Index

1. Introduction................................................................................................................................................... 3

1.1. Symbols ................................................................................................................................................. 3

1.2. Abbreviations ......................................................................................................................................... 3

1.3. General.................................................................................................................................................. 3

1.3.1. Manufacturer’s liability............................................................................................................................ 3

1.3.2. Installer’s liability .................................................................................................................................... 4

1.3.3. User’s liability ......................................................................................................................................... 4

1.4. Certifications .......................................................................................................................................... 4

2. Safety instructions and recommendations ................................................................................................ 5

2.1. Safety instructions.................................................................................................................................. 5

2.2. Recommendations................................................................................................................................. 6

3. Description.................................................................................................................................................... 6

3.1. Operating principle................................................................................................................................. 6

3.1.1. Boiler..................................................................................................................................................... 6

3.1.2. Ventilation............................................................................................................................................. 7

3.1.3. Heat transfer fluid loop........................................................................................................................ 7

3.1.4. Regulation ............................................................................................................................................ 7

3.2. Main components................................................................................................................................... 8

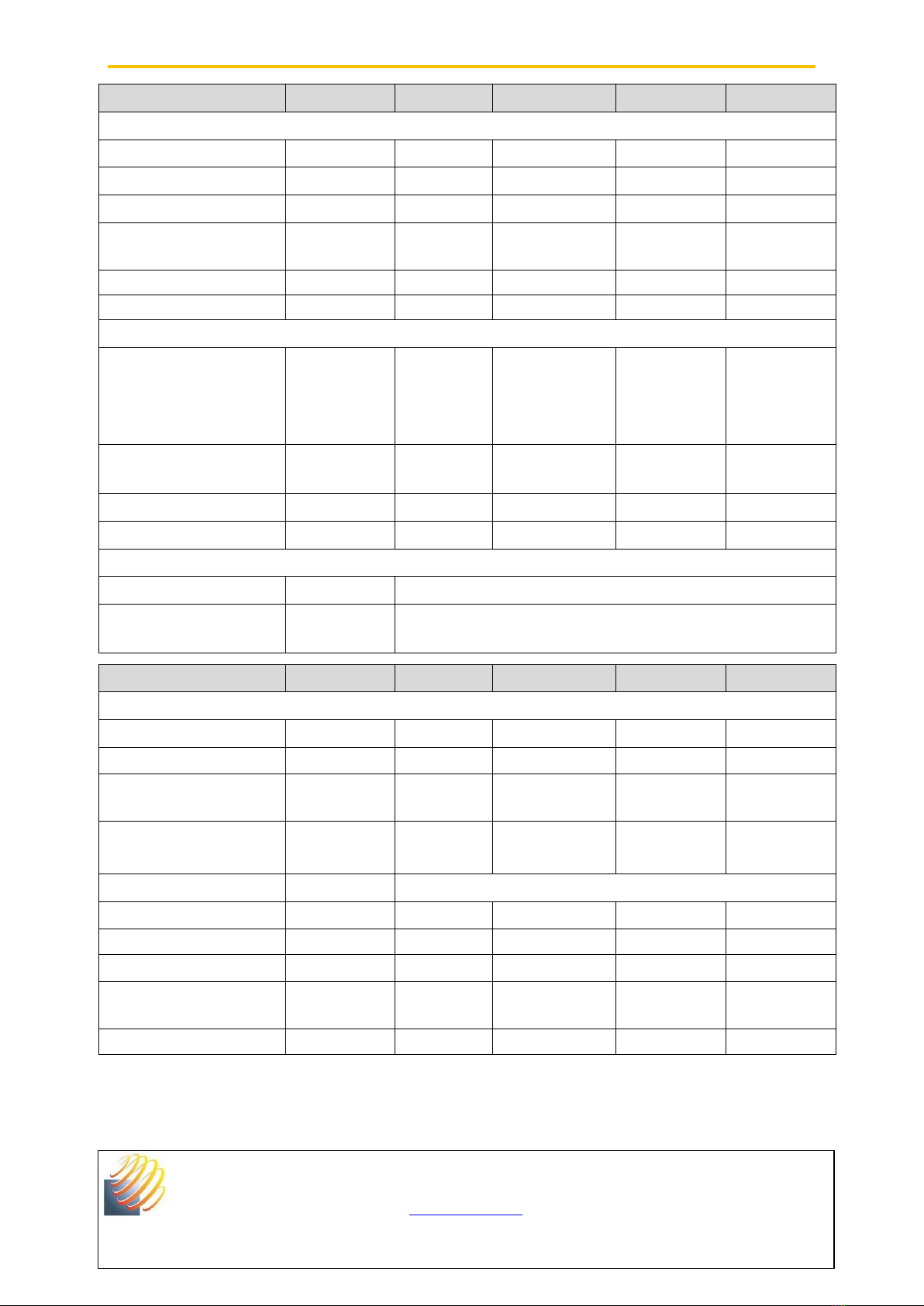

3.3. Technical characteristics........................................................................................................................ 9

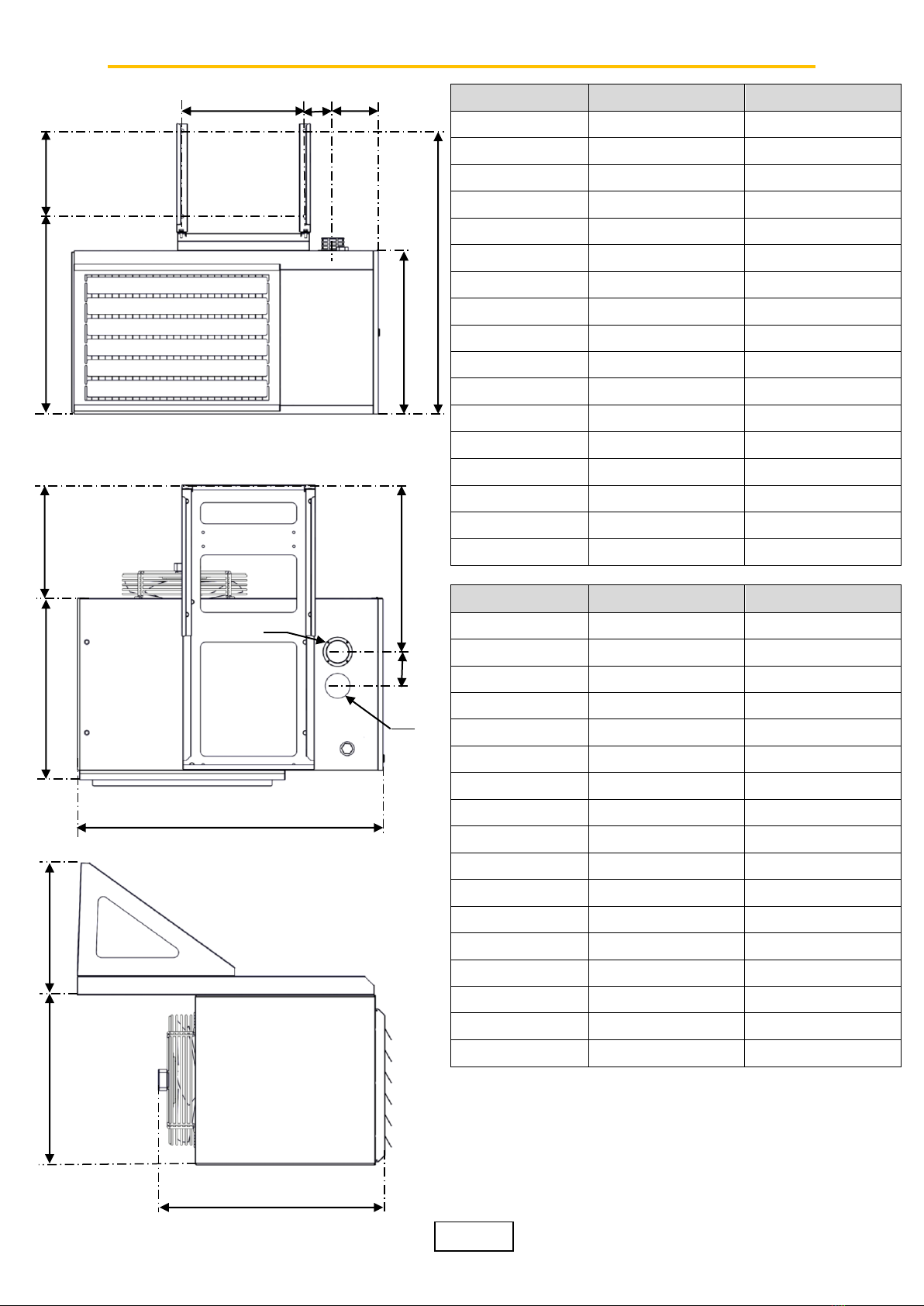

3.4. Overall dimensions............................................................................................................................... 10

4. Appliance installation................................................................................................................................. 11

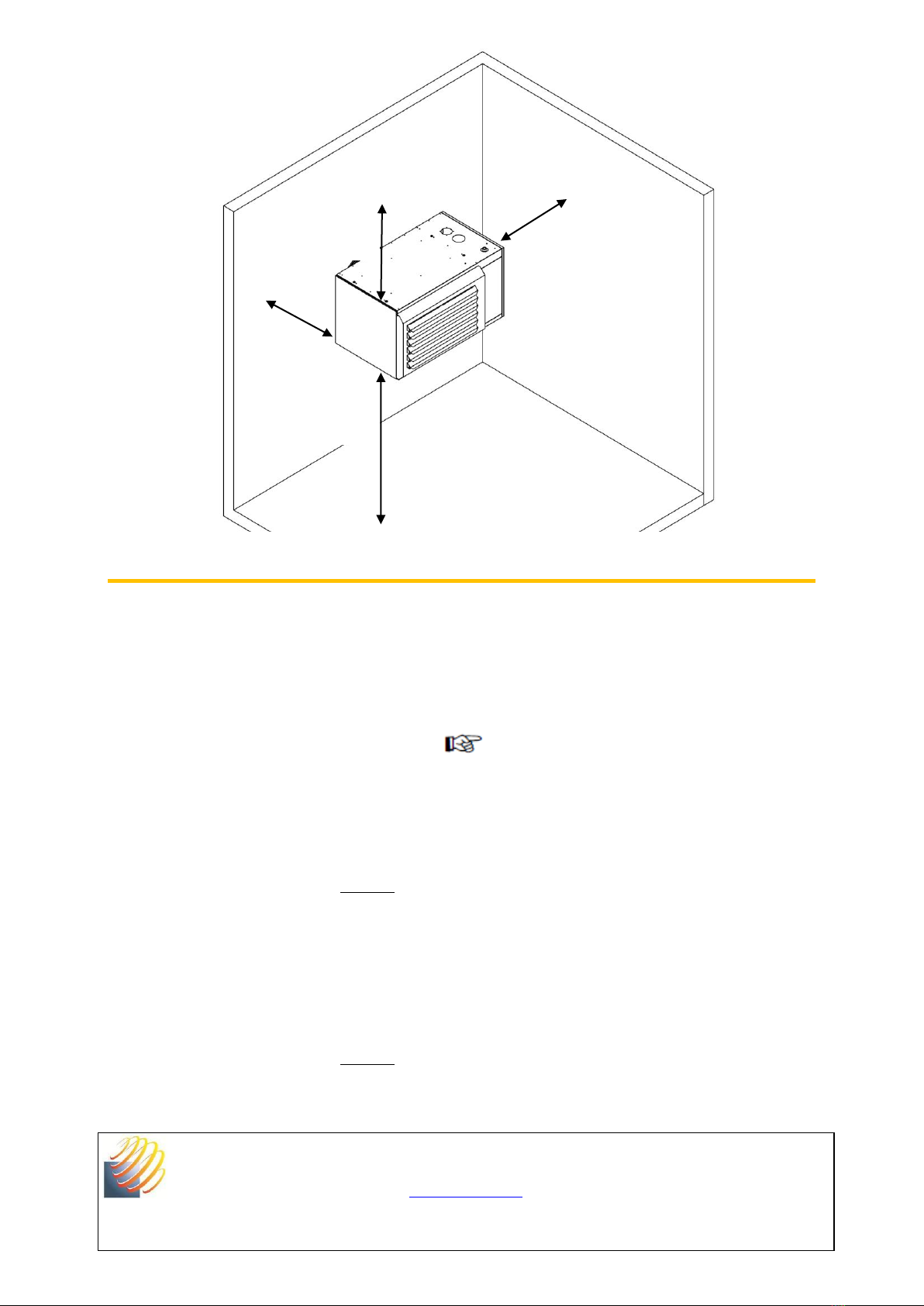

4.1. General rules........................................................................................................................................ 11

4.2. Fixing the appliance............................................................................................................................. 13

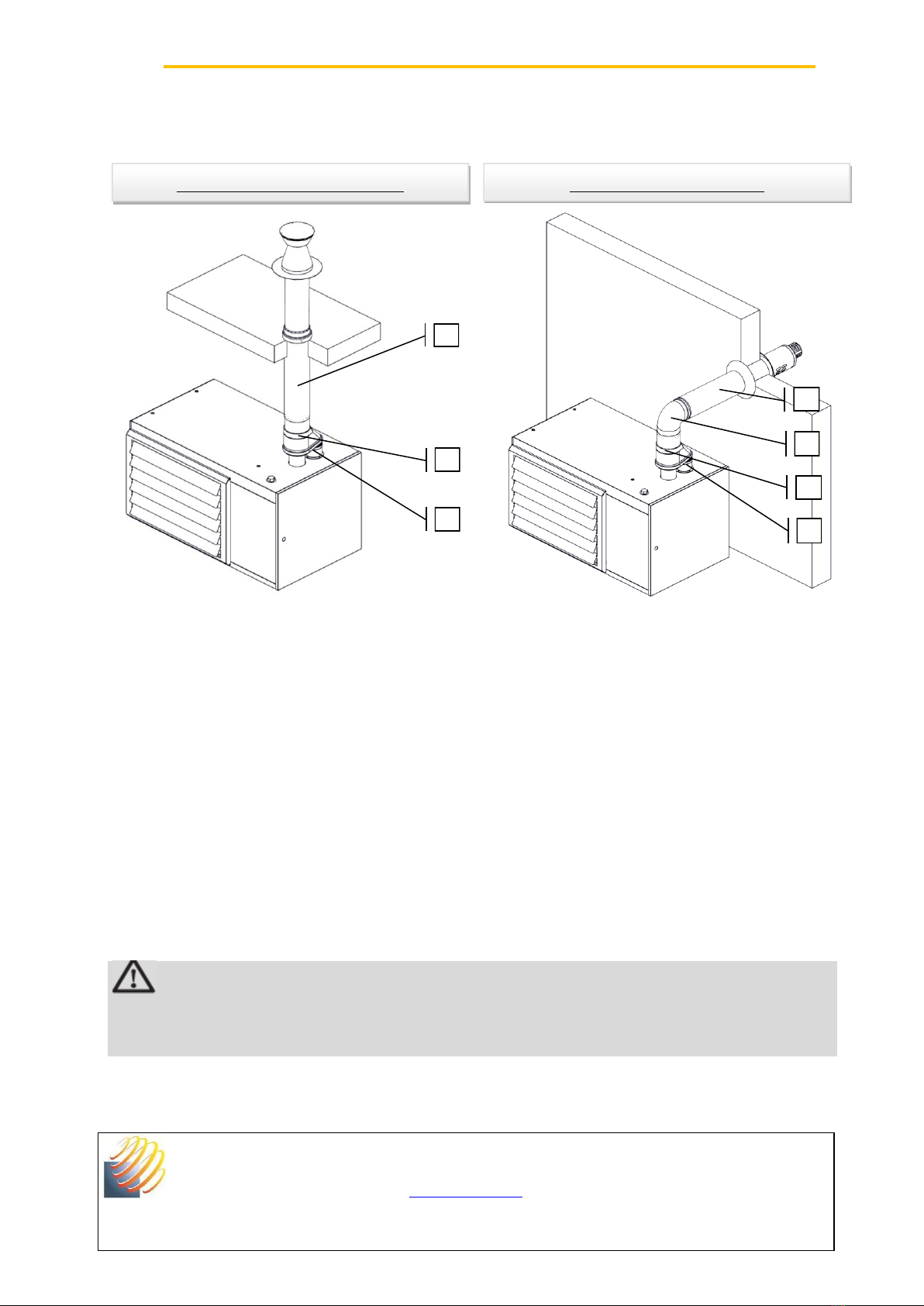

4.3. Connecting flue pipes........................................................................................................................... 14

4.3.1. B23 type evacuation flue connection.................................................................................................... 16

4.3.2. C33 and C13 type evacuation flue connection..................................................................................... 17

4.3.3. C53 type evacuation flue connection ................................................................................................... 18

4.4. Condensate drain................................................................................................................................. 19

4.5. Gas connection.................................................................................................................................... 20

5. Temperature control –Electric connection.............................................................................................. 22

5.1. Temperature control............................................................................................................................. 22

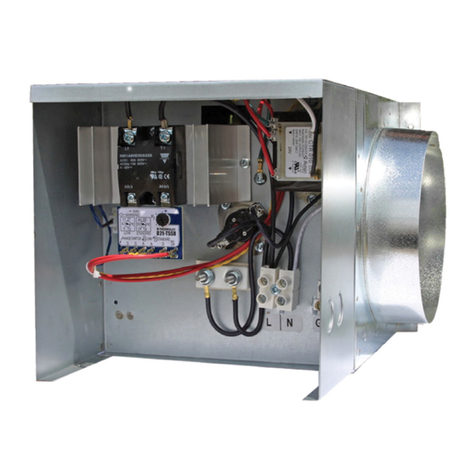

5.2. Electric connection............................................................................................................................... 23

5.2.1. Description........................................................................................................................................... 23

5.2.2. Connexion............................................................................................................................................ 25

5.2.3. Internal wiring diagram......................................................................................................................... 26

6. Commissioning........................................................................................................................................... 27

6.1. Start ..................................................................................................................................................... 27

6.2. Burner setting....................................................................................................................................... 28

7. Troubleshooting.......................................................................................................................................... 30

7.1. Troubleshooting ................................................................................................................................... 30

7.2. Spares.................................................................................................................................................. 31

8. Maintenance................................................................................................................................................ 32

9. Warranty ...................................................................................................................................................... 36