

data located/selected will be displayed in sequence on preview interface, and can

be viewed scaled up and down by times of 1 and2.

Note: Drag the scroll bar horizontally to view the data when it exceeds the screen horizontally.

5.2.2 Start Printing / Printing Report

5.2.3 Printing Delay

Click , printing delay

setting interface appears (see

Figure 4)

See Appendix 1:Terms

and Definitions 1 for more

information.

(Figure 4)

A. Printing delay default value:30mm;

B. Printing delay value range:0.0-999.9mm;

C. It is allowed to set printing delay value during printing process: the newly set value becomes valid for

immediately nextprinting.

D. Printing delay value for each message are independent from one another, the delay setting for current

data file will not affect another datafile.

Click

button to start

printing. When printing starts,a

printing report appears (see Figure3).

Printing report: It is the timely record

of printing in process, includingdata

file name in process, print output

quantity, counter value, shift code,

system time. The printing report

exits when printing stops.

Stop

printing

Printing

report

(Figure 3)

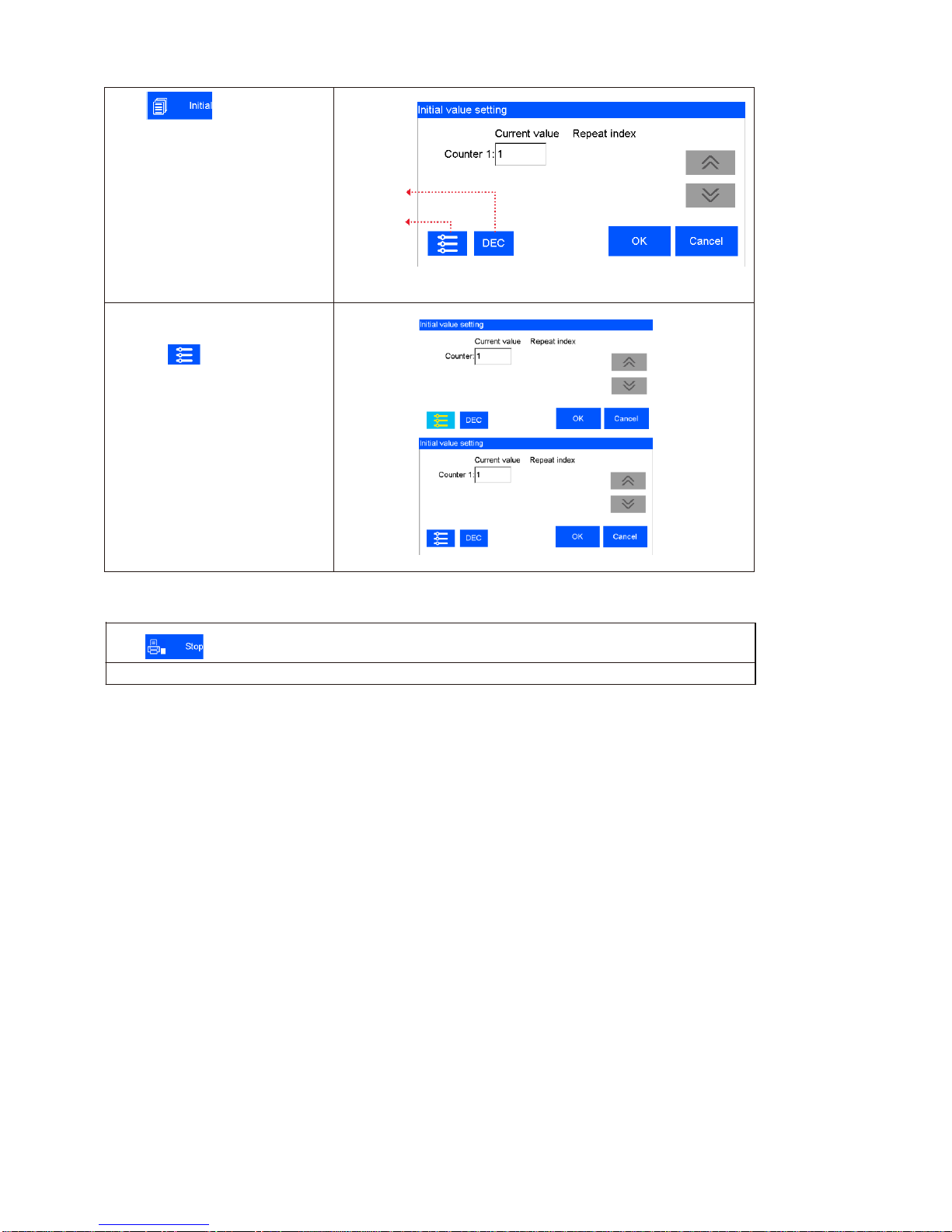

5.2.4 Print Initial Values

Click , the interface of

initial values setting and repeated

index value checking appears.

System switch

DEC-10 decimal (0-9)

H36-36 hexadecimal (0-Z)

The Generic Binary is editable;

See5.4.2

System switch

Counter

synchronizing

Counter Synchronizing: when

multi counter included in the same

file, click , then all counters’

current value will be synchronized

to counter 1’s current value.

After confirmed, a dialog boxwill

display the counters’ setting, user

can set the counter’s

begin/end/step/repeat numberand

the binary regulation.

5.2.5 Stop Printing

Click

to stop printing and exit printing report, return to Start Printing status (see Figure2).

Note: Printer automatically stops printing when there is case as power-off, out of ink, alarming etc.

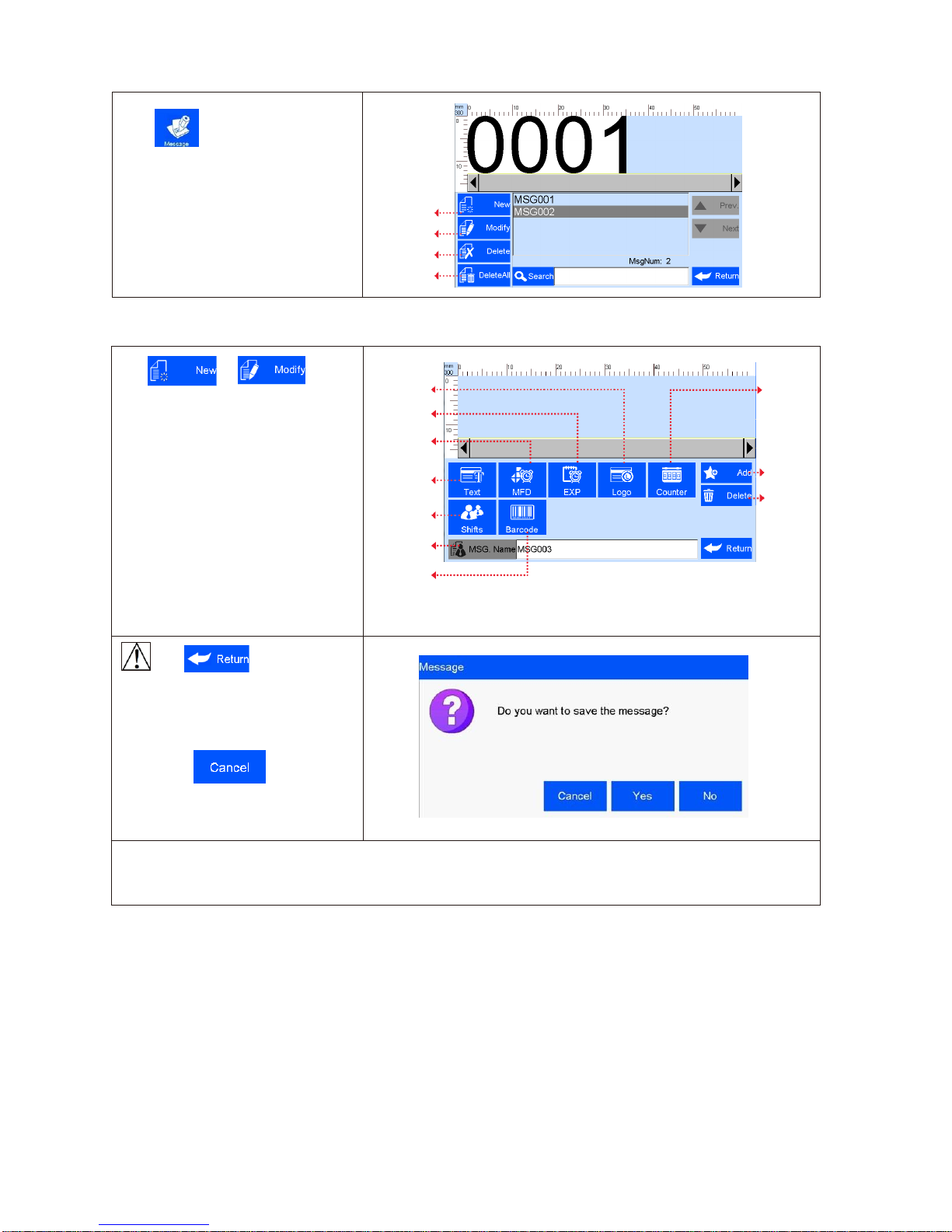

5.3 New/Edit Data

Click on main interface to

enter data management interface.

New

Modify

Delete

DeleteAll

5.3.1 New/Edit Data

Click or on Data

Management interface to enter data

edit interface (see Figure7).

A. New: text, counter, shift,production

date, expiration date, image logo,

barcode.

B. Edit: data in printing processcannot

be edited.

C. File name: maximum 15 characters,

empty file name or repeated filename

not allowed.

Image Logo

Counter

Expiration

date

Production

date

Add

Text objects

Delete

objects

Shift code

File name

barcod

e

(Figure 7)

Click to save data

when finish editing, a check box

appears to ask “Are you sure youwant

to save the message? Cancel, Yes,

No” (see Figure8).

If you click “ ”, the machine

will remain on editinginterface.

(Figure 8)

Note: “MSG001” is default data in system, not editable and not erasable.

The system allows maximum 500 files of data (including defaultMSG001).

The system does not save emptydata.

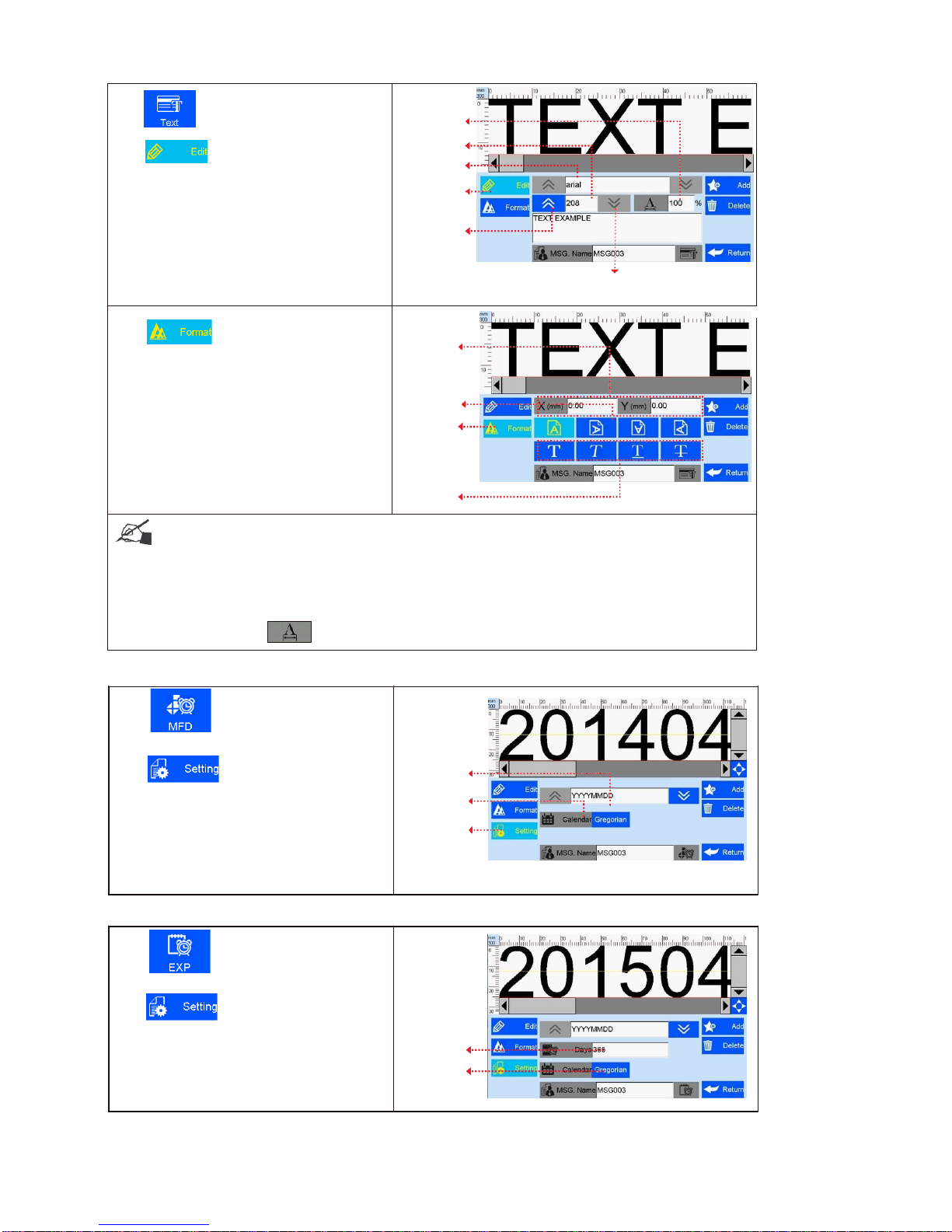

5.3.2 Add Text Object

Click to add text object, see Figure9.

Horizontal

scale

Click to enter text editinginterface:

A. Font: default font Arial, support 2 fontsat

Height

Text

same time, Arial and one alternativefont.

Edit

B. 16-208( adjust freely within the scopeof

1-12.7mm);

Vertical

scale down

C. Texthorizontal scale: 1-300%;

D. Textcontent cannot exceed 25 characters.

and

locationup

Vertical scale upand

locationdown

(Figure 9)

Click to enter textadjustment

interface.

E. Coordinate location: adjustable range for

X axis 0-3000mm; for Y axis, 0-12.7mm.

F.Textorientation: 0°, 90°, 180°, 270°.

Four orientations adjustable.

G. Font effects: bold, italy,underline,

strikeout, four effects adjustable.

Coordinate

position

Orientation

Adjust

Font effect

(Figure 10)

Note: Please refer to this Section (Section5.3.2) regarding how to add objectsas “production date”,

“expiration date”, ”image Logo”, ”counter”, ”shift code”,"dynamical text""dynamical logo", butthe

content of “production date”, “expirationdate”, ”counter”, ”shift code”"dynamical text""dynamical logo"

cannotbe revised or adjusteddirectly when you add, and the font, height,

content and font effect of “image Logo”"dynamical logo" cannotbe reviseddirectly. There is no option

of horizontalscale“” for “logo” “barcode”,"dynamical logo".

5.3.3 Add Production Date

5.3.4 Add Expiration Date

Click

date.

to add object of expiration

Click

to enter date formatsetting

and days to expire (scope: 0~9999)�

Gregorian and Hijri available.

(see Figure 12).

Days to

expire

Calendar Type

(Figure 12)

Click

date”.

to add object“production

Click

to enter date formatsetting,

choose a format by arrow up anddown�

Gregorian and Hijri available.

(see Figure 11).

Date format

Calendar Type

Adjust

(Figure 11)

for

5.3.5 Add Image Logo

Click to addobject

imageLogo.

Select a logo on filelist by page up

and down (see Figure13).

Image

file list

(Figure 13)

Note:Whenthereis no imagefilefound,

a message box appears to promptimage

import (see Figure 14).

See Section 5.5.1 ImageManagement

for image logoimport.

(Figure 14)

5.3.6 Add Counter

Click to add object counter.

Click to for option ofcommon

counter, box number,lotnumber.

A. Click for common countersetting:

minimumvalue,maximumvalue, stepping

value, repetition number.

Commo

n

counter

Box No.

Lot No.

Stepping

value

Repetition

number

B. Click and option ofbox

numberand lot numbersetting:minimum

value,maximum value, stepping value for box

number and lot number (see Figure16).

Note: There is no repetition number forbox

number or lot number.

Minimum

value

Maximum

value

(Figure 16)

5.3.7 Add Shift Code

Click

to add object “shift code”.

Click to entersetting

(see Figure 17).

Shift code: shift name and time forsetting.

Shift name: maximum fivecharacters.

Shift time: four different times for setting.Shift

code varies according to different timeperiods.

(Figure 17)

5.3.8 Add Barcode

Click to add object“barcode”.

A. Click to enter barcode edit:

Barcodetype, horizontal scalelevel, barcode

height, barcode text (see Figure18).

Barcode

height

Barcode

type

Horizontal

scalelevel

Barcode

text

(Figure 18)

B. Click to enter barcode

adjustment:coordinatelocation, text

orientation, text display/hide, text height,

error correctionlevel, white space level

(see Figure 19,20).

Note: Setting options may differdepending

on different barcodetypes.

: Textdisplay;

: Texthide;

~: errorcorrection

level;

~

: whitespace

level.

Textdisplay

Textheight (Figure 19)

Error

correctio

n level

White

space level (Figure 20)

Table of contents

Other Sojet Printer manuals