Air Monitor recommends that signal tubing between the transmitter enclosure and all sensors be stainless steel or copper

of the appropriate size. Use tees or manifolds to combine multiple sensors into single high and low pressure lines running

to the transmitter’s channel ttings for each channel. UV resistant, exible, plastic tubing specically designed for outdoor

use, such as Tygon R-3400 or equivalent, may also be used. Use brass inserts with the plastic tubing as required to ensure

a leak free connection. The connection types can be either compression ttings which are recommend with metal tubing

or barb ttings which are recommended for plastic tubing.

727.447.6140 Page 2 www.airmonitor.com/hvac/

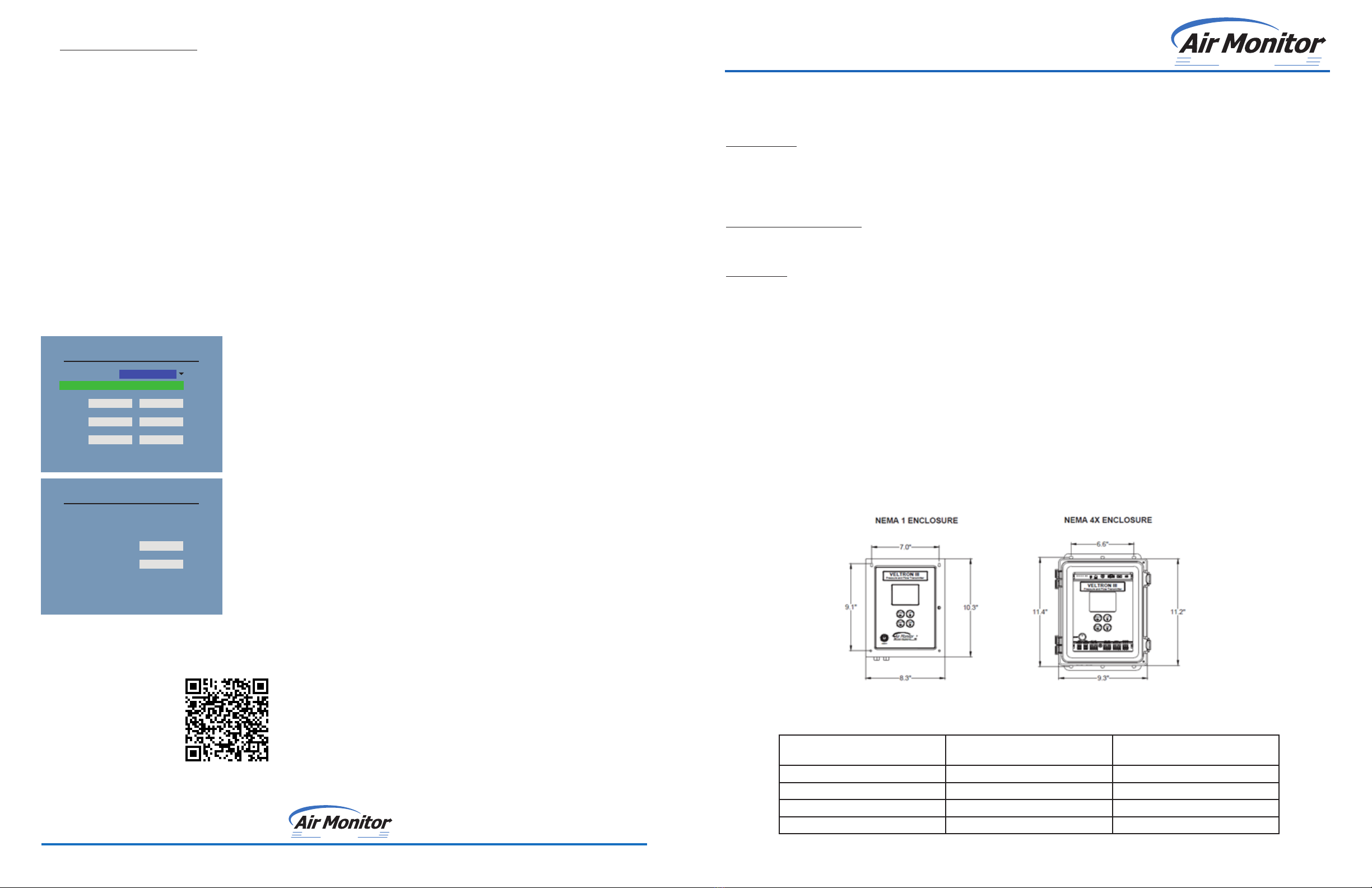

VELTRON III

QUICK START GUIDE

727.447.6140 Page 3 www.airmonitor.com/hvac/

VELTRON III

QUICK START GUIDE

STEP 3: ELECTRICAL INSTALLATION

1. POWER

I. Verify that correct AC/DC voltage is available at the power supply input terminals per its wiring diagram.

II. Input voltages should be supplied via one of the two methods below:

• 24 VAC, 15VA @ 24 VAC (40 VA with heater)

• 24 VDC, 10W @ 24 VDC (35W with heater)

2. CONNECTING VIA BACNET MS/TP

I. Power on unit to verify it is functioning properly. After verifying, power down the unit.

II. Wire RS485 cables to unit. The network cable connections are polarity sensitive and must be connected the

same way on every device (i.e. + to + and - to -). Shield drain connections should be daisy chained in the same

manner as the signal cables for RS485. The shield drain wire should be left unterminated at the end of the cable

and connected to earth only at the network master controller. Shield wires must not be connected to the RS485

connector on the Veltron III. The maximum number of devices allowed on an RS485 network segment without a

repeater is 32. Adding more than 32 devices to a single segment may reduce the transceiver output voltage to a

level that is too low to be distinguished from background noise on the cable.

III. Connect power to unit.

IV. Navigate to the Veltron III network conguration. Select Main MenugNetwork CongurationgBACnet or

MODBUS.

V. Congure device the Baud Rates, Device Address Range, Device Instance Range, and Max Master.

VI. Power cycle the device and it is now ready to connect to the controller or next device in the trunk.

3. ANALOG OUTPUT

I. For each analog output wire the two wires, the signal and the common for the device to provide 4-20mA, 0-5V, or

0-10V signal for each output.

II. Analog loop should not have power supplied to or it will damage the analog output.

4. RTD (IF SELECTED)

I. Remove the RTD from the transmitter enclosure (taped in bag at bottom).

II. Select a convenient mounting location(s) near the inlet or inside the air handler/duct to mount the RTD(s).

III. Use the supplied sheet metal screws to mount the RTD(s).

IV. Wire the RTD to the unit.

STEP 4: PROGRAMMING

TEMPERATURE FIELD CHARACTERIZATION

To navigate to the Temp Field Characterization menu. Select Main MenugTemp Field Characterization or System1/

System2gTemp Field Characterization for Dual Channel, Dual split.

I. If the device was congured for an RTD, the user will be prompted to enter a reference temperature to calibrate

the RTD in the eld.

II. If the device was congured without an RTD, the temperature will manually be entered into the Process

Temperature screen.

2. HUMIDITY CORRECTION

To navigate to the Humidity Correction menu. Select Main MenugHumidity Correction Option or System1/System2g

Humidity Correction Option for Dual Channel, Dual system.

This function allows the user to set the air to be adjusted for Supply Air, Return Air, or Custom. For supply air RH is set to

20% RH if Temp > 85°F and then switches to RH of 98% if <85°F. Return Air RH is set at 60% regardless of Temp rading

from RTD. For Custom you can enter your low RH value and high RH value, the Low RH value will be used when RTD Temp

is >65°F.

EARTH

GROUND

RS485(+) SHIELD

RS485(-) GROUND

+24 V AC/DC (L)

(-) COMMON (N)

+SIGNAL

-COMMON

Rb2 Ra

Rb1 (WHT)

3.

4. 2.

1.

H - High Pressure port connects to the high pressure side of a DP sensor

L - Low Pressure port connects to the low pressure side of a DP sensor

AMC Probes will be labeled TP=High Pressure, and SP=Low Pressure