To select NOZTR, press and release the button. The lower

display will indicate NOZTR.

Press and release the SEL button to move on to the next

parameter.

Analog Output Range Lower Limit Adjust

The upper display will indicate the pressure value correspond-

ing to the minimum retransmission output, either 4 mA, 0 VDC,

or –2 VDC depending on the particular gauge model. The lower

display will display RNGLO.

Use the and buttons to adjust the display to the desired

value.

Press and release the SEL button to move on to the next

parameter.

Analog Output Range Upper Limit Adjust

The upper display will indicate the pressure value correspond-

ing to the maximum retransmission output, either 4 mA or

+2 VDC depending on the particular gauge model. The lower

display will display RNGHI.

Use the and buttons to adjust the display to the desired

value.

Press and release the SEL button to move to the next parameter.

Output Test Adjust Mode Pass Code Protection

The upper display section will be blank, and the lower section

will display either TSTPC or NOTPC.

To enable Output Test Adjust Mode pass code protection,

press and release the button. The lower display will indicate

TSTPC.

To disable Output Test Adjust Mode pass code protection,

press and release the button. The lower display will indicate

NOTPC.

Press and release the SEL button to save the configuration

parameters and restart the unit. Note: The configuration

parameters will not be saved if the procedure is interrupted

before completion.

The gauge is calibrated at the factory using equipment trace-

able to NIST. There is no need to calibrate the gauge before

putting it in service. Calibration should only be performed by

qualified individuals using appropriate calibration standards

and procedures.

The calibration equipment should be at least four times more

accurate than the gauge being calibrated. The calibration sys-

tem must be able to generate and measure pressure/vacuum

over the full range of the gauge. A vacuum pump able to

produce a vacuum of 100 microns (0.1 torr or 100 millitorr) or

lower is required for vacuum and absolute gauges.

Use an accurate volt or mA meter for calibration of the retrans-

mission output.

Allow the gauge to equalize to normal room temperature (about

20 minutes minimum) before calibration.

To enter the calibration mode from the normal operating mode

with applied pressure being displayed, press and hold the TEST

and the buttons. Then press the SEL button. Release all but-

tons when the display indicates CAL.

When the gauge enters the calibration mode, the display ini-

tially indicates _ _ _ _ with the first underscore blinking, and

with CALPC on the lower display.

Enter the pass code as described in the Pass Code Entry

section.

Upon successful calibration pass code entry, the upper display

will indicate the applied pressure in the configured engineer-

ing units.

The lower display of the display will alternate between CAL and

the calibration region corresponding to the applied pressure

(ZERO, +MID, +SPAN, MID, or SPAN).

Note: To store the calibration parameters and exit calibration

mode at any time, press and hold the SEL button until the

display indicates – – – – .

Calibration of the Retransmission Output

Calibration of the retransmission output coordinates the

retransmission output to the display indication, and is per-

formed independently of applied pressure. It requires a direct

physical measurement of the retransmission output with an

accurate mA or Volt meter.

Retransmission Output Low Value

Press and release the SEL button to step to the retransmission

output low value calibration sequence, indicated by LCAL on

the display.

Note: If the SEL button is held depressed for longer than 2 sec-

onds, the display will change to indicate – – – –, and the gauge

will exit the calibration mode when all buttons are released.

The upper display will indicate the pre-configured pressure

corresponding to the retransmission output low value.

The lower display will alternate between CAL and 4 mA, 0 VDC,

or –2 VDC depending on retransmission option.

Use the and buttons to adjust the actual retransmission

output to its low value.

Retransmission Output High Value

Press and release the SEL button to step to the retransmission

output high value calibration sequence, indicated by HCAL on

the display.

Note: If the SEL button is held depressed for longer than 2 sec-

onds, the display will change to indicate – – – –, and the gauge

will exit the calibration mode when all buttons are released.

The upper display will indicate the pre-configured pressure

corresponding to the retransmission output high value.

The lower display will alternate between CAL and 20 mA or +2

VDC depending on retransmission option.

Use the and buttons to adjust the actual loop current to

its high value.

Press the SEL button briefly to proceed to pressure calibration

or hold the SEL button for 2 seconds to save and exit.

The pressure calibration procedure adjusts the display indica-

tion, and the retransmission output to correspond to the actual

applied pressure.

If the applied pressure is not being displayed, press and release

the SEL button to step to the pressure calibration sequence,

indicated by CAL on the display.

Note: If the SEL button is held depressed for longer than 2

seconds, the display will change to indicate – – – – , and

the gauge will exit the calibration mode when all buttons are

released.

Zero Calibration

Apply zero pressure.

The lower display will alternate between CAL and ZERO.

Use the and buttons to adjust the upper display to

indicate zero.

Span Calibration

Apply full-scale pressure.

The lower display will alternate between CAL and +SPAN.

Use the and buttons to adjust the upper display to indi-

cate the applied pressure value.

Midpoint Non-Linearity Calibration

Apply 50% full-scale positive pressure.

The lower display will alternate between CAL and +MID.

Use the and buttons to adjust the upper display to indi-

cate the applied pressure value.

Negative Span Calibration (bipolar and compound ranges

only)

Apply full-scale negative pressure.

The lower display will alternate between CAL and SPAN.

Use the and buttons to adjust the upper display to indi-

cate the applied pressure value.

Continued on next page.....

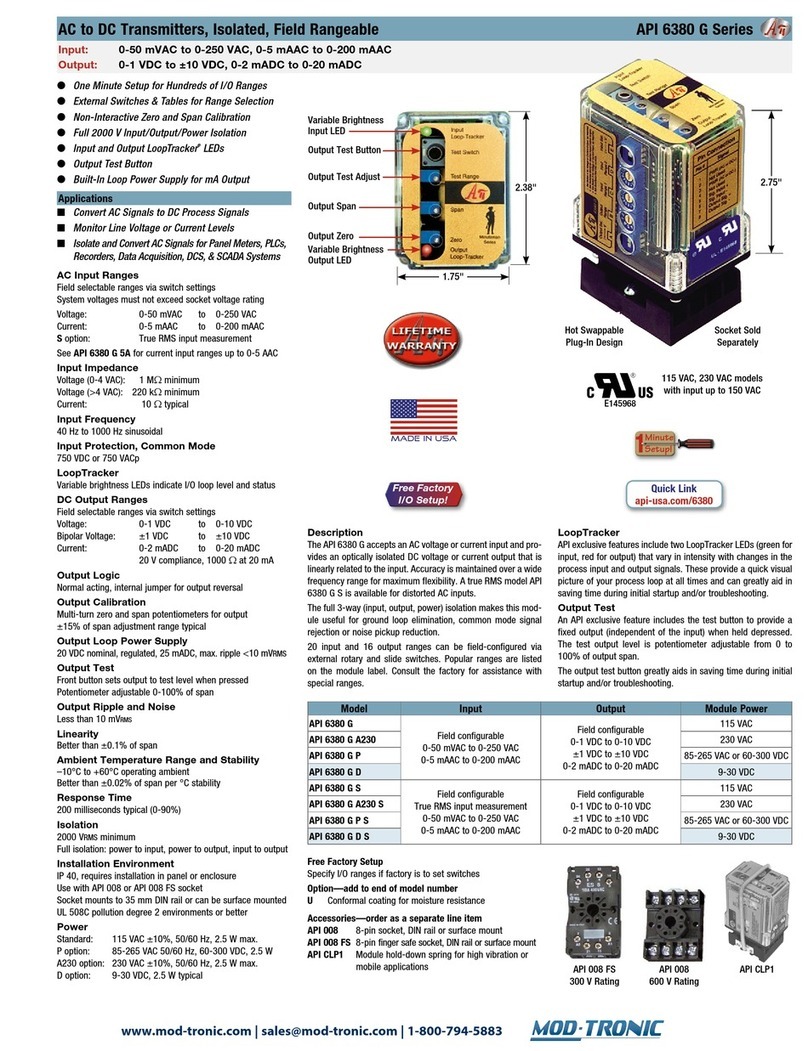

Output Calibration

Calibration Pass Code

A pass code is required to calibrate and configure the gauge.

Additional levels of security may be enabled by defining

separate pass codes for calibration, user configuration, and

output test.

See Changing the User-Defined Pass Code at the end of this

manual to change pass codes.

Functions in user configuration mode

Restore original factory configuration

Enable/disable zero tare function

Retransmission output upper and lower limits

Enable/disable a pass code for output test

When the gauge enters a mode requiring a pass code, the

display indicates _ _ _ _ with the first underscore blinking,

and either TSTPC, CFGPC, CALPC on the lower display. All

three pass codes are initially set to the factory default of 3510.

Note: During pass code entry the gauge will not respond to

changes in applied pressure. The gauge will automatically

revert to the normal operation if no buttons are operated for

approximately 15 seconds.

Use the and buttons to set the left-most digit to 3.

Press and release the SEL button to index to the next position.

The 3 will remain, and the second position will be blinking.

Use the and buttons to select 5.

Press and release the SEL button to index to the next position. 3

5 will remain, and the third position will be blinking.

Use the and buttons to select 1.

Press and release the SEL button to index to the next position. 3

5 1 will remain, and the fourth position will be blinking.

Use the and buttons to select 0.

Press and release the SEL button to proceed.

If an incorrect pass code was entered, the gauge will to exit to

the normal operating mode.

Upon successful pass code entry, follow the steps in the appro-

priate section of this manual.

Note: To exit a mode at any time, press and hold the SEL button

until the display indicates – – – – .

From the normal operating mode, press and hold the TEST and

the buttons.

Then press the SEL button.

Release all buttons when the display indicates CFG.

Before the gauge enters the Configuration mode, the display

initially indicates _ _ _ _ with the first underscore blinking,

and with CFGPC on the lower display.

Enter the pass code as described in the Pass Code Entry section.

Restore Factory Configuration

The upper display will be blank, and the lower display will

display either USER_ or FCTRY.

If USER_ is selected, the existing user configuration will be

retained and will be accessible for modification in the following

steps. To select USER_, press and release the button. The

lower display will indicate USER_.

If FCTRY is selected, the existing user configuration will be

replaced by the configuration as it left the factory and will be

accessible for modification in the following steps. To select

FCTRY, press and release the button. The lower display will

indicate FCTRY.

Press and release the SEL button to move on to the next

parameter.

Zero Tare Configuration

The upper display will be blank, and the lower display will

indicate either ZTARE or NOZTR.

If ZTARE is selected, the user will be able to manually zero the

gauge from the normal operating mode.

To select ZTARE, press and release the button. The lower

display will indicate ZTARE.

If NOZTR is selected the user will be prevented from zeroing the

gauge from the normal operating mode. This is default setting

for absolute reference ranges.

User Configuration

Pass Code Entry

Instructions F16DR, F16DRN

cecomp.com

1220 American Way Libertyville, IL 60048

Phone: 800-942-0315 Fax: 800-949-7502

BSOLUTE ROCESS NSTRUMENTS, Inc.

Division of

Calibration Preparation

User Configuration—continued

Pressure Calibration

MOD-TRONIC Instruments ·Brampton, ON · 905-457-6322 or 1-800-794-5883 ·sales@mod-tronic.com · www.mod-tronic.com