3

TABLE OF CONTENTS

1. INTRODUCTION.......................................................................................................................................................... 5

2. SAFETY INSTRUCTIONS ............................................................................................................................................. 6

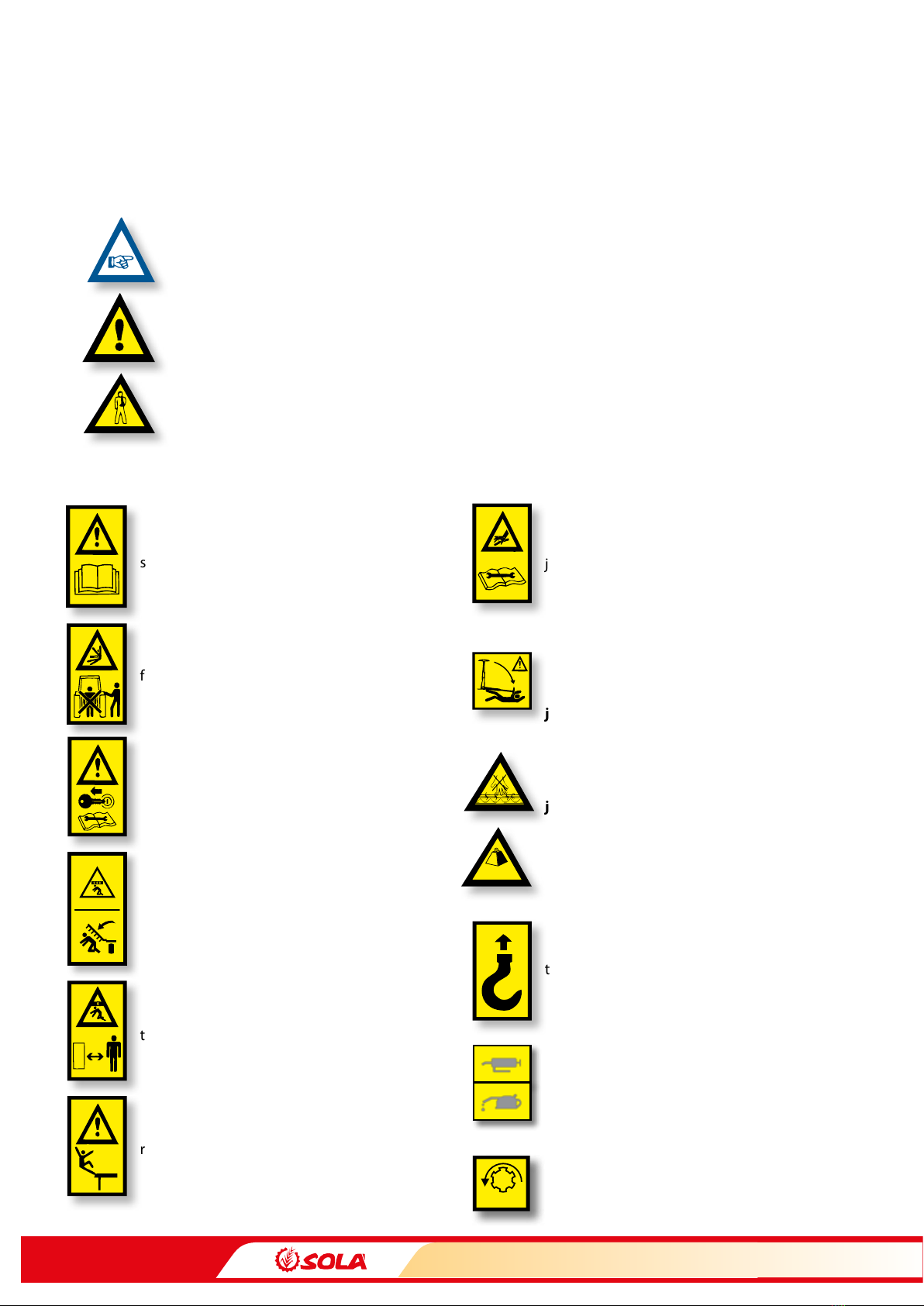

2.1 SAFETY SYMBOLS........................................................................................................................................................................ 6

2.2 GENERAL SAFETY REGULATIONS ............................................................................................................................................ 7

2.3 LOADING AND UNLOADING INSTRUCTIONS......................................................................................................................... 7

3. OVERVIEW.................................................................................................................................................................. 8

3.1 SEED DRILL OVERVIEW ............................................................................................................................................................... 8

3.2 TECHNICAL CHARACTERISTICS ................................................................................................................................................ 9

3.3 MACHINE IDENTIFICATION........................................................................................................................................................ 9

3.4 USE ACCORDING TO DESIGN..................................................................................................................................................... 9

3.5 STANDARD EQUIPMENT........................................................................................................................................................... 10

3.6 OPTIONAL EQUIPMENT............................................................................................................................................................ 10

4. ESSENTIAL SOWING CONCEPTS............................................................................................................................... 10

4.1 TERRAIN ...................................................................................................................................................................................... 10

4.2 SEEDS........................................................................................................................................................................................... 10

4.3 SEED PLANTING DEPTH ........................................................................................................................................................... 10

5. STARTING ..................................................................................................................................................................12

5.1 COUPLING THE SEED DRILL ..................................................................................................................................................... 12

5.2 CONNECTING AND ADAPTING THE PTO SHAFT.................................................................................................................. 13

5.3 HYDRAULIC SYSTEM................................................................................................................................................................. 13

5.4 TRANSPORT POSITION ............................................................................................................................................................. 14

5.5 FILLING AND EMPTYING THE HOPPER.................................................................................................................................. 15

5.6 SUPPORTING LEGS .................................................................................................................................................................... 16

5.6.1 FRONT SUPPORTING LEG........................................................................................................................... 16

5.6.2 REAR SUPPORTING LEGS ........................................................................................................................... 16

5.7 PARKING ...................................................................................................................................................................................... 16

5.8 FINISHING WORK WITH THE SEED DRILL.............................................................................................................................. 16

6. ADJUSTMENTS ..........................................................................................................................................................17

6.1 LEVELLING THE SOWING EQUIPMENT................................................................................................................................... 17

6.2 ADJUSTING SEED PLANTING DEPTH..................................................................................................................................... 17

6.2.1 ADJUSTING THE PLANTING DEPTH SPINDLES ...................................................................................... 17

6.2.2 DEPTH ADJUSTMENT WHEELS ................................................................................................................. 17

6.2.3 TINE COULTERS............................................................................................................................................ 18

6.3 DOSAGE....................................................................................................................................................................................... 18

6.3.1 REGULAR SEEDS (POSITION N) ................................................................................................................. 19

6.3.2 FINE SEEDS (POSITION F) .......................................................................................................................... 19

6.4 SEED DOSING ADJUSTMENTS................................................................................................................................................. 20

6.5 PREVIOUS FLOW TEST .............................................................................................................................................................. 20

6.6 DOSING FIELD TEST .................................................................................................................................................................. 21

6.7 HARROW...................................................................................................................................................................................... 22

6.8 LEVELLER..................................................................................................................................................................................... 22

6.9 TRACK ERASER ........................................................................................................................................................................... 22

6.10 HYDRAULIC TRACK MARKERS............................................................................................................................................... 22

6.10.1 ADJUSTING TRACK MARKER’S LENGTH ................................................................................................ 23

6.10.2 ADJUSTING TRACK MARKER’S INCLINATION....................................................................................... 23

6.11 INCLINATION OF THE FOLDING PARTS................................................................................................................................ 23

7. TYPES OF DISTRIBUTION.......................................................................................................................................... 24

7.1 SEED DISTRIBUTION BY MECHANICAL FAN ......................................................................................................................... 24

7.2 SEED DISTRIBUTION BY HYDRAULIC FAN............................................................................................................................. 24

8. ELECTRONICAL CONTROLLER.................................................................................................................................. 25

8.1 FRONT PANEL DESCRIPTION ................................................................................................................................................... 25

8.2 FORWARD SPEED - C1.............................................................................................................................................................. 25

8.3 TOTAL AREA / SEED DRILL WIDTH – C2................................................................................................................................. 26

8.4 FRONT PANEL WITH PATH MARKER....................................................................................................................................... 26

8.5 TRAMLINING – C3...................................................................................................................................................................... 27

8.6 FAN RPM / FAN ALARMS – C4.................................................................................................................................................. 30

8.7 SEED SHAFT RPM – C5 .............................................................................................................................................................. 30

8.8 HOPPER LOW LEVEL ALARM – C6........................................................................................................................................... 30

8.9 TOTAL SOWING SHUT-OFF (OPTIONAL)................................................................................................................................ 31

8.10 SHUT-OFF SOWING FROM FOLDING PARTS (OPTIONAL)................................................................................................ 31

TABLE OF CONTENTS