2 Safety information

3.1 Technical specifications for warranty

and guarantee claims

A prerequisite for the assertion of warranty and gua-

rantee claims is compliance with the following tech-

nical specifications.

For more information on the individual points, see the

boiler installation instructions.

Regular maintenance and cleaning

–The boiler and the components of the heating sys-

tem must be maintained and checked regularly.

–This is the prerequisite

–for permanently reliable functioning of the boi-

ler,

–for energy-saving and environmentally friendly

operation of the boiler,

–for a long service life of the boiler.

–Option/Recommendation: Conclude maintenance

contract.

–Keyword documentation: In the course of main-

tenance by qualified personnel, the completed

activities/measures are documented in the main-

tenance log. It is recommended to keep a plant

logbook (for documentation/evidence purposes of

own activities), especially if specialist main-

tenance is not carried out.

Fuel

–The fuel used must comply with the spe-

cifications.

–Unapproved fuel can lead to inefficient

combustion and can damage the boiler.

Specifications for the filling/supplementary

water of the heating system

–Control the pH value: must be between 8.2

and 9.5

–Avoid of stone formation (= limescale on heat

exchanger surfaces):

–Pay attention to the water hardness

–Soften filling water, or better: desalinate.

–Avoid the corrosion on the water side (is usually

triggered by the available oxygen in the water):

–Correct system planning, correct dimen-

sioning, pay attention to material com-

binations.

–Repair leaks immediately.

–Expansion vessel (prevents air suction when

the system cools down): Set pressure cor-

rectly, check regularly.

–Existing underfloor heating: Attention with old,

diffusion-open plastic pipes (carry out a sys-

tem separation).

Return temperature to the boiler

–A sufficiently high return temperature into the boi-

ler must prevent the temperature from falling

below the dew point (resulting in corrosion in the

boiler).

–This is ensured at ecotop zero/light by the inte-

grated return lift as standard.

Supply air to the boiler

–The supply air to the boiler must not contain any

aggressive substances. These can cause cor-

rosion in boiler and fireplace.

–Aggressive substances are, e.g. chlorine or fluo-

rine compounds (used in cleaning agents, sol-

vents, adhesives,...).

3.2 Conditions for entitlement to benefits

For warranty and warranty claims observe the fol-

lowing points:

–The warranty begins at the time at the time of han-

dover (delivery note, commissioning form).

–The warranty period is calculated from the date of

initial commissioning (according to the meter of

the operating hours of the control).

–The warranty periods are based on the relevant

regulations.

–We must be notified promptly and accurately of

any damage incurred, so that the cause can be

clarified.

–If the system has defects despite correct instal-

lation (in compliance with the technical docu-

mentation), we grant a warranty provided that the

system has been examined by the plant customer

service (commissioning form).

–The guarantee applies to technical, construction-

related faults and faults in the manufacture of the

system that prevent correct and problem-free

usage.

–We are not liable for parts that were not produced

by SOLARFOCUS. However, we are prepared to

assign our claims against the producer (con-

cerning this defect) to the buyer.

–In fulfilling the warranty/guarantee services, we

shall cover only the assembly time and the mate-

rials used, but not any travel or accommodation

costs necessary for the fitters/engineers or any

return transport costs.

–SOLARFOCUS GmbH assumes no liability for

any consequential costs of damages.

–The repair and/or warranty replacement shall be

carried out on site or in the SOLARFOCUS fac-

tory at our discretion.

–The company SOLARFOCUSwill determine whe-

ther such work requires a repair or whether the

parts are to be replaced free of charge.

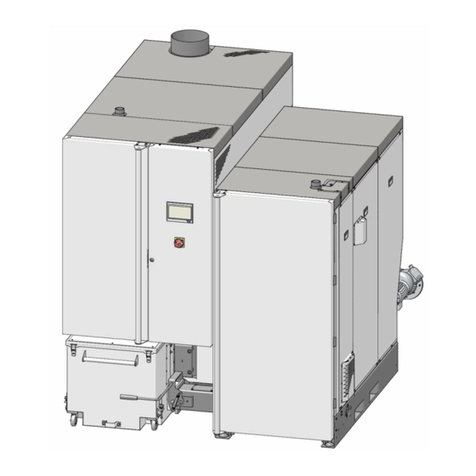

4 Operation manual ecotop-zero, ecotop-light