Solar MD SS4143-11 User manual

INSTALLATION MANUAL

SS4143-11

Advanced Lithium-Ion battery

0

Introduction 2

Product Description 2

Product Specifications 3

Errors or Inaccuracies 3

Copyrights 3

Safety Information 3

⚠Warnings ⚠Cautions 3

Specification 4

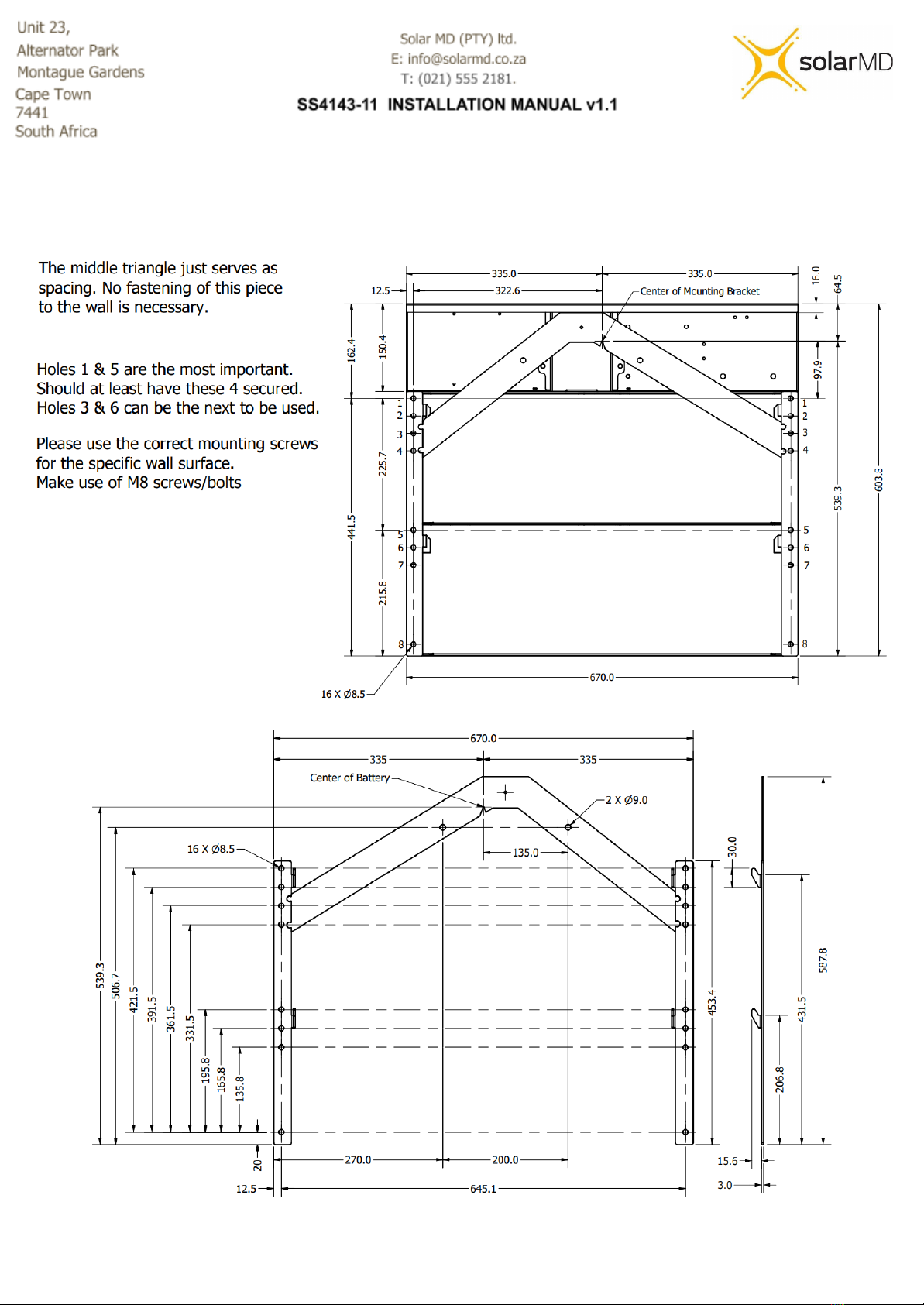

Mechanical installation 5

Installing cover plates 6

Electrical installation 9

Switching the battery ON 11

Multicolor multipurpose button 12

Button function 12

Button indication 18

Firmware 19

How to Update 19

Communication 20

Pinout 21

Monitoring and control 22

CANBUS connection. 23

CANBUS warnings and errors 25

BMS Warnings and Errors 26

Troubleshooting Warnings / Errors 27

Warning register 29

Error register 32

Maximum charging / discharging voltages for non supported devices. 36

Annex A: BMX-EX Inverter / Charger control and cluster operation 37-53

1

Introduction

This manual is intended to provide assistance to an installer for the installation and

commissioning of the range of Solar MD Lithium Ion phosphate (LiFePO4) energy storage

solutions.

Product Description

The SS4143-11 battery solution is available in one standard size and can be paralleled to

meet most residential applications. The rated voltage is 51.2V nominal (to suit 48V systems).

Larger systems are provided by Solar MD based on specific project requirements.

WARNING: Read the entire document before installing or using the Solar MD battery. Failure

to comply with the instructions or warnings in this document could result in electrical shock or

serious injury that can result in death or damage to the product that can render the SS4143

Solar MD battery inoperable.

2

Product Specifications

All SS4143-11 specifications & descriptions contained in this document are verified to

be accurate at the time of printing. Solar MD reserves the right to make any product

revisions & improvements at any time.

Errors or Inaccuracies

To communicate any inaccuracies, omissions or to provide general feedback regarding this

manual, send an email to [email protected]

Copyrights

All information in this document is subject to the copyright of Solar MD (Pty) Ltd. Additional

information is available upon request.

Safety Information

This manual contains important instructions and warnings that must be followed when using

SS4143-11.

Read all instructions before installing and using the SS4143-11.

Warnings Cautions

● Use SS4143-11 only as instructed.

● For communication and other information please read the BMS manual.

● Do not attempt to disassemble, repair, modify, or tamper with this battery unit.

● Do not insert foreign objects into any part of the battery unit.

● Avoid exposure to any moisture.

● Do not expose to extreme temperatures.

● Do not drill any holes into the box.

● Use only an approved Solar MD installer to install this product.

Failure to comply will void the warranty

3

Specification

Solar MD 14.3kWh SS4143-11 specification

Battery type

Lithium Iron

Phosphate

Scalability

Yes

Battery module

SS4143

Communication

CANBUS 500kbps / CAN

2.0B

Rated battery capacity

14336 Wh

Can BUS termination

Single 120 Ohm

Output power

Max 10 kW

Canbus ID range:

256 - 499

Usable battery energy @

0.3℃

13.00 kWh

Protection method

Cell level: uv / ov / oc

Position: x / y / x

Acceleration: x / y / z

Temperature: ot / ut

Nominal voltage

51.2V

Protection phy

Mechanical relay NO

Rated Current (Ampere)

200A

C Rating

0.71C

Number of battery modules

1 module

Com (CANBUS ) isolation

Yes 1.5kV

Weight

118kg

Transportation protection

Yes

Operating voltage

44.8V - 55.6Vdc

Indicator

Led, programmable

Communication

CANBUS

Addition IO

3 GPO

Dimensions of SS4143:

h/w/d (mm)

650/600

/210

Cell balancing

Passive balancing

Net Weight of SS4143

118 kg

Counters

Cycle counters and SoH

Battery cycle life [+25 ℃]

> 4000

AUX power output

5V 1A max

Charging efficiency

99%

Storage duration

6 months@+25℃

Operating temperature

-5℃~+50℃

Safety standards

compliance

IEC 62619/UN 38.3/UL1642

Transport

UN3480 & UN38.3

Cell Certificate

TUV / CE / RCM / UL1642

4

Mechanical installation

5

Installing top cover plate

Figure 3a: Top cover installation single or multiple batteries in line

6

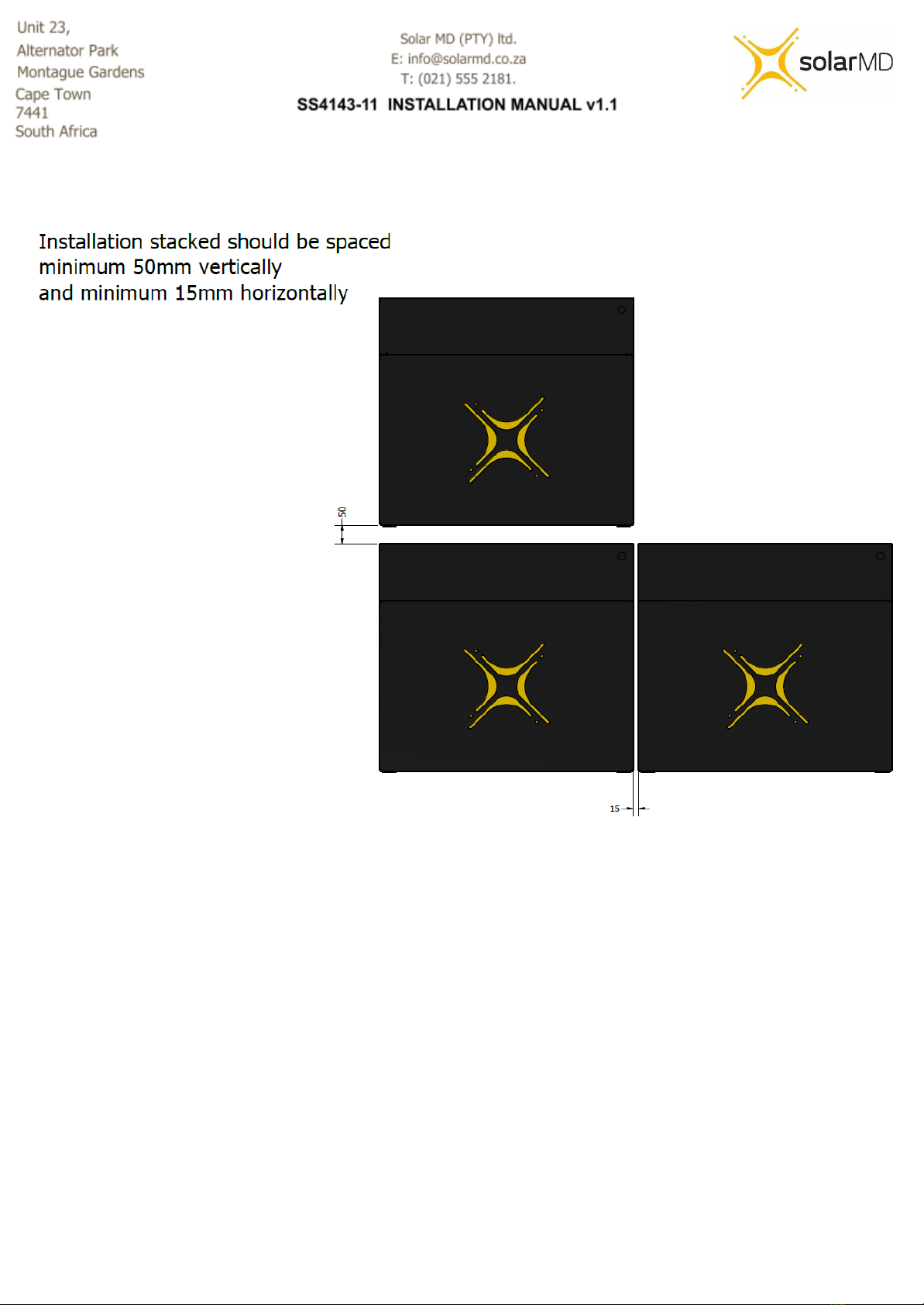

Figure 3b: Battery spacing - installation single or multiple batteries in line

7

Figure 3c: Battery feet - installation of battery feet

8

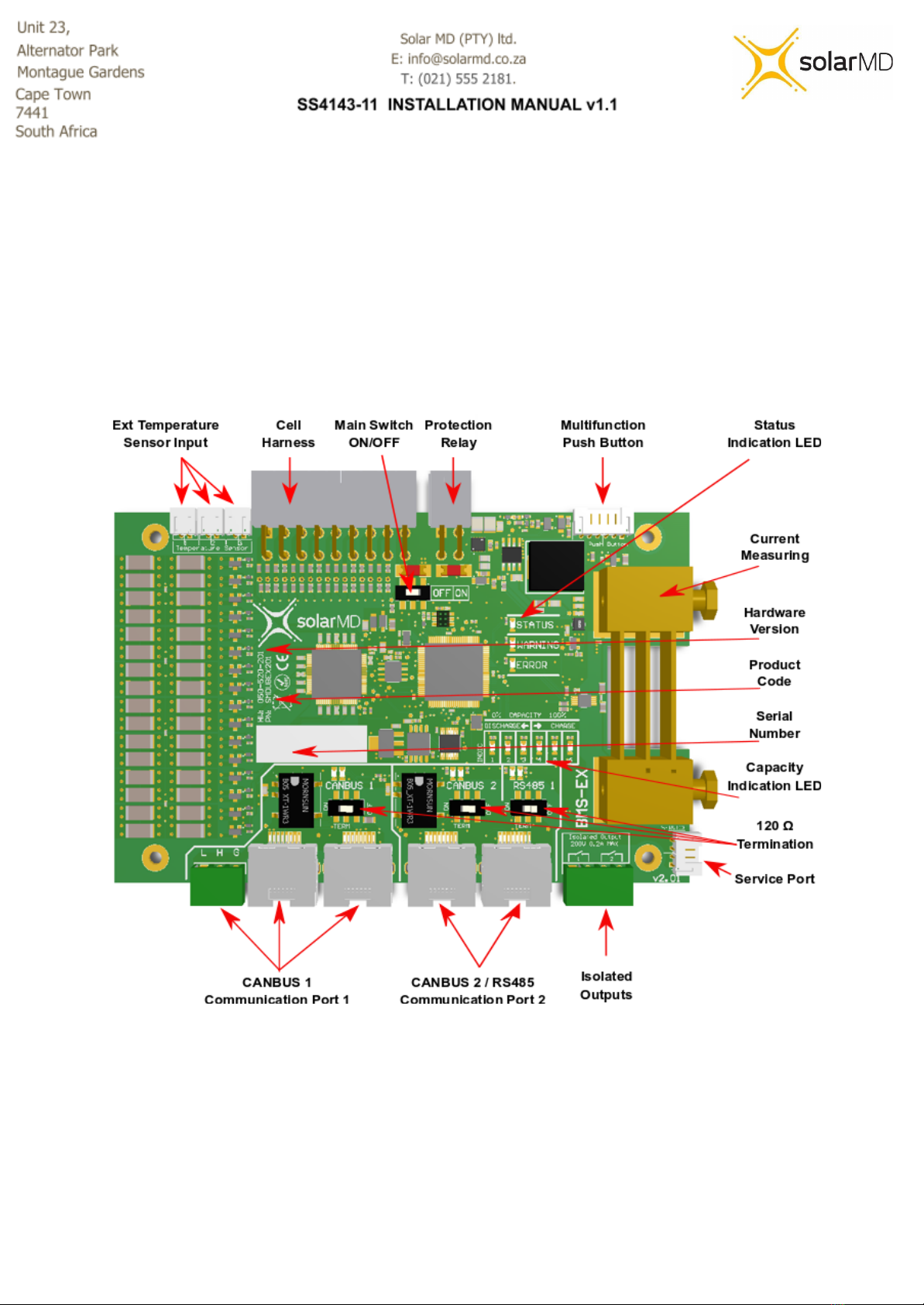

Electrical installation

Step 1. Before connecting anything be sure that the battery ON/OFF switch is at OFF

position. (figure 4)

Figure 4: BMS board component locations

9

Connecting Inverters/chargers/UPS to the battery unit while it is ON can cause big sparks due

to capacitors inside the connected device. This can be harmful to people.

Connecting the main battery terminal must be with the correct size cable

based on the rated current of the battery and the charger/inverter in case it’s lower.

Figure 5: Connection terminals

Step 2. Connect the negative cable to the battery negative busbar and positive cable to the

battery positive busbar as shown in figure 5.

10

Switching the Battery ON

Step 1. Make sure all DC cables are tightened according to specifications.

Step 2. If the battery operates in parallel with other energy sources, make sure that the

difference between battery voltage and DC bus is not more than 2.5V. If greater than 2.5V

please charge or discharge the other source accordingly until the voltage difference is in a

safe range under 2.5V.

Caution! A hot connection with difference in voltage can cause very high

equalization current which can burn the fuses of the battery!

Caution! Measure the voltage of the battery before connecting the DC

cables.

Step 3. Turn the BMS board ON/OFF switch to the ON position (figure 4).

Step 4. Connect Multipurpose button if not connected to the BMS board connector (figure 4).

Step 5. Hold the multi purpose button until the light comes on.

Warning! If the battery does not switch the main protection contactor ON in

7 sec, please check the BMS board indication LED for faults. See section BMS

Error and Warnings.

11

Multicolor multipurpose button

Figure 6 : Multicolor / Multipurpose button.

Button functions

The main functions of MFB (Multi Function Button) are:

- Switching Battery On/Off

- Representing various states of the battery with its built-in LED.

- Accessing quick function list

- Parameter Menu

1. Switching battery ON/OFF

- Start by putting the ON/OFF micro switch on the BMS into the ON position.

- To switch the battery ON, simply push and press the button until boards get illuminated.

- To switch the battery OFF, press and hold the MFB for 10 sec until the board switches all

lights off.

12

2. LED States

The MFB is equipped with an LED bezel which can be configured to show different types of

battery information. Under normal battery conditions it can be configured to display battery

capacity, Current flow direction (charge or discharge) or OFF. This setting will be overridden if

the battery is in warning mode or error mode. When in warning mode the LED will flash orange

and when in error mode the LED will flash red.

3. Accessing a quick function list.

MFB can execute 4 predefined functions. These functions are accessed by pressing and holding

the MFB. While holding, the Indication LEDs (see Figure 10 below) will start to illuminate from

left to right . The amount of illuminated LEDs represents the number of the function (1 - 6). To

activate a function, release the button when the desired function is selected, then the LEDs will

start blinking quickly for around 3 sec. While the LED is blinking, quickly press and release the

MFB to confirm the function activation. If no confirmation is triggered the operation will be

canceled. The available functions are:

- Function 1: Reserved

- Function 2: By selecting function 2 you can toggle between 3 Indication LEDs

functions:

- Show current flow and direction

- Show battery capacity

- LEDs off.

- Function 3: Reserved

- Function 4: Accessing Parameter Menu

- Function 5: Execute override ON for 120 seconds

- Function 6: Execute override OFF for 120 seconds

4. Parameter Menu

After entering the parameter menu from calling Function 4 you can change BMS parameters.

The Parameter Menu uses all 6 indication LEDs to represent a Parameter Number and 6 LEDs

from CANBUS1, CANBUS2, RS485 to represent a parameter value. The selected state between

13

parameter number and parameter value is represented by LEDs flashing e.g if Indication LEDs

are flashing the current menu state is Parameter number.

Changing Parameter number is done by a single quick press of MFB, to switch to value mode

press and hold MFB for more than 2 seconds, after that the value LEDs will start blinking quickly.

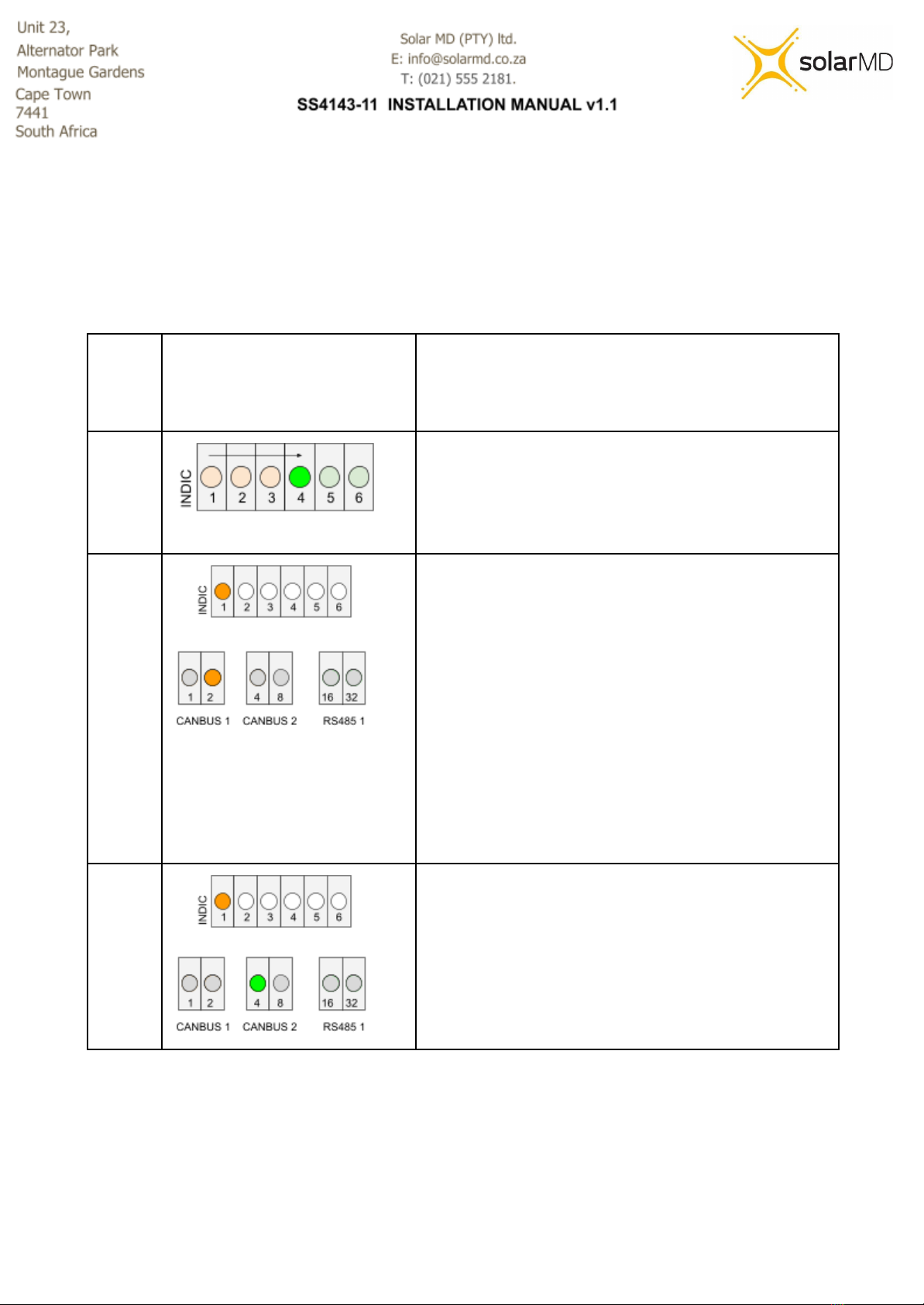

● Converting LEDs to values.

Group of LEDs can represent a single digit. These digits can be simply read by a simple

method of summing. Each LED in the group represents a number. LED 1 = 1, LED 2 = 2,

LED 3 =4, LED 4 = 8, LED 5 = 16 and LED 6 = 32.

Summing the values of the illuminated LEDs will give you the calculated number.

Example

Visual Representation

Description

1

Sum up all the LEDs that are illuminated to get the

represented value.

0 + 2 + 0 + 0 + 0 + 0

= 2

2

Sum up all the LEDs that are illuminated to get the

represented value.

1 + 0 + 0 + 8 + 16 + 0

= 25

14

Figure 7: LEDs on the BMS

Main menu navigation

Parameter

number

Parameter

Possible value

1

Reserved

2

Function of Indication LEDs

1. Show current flow and direction

2. Show battery capacity

3. LEDs off

3

Reserved

4

Enter Sub menu

(see below for more detail)

See table below for more info

5

Execute override OFF for 120 seconds

6

Execute override ON for 120 seconds

15

Sub menu navigation

Parameter

number

Parameter

Possible value

1

Operation mode

1. Test mode

2. Low voltage mode

3. Production mode

4. High voltage mode

2

Reserved

3

Inverter type

(Low voltage Mode)

1. None (Feature disabled)

2. SMA

3. Victron

4. Sunsynk

5. Goodwe

6. Growatt

4

Reset Cluster Nodes

1. None

2. Reset

5

Reserved

6

Reserved

16

Example: Navigating the sub menu to change BMS operation from Standalone mode to High

Voltage mode.

Visual Representation

Description

Step 1

- Press and hold until the 4th LED starts

blinking (the LEDs will blink sequentially from

left to right starting at LED 1).

- Long press the button to enter into the sub

menu.

Step 2

You are now in the Sub menu

- Quick press to navigate the sub menu until

the 1st indication LED is blinking to enter the

operation mode (parameter 1 of the sub

menu).

- Long press to enter into the operation mode

setting.

- The CANBUS 1, 2 and RS485 LEDs will now

start blinking, showing the current settings for

the specific parameter.

(it's currently showing Standalone mode)

Step 3

- Quick press to navigate to production high

voltage mode.

- Long press to save the setting.

- All done! Leave the button for 20 seconds or

long for it to go back to its home screen

17

Button indication

**Access to all features in future development

The Multipurpose button advanced indication functionality, allows the user to choose

between 5 different states. Mixed combinations are also allowed when a combination of

multiple batteries with BMS-EX are

used. The User can change the prefered stage by logging into their mypower24 Energy

Portal and going to the Battery Settings.

Illumination off

**For future development

When this state has been selected, the button serves as an on/off switch without illumination

(fixed colour).

Color based on capacity

When this state has been selected, the button shows static illumination in a color based on

the state of charge. From RED at 0% SoC (State of Charge) to GREEN at 100% state of

charge.

Color based on capacity with current direction based on

shading.

**For future development

When this state has been selected, the button shows flashing illumination in a color based

on the state of charge and flashing code based on the electrical current direction (charge /

discharge). From RED at 0% SoC (State of Charge) to GREEN at 100% state of charge.

The flashing code for charge goes through illumination interruption for 1 interval and slow

illumination into the color based on the SoC for 5 intervals. The flashing code for discharge

represents the opposite from charge - study color for 1 interval and slow loss of color

following illumination interruption. Solar MD users refer to both as charging / discharging

waves.

18

Fixed color with current direction based in shading

**For future development

When this state has been selected, the button shows illumination in a color based on the

user choice and flashing code based on the electrical current direction (charge / discharge).

The flashing code for charge goes through illumination interruption for 1 interval and slow

illumination for 5 intervals. The flashing code for discharge represents the opposite from

charge - study color for 1 interval and slow loss of color following illumination interruption.

Solar MD users refer to both as charging / discharging waves.

Firmware

BMS EX can store multiple firmware versions. Upon startup the bootloader will start the latest

version available.

How to Update

Logger V2 can update the firmware of a connected and communicating BMS via CANBUS. The

logger stores available BMS-Ex firmwares locally and can send it to the BMS as requested.

Firmware Update Settings

-Refresh Loaded Firmware info BMS: Press “Refresh”to see the latest BMS firmware

version that has been sent from the logger to the BMS.

-Check Available Updates: Press the “Check”button to see the latest BMS firmware

version available.

-Upload Available Firmware to BMS: If the BMS firmware version is lower than the latest

available firmware version then type in the firmware version you would like to upload in the

space provided and click “upload”.

- Write Loaded Firmware: Once the firmware has been fully uploaded from the logger to

the BMS (progress bar should show 100%) click the “write” button. This will start the two

step installation process on the BMS.

- The BMS will first verify the uploaded firmware, during this process the indication

LEDs on the BMS will flash slowly from left to right.

- The second part is installing the firmware, during this process the indication LEDs

on the BMS will flash fast from right to left. Once successfully installed the BMS will

restart. Verification of a successful update can be seen on the MyPower24 portal.

19

Table of contents

Other Solar MD Camera Accessories manuals