Solar MD mypower24 Operating and maintenance instructions

Solar MD Proprietary Limited

Company Registration: 2014/169938/07

T: 021 555 2181

W: www.mypower24.co.za

1. Specification

2. Product overview

mypower24 3.7k SS106 specification

Battery type

Lithium Iron Phosphate

Scalability

Up to 22 KWh

Battery module

SS106

Communication

CANBUS 500kbps/CAN

2.0B

Rated battery capacity

3.84 kWh

CANBUS termination

Single 120 Ohm

Output power

Max 5 kW

Canbus id range:

256 - 499

Usable battery energy

@0.3C

3.7 kWh

Protection method

Cell level: uv / ov

Nominal voltage

51.2V

Protection phy

Mechanical relay NO

Number of battery modules

1 module

Com isolation

Yes 800V

Weight of MSS

34kg

Transportation

protection

Yes

Operating voltage

44.8V-55.6Vdc

Indicator

Led, programable

Communication

CAN

Addition IO

3 GPO

Dimension enclosure

Albro6: h/w/d

600mm/400mm/200mm

Configuration method

Over mypower24 web

portal

Dimensions of SS106:

h/w/d

500mm/320mm/150mm

Cell balancing

Passive balancing

Net Weight of SS106

35 Kg

Health monitoring

Cycle counters and state

of health

Battery cycle life [+25 ‘C]

> 4000

AUX power output

5V 2A max

Charging efficiency

99%

Storage duration

6 months@+25’C

Operating temperature

-5’C ~+50’C

Safety standard

compliance

IEC 62619/UN

38.3/UL1642

Transport

UN3480 & UN38.3

Cell Certificate

TUV / CE / RCM /

UL1642

IP level

IP65

Solar MD Proprietary Limited

Company Registration: 2014/169938/07

T: 021 555 2181

W: www.mypower24.co.za

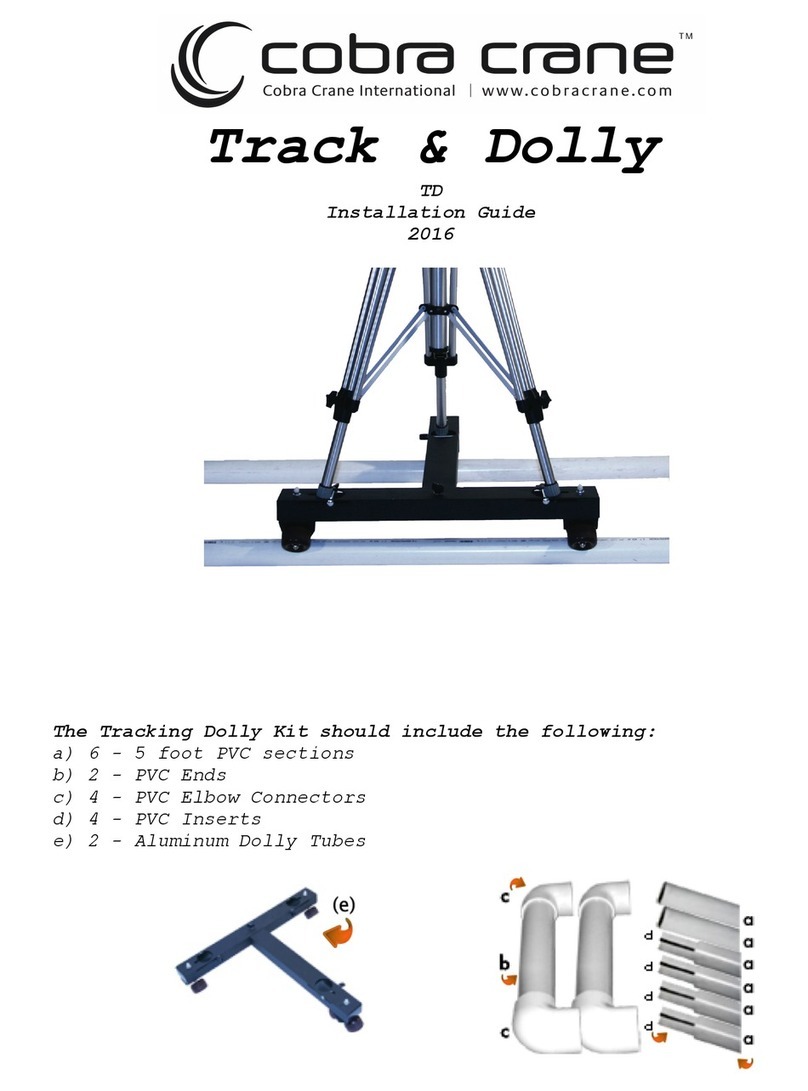

Figure 1 Overview SS106

Position bracket vertically and

slide all the way down until

the limiting notch hit the end.

Tight the screw with big flat

screwdriver.

3. Mechanical installation

3.1.Box bracket assembly

Figure 2 bracket assembly

3.2. Box mounting.

Please use the correct mounting screws for the correct wall surface. The

Battery is only to be installed in upwards position!!!

Figure 3 Dimensions of the wall fixation points.

Figure 4 Installation layout

Solar MD Proprietary Limited

Company Registration: 2014/169938/07

T: 021 555 2181

W: www.mypower24.co.za

3.3. Drilling holes for cable glands and ON/OFF button

Figure 5. Enclosure section bottom view, safe areas for drilling and installation of cable glands.

Please pay attention while drilling, drilling into the cell will cause

internal short circuit, which will cause overheating accompanying with

smoke and risk for damaging nearest cells.

In case accident and fire starts call the fire department immediately.

The only extinguisher that will work on a Lithium-ion Battery fire is a

Class D Fire Extinguisher or Dry Sand or Dry Table Salt.

As shown in Fig 5 the drilling points for the cable glands and switch button.

Example hole 1 is located in front left safe zone for drilling assuming that safe

zone end 55mm from the beginning of the box the center of the hole can be

mark from the bottom of the box by simple calculation end of zone -radius of

the maximum diameter of the gland which normally is gland nut Example with

19mm: from the left side marker is 55-22=33mm from the front side 70-

22=48mm. Hole 2 and 3 with dimension for center hole.

Solar MD Proprietary Limited

Company Registration: 2014/169938/07

T: 021 555 2181

W: www.mypower24.co.za

Figure 6 Top clearance

The top side of the box is clear for drilling

in entire section. Avoid using long drill

bits clearance is 57mm shown in figure 6

4. Electrical installation

Step 1. Before connecting anything be sure that battery is off and the safety

jumper is removed (figure 7 safety jumper).

Figure 7 BMS board component location

Solar MD Proprietary Limited

Company Registration: 2014/169938/07

T: 021 555 2181

W: www.mypower24.co.za

Connecting Inverters/chargers/UPS to the battery unit while is ON

can cause big sparks due to capacitors inside the connected device.

This can be harmful for human.

Connecting main battery terminal must be with right size cable based

on the rated current of the battery the charger/inverter in case it is

lower. Use only 5mm hole diameter for the cable lugs.

Figure 8 connection terminal

Step 2. Connect negative cable to battery negative terminal and positive to

battery positive shown is figure8

Step 3. Install back safety jumper figure7

Step 4. Connect On/Off button to the board connector see figure7

Solar MD Proprietary Limited

Company Registration: 2014/169938/07

T: 021 555 2181

W: www.mypower24.co.za

5. Communication

5.1 Physical connection CANBUS interface devices communicate to each

other over CANBUS interface. This interface contains two pins: CAN

HIGH and CAN LOW. All devices must be connected in parallel see

Figure 9

Only one termination resistor 120 Ohm must be connected for entire

network. Each device has built in termination resistor which can be

activated with jumper. For Bmspl this jumper is located on top of

connector1 see Figure 7. In Figure 9 only Logger has active termination jumper.

Table 1 Connectors pin map

Connector 1(figure7)

Connector 2 (figure7)

Pin

Function

Pin

Function

1

CAN LOW

1

5V aux power supply 2A max

2

CAN HIGH

2

General purpose input1.

3

CAN GROUND

3

General purpose input2.

4

Bat + (51.2) pack voltage

4

General purpose input3.

5

5V aux power supply 2A max

5

General purpose output1.

6

Not connected

6

General purpose output2.

7

Not connected

7

General purpose output3

8

Ground

8

Ground

Figure 9 CANBUS architecture

Solar MD Proprietary Limited

Company Registration: 2014/169938/07

T: 021 555 2181

W: www.mypower24.co.za

Connecting to CANBUS with CAN LOW and CAN HIGH only see table 1.

After successful installation with other devices Canbus status LED should

immediately switch on with green light. To detect correctly that bus is

connected properly BmsPl require to see at least one device on the bus.

Connecting device with same CANBUS ID can cause software issues,

check devices ID before connecting!

Troubleshooting communication.

Canbus status LED

is OFF after

everything is

connected

1. Check that the other devices are switched ON

2. Check that only one termination resistor is enabled

on the bus.

3. Check cable connection of all device on the bus.

Other devices are

losing

communication

after BmsPl has

been connected

1. Check termination resistor. Only one must be

enabled

2.

6. Maximum charging / discharging voltages for not supported devices.

Equalization must be disabled. Please check if your inverter charger has

been approved by Solar MD and it is CAN compatible.

Table 2 Recommended discharge/ charge voltages

Charging

Discharging

Parameter

Value

Parameter

Value

Bulk voltage

54.8V

Low voltage

49V

Float voltage

53.5V

Cut off voltage

47V

This manual suits for next models

1

Table of contents

Other Solar MD Camera Accessories manuals