Solar MD SS4037-02 User manual

Solar MD (PTY) ltd.

Unit 23, Alternator Park

Montague Gardens 7441

Cape Town, South Africa

INSTALLATION MANUAL

SS4037-02

Advanced Lithium-Ion battery

Unit 23, Alternator Park

Montague Gardens 7441

Cape Town, South Africa

Introduction 2

Product Description 2

Product Specifications 2

Errors or Inaccuracies 2

Copyrights 3

Safety Information 3

⚠ Warnings ⚠ Cautions 3

Specification 4

Mechanical installation 5

Installing bottom cover plate 6

Electrical installation 7

Commissioning 9

Multicolor multipurpose button 10

Button function 10

Button indication 10

BMS Warnings and Errors 12

CANBUS connection. 16

CANBUS warnings. 17

Troubleshooting Warnings / Errors 18

Maximum charging / discharging voltages for non supported

devices. 19

1

Unit 23, Alternator Park

Montague Gardens 7441

Cape Town, South Africa

Introduction

This manual is intended to provide assistance to an installer for the installation and

commissioning of the range of Solar MD Lithium Ion phosphate (LiFePO4) energy storage

solutions.

Product Description

The SS4037-02 battery solution is available in one standard size and can be paralleled to

meet most residential applications. The rated voltage is 51.2V nominal (to suit 48V systems).

Larger systems are provided by Solar MD based on specific project requirements. The

SS4037-02 is also available in 24V and 12V systems respectively.

WARNING: Read the entire document before installing or using the Solar MD battery. Failure

to comply with the instructions or warnings in this document could result in electrical shock or

serious injury that can result in death or damage to the product that can render the SS4037

Solar MD battery inoperable.

2

Unit 23, Alternator Park

Montague Gardens 7441

Cape Town, South Africa

Product Specifications

All SS4037-02 specifications & descriptions contained in this document are verified to be

accurate at the time of printing. Solar MD reserves the right to make any product Revisions &

improvements at any time.

Errors or Inaccuracies

To communicate any inaccuracies, omissions or to provide general feedback regarding this

manual, send an email to [email protected]

Copyrights

All information in this document is subject to the copyright of Solar MD (Pty) Ltd. Additional

information is available upon request.

Safety Information

This manual contains important instructions and warnings that must be followed when using

SS4037-02.

Read all instructions before installing and using the SS4037-02.

⚠ Warnings ⚠ Cautions

● Use SS4037-02 only as instructed.

● For communication and other information please read the BMS manual.

● Do not attempt to disassemble, repair, modify, or tamper with this battery unit.

● Do not insert foreign objects into any part of battery unit.

● Avoid exposure to any moisture.

● Do not expose to extreme temperatures.

● Do not drill any holes into the box.

● Use only an approved Solar MD installer to install this product.

3

Unit 23, Alternator Park

Montague Gardens 7441

Cape Town, South Africa

Specification

Solar MD 3.7kWh SS4037-02 specification

Battery type

Lithium Iron

Phosphate

Scalability

Yes

r Battery module

SS4037

Communication

CANBUS 500kbps/CAN 2.0B

Rated battery capacity

3686 Wh

Can BUS termination

Single 120 Ohm

Output power

Max 5 kW / 100A

Canbus id range:

256 - 499

Usable battery energy @ 0.3\C

3.68 kWh

Protection method

Cell level: uv / ov / oc

Position: x / y / x

Acceleration: x / y / z

Temperature: ot / ut

Nominal voltage

51.2V

Protection phy

Mechanical relay NO

Number of battery modules

1 module

Com (CANBUS ) isolation

Yes 1.5kV

Weight

37kg

Transportation protection

Yes

Operating voltage

44.8V-55.6Vdc

Indicator

Led, programmable

Communication

CANBUS

Addition IO

3 GPO

Dimensions of SS44037: h/w/d

620mm/320mm

/200mm

Cell balancing

Passive balancing

Net Weight of SS4037

35 Kg

Counters

Cycle counters and SoH

Battery cycle life [+25 ‘C]

> 4000

AUX power output

5V 1A max

Charging efficiency

99%

Storage duration

6 months@+25℃

Operating temperature

-5℃ ~+50℃

Safety standards compliance

IEC 62619/UN 38.3/UL1642

Transport

UN3480 & UN38.3

Cell Certificate

TUV / CE / RCM / UL1642

4

Unit 23, Alternator Park

Montague Gardens 7441

Cape Town, South Africa

Mechanical installation

Figure 1: Rear Battery Bracket

Please use the correct mounting screws for the correct wall surface. Screw head should not

be bigger than 16mm in diameter. The Battery is only to be installed in the upright position

with a maximum tilt angle of 30 degrees.

5

Unit 23, Alternator Park

Montague Gardens 7441

Cape Town, South Africa

Figure 2: Maximum tilt angle

Installing bottom cover plate

Figure 3: Bottom cover installation for single or dual cable exit points

The Battery comes with two covers for single or dual cable exit points. Use the 1 or 2 way out cover

plate and fix it with the two M5x6 bolts provided in the box.

6

Unit 23, Alternator Park

Montague Gardens 7441

Cape Town, South Africa

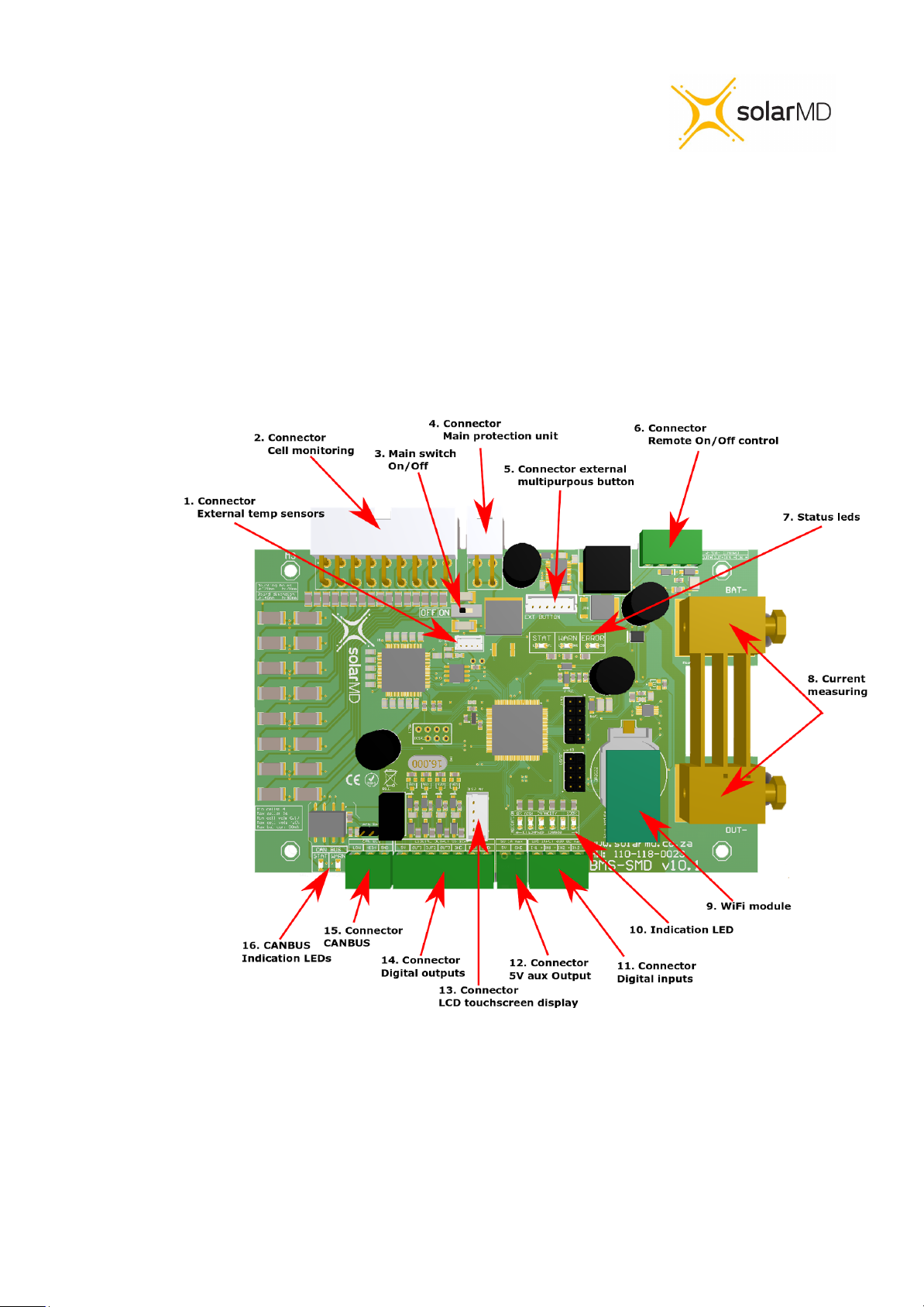

Electrical installation

Step 1. Before connecting anything be sure that battery is off and the ON/OFF switch (fig4

pos 3) is in the OFF position.

Figure 4: BMS board component location

7

Unit 23, Alternator Park

Montague Gardens 7441

Cape Town, South Africa

Connecting Inverters/chargers/UPS to the battery unit while it is ON can cause big sparks

due to capacitors inside the connected device. This could cause serious injuries.

Connecting main battery terminal must be with the correct size cable.

Based on the rated current of the battery and inverter as well as cable length.

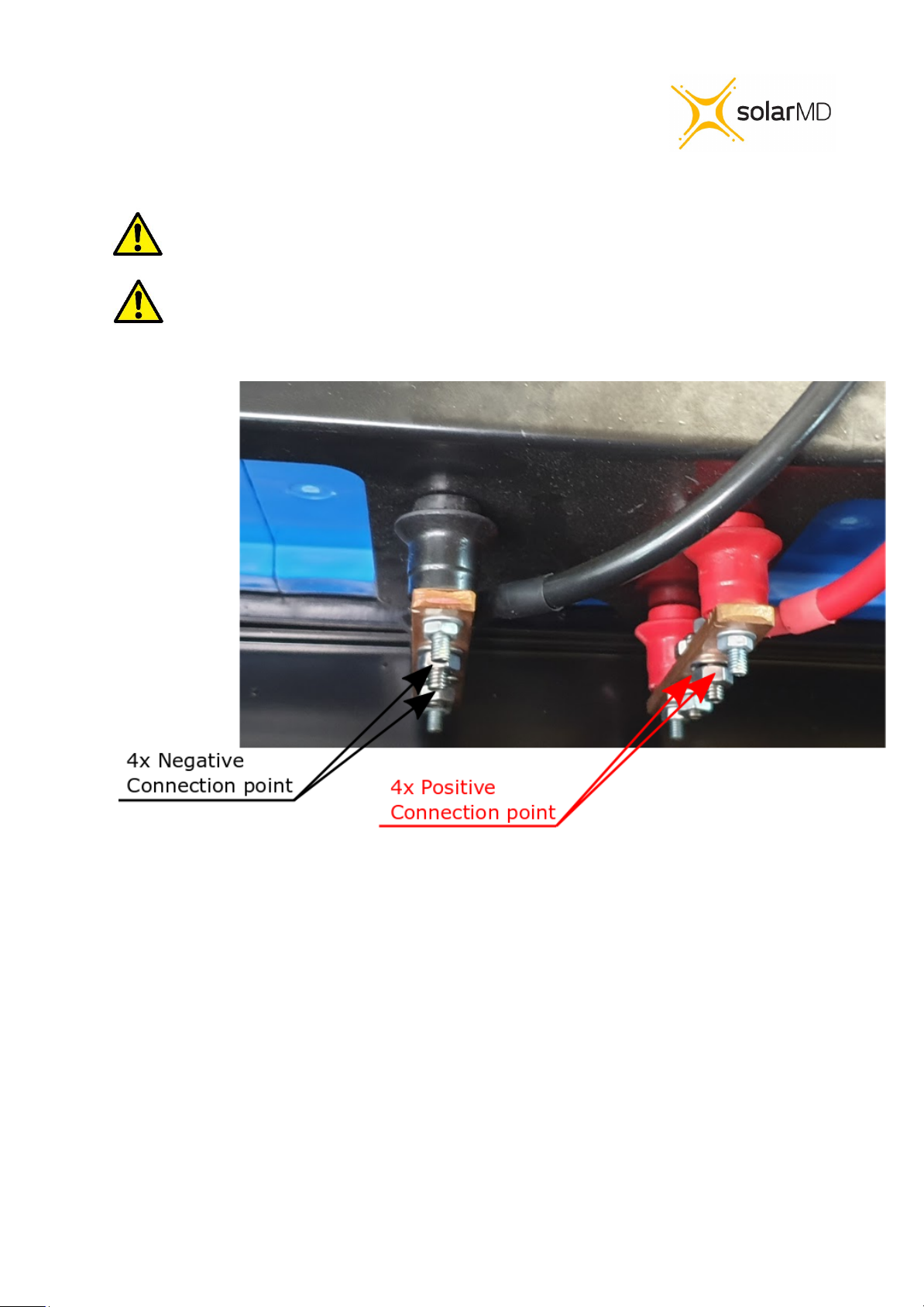

Figure 5 connection terminal

Step 2. Connect the negative cable to the battery negative busbar and positive to battery

positive as shown is figure 5 Make sure that all the connections are tight.

All used connection points should be a suitably tightened, ensuring good electrical

connection between the lug and busbar. A bad connection could cause serious damage to

the battery and inverter, and could void the warranty.

8

Unit 23, Alternator Park

Montague Gardens 7441

Cape Town, South Africa

Commissioning

Step 1. Ensure all DC cables are tight according to specifications.

Step 2. If the battery operates in parallel with other Energy sources, make sure that the

difference between battery voltage and DC bus is not more than 2.5V. If greater than 2.5V

please Charge or Discharge other source accordingly until voltage difference is in safe

ranges under 2.5V.

Caution! A hot connection with difference in voltage can cause very high

equalization current which can burn the fuses of the battery!

Caution! Measure the voltage of the battery before connecting the dc

Cables.

Step 3. Turn BMS board ON/OFF switch to the ON position (figure 4 pos 3)

Step 4. Connect Multi-purpose button if not connected to the BMS board connector see

(figure 4 pos 5)

Step 5. Hold multi-purpose button until light come on.

Note: If commissioning two or more batteries.

Once the system is switched on and load is added, measure current flow on

each battery. Ensure that the load is distributed across each battery equally.

Warning! If the battery does not switch the main protection Contact ON in 7

seconds, please check BMS board indication LED for faults. See section BMS

Error and Warnings on page 13 of this manual.

9

Unit 23, Alternator Park

Montague Gardens 7441

Cape Town, South Africa

Multicolor multipurpose button

Figure 6 : Multicolor / Multipurpose button

.

Button function

The new Solar MD Multipurpose button has an extended functionality in combination with the BMS-EM v10.01.

The Multipurpose Button can be used to directly execute 6 predefined functions and a shutdown instruction. In

combination with the 6 Indication LEDs on BMS-EM v10.01, the user can choose between each function by

holding the button until the LEDs count match the number of the function. By releasing the button while moving

through the functions, LEDs will start blinking and wait for the user to press the button again within 3 seconds.

The predefined functions are:

1. Reserved

2. Change indication LED function between: Show Capacity, Show Current, and

Off

3. Reserved

4. Wake up if Sleep mode is active.

5. Activate Override Off state for 60sec

6. Activate Override On state for 60sec

If the button is held continuously after function 6, shutdown mode is activated and the battery will send a signal

to switch off in 4sec.

Further holding the button causes the BMS to delay complete shutdown for a maximum of 3 minutes. This

operation is used when the technician wants to continue read or write parameters after shutdown.

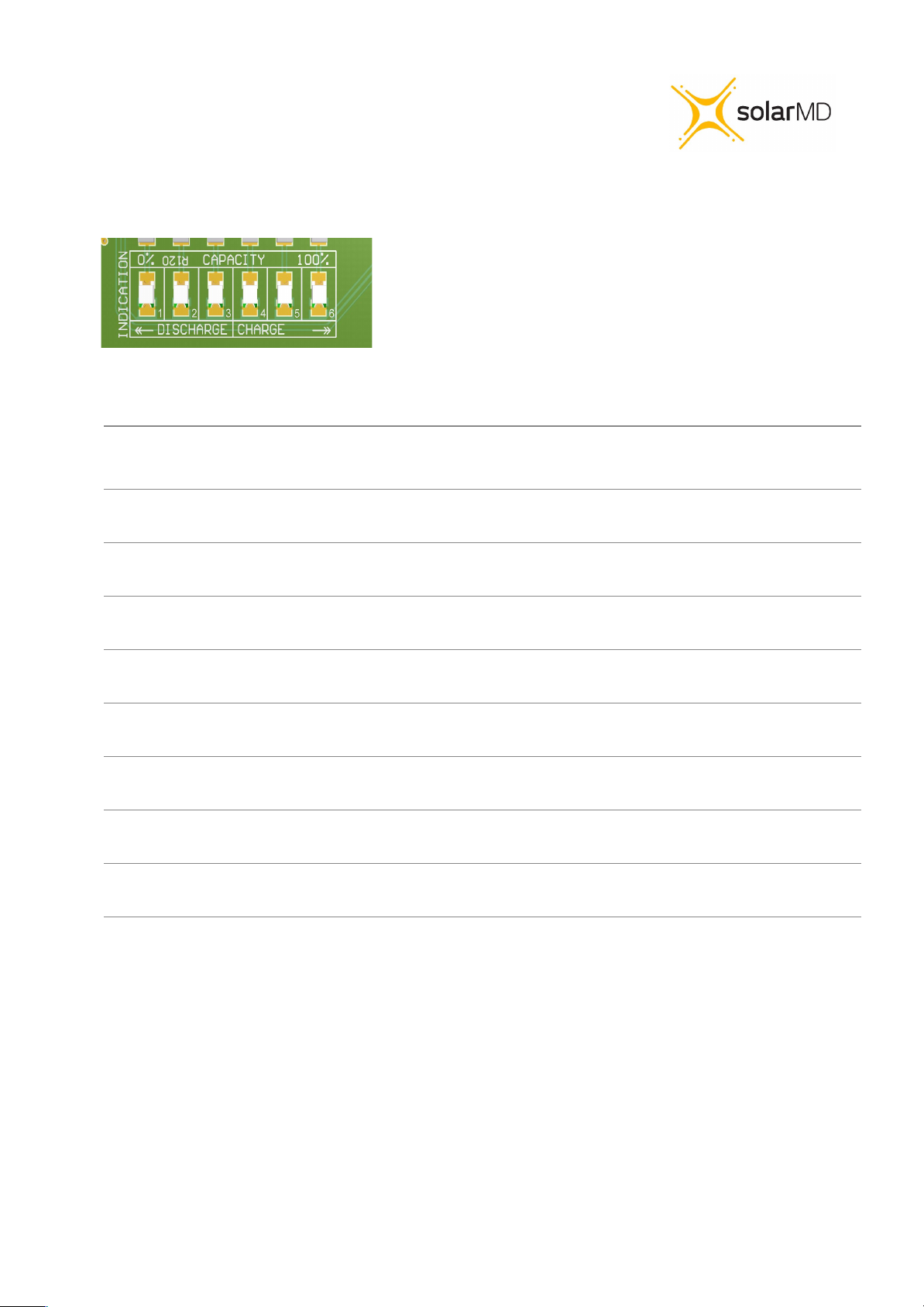

Button indication

The Multipurpose button advanced indication functionality, allows the user to choose between 5 different

states. Mixed combinations are also allowed when a combination of multiple batteries with BMS-EM v10.01 are

used. The User can change the preferedstage by logging into his mypower24 Energy Portal and go to the

Battery Settings.

10

Unit 23, Alternator Park

Montague Gardens 7441

Cape Town, South Africa

Illumination off

When this state has been selected, the button serves as an on/off switch without illumination (fixed color).

Color based on capacity

When this state has been selected, the button shows static illumination in a color based on the state of charge.

From RED at 0% SoC (State of Charge) to GREEN at 100% state of charge.

Color based on capacity with current direction based on shading.

When this state has been selected, the button shows flashing illumination in a color based on the state of

charge and flashing code based on the electrical current direction (charge / discharge). From RED at 0% SoC

(State of Charge) to GREEN at 100% state of charge. The flashing code for charge goes through illumination

interruption for 1 interval and slow illumination into the color based on the SoC for 5 intervals. The flashing

code for discharge represents the opposite from charge - study color for 1 interval and slow loss of color

following illumination interruption. Solar MD users refer for both as charging / discharging waves.

Fixed color with current direction based in shading

When this state has been selected, the button shows illumination in a color based on the user choice and

flashing code based on the electrical current direction (charge / discharge). The flashing code for charge goes

through illumination interruption for 1 interval and slow illumination for 5 intervals. The flashing code for

discharge represents the opposite from charge - study color for 1 interval and slow loss of color following

illumination interruption. Solar MD users refer for both as charging / discharging waves.

11

Unit 23, Alternator Park

Montague Gardens 7441

Cape Town, South Africa

BMS Warnings and Errors

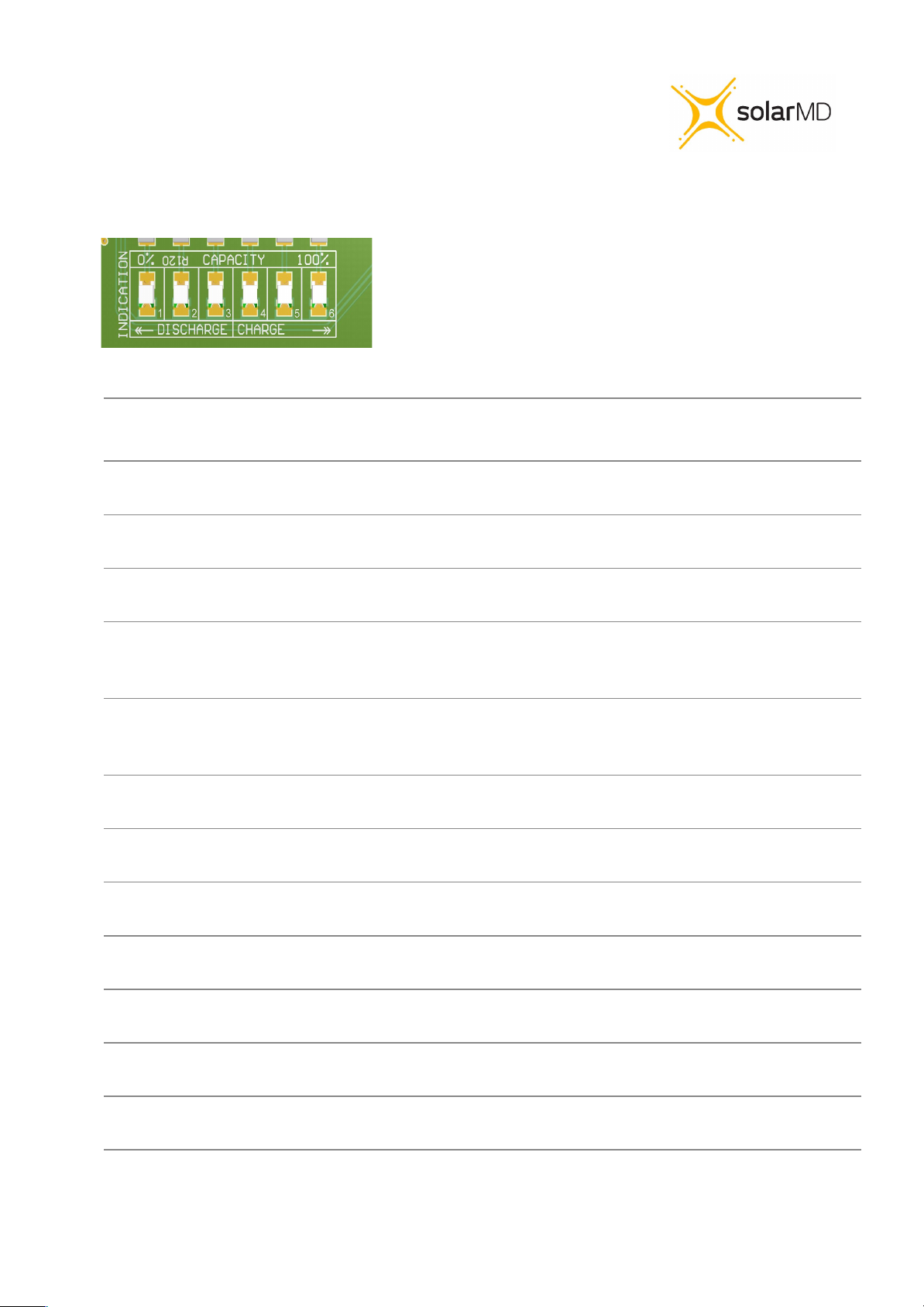

Method of displaying general warnings and errors:

Figure 7 : Display general warnings and errors, Main stat LEDs and Indication LEDs

The board uses 2 main LED for displaying warnings and Errors. If an Error is present the ERROR LED

(fig. 7 top right) will start blinking synchronized with the LEDs at Indication led group (fig. 7 bottom). If

Warning is present the WARN LED (fig. 7 top middle ) will start blinking synchronized with Some LEDs at

Indication led group (fig. 7 bottom). Reading Indication LEDs will show you the exact error or warning.

Errors are always with priority regardless warnings. This means that the board will show you only the error

on the Indication LEDs if both Error and Warnings are present.

12

Unit 23, Alternator Park

Montague Gardens 7441

Cape Town, South Africa

Warning codes.

Figure 8. Indication LEDs: (1,2,3) orange left and (4,5,6) green right. In combination with Orange Stat LED (WARNING)

◼ + ◻◻◻◻◻◼ - Battery cell voltage is too low. [1]

◼ + ◻◻◻◻◼◻ - Battery cell voltage is too high. [2]

◼ + ◻◻◻◻◼◼ - Battery charging current is higher than the maximum allowed

charging current . [3]

◼ + ◻◻◻◼◻◻ - Battery discharging current is higher than the maximum allowed

electrical discharging current. [4]

◼ + ◻◻◻◼◻◼ - Override ON active, protection is forced to work at extreme levels for

preset period. [5]

◼ + ◻◻◻◼◼◻ - Override OFF active, protection is forced to switched off the main

protection relay for preset period. [6]

◼ + ◻◼◼◼◻◼ - Pending awake LOW state indicate that battery is forced to switched

On for predefined amount of time normally 1min waiting for charger to

start charging.[29]

◼ + ◻◼◼◼◼◻ - Pending awake HIGH state indicate that battery is forced to

switched Off and waiting for all voltages to drop in safe margins.[30]

Addition configuration are used for internal diagnostic.

13

Unit 23, Alternator Park

Montague Gardens 7441

Cape Town, South Africa

Error codes.

Figure 9. Indication LEDs: (1,2,3) orange left and (4,5,6) green right. In combination with Red Stat LED (ERROR)

◼ + ◻◻◻◼◻◼ - Battery position X axis is out of range. [5]

◼ + ◻◻◻◼◼◻ - Battery position Y axis is out of range. [6]

◼ + ◻◻◻◼◼◼ - Battery position Z axis is out of range. [7]

◼ + ◻◻◼◼◻◻ - Battery Protection in critical stage, pending shutdown in 3sec. [12]

◼ + ◻◻◼◼◻◼ - Battery Protection in critical stage, Override mode reached the

maximum permitted values, pending shutdown in 3sec. [13]

◼ + ◻◻◼◼◼◻ - Battery Protection in critical stage, Normal mode reached the

maximum permitted values, pending shutdown in 3sec. [14]

◼ + ◻◻◼◼◼◼ - Battery Protection in critical stage, pending shutdown in 3sec. [15]

◼ + ◻◼◻◻◻◻ - Remote Shutdown instruction received, pending shutdown in 3sec. [16]

◼ + ◻◼◻◻◻◼ - User Shutdown instruction received, pending shutdown in 3sec. [17]

◼ + ◻◼◻◻◼◻ - Discharging current is too high. [18]

◼ + ◻◼◻◻◼◼ - Charging current is too high. [19]

◼ + ◻◼◻◼◻◼ - Incorrect cell count detected. [21]

◼ + ◻◼◻◼◼◻ - Cell voltage too low. [22]

14

Unit 23, Alternator Park

Montague Gardens 7441

Cape Town, South Africa

Error codes continued.

Figure 10 Indication LEDs: (1,2,3) orange left and (4,5,6) green right. In combination with Red Stat LED (ERROR)

◼ + ◻◼◻◼◼◼ - Cell voltage too high. [23]

◼ + ◻◼◼◻◻◻ - Internal error. Additional information on request.[24]

◼ + ◻◼◼◻◻◼ - Internal error. Additional information on request.[25]

◼ + ◻◼◼◻◼◻ - Internal error. Additional information on request.[26]

◼ + ◻◼◼◻◼◼ - Internal error. Additional information on request.[27]

◼ + ◻◼◼◼◻◻ - Internal error. Additional information on request.[28]

◼ + ◻◼◼◼◻◼ - Internal error. Additional information on request.[29]

◼ + ◻◼◼◼◼◻ - Internal error. Additional information on request.[30]

◼ + ◻◼◼◼◼◼ - Internal error. Additional information on request.[31]

15

Unit 23, Alternator Park

Montague Gardens 7441

Cape Town, South Africa

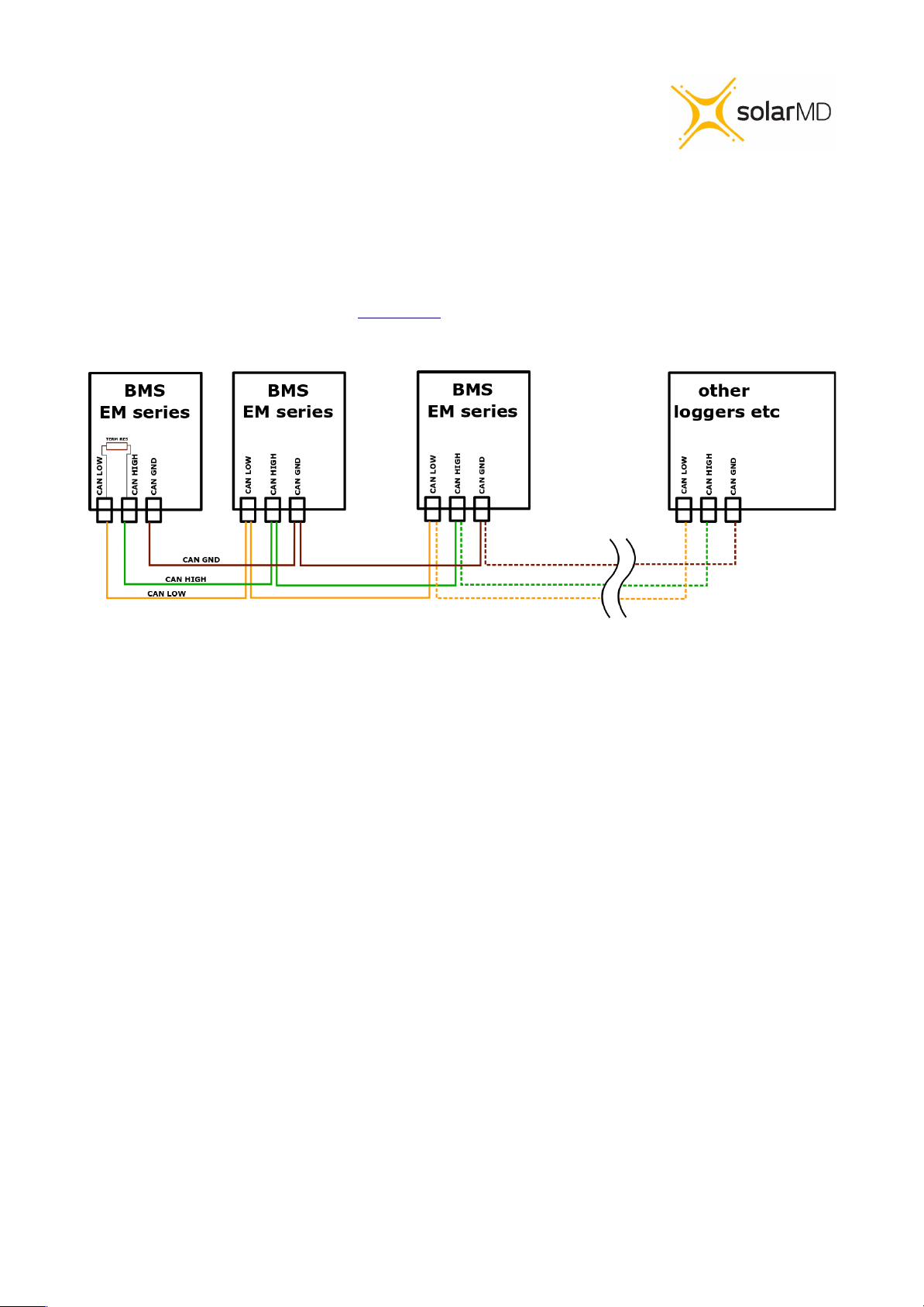

CANBUS connection.

Bms EM used CAN 2.0B @ 500000 kb. Connecting other device operating at different speed rate is not

allowed. For connection please use twisted pair wires in a shielded cable to minimize RF emissions.

The output of the BmsEm CAN transceiver is galvanically isolated.

Figure 11: BMS-EM connection to the CANBUS.

16

Unit 23, Alternator Park

Montague Gardens 7441

Cape Town, South Africa

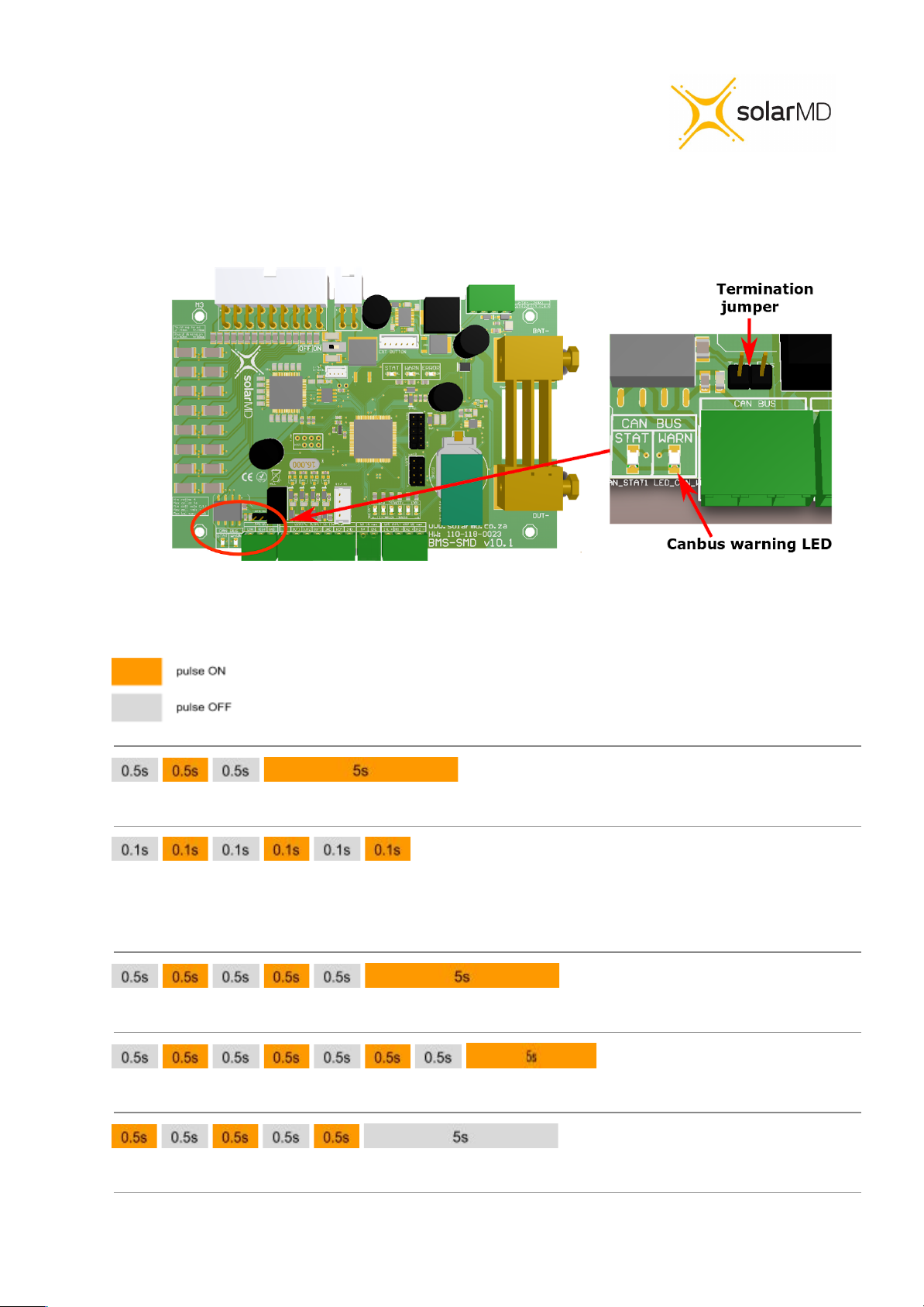

CANBUS warnings.

Figure 12 CANBUS Termination resistor and Warning LED location

The Orange LED (WARN) is used to display warning for canbus only. Reading this warning is

possible with pulse counting.

- CANBUS line open or no termination resistor set. [1]

......

- CAN BUS line in initialization stage. Canbus init occur when the line was opened and then

established. Minimum period for initialization is 30sec. In this period all nodes are scanned in the

network and scanned for ID and serial number collisions. [2]

- Duplicate CAN ID detected with no “auto ID” set. [3]

- Duplicate Serial number detected. [4]

- CANBUS Internal fault. [5]

17

Unit 23, Alternator Park

Montague Gardens 7441

Cape Town, South Africa

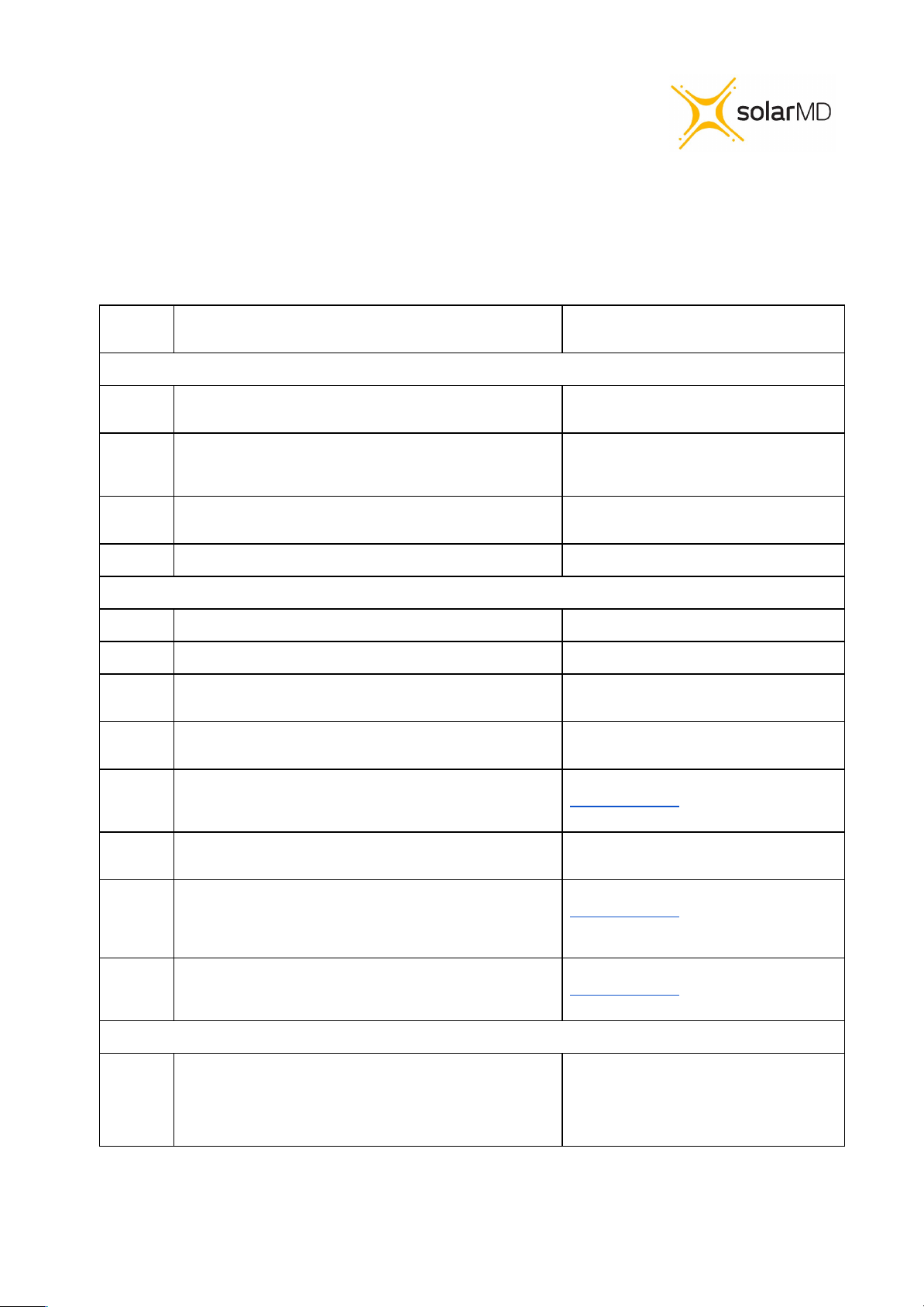

Troubleshooting Warnings / Errors

Error

Code

Cause

Solution

Warnings ( Figure 8)

1-2

1. Inverter / rectifier settings may not be correct.

2. Battery cells may be disbalanced

1. Check the battery settings

2. Contact Solar MD support

3-4

System design is not correct.

Add additional battery, decrease charging /

discharging current from

your inverter / rectifier / load

5-6

Manual override

Manual override has been activated - please

check with your installer

29-30

The BMS is ready to switch on after deep discharge / charge

Connect charger / load to the Battery

Errors (Figure 9 & 10)

5,6,7

The battery is not installed in upright position

Install the battery in the right position

15,16,17

The BMS has been shut down manually or remotely

Switch on the BMS

18,19

The absolute maximum charge/discharge current has been

achieved

The BMS will restart automatically, please

contact support team or approved installer

21

The BMS is set for different number cells in series as the actually

installed

Contact your installer or Solar MD support team

22

Battery cell voltage way too low.

Fill in the failure report and send to

The unit needs to return to the factory for testing

23

Battery cell voltage way too high

The BMS will restart automatically after pending

awake condition

24,25,26,

27,28,30,

31

BMS internal failure.

Fill in the failure report and send to

The BMS will be dispatched to you for

replacement

29

Battery factory failure

Fill in the failure report and send to

The unit needs to return to the factory for testing

CANBUS Warning (Figure 12)

1

1. Canbus line open.

2. Single CANBUS resistor not terminated.

1.Check if the minimum of two nodes are

connected on the line with the same

transmission speed.

2.Check if single resistor is terminated via the

jumper. Located top right of CAN LEDs (Fig 12).

18

Unit 23, Alternator Park

Montague Gardens 7441

Cape Town, South Africa

Maximum charging / discharging voltages for non supported devices.

- Bulk charge (stop charging) 54.6V

- Float charge (if applicable) 53.8V

- Low battery discharge: 48V

Check that the Equalisation function are disalled, then verify if there is a voltage difference on

the inverter display and the battery terminals @0.3C discharge / charge current. If so adjust

the values above.

Please check if your inverter charger has been approved by Solar MD and it is CAN

compatible.

For the latest Solar MD installation documents go to:

shop.solarmd.co.za

To secure the full 10-year product warranty for the end user, be

sure to register your battery online – login.mypower24.co.za.

19

Table of contents

Other Solar MD Camera Accessories manuals

Popular Camera Accessories manuals by other brands

Night Vision Systems

Night Vision Systems CORONAFINDER Operating and maintenance manual

Panasonic

Panasonic FL360 - DMW - Hot-shoe clip-on Flash user guide

Voltacon

Voltacon Li2021 48V50Ah LFP user manual

Bosch

Bosch Rexroth HAB-7X Series Installation and operating instructions

BYD

BYD B-BOX 2.5 Installation guidance

Blueshape

Blueshape MVQUICKAB operating instructions