Solartron Mobrey 7828 User manual

Precision measurement solutions

7828

Density Transmitter

TECHNICAL MANUAL

78285000

Copyright © 2001

Solartron Mobrey Ltd.

All Rights Reserved

Solartron-Mobrey pursues a policy of continuous development and product improvement. The

specification in this document may therefore be changed without notice.

To the best of our knowledge, the information contained in this document is accurate and Solartron-

Mobrey cannot be held responsible for any errors, omissions or other misinformation contained herein.

No part of this document may be photocopied or reproduced without the prior written consent of

Solartron-Mobrey.

7828 Density Transmitter Technical Manual

78285000_AB iii

IMPORTANT

HANDLE THE 7828 WITH CARE

DO NOT drop the transmitter.

DO NOT use liquids incompatible with materials of

construction.

DO NOT operate the 7828 above its rated pressure.

DO NOT pressure test beyond the specified Test pressure.

ENSURE all explosion proof requirements are applied

ENSURE transmitter and associated pipework are pressure

tested to 1½ times the maximum operating pressure

after installation.

ALWAYS store and transport the 7828 in its original

packaging.

7828 Density Transmitter Technical Manual

iv 78285000_AB

7828 Density Transmitter Technical Manual Contents

78285000_AB v

Contents

SECTION 1 - INTRODUCTION

1.1 ABOUT THE 7828 DENSITY TRANSMITTER.................................... 1-1

1.1.1 What is it?..........................................................................................1-1

1.1.2 7828 measurements..........................................................................1-2

1.1.3 What is it used for?............................................................................1-2

1.1.4 Typical 7828 application....................................................................1-3

1.2 7828 OPTIONS...................................................................................1-4

SECTION 2 - MECHANICAL INSTALLATION

2.1 INTRODUCTION................................................................................2-1

2.2 BOUNDARY AND VISCOSITY EFFECTS.......................................... 2-3

2.2.1 Boundary effects................................................................................2-3

2.2.2 Viscosity effects.................................................................................2-6

2.3 STANDARD INSTALLATIONS...........................................................2-7

2.3.1 7828 orientation.................................................................................2-8

2.3.2 Free stream installation - flanged fitting.............................................2-9

2.3.3 Free stream installation - weldolet...................................................2-10

2.3.4 T-piece installation...........................................................................2-11

2.3.5 T-piece weldolet installation.............................................................2-12

2.3.6 Flow-through chamber installation...................................................2-13

2.4 INSTALLATION INTHE PIPELINE OR SYSTEM............................ 2-14

2.4.1 Fluid at the sensor...........................................................................2-14

2.4.2 Thermal effects................................................................................2-14

2.4.3 Flow rate..........................................................................................2-15

2.4.4 Entrained gas...................................................................................2-15

2.4.5 Solids contamination........................................................................2-15

2.4.6 Example installation.........................................................................2-15

2.5 COMMISSIONING............................................................................ 2-16

7828 Density Transmitter Technical Manual

vi 78285000_AB

SECTION 3 - ELECTRICAL INSTALLATION

3.1 INTRODUCTION.................................................................................3-1

3.2 INSTALLATION CONSIDERATIONS.................................................3-2

3.2.1 Power supply .....................................................................................3-2

3.2.2 EMC...................................................................................................3-2

3.2.3 Ground connections...........................................................................3-2

3.2.4 Cabling...............................................................................................3-2

3.2.5 Surge protection.................................................................................3-3

3.3 WIRING THE 7828..............................................................................3-4

3.3.1 Wiring Procedure...............................................................................3-5

3.4 CONNECTIONS..................................................................................3-7

3.4.1 Power.................................................................................................3-7

3.4.2 RS485................................................................................................3-7

3.4.3 RS485 to RS232................................................................................3-8

3.4.4 RS485 Multidrop..............................................................................3-11

3.4.5 Transmission mode .........................................................................3-11

3.4.6 Analog 4-20mA output.....................................................................3-11

3.5 INSTALLATION INEXPLOSIVE AREAS..........................................3-12

SECTION 4 - USING ADVIEW

4.1 WHAT IS ADVIEW?............................................................................4-1

4.2 INSTALLING ADVIEW........................................................................4-1

4.3 STARTING ADVIEW...........................................................................4-2

4.3.1 Setting up serial communications......................................................4-2

4.4 USING ADVIEW..................................................................................4-5

4.4.1 ADView facilities................................................................................4-5

4.4.2 Menu bar............................................................................................4-6

4.4.3 Configuring a slave address..............................................................4-6

4.4.4 Board configuration............................................................................4-7

4.4.5 Data logging.....................................................................................4-10

4.4.6 Register Dump/load.........................................................................4-11

4.4.7 Register Read/write.........................................................................4-12

7828 Density Transmitter Technical Manual Contents

78285000_AB vii

SECTION 5 - CALIBRATION CHECK

5.1 CALIBRATION................................................................................... 5-1

5.1.1 Factory calibration .............................................................................5-1

5.1.2 Calibration of transfer standards .......................................................5-1

5.1.3 Instrument calibration ........................................................................5-1

5.1.4 General density equation...................................................................5-2

5.2 SAMPLE CALIBRATION CERTIFICATE............................................ 5-3

5.3 USER CALIBRATIONCHECKS.........................................................5-4

5.3.1 Ambient air calibration check.............................................................5-4

5.3.2 On-line calibration adjustment...........................................................5-4

SECTION 6 - MAINTENANCE

6.1 GENERAL..........................................................................................6-1

6.2 GENERAL MAINTENANCE ...............................................................6-2

6.2.1 Physical checks.................................................................................6-2

6.2.2 Electrical checks................................................................................6-2

6.2.3 Calibration check...............................................................................6-2

6.3 FAULT ANALYSIS AND REMEDIAL ACTION...................................6-3

6.3.1 Mechanical servicing .........................................................................6-3

6.3.2 Time Period Trap...............................................................................6-3

APPENDIX A - SPECIFICATION

A.1 GENERAL..........................................................................................A-1

A.2 SPECIFICATION................................................................................A-1

A.2.1 Sensor performance..........................................................................A-1

A.2.2 Environmental....................................................................................A-2

A.2.3 Transmitter power supply ..................................................................A-2

A.2.4 Analog output.....................................................................................A-2

A.2.5 RS485 Interface.................................................................................A-3

A.2.6 Approvals...........................................................................................A-3

A.3 FACTORY DEFAULTCONFIGURATION ..........................................A-4

7828 Density Transmitter Technical Manual

viii 78285000_AB

APPENDIX B - CALCULATED PARAMETERS

B.1 INTRODUCTION................................................................................B-1

B.2 BASE DENSITY REFERRAL.............................................................B-2

B.2.1 Matrix density referral....................................................................... B-2

B.2.2 API density referral........................................................................... B-3

B.3 CALCULATED PARAMETERS..........................................................B-6

B.3.1 Specific Gravity................................................................................. B-6

B.3.2 Degrees Baumé................................................................................ B-6

B.3.3 Degrees Brix..................................................................................... B-6

B.3.4 Quadratic Equation........................................................................... B-6

B.3.5 % Mass............................................................................................. B-7

B.3.6 % Volume ......................................................................................... B-7

B.3.7 API degrees...................................................................................... B-7

APPENDIX C - SAFETY CERTIFICATION

C.1 INTRODUCTION................................................................................C-1

APPENDIX D - MODBUS COMMUNICATIONS

D.1 INTRODUCTION................................................................................D-1

D.2 ACCESSING MODBUS REGISTERS................................................D-2

D.2.1 Establishing Modbus Communications.............................................D-2

D.3 MODBUS IMPLEMENTATION...........................................................D-3

D.3.1 Register size and content.................................................................D-3

D.4 MODBUS REGISTER ASSIGNMENTS .............................................D-4

D.5 INDEX CODES...................................................................................D-7

D.5.1 API product type...............................................................................D-7

D.5.2 Pressure, temperature, density and other units................................D-7

D.5.3 Special function.................................................................................D-8

D.5.4 Special function quadratic equation name........................................D-8

D.5.5 Special function quadratic equation units.........................................D-9

D.5.6 Output averaging time ......................................................................D-9

D.5.7 Analog output selection.....................................................................D-9

D.5.8 Referral temperature.......................................................................D-10

D.5.9 Alarm coverage............................................................................... D-10

D.5.10 Alarm hysteresis.............................................................................D-10

D.5.11 Software version.............................................................................D-10

D.5.12 Hardware type.................................................................................D-11

7828 Density Transmitter Technical Manual Contents

78285000_AB ix

D.5.13 User selected alarm variable.......................................................... D-11

D.5.14 Unit type.......................................................................................... D-11

D.5.15 Status Register flags....................................................................... D-12

D.6 ESTABLISHING MODBUS COMMUNICATIONS ............................D-13

D.7 EXAMPLE OF DIRECT MODBUS ACCESS....................................D-15

D.7.1 Example 1: Reading line density (16-bit register size).................... D-15

D.7.2 Example 2: Reading line density (32-bit register size).................... D-16

APPENDIX E - REFERENCE DATA

E.1 CONVERSION TABLES.....................................................................E-1

E.1.1 Length units.......................................................................................E-1

E.1.2 Mass units..........................................................................................E-1

E.1.3 Mass flow units..................................................................................E-1

E.1.4 Volume flow units...............................................................................E-2

E.1.5 Volume/capacity units........................................................................E-2

E.1.6 Temperature units .............................................................................E-2

E.1.7 Pressure units....................................................................................E-2

E.1.8 Density units......................................................................................E-3

E.1.9 Dynamic viscosity units......................................................................E-3

E.1.10 Kinematic viscosity units....................................................................E-3

E.2 PRODUCT DATA...............................................................................E-4

E.2.1 Density/temperature relationship of hydrocarbon products...............E-4

E.2.2 Platinum resistance law (to DIN 43 760)...........................................E-6

E.2.3 Density of ambient air (in kg/m3)........................................................E-6

E.2.4 Density of water (in kg/m3to ITS-90 temperature scale)...................E-6

APPENDIX F - COSSH FORM

7828 Density Transmitter Technical Manual

x78285000_AB

78285000_AB 1-1

1

Introduction

1.1 ABOUT THE 7828 DENSITY TRANSMITTER

1.1.1 WHAT IS IT?

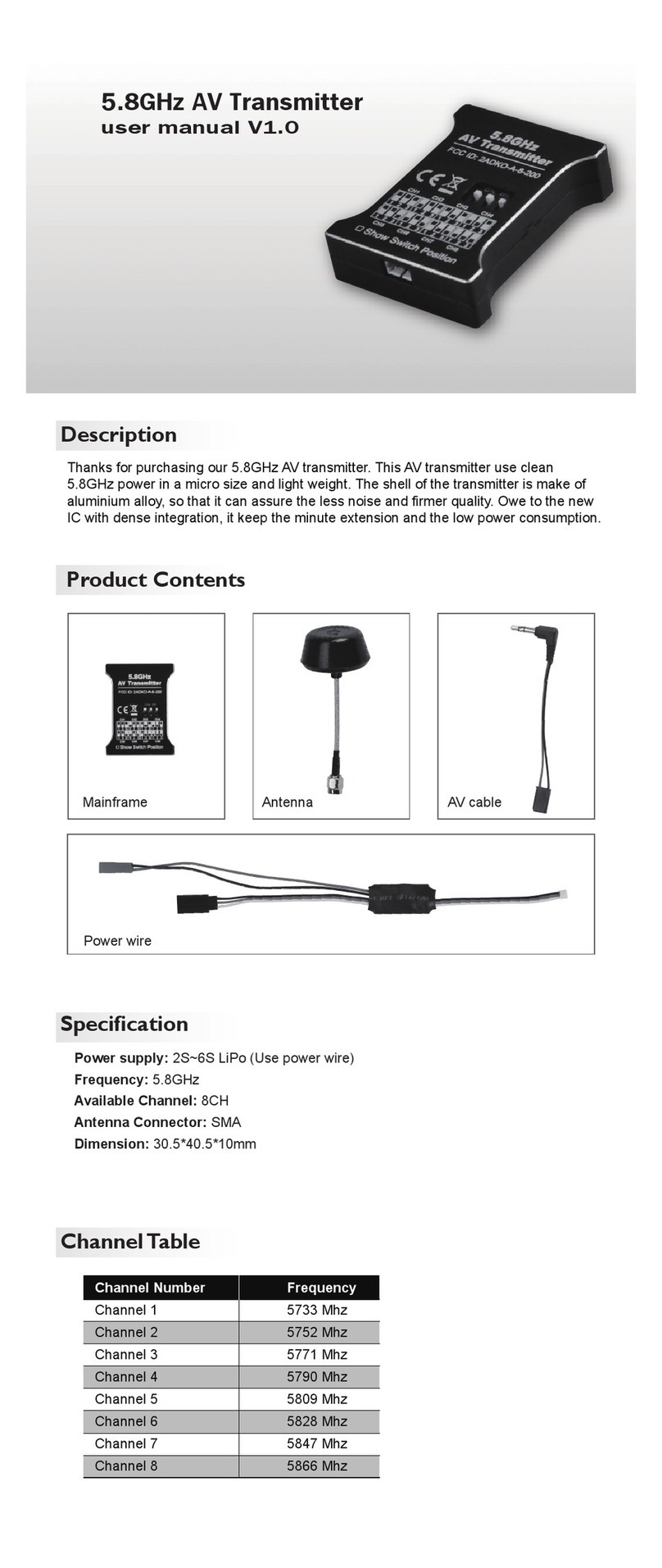

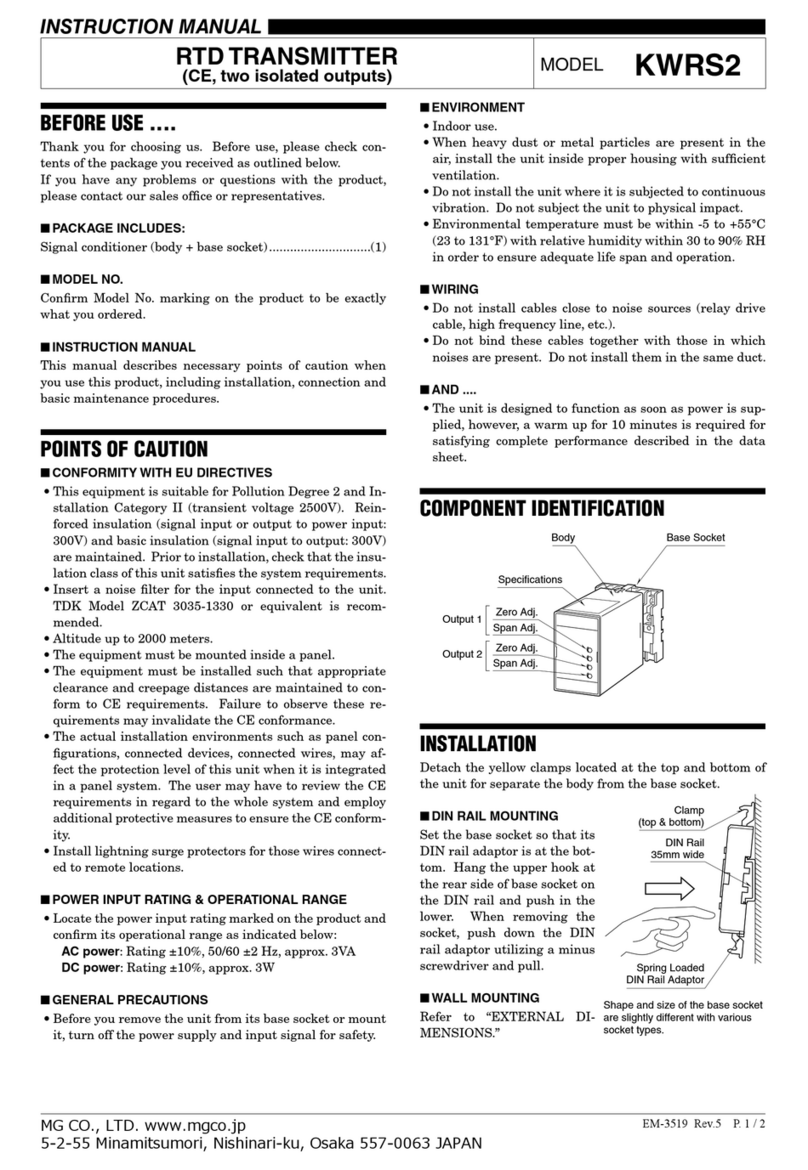

The 7828 Density Transmitter is based on Solartron's proven tuning fork technology. It is

an all-welded sensor designed to be mounted directly in-line or into a tank. Density is

determined directly from the resonant frequency of the tuning fork immersed in the fluid,

and a temperature sensor (PRT) is also fitted within the transmitter.

The transmitter contains integral processing electronics to provide full ‘on node’

configuration, enabling it to perform a variety of calculations. Two outputs are available:

1. A direct 4-20mA output giving an output proportional to a user selected process

parameter or calculation result, with configurable span, bias, limits and filter

options:

•=line density

•=line temperature

•=°API

•=S.G.

•=base density (API)

•=base density (Solartron matrix method)

•=special calculation result.

2. An RS485(Modbus) interface, giving access to other measurement results,

system information and configuration parameters.

No signal converter is required, which simplifies wiring and enables the 7828 to be

connected directly to a plant monitoring and control systems and/or a local indicator.

The 7828 is factory set to perform either API or Matrix referrals. Re-configuration of the

7828’s default settings (see Appendix A) is achieved by linking a PC to theModbus

(RS485) connection and running Solartron's ADView software. Once configured, the PC

can be removed.

Introduction 7828 Density Transmitter Technical Manual

1-2 78285000_AB

1.1.2 7828 MEASUREMENTS

The 7828 measures the following fluid properties:

•=Line Density (Measured in kg/m3, g/cc, lb/gal, or lb/ft3)

•=Temperature (Measured in °C or °F)

From these properties, the following are calculated:

•=API base density at 15°C, 1.013bar; or at 60°F, 14.5psi

•=Base density by the Solartron matrix referral method

•=°API

•=S.G.

•=Special function calculations such as °Brix, °Baume, °Twaddle, % solids, etc.

1.1.3 WHAT IS IT USED FOR?

The 7828 Transmitter is ideally suited to applications where continuous real time

measurement of density is required, for example in process control where density is the

primary control parameter for the end product, or is an indicator of some other quality

control parameter such as % solids or % concentration.

Some examples are:

•=Blending

•=Mixing

•=Evaporator control

•=End point detection in batch reactions

•=Interface detection in continuous separators

•=Interface detection in multi-product pipelines

Typical industries include:

•=Oil and petrochemical

•=Brewing

•=Food

•=Pharmaceutical

•=Minerals processing (clays, carbonates, silicates, etc.

7828 Density Transmitter Technical Manual Introduction

78285000_AB 1-3

1.1.4 TYPICAL 7828 APPLICATION

Net Mass flowrate calculation

Magnetic

Flow

Meter

Volume

Flow Rate

7828

Density

Transmitter

% Solids

Net

Mass

calc.

RS485 Solartron’s

ADView

WindowsTM Tool

This shows and outline of a typical wet process mineral application where 7828 provides a

4-20mA signal of the %solids determination from the slurry stream. From this signal and

the measured volumetric flowrate, net mass flowrate is determined.

The output signal could also be used for %solids control or for net mass flow rate ratio

blend control.

The optional RS485/Modbus connection to a PC running ADView can be used for

configuration and access to other measured values.

Introduction 7828 Density Transmitter Technical Manual

1-4 78285000_AB

1.2 7828 OPTIONS

A number of options are available for the 7828. They are identified by suffixes appended

to the transmitter type number. The table below summarises these. Some of the suffixes

are allocated to future developments and the letter code is currently fixed.

Part number 7828 * * A * A * L * B * *

Wetted parts: materials and finish

Stem + connections Tines Finish

316 Stainless Steel 316 Stainless Steel Standard A

316 Stainless Steel 316 Stainless Steel Electro-polished C

316 Stainless Steel 316 Stainless Steel PTFE laminated F

Hastelloy C22 Hastelloy C22 Standard E

Hastelloy C22 Hastelloy C22 Electro-polished D

Hastelloy C22 Hastelloy C22 PTFE laminated G

Monel 400 Monel 400 Standard H

Monel 400 Monel 400 Electro-polished J

Monel 400 Monel 400 PTFE laminated L

Special Special Special S

Sensor electronics

Standalone (on-node): 4-20mA BASEEFA EEx d IIC T4 C

Process connections

2" ANSI 150RF A

2" ANSI 300RF B

2" ANSI 600RF C

2" ANSI 900RF D

2" ANSI 1200RF E

2" ANSI 1500RF F

50mm DIN 2527 RF DN50/PN40 G

50mm DIN 2527 RF DN50/PN100 H

2" Ladish Triclamp (Hygienic) J

3" Ladish Triclamp (Hygienic) K

2" IDF (Hygienic) L

3" IDF (Hygienic) M

40mm Cone seat compression fitting N

Special S

Factory Configuration

Line density A

API Base density B

Matrix base density C

Factory Calibration type

Free stream A

2" boundary (Sch 40) B

3" boundary (Sch 40) C

Special S

Traceability

None A

Certificate of materials traceability X

Manufacturing status Factory determined

78285000_AB 2-1

2

Mechanical Installation

2.1 INTRODUCTION

There are a variety of external factors which affect the ability of the 7828 to operate

successfully. In order to ensure that your system works correctly, the effects of these

factors must be taken into consideration when designing your installation.

There are two main aspects to consider:

1. The accuracy and repeatability of the measurements;

2. The relevance of the measurements to the overall purpose of the system.

Factors which may adversely affect accuracy and repeatability include:

•=The presence of gas or bubbles within the fluid being measured

•=Non-uniformity of the fluid

•=The presence of solids as contaminants

•=Fouling of the transducer

•=Temperature gradients

•=Cavitation and swirls caused by valves or discontinuities in thepipework

•=Operating at temperatures below the wax point of crude oils

•=The measured fluid being unrepresentative of the main flow.

In some applications, absolute accuracy is less important than repeatability. For example,

in a system where the control parameters are initially adjusted for optimum performance,

and thereafter only checked periodically.

The term achievable accuracy can be used to describe a measure of the product quality

that can be realistically obtained from a process system. It is a function of measurement

accuracy, stability and system response. High accuracy alone is no guarantee of good

product quality if the response time of the system is measured in tens of minutes, or if the

measurement bears little relevance to the operation of the system. Similarly, systems

which require constant calibration and maintenance cannot achieve good achievable

accuracy.

Factors which may adversely affect the relevance of the measurements could include:

•=Measurement used for control purposes being made too far away from the point of

control, so that the system cannot respond properly to changes;

•=Measurements made on fluid which is unrepresentative of the main flow.

Mechanical Installation 7828 Density Transmitter Technical Manual

2-2 78285000_AB

This chapter has the following sections:

Section 2.2 - The importance of boundary and viscosity effects

Section 2.3 - Mechanical details for mounting and installing 7828

Section 2.4 - Optimising measurement accuracy and repeatability

Section 2.5 - Commissioning the system

7828 Density Transmitter Technical Manual Mechanical Installation

78285000_AB 2-3

2.2 BOUNDARY AND VISCOSITY EFFECTS

Unlike Solartron’s tube density sensors, the tines of the 7828 are not totally enclosed. The

walls of the pipe or tank in which the transmitter is installed will introduce boundaries to

the fluid flow, and this will have an effect on the calibration of the sensor. To overcome

this, Solartron calibrate the 7828 under a variety of pre-defined conditions corresponding

to the installation and pipe schedule. This condition is selected when ordering the 7828,

so that, by calibrating the sensor under the same boundary conditions as the installation,

the need for additional on site calibration is eliminated.

2.2.1 BOUNDARY EFFECTS

Any insertion device or transducer can only measure the properties of the fluid within the

region of fluid to which it is sensitive.

For practical reasons it is helpful to consider the sensitive or effective region for the

transmitter as an three-dimensional ellipse centred on the tips of the tines with its long

axis aligned with the direction in which the tines vibrate, as shown below. The 7828 is

insensitive to the properties of the fluid outside this region.

long axis

short

axis

If part of this volume is taken up by the pipework or fittings there is said to be a boundary

effect; i.e. the intrusion of the pipe walls will alter the calibration.

The diagram below illustrates the 7828 installed in a pocket on the side of a 4” (100mm)

horizontal pipe line (viewed from above). The effective region is completely enclosed

within the pipe line and thus is completely fluid.

Mechanical Installation 7828 Density Transmitter Technical Manual

2-4 78285000_AB

Top or Plan view

4” horizontal pipe

2”Schedule 40

Pocket or “T”

This next view shows other pipe outlines superimposed:

Top or Plan view

4” (100mm)

vertical pipe 6”(150mm)

vertical pipe

2”Schedule 40

Pocket or “T”

The smaller circle represents a 4” vertical pipe, which intersects the effective region. The

6” (150mm) pipe is the smallest pipe diameter to completely enclose the effective region

when the pipe is vertical. Thus smaller pipe diameters can lead to a variety of different

geometries which would each require a separate calibration.

An alternative condition is shown in the next diagram where the side pocket is extended

until it passes completely through the effective region producing a “core”:

7828 Density Transmitter Technical Manual Mechanical Installation

78285000_AB 2-5

Top or Plan view

2”Schedule 40

Pocket or “T”

From this, it would appear that almost every installation requires a separate in situ

calibration - a very undesirable situation. The problem is resolved by providing standard

calibration geometries which can be used in all pipe work configurations and thereby allow

the factory calibration conditions to be reproduced in the process. These standard

geometries are described in section 2.3.

Mechanical Installation 7828 Density Transmitter Technical Manual

2-6 78285000_AB

2.2.2 VISCOSITY EFFECTS

The 7828 can be affected by the viscosity of the fluid surrounding it. This is manifested in

two ways:

1. An error in the density measurement, due to the effect of viscosity on the vibration of

the fork tines;

2. In T-piece installations, where the 7828 is retracted into a pocket away from the main

fluid flow, high viscosity impedes the flushing of fluid near the tines. This may mean

that, if a step change in density occurs, the fluid being measured will not representative

of the fluid in the main flow, and the density response time may be extended

significantly.

A summary of these effects and the action to be taken to minimise them is given below:

Viscosity range Remedy

T-piece installations only:

Less than 100cP:

Greater than 100cP:1

None required

Density measurements may be unpredictable; use

flow-through chamber or free stream installation

All other installations:

Up to 500cP None required

500 to 20,000cP steady: Perform simple on-site calibration to derive density

offset adjustment (see Calibration section)

500 to 20,000cP variable:

- where changes in density

and viscosity are correlated:

- where there is little or no

correlation between viscosity

and density:

Perform three-point on-site calibration to derive

revised K0, K1 and K2 factors - consult Solartron

Consult Solartron for advice.

Above 20,000cP Density measurements may be unpredictable

1Where the main flow is greater than 1.5m/s and there is no waxing present, the T-piece

installation can be used for viscosities not exceeding 250cP.

Table of contents

Popular Transmitter manuals by other brands

FlowLine

FlowLine EchoPod UG06 Series manual

Mueller Systems

Mueller Systems Mueller Cellular Node installation manual

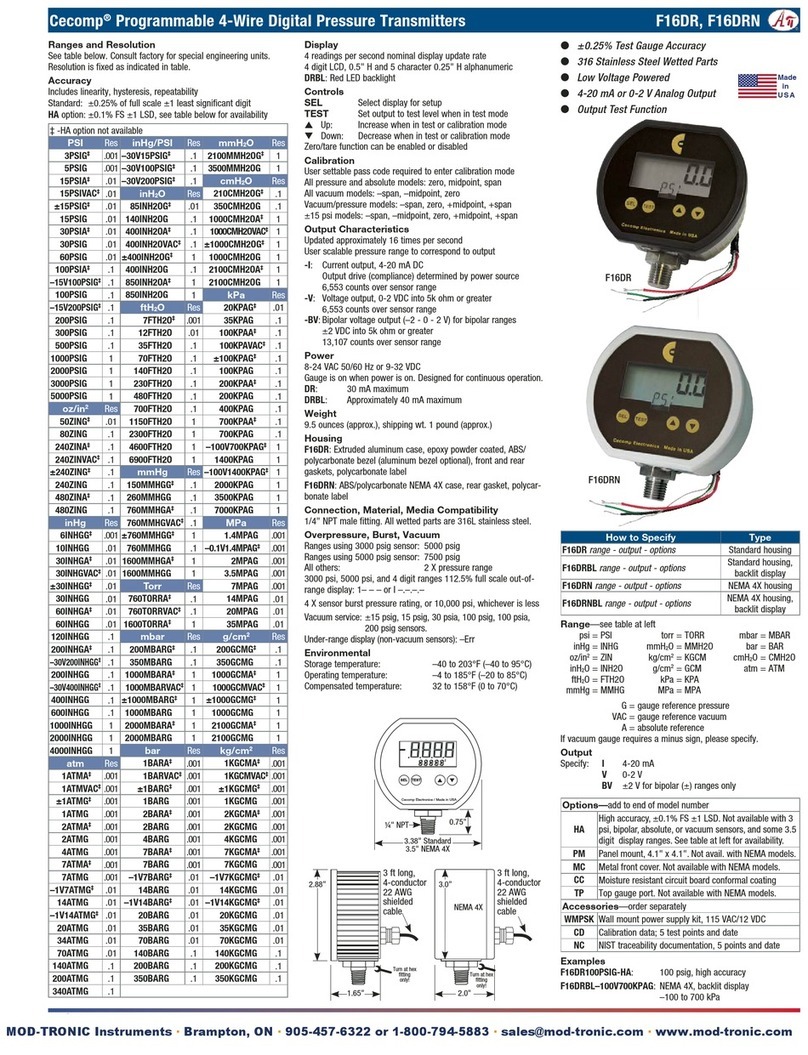

Mod-tronic

Mod-tronic Cecomp F16DR manual

GRAUPNER

GRAUPNER mz-10c manual

HOLATRON SYSTEMS

HOLATRON SYSTEMS SPREAD SPECTRUM 12V Operation & maintenance guide

Meister

Meister MONITOR operating instructions