4/29

INSTRUCTIONS— GAS AIR HEATER - MINIGAZ Eco MH Eco, MC Eco, MV Eco– NT09004I-GB – 29/11/2017

1.4. Safety

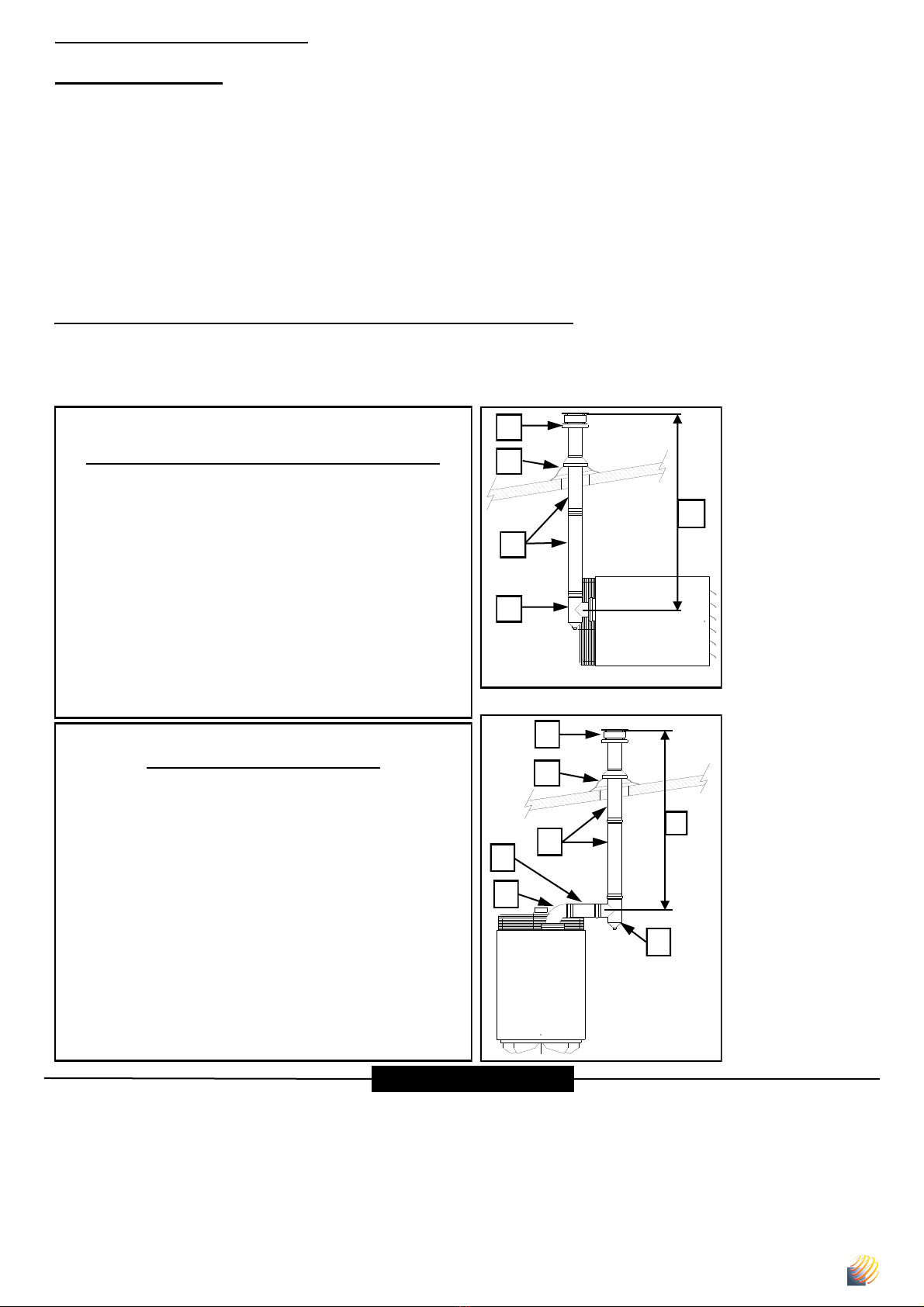

- Any flame failure is detected by an ionization sensor and the gas by-pass valves immediately close.

- The exchanger thermal protection is made by two thermostats. The first one, with automatic resetting, protects from insuffici ent air output

(clogging, fan failure). The second one, with manual resetting, is set at upper threshold than the first one. It protects the device from major

overheating due to malfunction or inadequate using.

In case of trouble, please contact us.

Make sure that the device can be normally fed with combustion air at atmospheric pressure (any modification of the building f urther to the

installation must be made considering this point). Over-depression inside the premises can disturb the device operation by depriving it of

necessary air for combustion.

1.5. Switch-off

- To switch off the device for a short period, just cut off the thermostatic line (put the thermostat at minimum set point or c ut off the thermostat

switch).

- For extended stop, cut off the thermostatic line, close the gas valve and cut off the electrical power, carefully waiting for the

fan stop

.

Gas and electricity must be cut off only in case of emergency or for extended stop periods.

1.6. Warranty

(General terms of business excerpt, chapter WARRANTY)

:

The devices must be installed by skilled professionals, in conformity with the rules in force, the rule book and the recommen dations mentioned on

our assembly instructions).

SOLARONICS CHAUFFAGE offers 1 year-warranty on parts and « manufacture » manpower from the devices delivery (5 years on the

exchanger).

This warranty is valid with the provision that the manufacturer recommendations mentioned in these instructions have been obs erved and that the

warranty supplied with each device has been returned.

The warranty will come in force on the manufacturing date defined by the company and provided the attested and signed warrant y has been

returned. We accept no responsibility and no warranty applies in case of customer carelessness, faulty, inadequate or non con form installation.

Only the manufacturing or raw materials malfunctions are concerned.

The warranty is limited to the parts replacement, when recognized as faulty, by identical parts; the cost of manpower, travelling, transportation and

access to the equipment are excluded.

Any replacement made during the warranty period, even if no equipment immobilization is requested, does not extend the warran ty period in any

case. No damages can be claimed for direct or indirect injury.

Any installation, maintenance and trouble shooting must imperatively made by skilled professionals. Any intervention must be made according to

the rule book according to the rules in force and our recommendations as per these instructions. The good operation of the de vice depends upon

correct installation and start up. Any non observance of the rules would immediately imply our company’s responsibility disch arge

The devices must only be equipped with genuine vent parts and air intake.

In case of using accessories that are not recommended by our company, make sure of the compatibility. Our company is not resp onsible for

possible damages or injury resulting from inappropriate use of the devices.

The knowledge and respect of legal rules, as well as design, installation, start up and maintenance norms are exclusively of the responsibility of

the Engineering and Design office, installer and user.

Our warranty does not consider nor cover the damages due to:

- Outside phenomena,

- User negligence,

- Non respect of our technical instructions recommendations,

- Immediate or delayed damaging further to faulty handling on transportation or wrong move,

- Using other accessories than the original ones,

- Lack of maintenance or supervision.

Our company is not responsible for any physical or material injury, to the buyer or any other person, that may be caused by o ur products or that

would directly or indirectly ensue these products use.