- 3 -

TABLE OF CONTENTS

1- INTRODUCTION .......................................................................................................................................................... 5

2. SAFETY INSTRUCTIONS ............................................................................................................................................. 6

2.1 SAFETY SYMBOLS ....................................................................................................................................................................... 6

2.2 GENERAL SAFETY PROVISIONS ................................................................................................................................................ 7

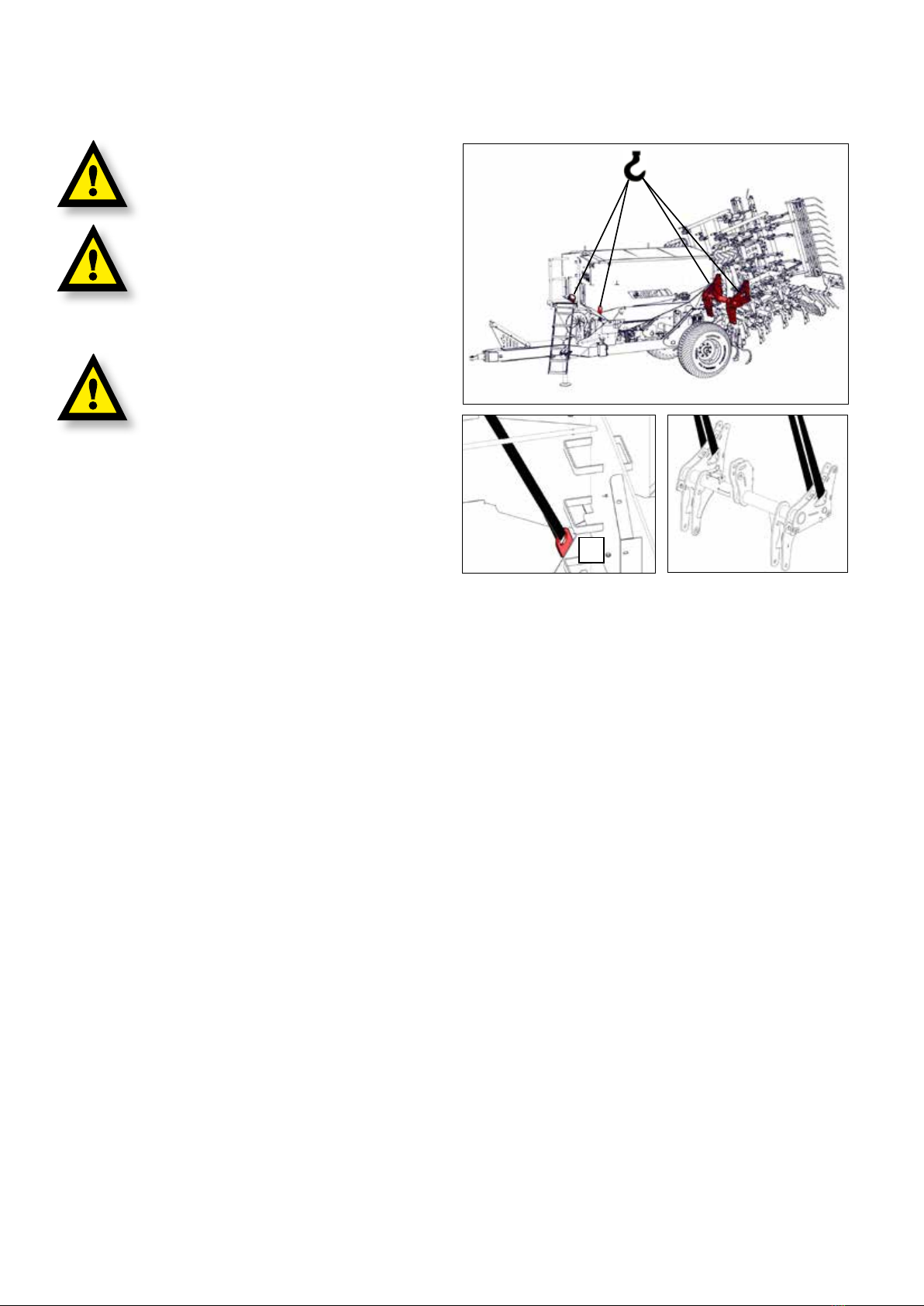

2.3 LOADING AND UNLOADING INSTRUCTIONS.......................................................................................................................... 8

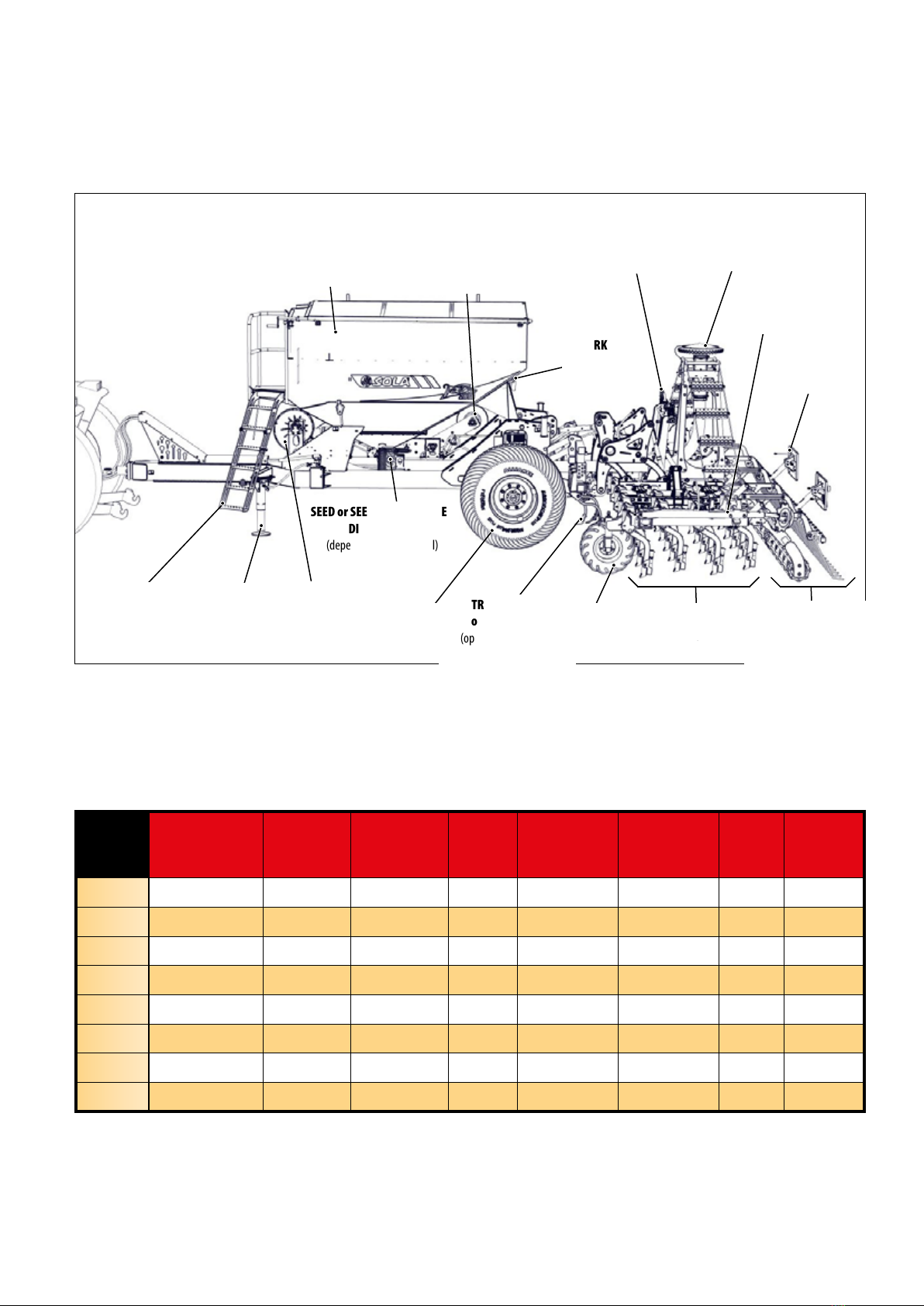

3. GENERAL DESCRIPTION.............................................................................................................................................. 9

3.1 OVERVIEW OF THE MACHINE..................................................................................................................................................... 9

3.2 TECHNICAL SPECIFICATIONS ..................................................................................................................................................... 9

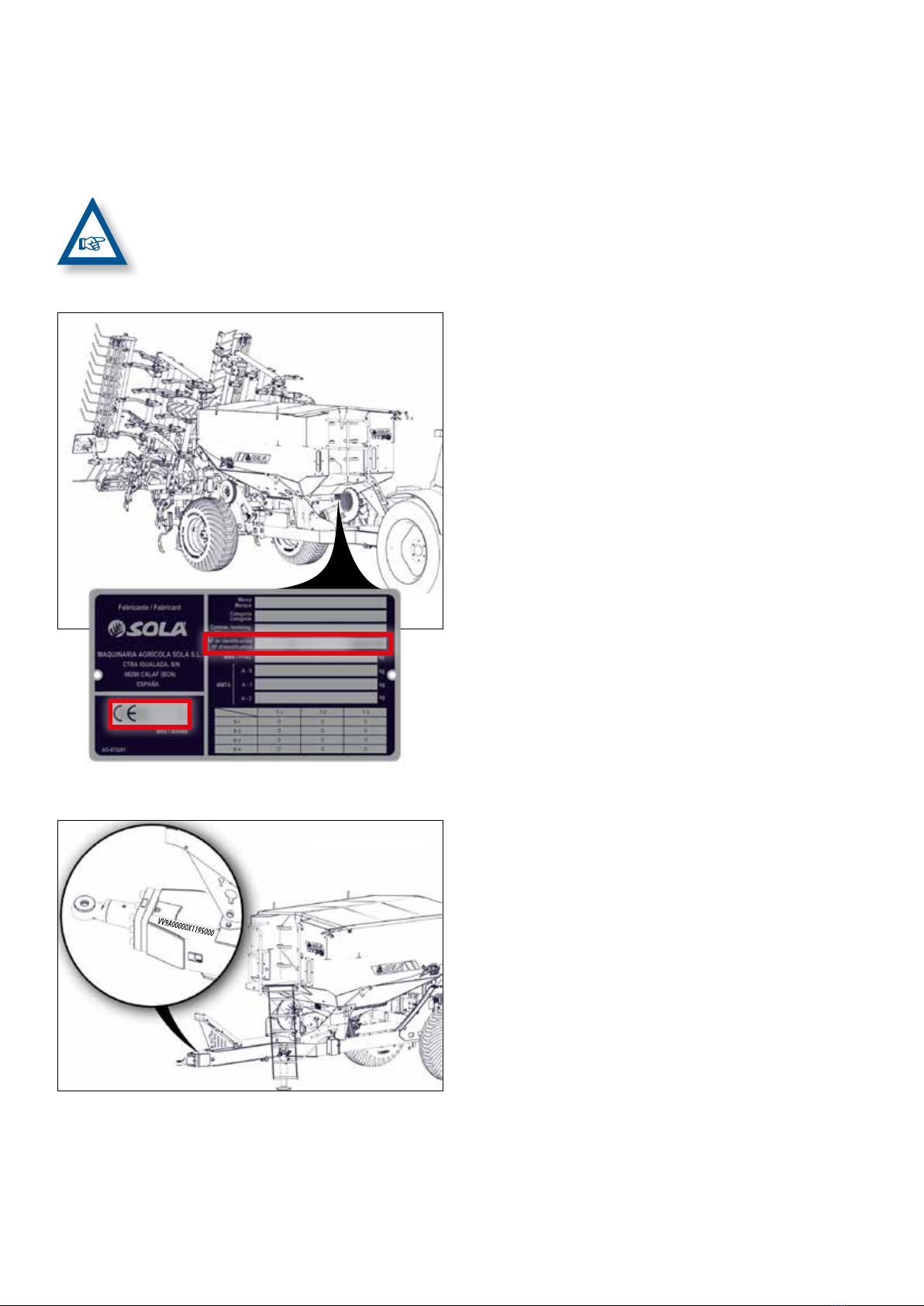

3.3 MACHINE IDENTIFICATION....................................................................................................................................................... 10

3.4 USE ACCORDING TO DESIGN ................................................................................................................................................... 10

4. KEY CONCEPTS FOR SOWING.................................................................................................................................... 11

4.1 SOIL .............................................................................................................................................................................................. 11

4.2 SEED ............................................................................................................................................................................................. 11

4.3 DEPTH .......................................................................................................................................................................................... 11

5. COMMISSIONING...................................................................................................................................................... 12

5.1 COUPLING THE SEED DRILL TO THE TRACTOR...................................................................................................................... 12

5.2 ELECTRICAL CONNECTIONS..................................................................................................................................................... 13

5.2.1 WORK LAMPS.................................................................................................................................................................... 13

5.2.2 SIGNALLING LIGHTS........................................................................................................................................................ 13

5.2.3 ISOBUS ............................................................................................................................................................................... 13

5.3 HYDRAULIC CONNECTIONS ..................................................................................................................................................... 13

5.4 TRANSPORT POSITION.............................................................................................................................................................. 15

5.5 LOADING AND EMPTYING THE HOPPERS.............................................................................................................................. 17

5.5.1 SEED/FERTILIZER HOPPER (depending on the model)............................................................................................. 18

5.6 SUPPORT LEGS ........................................................................................................................................................................... 22

5.6.1 FRONT SUPPORT LEG...................................................................................................................................................... 22

5.6.2 REAR SUPPORT LEG......................................................................................................................................................... 23

5.7 PARKING ...................................................................................................................................................................................... 24

5.8 END OF WORK WITH THE MACHINE........................................................................................................................................ 24

6. ADJUSTMENTS ......................................................................................................................................................... 25

6.1 LEVELLING THE COULTER UNIT ............................................................................................................................................... 25

6.2 DEPTH CONTROL ....................................................................................................................................................................... 25

6.2.1 DEPTH ADJUSTERS .......................................................................................................................................................... 27

6.2.2 DEPTH CONTROL WHEELS.............................................................................................................................................. 28

6.2.3 FOLDING PART ANGLE STOPS ....................................................................................................................................... 29

6.2.4 COULTERS.......................................................................................................................................................................... 29

6.2.4.1 SM MODEL............................................................................................................................................................... 30

6.2.4.2 NS PLUS MODEL (STRAIGHT COULTERS) ........................................................................................................... 31

6.2.4.3 NS PLUS MODEL (SUFFOLK COULTERS) ............................................................................................................. 31

6.3 DOSAGE ....................................................................................................................................................................................... 32

6.3.1 VOLUMETRIC DISPENSER ............................................................................................................................................... 32

6.3.1.1 REGULAR SEED OR CONVENTIONAL FERTILIZER............................................................................................. 33

6.3.1.2 FINE SEED OR MICROGRANULATE FERTILIZER................................................................................................. 34

6.3.2 ROLLER DISPENSER ......................................................................................................................................................... 35

6.3.3 DISPENSERS FOR FERTILIZER AND/OR MICROGRANULATOR KITS......................................................................... 36

6.3.3.1 INTERNAL KIT HOPPER - FERTILIZER AND/OR MICROGRANULATE DISPENSER......................................... 37

6.3.3.2 EXTERNAL KIT HOPPER - MICROGRANULATE FERTILIZER DISPENSER ........................................................ 38

6.4 SETTING THE SEED DOSE ......................................................................................................................................................... 40

6.5 FLOW PRE-TEST .......................................................................................................................................................................... 41

6.5.1 MODELS WITH MECHANICAL TRANSMISSION ........................................................................................................... 41

6.5.2 MODELS WITH ISOBUS ELECTRIC TRANSMISSION .................................................................................................... 44

6.6 FIELD TEST FOR DOSAGE (models with mechanical transmission).................................................................................. 47

6.7 MECHANICAL TRANSMISSION................................................................................................................................................. 48

6.8 HARROW...................................................................................................................................................................................... 49

6.9 COMPACTING ROLLER............................................................................................................................................................... 50

6.10 TRACK ERASERS ....................................................................................................................................................................... 51

6.11 HYDRAULIC TRACK MARKERS ............................................................................................................................................... 52