10 © Solarbayer GmbH [02.16]

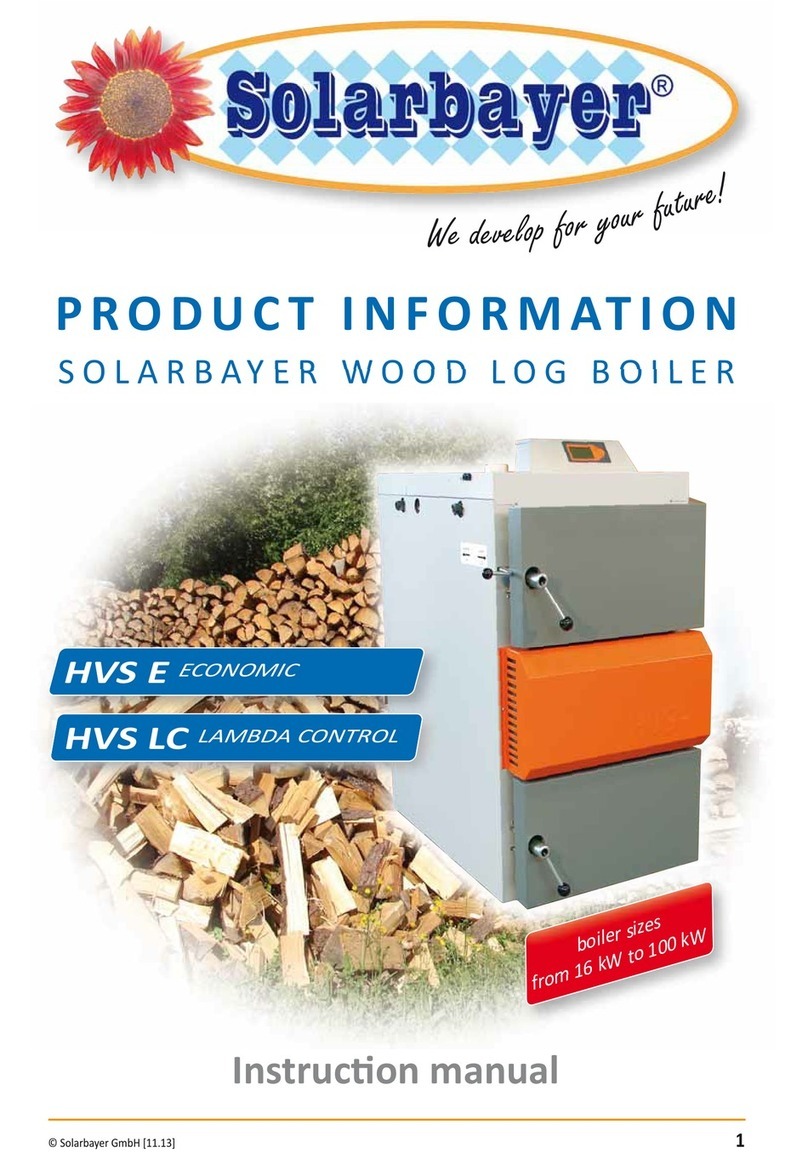

PRODUCT INFORMATION Wood log boiler HVS

General Information

Technical specificaons

General facts

HVS 16 LC HVS 25 E

HVS 25 LC

HVS 40 E

HVS 40 LC

HVS 60 E

HVS 60 LC

HVS 100 E

HVS 100 LC

nominal output in kW kW 16 25 40 60 100

efficiency factor % 88 – 92 %

water capacity l 60 75 93 180 215

max. operating pressure bar 3 3 3 3 3

pressure loss at nominal load (Δt 10 K) mbar 9,35 9,75 10,48 12,77 11,5

pressure loss at nominal load (Δt 20 K) mbar 1,00 1,05 2,55 3,19 2,82

permissible pressure range safety valve bar min. 1 to max. 4

water inlet temperature safety valve °C 4 – 15 °C

opening temperature safety valve °C approx. 95 °C

noise level dB 45,0 45,5 47,7 51,4 54,2

Fuel chamber/fuel consumption

HVS 16 LC HVS 25 E

HVS 25 LC

HVS 40 E

HVS 40 LC

HVS 60 E

HVS 60 LC

HVS 100 E

HVS 100 LC

admissible fuel untreated, split wood log with residual moisture of <20%

max. wood log length mm 350 550 550 700 1000

fuel chamber depth mm 370 560 560 750 1085

fuel chamber height mm 490 490 750 730 730

fuel chamber width mm 440 440 440 575 575

dimension of the filling hole w/h mm 435/255 435/255 435/255 575/318 575/318

fuel chamber capacity, volume liter approx. Liter 80 116 180 310 455

max. filling weight (beech) approx kg 20 30 48 80 120

fuel consumption at nominal load (beech) approx. kg/h 4,5 7,1 11,2 17 25

combustion period at nominal load (beech) approx. hrs 4,4 4,2 4,3 4,5 4,5

Exhaust gas routing

HVS 16 LC HVS 25 E

HVS 25 LC

HVS 40 E

HVS 40 LC

HVS 60 E

HVS 60 LC

HVS 100 E

HVS 100 LC

recommended min. chimney cross section Ø mm 140 150 180 180 200

draft requirements Pa 15‐25 15‐25 15‐25 15‐30 15‐30

effective minimum chimney height m approx. 7 mtr

exhaust gas mass flow (at 13% CO2)g/s 10 16 25 38 64

modulating exhaust gas temperature °C approx. 180 (±30)

recommended exhaust gas routing m effecve length < 1,5 mtr (max. 2 bends)

barometric damper recommended

Hydraulic

HVS 16 LC HVS 25 E

HVS 25 LC

HVS 40 E

HVS 40 LC

HVS 60 E

HVS 60 LC

HVS 100 E

HVS 100 LC

min. buffer tank volume1l 1000 1500 2200 3300 5500

manufacturer’s recommendation1l 1500 2000 3000 5000 6000

min. tube dimension (CU‐/steel presision tube)² mm Ø 28 Ø 28 Ø 35 Ø 42 Ø 54

min. tube dimension (steel tube)² – DN25/1” DN25/1” DN32/1¼” DN40/1½” DN50/2”

recommended boiler return line temperature °C 70 °C

1

Regulatory framework and government grants should to be paid attention to.

²Depending on tube length, number of elbows installed, mixing valves, changeover valves, etc., you might need a bigger dimension. The above

mentioned tube dimensions are only a recommendation and do not replace professional technical planning.