4

PRODUCT DESIGN

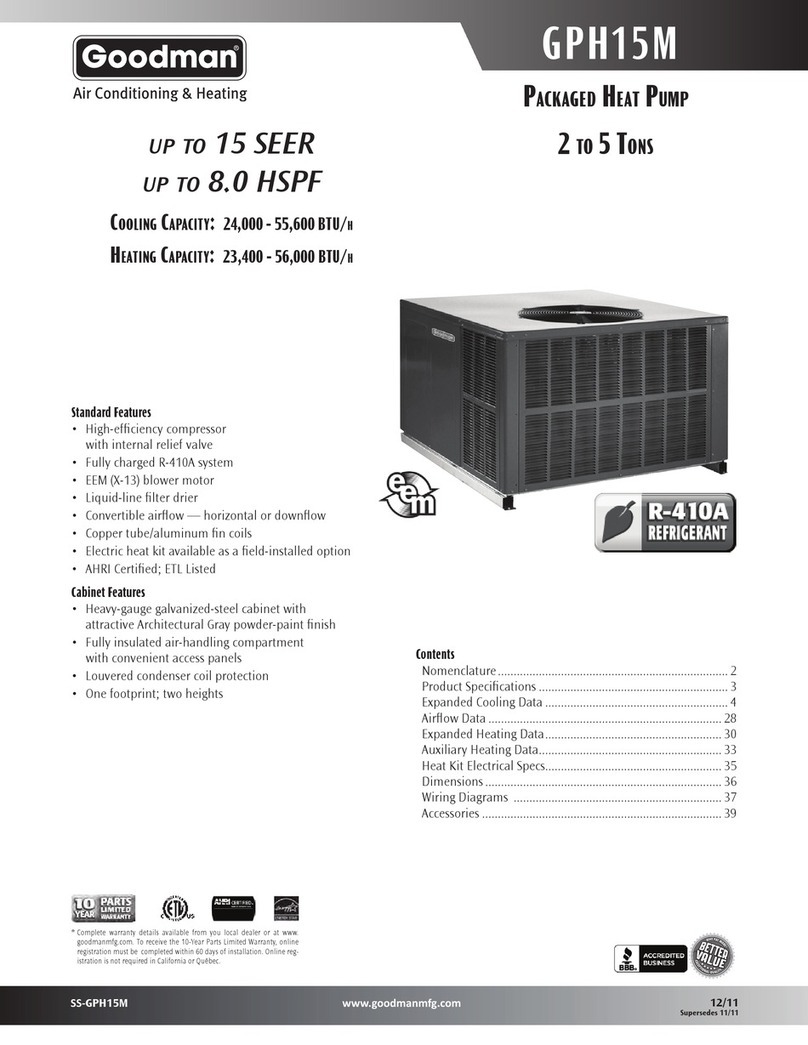

GPH13 (M Series) Package Units are designed for outdoor

installationsonlyin either residential orlightcommercial ap-

plications and are available in 2, 2.5, 3, 3.5, 4 & 5 ton sizes.

Theyaredesignedfor208/230 voltsinglephase applications.

The connecting ductwork (Supply and Return) can be con-

nectedfor either horizontal orvertical airflow. In thevertical

application, a matching Roof Curb is recommended and a

horizontalduct cover kit isrequired.

Areturnairfiltermustbeinstalledbehindthereturnairgrille(s)

or provision must be made for a filter in an accessible loca-

tionwithinthereturnairduct.Theminimumfilterareashould

not be less than those sizes listed in the Specification Sec-

tion. Under no circumstances should the unit be operated

withoutreturnair filters.

A3/4"pipeisprovidedforremovalofcondensatewaterfrom

the indoor coil. A trap must be provided to have proper con-

densatedrainage. (Do not reducethe drain line size).

Refrigerant flow control is achieved by use of restrictor ori-

fices.

All heat pump models also have a suction line accumulator

installed between the reversing valve and the compressor.

The object of the accumulator is to:

1. Providealiquidrefrigerantstoragevesselduringprolonged

system off cycles.

2. Storeexcessliquidrefrigerantnot needed by the system

whilerunning.

3. Return oil and saturated vapor to the compressor at a

controlledrate.

4. Retainstoredexcess refrigerant during a sudden system

pressure fluctuation such as seen in defrost cycles.

Refrigerant flow control is achieved by use of restrictor

orifices. These models use the FasTest Access Fitting

System, with a saddle that is either soldered to the suction

andliquidlinesorisfastenedwithalockingnuttotheaccess

fitting box (core) and then screwed into the saddle. Do not

remove the core from the saddle until the refrigerant

chargehasbeen removed. Failuretodo socouldresult

in property damage or personal injury.

Thesingle phase units use permanentsplit capacitor (PSC)

design compressors. Starting components are not required

for these units. A low microfarad run capacitor assists the

compressor to start and remains in the circuit during opera-

tion.

Theoutdoorfan motors are single phasecapacitortypemo-

tors.Some models use PSC typeindoorblowermotorswhile

others use EEM type blower motors. EEM motors are ener-

gized by a 24V signal from the thermostat and are constant

torquemotorswithvery low power consumption.

TheEEMfeatures an integral control module.

Air for condensing (cooling cycle) or evaporation (heating

cycle) is drawn through the outdoor coil by a propeller fan,

and is discharged vertically out the top of the unit. The out-

door coil is designed for .0 static. No additional restriction

(ductwork)shallbeapplied.

Conditioned air is drawn through the filter(s), field installed,

across the coil and back into the conditioned space by the

indoorblower.

PackageHeatPumpindoorsectionsaredesigned to accept

optional components such as auxiliary electric heaters and

circuitbreakers. Provisions for thesecomponentshavebeen

madeattime of manufacture.

GPH13series package units usethe Compliant Scroll com-

pressor;there are a number of design characteristicswhich

aredifferentfromthetraditionalreciprocatingcompressor.

-DuetotheirdesignScrollcompressorsare inherently more

tolerant of liquid refrigerant. NOTE: Even though the com-

pressor section of a Scroll compressor is more tolerant of

liquidrefrigerant, continued flood back or flooded startcondi-

tionsmay wash oil fromthebearingsurfacescausingprema-

turebearing failure.

-TheseScrollcompressorsuse"POE"orpolyolesteroilwhich

isNOT compatible withmineraloilbasedlubricants like 3GS.

"POE" oil must be used if additional oil is required.

- Compliant scroll compressors perform “quiet” shutdowns

thatallow the compressor to restartimmediately without the

needforatimedelay. This compressor will restart even if the

system has not equalized.

- Operating pressures and amp draws may differ from stan-

dard reciprocating compressors. This information may be

foundinthe“CoolingPerformanceData” section.

LocationandClearances

NOTE:To ensure proper condensate drainage, unit must be

installed in a level position.