Summary

1. Introduction .......................................................................................................................4

1.1. General ....................................................................................................................................................... 4

1.1.1. Manufacturer’s liability................................................................................................................................................4

1.1.2. Installer’s liability ........................................................................................................................................................4

1.1.3. User’s liability.............................................................................................................................................................5

1.2. Certifications.............................................................................................................................................. 5

2. Safety instructions and recommendations......................................................................5

2.1. Safety instructions..................................................................................................................................... 5

2.2. Caution ....................................................................................................................................................... 6

2.3. Recommendations..................................................................................................................................... 6

3. Description.........................................................................................................................7

3.1. Main components ...................................................................................................................................... 7

3.2. Operation.................................................................................................................................................... 7

3.3. Safety.......................................................................................................................................................... 7

3.4. Switching off .............................................................................................................................................. 8

3.5. Control board............................................................................................................................................. 8

4. Technical Characteristics .................................................................................................9

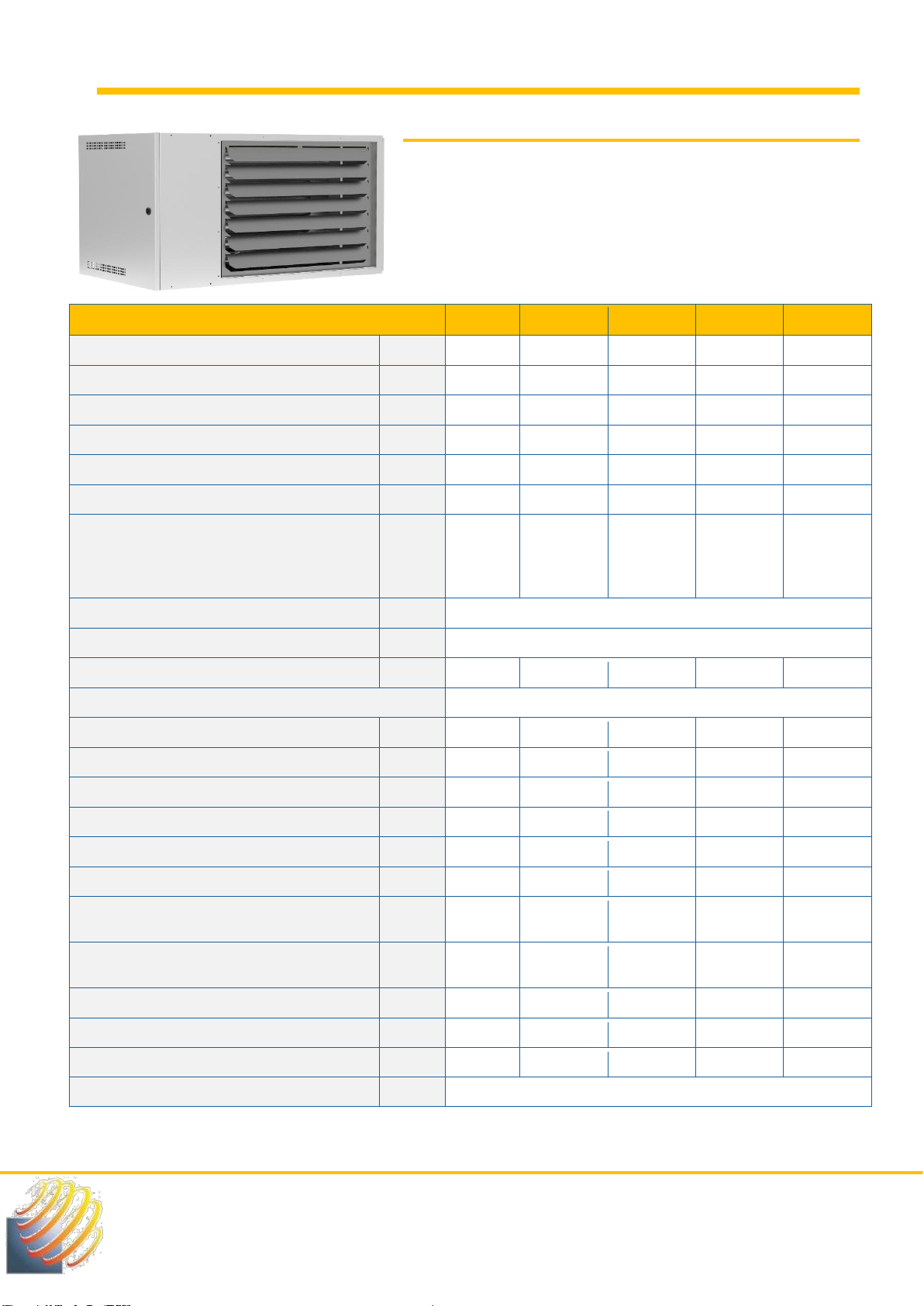

4.1. MH ECO3 Model......................................................................................................................................... 9

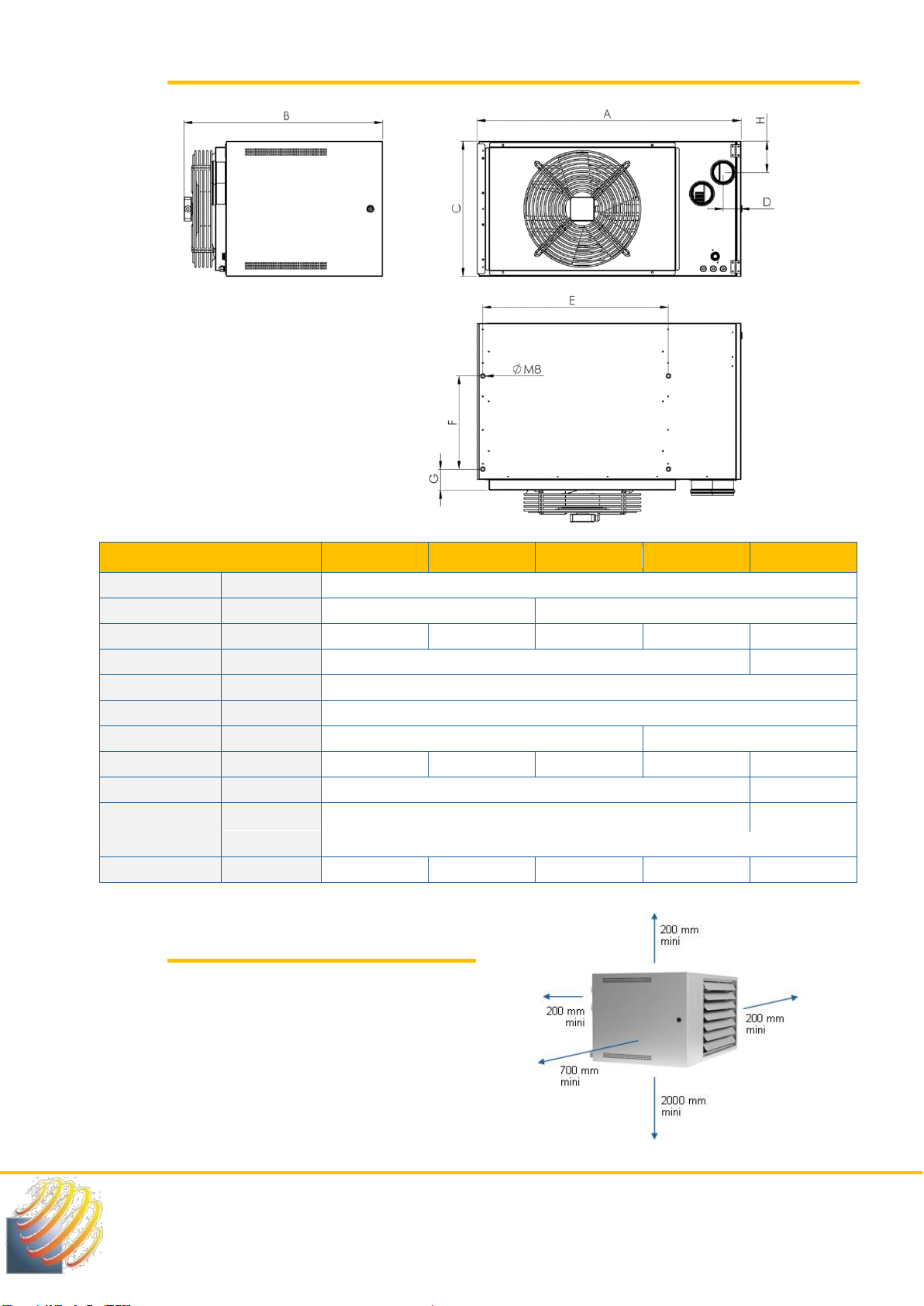

4.1.1. MH ECO3 Dimensions.............................................................................................................................................10

4.1.2. Installation recommendations for MH ECO3.............................................................................................................10

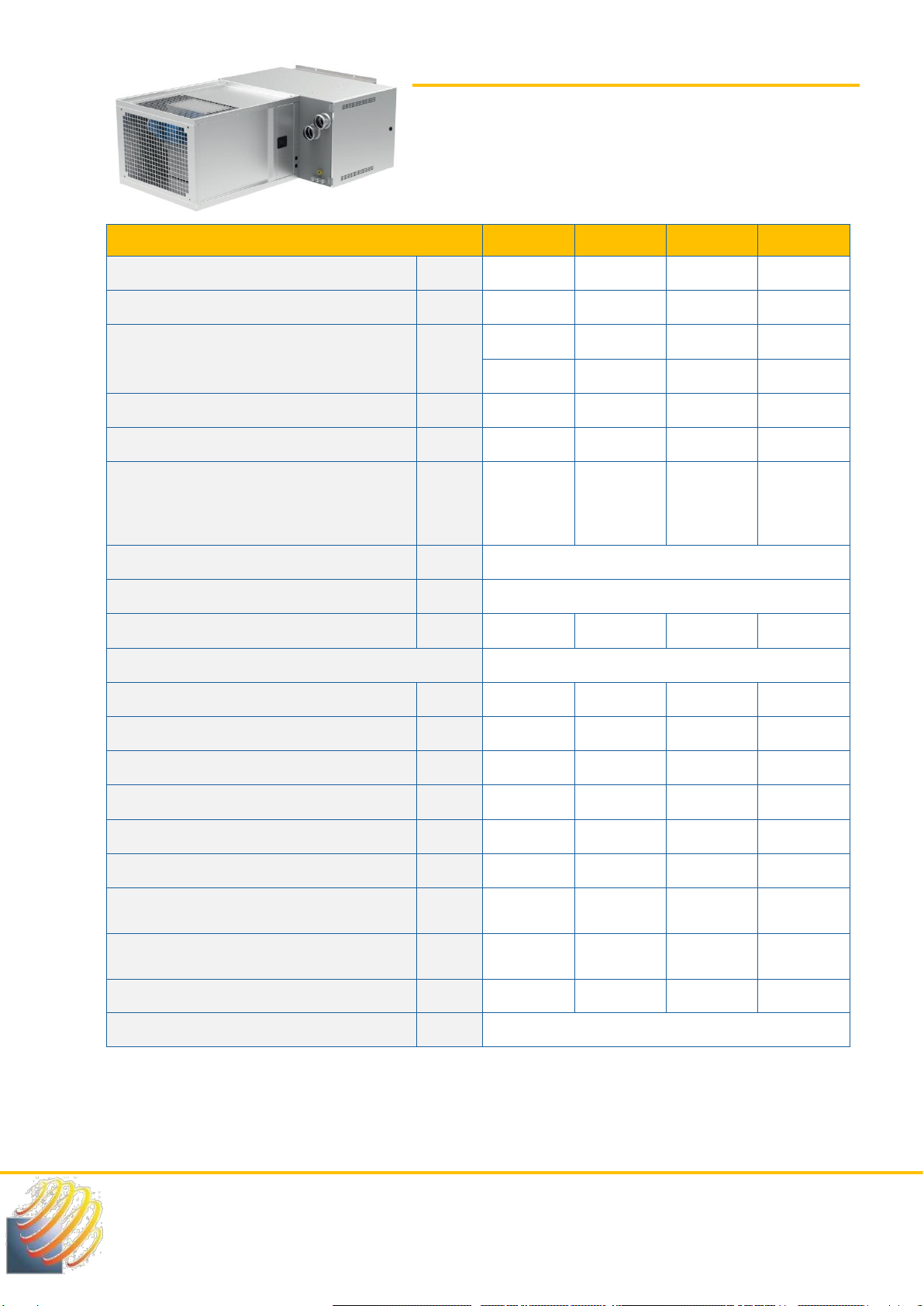

4.2. MV ECO3 Model ........................................................................................................................................11

4.2.1. MV ECO3 Dimensions .............................................................................................................................................12

4.2.2. Installation recommendations for MV ECO3.............................................................................................................12

4.3. MC ECO3 Model........................................................................................................................................13

4.3.1. Pressure / Air flow ratio for MC ECO 3.....................................................................................................................14

4.3.2. MC ECO3 Dimensions.............................................................................................................................................16

4.3.3. Variable Speed Driver..............................................................................................................................................17

5. Fixing the devices ...........................................................................................................19

5.1. Summary of existing supports ................................................................................................................19

5.1.1. Rotating wall bracket................................................................................................................................................19

5.1.2. Fixed wall bracket ....................................................................................................................................................19

5.1.3. Suspension bracket..................................................................................................................................................19

5.2. SMR rotating wall bracket........................................................................................................................20

5.2.1. SMR dimensions......................................................................................................................................................20

5.2.2. SMR furniture...........................................................................................................................................................20

5.3. SMF fixed wall bracket .............................................................................................................................21

5.3.1. SMF dimensions ......................................................................................................................................................21

5.3.2. SMF furniture...........................................................................................................................................................21

5.4. IPN fixing kit..............................................................................................................................................22

5.5. SDS suspension support .........................................................................................................................22

6. Electrical Wiring ..............................................................................................................23

6.1. Internal wiring diagram of ECO 3 heaters...............................................................................................23

6.2. Electrical connection between internal components ............................................................................24

6.3. Pilot wire principle....................................................................................................................................25

6.3.1. Pilot wire principle diagram ......................................................................................................................................25

6.4. Connection of standard controllers........................................................................................................26

6.4.1. TM1 EVO simple Thermostat...................................................................................................................................26

6.4.2. TM2 EVO V2 Touchscreen multi setting thermostat.................................................................................................27

7. Connections flue pipes...................................................................................................28

7.1. General information..................................................................................................................................28

7.2. Summary of existing flue kits..................................................................................................................28