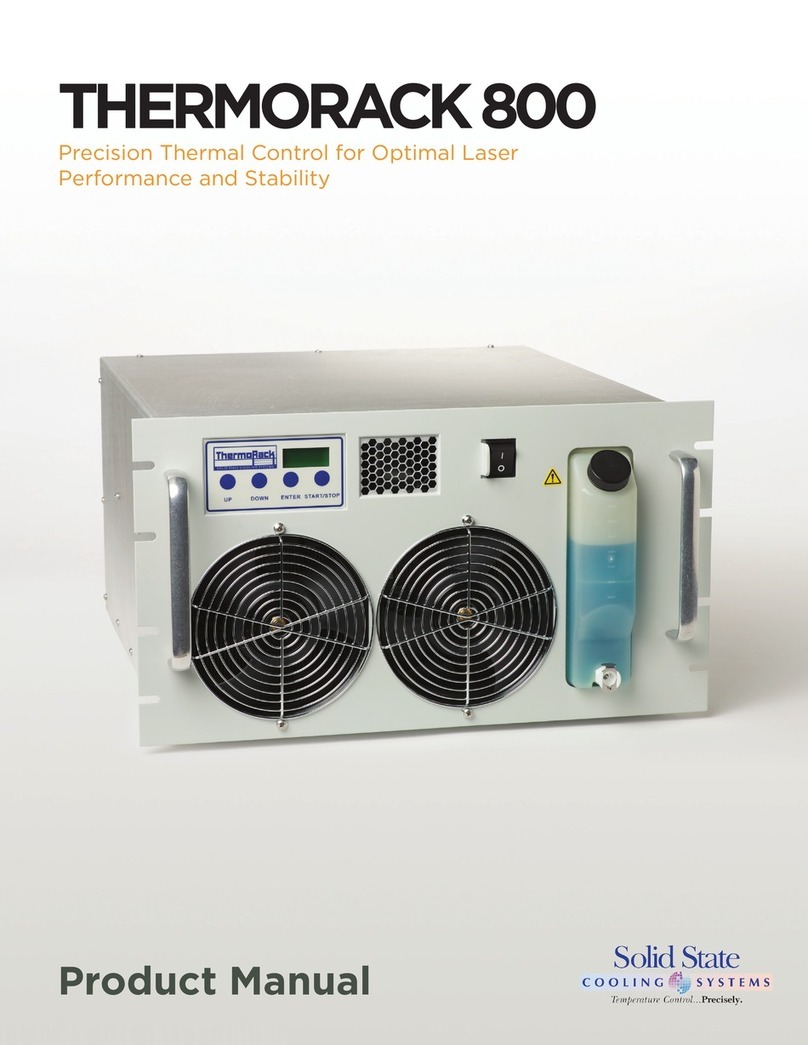

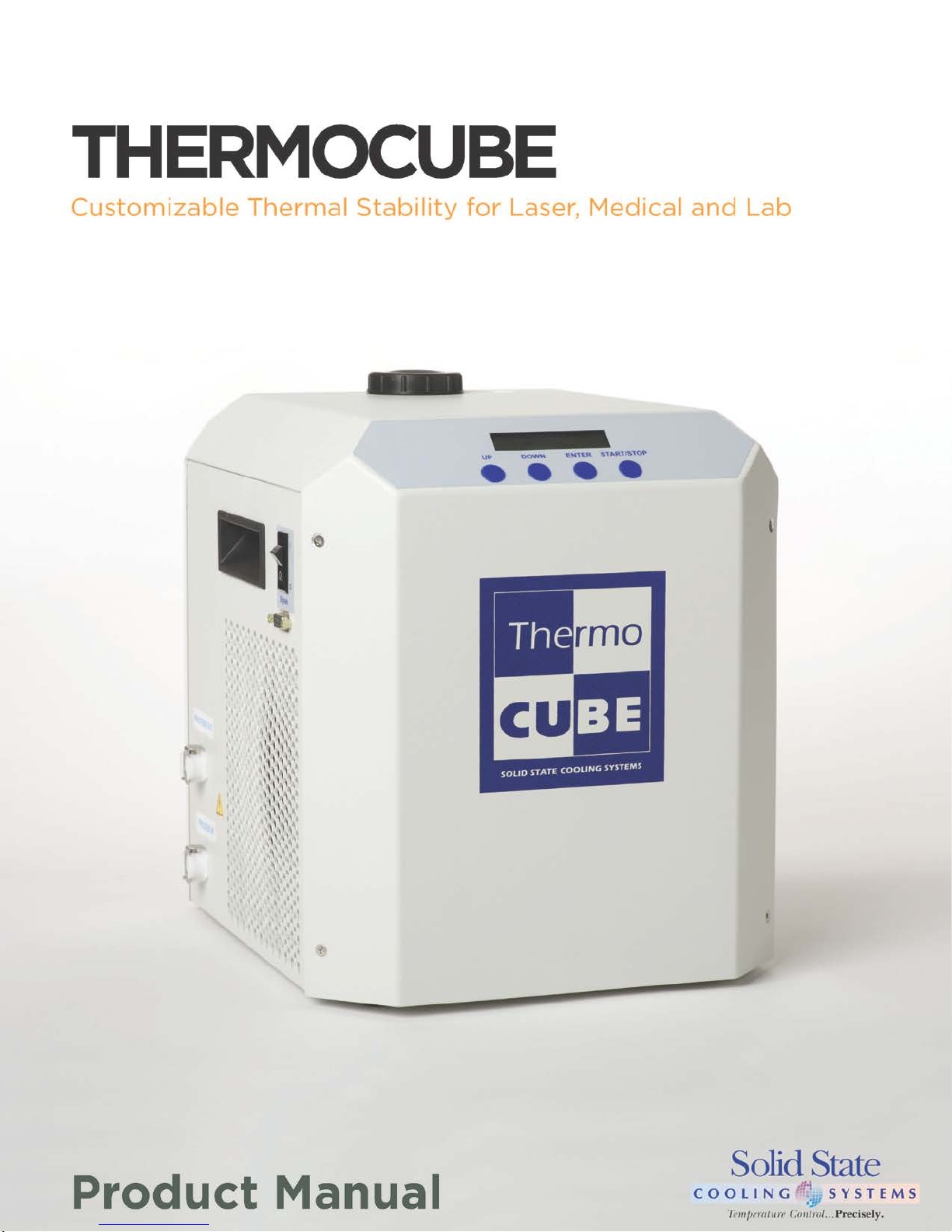

Solid State Cooling Systems THERMOCUBE 200 User manual

THERMOCUBE 200/300/400 THERMOELECTRIC CHILLER MANUAL 52-11300-1

SOLID STATE COOLING SYSTEMS,167 MYERS CORNERS ROAD,WAPPINGERS FALLS,NY 12590

TELEPHONE:(845) 296-1300 FAX:(845) 296-1303 WEB:WWW.SSCOOLING.COM VERSION M26

THERMOCUBE 200/300/400 THERMOELECTRIC CHILLER MANUAL 52-11300-1

SOLID STATE COOLING SYSTEMS,167 MYERS CORNERS ROAD,WAPPINGERS FALLS,NY 12590 1

TELEPHONE:(845) 296-1300 FAX:(845) 296-1303 WEB:WWW.SSCOOLING.COM VERSION M28

TABLE OF CONTENTS

SAFETY PRECAUTIONS AND SYMBOLS _____________________________________________ 3

SECTION 1 _________________________________________________________________________ 4

INTRODUCTION______________________________________________________________________ 4

SECTION 2 _________________________________________________________________________ 5

SPECIFICATIONS _____________________________________________________________________ 5

SECTION 3 _________________________________________________________________________ 7

HOOK UP__________________________________________________________________________ 7

3.1 Electrical Connections (see figure 3) _______________________________________________ 8

3.2 Plumbing Connections (see figure 3) _______________________________________________ 8

3.3 Air Considerations ____________________________________________________________ 10

3.4 Coolant Fill__________________________________________________________________ 10

SECTION 4 ________________________________________________________________________ 11

START UP_________________________________________________________________________ 11

SECTION 5 ________________________________________________________________________ 11

OPERATION _______________________________________________________________________ 11

5.1 Simple Operation _____________________________________________________________ 12

5.2 Advanced Operation ___________________________________________________________ 12

5.3 Alarms______________________________________________________________________ 15

5.4 Auto-tuning __________________________________________________________________ 15

5.5 Manual Tuning _______________________________________________________________ 16

5.6 Drain Procedure______________________________________________________________ 17

SECTION 6 ________________________________________________________________________ 17

SYSTEM ALARMS/TROUBLESHOOTING___________________________________________________ 17

SECTION 7 ________________________________________________________________________ 19

THERMOCUBE OPTIONS ______________________________________________________________ 19

7.1 ThermoCube Options and Part Number____________________________________________ 19

7.2 RS-232 Communications Option__________________________________________________ 20

7.3 Other Options ________________________________________________________________ 23

SECTION 8 ________________________________________________________________________ 26

CLEANING YOUR CHILLER ____________________________________________________________ 26

SECTION 9 ________________________________________________________________________ 26

TECHNICAL SUPPORT________________________________________________________________ 26

SECTION 10 _______________________________________________________________________ 27

MSDS FOR COOLANTS_______________________________________________________________ 27

10.1 MSDS for Koolance LIQ-702 Coolant Fluid _______________________________________ 27

10.2 MSDS for Ethylene Glycol _____________________________________________________ 32

WARRANTY POLICY ______________________________________________________________ 39

THERMOCUBE 200/300/400 THERMOELECTRIC CHILLER MANUAL 52-11300-1

SOLID STATE COOLING SYSTEMS,167 MYERS CORNERS ROAD,WAPPINGERS FALLS,NY 12590 2

TELEPHONE:(845) 296-1300 FAX:(845) 296-1303 WEB:WWW.SSCOOLING.COM VERSION M28

CE Declaration of Conformity

We: Solid State Cooling Systems

167 Myers Corners Road

Wappingers Falls, NY 12590

USA

declare under our sole responsibility that the

ThermoCube 200, 300, 300A, 400, 400L, 400A, 600L (All Models)

meets the provisions of the directives:

Emissions:

CFR Title 47 FCC Part 15 Subpart B, Class A

ICES-003, Issue 6, Class A

EN 61326-1: 2013 per EN 55011:2009 + A1: 2010 Group 1 Class A

ACMA AS/NZS CISPR 11:2009 + A1:2010

Immunity:

EN 61326-1: 2013 Electrical Equipment for Measurement, Control, and Laboratory Use - EMC

EN 61000-3-2 Harmonics Emissions

EN 61000-3-3 Voltage Fluctuations and Flicker

EN 61000-4-2 Electro-Static Discharge

EN 61000-4-3 Radiated Radio Frequency (RF) Immunity

EN 61000-4-4 Electrical Fast Transient/Burst Immunity

EN 61000-4-5 Surge Immunity

EN 61000-4-6 Conducted RF Disturbance Immunity

EN 61000-4-11 Voltage Dips, Interruptions and Short Variations

EN 61000-6-2 Electromagnetic Compatibility Part 6-2: Immunity for Industrial Environments

Safety:

EN 61010-1: 2010 3rd Edition Low Voltage Directive Safety requirements for electrical

UL 61010-1: 2012 Equipment for measurement, control, and laboratory use.

CAN/CSA C22.2 No. 61010-1 2012

Lloyd F Wright

Chief Technology Officer

Date

September 11, 2017

THERMOCUBE 200/300/400 THERMOELECTRIC CHILLER MANUAL 52-11300-1

SOLID STATE COOLING SYSTEMS,167 MYERS CORNERS ROAD,WAPPINGERS FALLS,NY 12590 3

TELEPHONE:(845) 296-1300 FAX:(845) 296-1303 WEB:WWW.SSCOOLING.COM VERSION M28

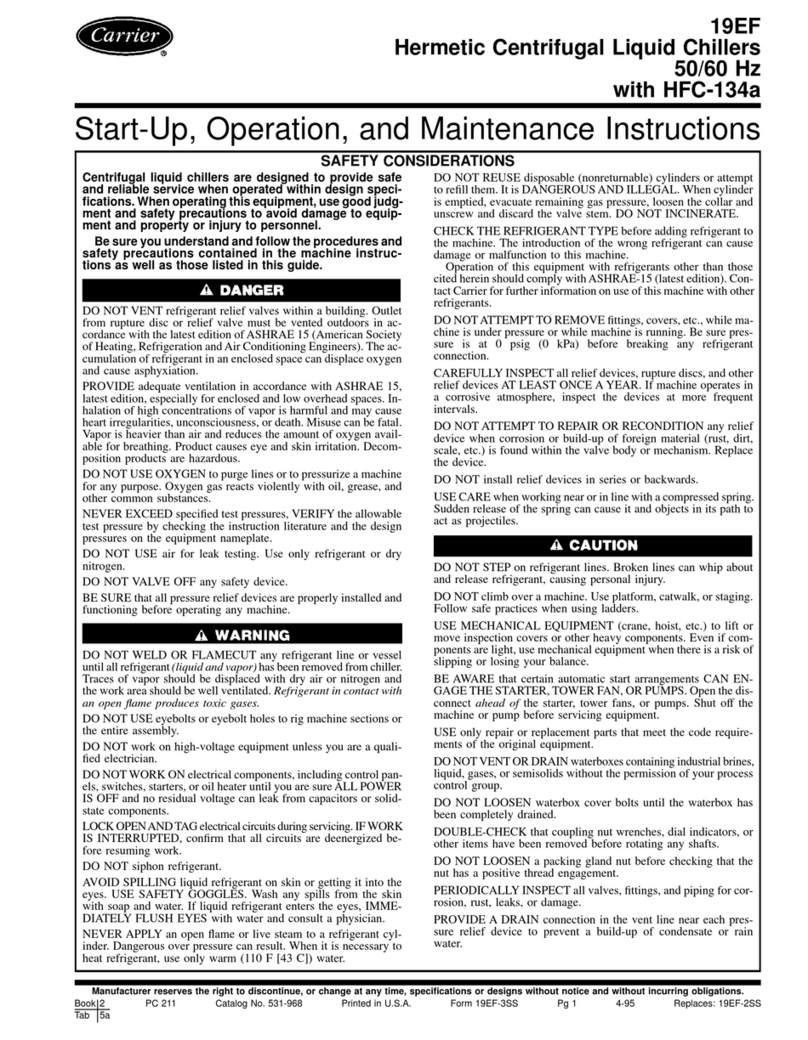

SAFETY PRECAUTIONS AND SYMBOLS _________________________

Read the MSDS for the coolant used and follow all safety precautions

listed in the MSDS prior to removing coolant tubes or opening the fill

cap as this could result in contact with the coolant inside.

Caution! Risk of electric shock. Disconnect the power cord prior to

servicing. This includes changing a fuse or opening the cover for any

reason.

CAUTION

Never disassemble the chiller as irreparable damage may occur.

Any attempt to open or repair the unit will void the warranty

Never store the chiller over 70 °C.

Never operate the chiller in ambient temperatures of 40 ºC or greater unless the unit has been

customized for high ambient operation.

Never operate the chiller within 5 ºC of the coolant’s freezing point.

Always use only proper coolants as specified in manual. Solid State Cooling Systems

recommends Koolance LIQ-702CL-B (27% propylene glycol and water)

Never ship the chiller with coolant inside the liquid cold plate as freezing temperatures may be

encountered which would damage the unit. Always pump all coolant out of the chiller prior to

shipping.

Symbols Used in this Manual

The red CAUTION equilateral triangle symbol appears throughout

the manual. Please follow the important instructions accompanying

this symbol to avoid significant damage to the chiller.

The red WARNING equilateral triangle symbol appears throughout

the manual accompanying certain maintenance and repair activities.

Please follow the important instructions accompanying this symbol

to avoid situations that could cause injury to the operator or other

personnel.

CAUTION

WARNING

THERMOCUBE 200/300/400 THERMOELECTRIC CHILLER MANUAL 52-11300-1

SOLID STATE COOLING SYSTEMS,167 MYERS CORNERS ROAD,WAPPINGERS FALLS,NY 12590 4

TELEPHONE:(845) 296-1300 FAX:(845) 296-1303 WEB:WWW.SSCOOLING.COM VERSION M28

Manual

THERMOCUBE 200/300/400

THERMOELECTRIC CHILLER

SECTION 1

INTRODUCTION __________________________________________________

The ThermoCube 200/300/400 recirculating chiller utilizes

thermoelectric technology to deliver up to 400 Watts of cooling

capacity without the use of compressors or refrigerants. The system

provides 1 to 3 liters per minute of constant temperature coolant,

with PID control for both cooling and heating. With fewer moving

parts, the system is highly reliable and energy efficient.

The ThermoCube 200/300/400 systems provide stable and precise

temperature control for a variety of applications, lasers, low-light

CCD cameras, analytical equipment, medical equipment, testing,

microelectronics production, and any other application requiring

±0.05°C control. The units include a cycling feature where two

different temperature set points may be entered with soak time at

each temperature and number of cycles desired.

The ThermoCube recirculating chillers are highly customizable,

with many different options available, which allow us to specifically

configure the system for your particular application.

From conception, The ThermoCube 200/300/400 systems have been

designed for long life and ease of use. The internal thermoelectric

modules have lifetimes greater than 200,000 hours.

P

RODUCT

THERMOCUBE 200/300/400 THERMOELECTRIC CHILLER MANUAL 52-11300-1

SOLID STATE COOLING SYSTEMS,167 MYERS CORNERS ROAD,WAPPINGERS FALLS,NY 12590 5

TELEPHONE:(845) 296-1300 FAX:(845) 296-1303 WEB:WWW.SSCOOLING.COM VERSION M28

SECTION 2

SPECIFICATIONS _________________________________________________

Operating Range (Set Point): 5°C to 50°C standard

(down to -5°C with low temp option - LT)

(up to 65°C with high temp option – HT, 60°C for centrifugal pumps)

Ambient Temperature Range: 0°C to 40°C non-condensing

Stability / Repeatability: ±0.05°C with constant load (even near ambient)

Cooling Capacity (typical1): 200, 300 or 400 Watts @ 20°C in 20°C ambient air

Heating Capacity (typical): 400, 600 or 800 Watts @ 20°C in 20°C ambient air

Noise Level (at 1 meter): < 63 dBA (down to 49 dBA with “-VS” variable speed fan option)

Coolant / Process Fluid: Koolance (27% propylene glycol / water mix)

or 27-50% ethylene glycol / water mix

Options available for PAO, Fluorinert / Galden or HFE

(contact SSCS for advice on other fluids)

Process Fluid Fittings: 1/4” John Guest standard (see options section for other fitting types)

Pumps: Diaphragm, Centrifugal or gear pumps available

(see options section for pump types and specifications)

Tank Volume: 300 ml with level sensor

Wetted Materials: Aluminum, stainless steel and polymers

or Copper, stainless steel and polymers (“-CU” option)

Dimensions (L x W x H): 13” x 11” x 13” (32cm x 28cm x 32cm)

Weight: 28 lbs (12.7 kg) – standard model

Power Input: Universal: 115-230 VAC, 50/60 Hz, 7-5 amps max

Controls: Digital PID controller for heating and cooling

Communications: Keypad or optional RS232 interface

Alarms Temperature, fluid level, system or component failure

(display and RS232 option)

Standards TUV listed to UL, CAN/CSA and EN 61010-1,

CE 61010-1

Other Options (see Section 7 for available options)

Warranty 2 years (diaphragm pumps are 1 year)

Note 1: Cooling capacity will vary with configuration.

THERMOCUBE 200/300/400 THERMOELECTRIC CHILLER MANUAL 52-11300-1

SOLID STATE COOLING SYSTEMS,167 MYERS CORNERS ROAD,WAPPINGERS FALLS,NY 12590 6

TELEPHONE:(845) 296-1300 FAX:(845) 296-1303 WEB:WWW.SSCOOLING.COM VERSION M28

Figure 1

ThermoCube 200/300/400 Cooling Capacity in 20°C Ambient (typical)

Figure 2

ThermoCube 200/300/400 Pump Performance @ 20°C (typical)

• 1C 1 lpm Centrifugal Pump

• 1CL 1 lpm Low Pres Centrifugal Pump

• 1D 1 lpm Diaphragm Pump • 1G 1 lpm Gear Pump

• 2D 2 lpm Diaphragm Pump • 2G 2 lpm Gear Pump

• 3D 3 lpm Diaphragm Pump • 3G 3 lpm Gear Pump

Note: ThermoCube 400 curve was

measured with 208 VAC input power

THERMOCUBE 200/300/400 THERMOELECTRIC CHILLER MANUAL 52-11300-1

SOLID STATE COOLING SYSTEMS,167 MYERS CORNERS ROAD,WAPPINGERS FALLS,NY 12590 7

TELEPHONE:(845) 296-1300 FAX:(845) 296-1303 WEB:WWW.SSCOOLING.COM VERSION M28

SECTION 3

HOOK UP_______________________________________________________

Figure 3A

Figure 3B

Figure 3C

Process Fluid Supply

(¼" push push-in-fittings)

On/Off Switch

Signal Connector

9-Pin D-sub

Fill Cap

Display Screen

Controller Input Buttons

Handle

Power Inlet Module

IEC 320 power inlet module with two 5X20

fuses

Optional 5-micron particle filter

Fasten the filter-mounting bracket

via the four screws located here

THERMOCUBE 200/300/400 THERMOELECTRIC CHILLER MANUAL 52-11300-1

SOLID STATE COOLING SYSTEMS,167 MYERS CORNERS ROAD,WAPPINGERS FALLS,NY 12590 8

TELEPHONE:(845) 296-1300 FAX:(845) 296-1303 WEB:WWW.SSCOOLING.COM VERSION M28

3.1ELECTRICAL CONNECTIONS (SEE FIGURE 3)

Power: The ThermoCube 200/300/400 AC power inlet is an

IEC320-C14 socket. Plug the line cord provided into this socket and

then into the appropriate 115 - 230 VAC 50/60 Hz wall outlet.

Continuous current draw is rated at 7 amps at 115 VAC or 5 amps at

230VAC (50/60 Hz). To ensure safe operation of the unit, it is

important to ensure that the outlet is properly grounded.

A wide variety of power cords are available to support universal

power operation:

Country / Region

Part Number

USA/Canada

22-22333-1

Europe

22-22333-2

Japan

22-22333-3

UK

22-22333-4

Israel

22-22800-1

Australia

22-23213-1

Korean

22-23526-1

China (3 prong)

22-23661-1

NEMA 6-15 208 US Straight

16-23918-1

NEMA L6-15 208 US Twist

16-23918-2

Brazil

22-25122-1

India/South Africa 6A (Type D)

22-26025-1

India/South Africa 15A (Type M)

22-26025-2

Fuses: 10 amp (5mm x 20mm) GDB quick acting glass, meets

IEC 127-2

Replacement Fuse: SSCS#20-22332-10, Allied Electronics

#70149445.

Optional Alarms: Alarm signals are TTL signals, normally high (>4

VDC), located on the 9-pin d-subminiature connector as follows:

System Alarm: Pin 7

Alarm Signal Return: Pin 8

Temperature Alarm: Pin 9

Optional RS-232: The ThermoCube 200/300/400 has an RS-232

communication link option. Connections are made via a 9-pin dsub

connector (see section 7 for wiring and communications details).

3.2PLUMBING CONNECTIONS (SEE FIGURE 3)

The standard process fluid inlet (coolant return) and outlet (coolant

supply) connections, located on the left side, are 1/4” John Guest

“push in” style fittings. See figure 4 for directions on using John

Guest fittings. Other fitting options are available (see section 7).

Important Note: The ThermoCube chiller should be located at

approximately the same level or above the system it is cooling to

avoid coolant draining back into the tank and overflowing after the

ThermoCube is turned off.

WARNING

Electrical Shock

Hazard: Never Plug

in a Line Cord with

Wet Hands

THERMOCUBE 200/300/400 THERMOELECTRIC CHILLER MANUAL 52-11300-1

SOLID STATE COOLING SYSTEMS,167 MYERS CORNERS ROAD,WAPPINGERS FALLS,NY 12590 9

TELEPHONE:(845) 296-1300 FAX:(845) 296-1303 WEB:WWW.SSCOOLING.COM VERSION M28

Figure 4: Using John Guest Fittings

THERMOCUBE 200/300/400 THERMOELECTRIC CHILLER MANUAL 52-11300-1

SOLID STATE COOLING SYSTEMS,167 MYERS CORNERS ROAD,WAPPINGERS FALLS,NY 12590 10

TELEPHONE:(845) 296-1300 FAX:(845) 296-1303 WEB:WWW.SSCOOLING.COM VERSION M28

3.3 AIR CONSIDERATIONS The air inlet and outlet are located on the left and right sides

respectively. Restricting airflow into or out of the unit will impair

performance. At least 3 inches of clearance is required on each side

to ensure adequate airflow.

An optional Air Filter is also available (see Section 7 for options).

3.4COOLANT FILL The coolant fill cap is located at the top rear of the unit. Twist off

the cap counter-clockwise to open. Fill reservoir prior to starting

unit. Close cap before operating

Recommended Coolants:

Solid State Cooling Systems recommends using Koolance, a pre-

mixed 27% propylene glycol/water based coolant containing an

algaecide and corrosion inhibitors. Though it comes in several

colors, SSCS recommends the colorless or blue versions in 700 ml

bottles, part number: LIQ-702CL-B (clear) or LIQ-702B-B (blue),

as the dyes in the other colored versions can form small particulates

when not well mixed.

Contact Koolance for details:

Koolance USA

2840 West Valley Highway North

Auburn, WA 98001

(253) 893-7551

Water or ethylene glycol/water mixtures are also acceptable as

coolants.

Note that algae growth can occur when water is used without at

least 25% propylene or ethylene glycol.

WARNING

Read the Coolant MSDS

Prior to filling the chiller

Use only recommended

coolants

CAUTION

THERMOCUBE 200/300/400 THERMOELECTRIC CHILLER MANUAL 52-11300-1

SOLID STATE COOLING SYSTEMS,167 MYERS CORNERS ROAD,WAPPINGERS FALLS,NY 12590 11

TELEPHONE:(845) 296-1300 FAX:(845) 296-1303 WEB:WWW.SSCOOLING.COM VERSION M28

SECTION 4

START UP ______________________________________________________

Note: In order to avoid injury or damage, operators must only use this product in the

manner specified below.

Start-up the ThermoCube 200/300/400 using the following steps:

1) Connect coolant tubing to fluid connections located on the left

side of the unit, labeled Process Out (supply) and Process In

(return).

2) Connect Alarm Signal connector (if option chosen).

3) Remove the reservoir cap on top and fill the reservoir to just

below the bottom of its neck with coolant. Replace cap.

4) Plug line cord into 115 - 230 VAC, 50/60 Hz.

5) Turn on switch located on the left side of the unit. The front

display should read the current coolant temperature. If the front

display reads “TANK LEVEL LOW”, add more coolant to the

reservoir until the display changes to read the coolant

temperature.

Important Notes:

1) If the tank level low alarm persists, or if another alarm is

displayed, consult section 6.0 of this manual.

2) If using an alcohol/water mixture, do not exceed 25% alcohol or

the reservoir level float may not rise sufficiently when filled to

turn off the tank level low alarm.

SECTION 5

OPERATION _____________________________________________________

The ThermoCube 200/300/400 is operated via the control panel

located on the front panel. The control panel has a 16-character

LCD display and four input keys: UP, DOWN, ENTER, and

START/STOP. These keys work as follows:

Key

Action

UP

Pressing the UP key raises the parameter value displayed.

DOWN

Pressing the DOWN key lowers the parameter value displayed

ENTER

Pressing the ENTER key momentarily enters the parameter changed.

ENTER

Pressing and holding the ENTER key for 3 seconds causes the chiller to change the

display menu (see menu structure)

START/STOP

Pressing the START/STOP key turns on temperature control.

START/STOP

Pressing the START/STOP key while the chiller is operating turns off temperature

control (Operating Mode = *).

WARNING

Electrical Shock

Hazard: Never Plug

in a Line Cord with

Wet Hands

Running the

ThermoCube dry

(no fluid) may

damage the pump

CAUTION

THERMOCUBE 200/300/400 THERMOELECTRIC CHILLER MANUAL 52-11300-1

SOLID STATE COOLING SYSTEMS,167 MYERS CORNERS ROAD,WAPPINGERS FALLS,NY 12590 12

TELEPHONE:(845) 296-1300 FAX:(845) 296-1303 WEB:WWW.SSCOOLING.COM VERSION M28

5.1 SIMPLE OPERATION The ThermoCube 200/300/400 comes with preset operating

parameters that will work well for most applications. If temperature

control at one temperature is desired, follow the steps below.

1) Turn on the ThermoCube and wait for display to read TEMP.

2) Press the UP or DOWN keys to change SETTEMP1 to the

desired set point.

3) Press ENTER to accept the value.

4) Press the START/STOP key to begin controlling to the

temperature just entered (SETTEMP1). The Operating Mode

will now show “‒” (cooling) or “+” (heating).

5) Pressing START/STOP while the unit is controlling temperature

will stop temperature control. The Operating Mode will now

show “*” for Standby (not controlling).

Caution: Do not externally shut off the flow of coolant for more than

a ten second period; pump damage will result if run deadheaded for

extended periods of time.

The ThermoCube will now control to the set point temperature. To

change the set point temperatures just press the UP or DOWN keys

again to change SETTEMP 1 to the new set point, followed by

ENTER and then START/STOP.The Operating Mode will now

show “‒” (cooling) or “+” (heating). If the Operating Mode shows

“*”, press START/STOP to begin controlling.

5.2 ADVANCED OPERATION The ThermoCube 200/300/400 controller has three menus: the Status

Menu, the Temperature Input Menu and the Parameter Input Menu.

The Status Menu shows the chiller operating status and current

temperature of fluid leaving the chiller (see figure 5). The Status

Menu also allows input of new coolant temperature set-points when

the cycling feature is off. The Temperature Input Menu allows input

of set point temperatures; soak times, number of cycles if cycling

between two temperatures, and an alarm temperature. The Parameter

Input Menu allows input of the temperature units; the time units for

soak times, the PID parameters and the auto tune function.

The PID parameters have been preset at the factory for most

applications. If, however, temperature control in not sufficiently

accurate or if overshoot is excessive, the PID parameters may be

modified. Unless the user is well versed in PID theory, we

recommend calling Solid State Cooling Systems technical support

group for assistance.

THERMOCUBE 200/300/400 THERMOELECTRIC CHILLER MANUAL 52-11300-1

SOLID STATE COOLING SYSTEMS,167 MYERS CORNERS ROAD,WAPPINGERS FALLS,NY 12590 13

TELEPHONE:(845) 296-1300 FAX:(845) 296-1303 WEB:WWW.SSCOOLING.COM VERSION M28

MENU STRUCTURE:

UP = Increase Value

DOWN = Decrease Value

↵Press Enter Momentarily

START/STOP = Alternately Starts or Stops temperature control

Press & Hold Enter Key 3 Sec to move from one menu to another

SIMPLE OPERATION

ADVANCED OPERATION

STATUS MENU

TEMPERATURE INPUT MENU

PARAMETER INPUT MENU

TEMP: XX.X°C (current temp)

SETTEMP1 (set point 1)

TEMPUNIT

P

RESS

UP

OR

DOWN

(change set point)

↵

↵

SETTIME1 (time at set point 1)

TIMEUNIT

SETTEMP1 XX.X°C

↵

↵

↵

SETTEMP2 (set point 2)

AUTOTUNE

P

RESS

START/STOP

(to begin

controlling at SETTEMP1)

↵

↵

SETTIME2 (time at set point2)

P1 HEAT

TEMP: XX.X°C (current temp)

↵

↵

PRESS

START/STOP

(to stop

controlling temperature)

#OF CYCLES (default = 0)

I1 HEAT

↵

↵

ALARM TEMP

D1 HEAT

↵

↵

(return to top of menu)

P2 COOL

↵

I2 COOL

↵

D2 COOL

↵

(return to top of menu)

Press ENTER key once to scroll between menu items (↵).

Press and hold ENTER key for 3 seconds to move between menus ( ).

Pressing and holding ENTER key while in the Parameter Input Menu will return you to the Status Menu.

If the unit includes the AUTO RESTART option, the unit will begin temperature control when it is first

turned on using whatever Set Point was entered when the unit was powered off.

Note: If the user enters the temperature input or the parameter input menu and does not press a key for

10 seconds the display will revert back to the Status menu.

THERMOCUBE 200/300/400 THERMOELECTRIC CHILLER MANUAL 52-11300-1

SOLID STATE COOLING SYSTEMS,167 MYERS CORNERS ROAD,WAPPINGERS FALLS,NY 12590 14

TELEPHONE:(845) 296-1300 FAX:(845) 296-1303 WEB:WWW.SSCOOLING.COM VERSION M28

Status Menu: The status menu displays the chiller operating status

and coolant temperature. The chiller operating mode is shown in the

display’s first character: (See Figure 5)

Figure 5: Operating Display

* = Standby mode, chiller is not controlling temperature

‒ = Cooling mode, chiller is controlling temperature and process

fluid temperature is above the set point

+ = Heating mode, chiller is controlling temperature and process

fluid temperature is below the set point

The process fluid (coolant) outlet temperature is shown after TEMP

in °C or °F.

Pressing the UP or DOWN keys with the # of cycles set to zero

(default) will change the set point temperature upon pressing the

ENTER, then the START/STOP key.

Temperature Input Menu: The temperature input menu allows input

of operating temperatures, soak times, number of cycles desired, and

an optional alarm temperature. Note: If # of cycles is set to zero,

only TEMP 1 and ALARM TEMP will be used.

SETTEMP1 = Set-point of first control temperature.

If # OF CYCLES is set to zero, this is the control temperature.

SETTIME1 = Soak time at temperature 1.

Not used if # OF CYCLES is set to zero.

SETTEMP2= Set-point of second control temperature.

Not used if # OF CYCLES is set to zero.

SETTIME2 = Soak time at temperature 2.

Not used if # OF CYCLES is set to zero.

# OF CYCLES = Number of cycles between temperature 1 and

temperature 2, 0-999 cycles. If set to zero, then the

ThermoCube will continuously control at temperature 1.

ALARMTEMP = Alarm temperature range +/- set-point. The unit

will output an alarm via RS-232 when the coolant temperature

is above set-point + ALARMTEMP or below set-point

‒ ALARMTEMP.

‒ TEMP 20.0 °C

Temperature Units

Process Fluid Temperature

Operating Mode

THERMOCUBE 200/300/400 THERMOELECTRIC CHILLER MANUAL 52-11300-1

SOLID STATE COOLING SYSTEMS,167 MYERS CORNERS ROAD,WAPPINGERS FALLS,NY 12590 15

TELEPHONE:(845) 296-1300 FAX:(845) 296-1303 WEB:WWW.SSCOOLING.COM VERSION M28

Parameter Input Menu: The parameter input menu allows input of

temperature units, time units, PID parameters, and turns on or off

auto-tune.

TEMPUNIT = °C or °F

TIMEUNIT = s: seconds, m: minutes, h: hours

AUTOTUNE = ON/OFF.

ON turns on auto-tune where the controller determines PID

parameters. Once PID parameters have been determined AUTO-

TUNE reads OFF.

P1 HEAT = Proportional band for heating, 0-99.9 °C or °F.

P1 HEAT Factory Default Value = 5.6

I1 HEAT = Integral term for heating, 0-999 seconds

I1 HEAT Factory Default Value = 22

D2 HEAT = Derivative term for heating, 0-999 seconds

D2 HEAT Factory Default Value = 2

P2 COOL = Proportional band for cooling, 0-99.9 °C or °F

P2 COOL Factory Default Value = 2.8

I2 COOL = Integral term for cooling, 0-999 seconds

I2 COOL Factory Default Value = 22

D2 COOL = Derivative term for cooling, 0-999 seconds

D2 COOL Factory Default Value = 2

5.3 ALARMS The ThermoCube chiller has two TTL level alarms, one for

temperature and one for system failure:

Temperature: TTL high (>4 VDC) fluid temp below alarm set point

TTL low (<0.5 VDC) fluid temp above alarm set point

System: TTL high (>4 VDC) system operating normally

TTL low (<0.5 VDC) system failure has occurred

A list of system failures causing the system alarm to change to TTL

low can be found in Section 6. In the event of a system failure, the

alarm type will be shown on the front display.

5.4 AUTO-TUNING Some models of the ThermoCube 300 and 400 chillers come with an

automatic tuning (auto-tune) feature. Changing the PID parameters

is normally not recommended unless the RTD probe is moved to a

new location. However, the controller can calculate new PID

parameters via the auto-tune function.

THERMOCUBE 200/300/400 THERMOELECTRIC CHILLER MANUAL 52-11300-1

SOLID STATE COOLING SYSTEMS,167 MYERS CORNERS ROAD,WAPPINGERS FALLS,NY 12590 16

TELEPHONE:(845) 296-1300 FAX:(845) 296-1303 WEB:WWW.SSCOOLING.COM VERSION M28

The following keystrokes initiate the auto-tune function:

1) Press and hold the Enter key until the Status Menu changes to the

Temperature Input menu.

2) Press and hold the Enter key again until the Temperature Input

menu changes to the Parameter Input menu.

3) Press the Enter key three times. The display should read

AUTOTUNE off.

4) Press the Up key to change off to on.

5) Press and hold the Enter key until the parameter input menu

returns to the Status Display.

6) Press the Start key once. The left most display character will

show the letter A until the auto tune is complete. The

ThermoCube will then begin controlling at the set point

temperature.

5.5 MANUAL TUNING For users well versed in PID theory, Solid State Cooling Systems

recommends the closed-loop “Ziegler Nichols” method for manually

tuning the controller. The method consists of three steps:

1) Turn off both the integral and derivative terms for heating and

cooling by setting I1, I2, D1, and D2 to zero.

2) Set proportional band to 50 °C. Begin controlling the process at

the desired set-point temperature. Look for a small-sustained

oscillation in the coolant temperature. Observe the status menu

operating mode character and note if system is heating (+) or

cooling (-). If no oscillation occurs, lower the proportional band

in 50% increments until a small oscillation occurs. Write down

this proportional band setting (P)

3) Measure the “Natural Frequency” (t) of the system in seconds.

This is the time required for the temperature oscillation to cycle

from one maximum temperature to the next maximum

temperature.

Now set the controller input parameters as follows:

P1 HEAT = 2*P if system was heating in step 2.

P1 HEAT = 4*P if system was cooling in step 2.

I1 HEAT = 1.2*t

D1 HEAT = t/8

P2 COOL = P if system was heating in step 2.

P2 COOL = 2*P if system was cooling in step 2.

I2 COOL = 1.2*t

D2 COOL = t/8

THERMOCUBE 200/300/400 THERMOELECTRIC CHILLER MANUAL 52-11300-1

SOLID STATE COOLING SYSTEMS,167 MYERS CORNERS ROAD,WAPPINGERS FALLS,NY 12590 17

TELEPHONE:(845) 296-1300 FAX:(845) 296-1303 WEB:WWW.SSCOOLING.COM VERSION M28

5.6DRAIN PROCEDURE

1. Attach a hose the “Process Out” port of the chiller and place the

end of it in a container with at least a 3 liter capacity.

2. Turn the unit on (making sure to hold the drain hose in place)

and run it until air starts to shoot out of the hose.

3. Attach the drain hose to the “Process In” port of the chiller

4. Remove the tank cap and allow the liquid in the chiller’s lines to

drain out.

5. Replace and tighten the tank cap, then remove the drain hose.

6. Dispose of the coolant in a manner consistent with local

regulations.

SECTION 6

SYSTEM ALARMS/TROUBLESHOOTING ________________________________

The ThermoCube 200/300/400 has multiple system alarms that

when triggered will show on the display. When an alarm is

displayed the system will not attempt to heat or cool the coolant.

Alarms:

Tank Level Low: Liquid reservoir level is too low. Unless filling for

the first time, check all outside plumbing lines for leaks. Once all

leaks are sealed, remove the cap and add more coolant until the

alarm disappears.

RTD Open: The temperature sensor has failed or its connector has

come loose. Turn off the chiller and disconnect the AC power cord.

Contact SSCS for a replacement RTD, or for a RMA number to

return the unit for RTD replacement.

Fan Fail: Fan is supplying insufficient air to cool the thermoelectric

heat exchanger. Either the fan has failed or the airflow into or out

of the system is blocked. Check that the side air inlet and outlet

gratings are not blocked. The ThermoCube requires at least 3

inches of clearance around these gratings. If airflow is not blocked,

contact SSCS for a replacement fan, or for a RMA number to return

the unit for fan replacement.

Pump Fail: The liquid heat exchanger plate temperature is either too

hot or too cold, indicating pump failure, a blockage in the external

plumbing lines or operation outside the normal 5°C to 50°C coolant

temperature (without –LT or –HT options). Turn off the

ThermoCube and disconnect the AC power cord. Verify that no

kinks or blockages exist in plumbing line, both outside and inside

the ThermoCube. If no coolant flow blockages exist, contact SSCS

for a replacement pump, or for a RMA number to return the unit for

pump replacement.

WARNING

Read the Coolant MSDS

prior to draining the

chiller

Electrical Shock Hazard:

Always unplug the unit

before removing the cover.

WARNING

Do not attempt to service or

repair the unit beyond the

troubleshooting checks

described in this section

without first contacting

Solid State Cooling Systems

WARNING

THERMOCUBE 200/300/400 THERMOELECTRIC CHILLER MANUAL 52-11300-1

SOLID STATE COOLING SYSTEMS,167 MYERS CORNERS ROAD,WAPPINGERS FALLS,NY 12590 18

TELEPHONE:(845) 296-1300 FAX:(845) 296-1303 WEB:WWW.SSCOOLING.COM VERSION M28

No Display:If the liquid crystal display does not illuminate upon

turning on the ThermoCube, the internal 12 or 24VDC power

supply has failed, the diaphragm pump has failed, or the LCD

display has failed. Contact SSCS for a RMA number to return the

unit for replacement of the power supply, diaphragm pump, or

display.

Temperature Control Poor: If no other alarms are present, poor

temperature control indicates the heat load is too great for the chiller,

the TE cooling/heating engine is not receiving power, the PID

constants have been corrupted or the chiller needs repair. First check

the PID constant values shown section 5.2 match the factory

defaults. If not, change the values to the default values. Otherwise,

contact SSCS for technical support.

Important: The tank level low alarm will automatically reset when

the tank is filled. The RTD, Fan and Pump failure alarms will not

reset until the system power is turned off.

THERMOCUBE 200/300/400 THERMOELECTRIC CHILLER MANUAL 52-11300-1

SOLID STATE COOLING SYSTEMS,167 MYERS CORNERS ROAD,WAPPINGERS FALLS,NY 12590 19

TELEPHONE:(845) 296-1300 FAX:(845) 296-1303 WEB:WWW.SSCOOLING.COM VERSION M28

SECTION 7

THERMOCUBE OPTIONS____________________________________________

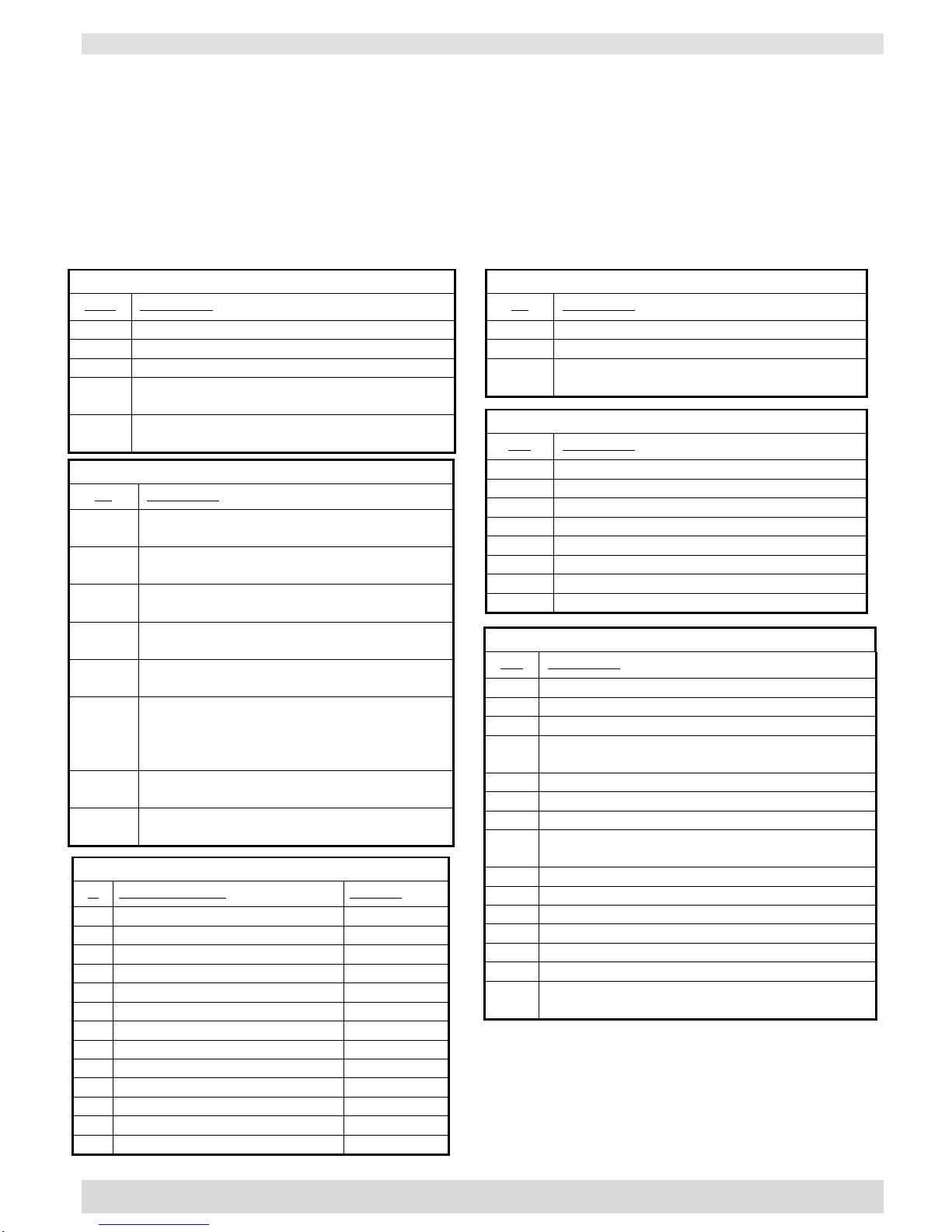

7.1THERMOCUBE OPTIONS AND PART NUMBER

ThermoCube P/N: 10 –CCC –PP –FF –X –YY –OO

Cooling Pump Fan Power Fittings Other

Capacity Type Type Cord Options

CCC = Cooling Capacity (choose one):

CCC

Description

200

200 W @ 20°C in 20°C ambient air

300

300 W @ 20°C in 20°C ambient air

400

400 W @ 20°C in 20°C ambient air

300A

300 W inert gas temperature control

(No pump, No tank, Includes -LT

400AC

400 Watts air conditioner from 20°C house

chilled water. (No pump, No tank)

PP = Pump Type (choose one):

PP

Description

-1D

>1 lpm @ 35 psig diaphragm

(1 year warranty)

-2D

>1.5 lpm @ 35 psig diaphragm

(1 yearr warranty)

-3D

>3 lpm @ 30 psig diaphragm pump

(1 year warranty) , Requires 3/8” fittings

-1G

>1 lpm @ 35 psig magnetic drive gear, low

vibration with stainless steel head

-2G

>2 lpm @ 35 psig magnetic drive gear, low

vibration

-3GXX

>3 lpm @ 30 psig magnetic drive gear, low

vibration (XX = adjusted flow rate: XX=20 for

2 lpm, XX=10 for 1 lpm, XX=15 for 1.5 lpm

etc.) or XX=RF for 3 lpm with run / fill

-1C

~1 lpm @ 17 psig, ~2 liter/min @ 15 psig

centrifugal

-1CL

~1 lpm @ 12 psig, ~2 liter/min @ 10 psig

centrifugal

YY = Inlet/Outlet Fitting Options:

YY

Description

Std

John Guest 1/4” x 1/4” Bulkhead

-J2

John Guest 3/8 x 3/8” Bulkhead

-CP

1/4” CPC shut off valve coolant

-CP2

3/8” CPC shut off valve coolant

-CPM

1/4” CPC metal

-SW

1/4” Swagelok kit

-S2

3/8” Swagelok kit

-FN

1/4” Female NPT Bulkhead

OO = Other Options:

OO

Description

-R2

RS232 interface controller, improved

-EF

5 micron external liquid filter

-AF

External air intake filter

-SS

Stainless steel tank and stainless steel plumbing

(Only available with gear pump)

-ST

Stainless steel tank

-PT

Preset control temperature: (Input temp:___ °C)

-LT

Low temperature (<5°C) operation)

-HT

High temperature up to 65 °C

(60°C max for Centrifugal pumps)

-DC

Dry contact alarm signals

-VD

Vibration dampening material added

-AR

Auto restart – software

-DI

DI water compatible

-FL

Set up for Fluorinert or Galden

-PA

Set up for PAO

-###

Custom engineered special (CES), sequential

number assigned by Engineering

X = Power Cord (select one)

X

Country / Region

Part No.

-1

USA/Canada

22-22333-1

-2

Europe

22-22332-2

-3

Japan

22-22333-3

-4

UK

22-22333-4

-5

Israel

22-22800-1

-6

Australia

22-23213-1

-7

Korean

22-23526-1

-8

China (3 prong)

22-23661-1

-9

NEMA 6-15 208 US Straight

16-23918-1

-10

NEMA L6-15 208 US Twist

16-23918-2

-11

Brazil

22-25122-1

-12

India/South Africa 6A (Type D)

22-26025-1

-13

India/South Africa 15A (Type M)

22-26025-2

FF = Fan Type (choose one):

FF

Description

Blank

Standard fan noise <63 dBA @ 1m

-QF

Quiet Fan (no longer available)

-VS

Variable speed fan, noise

49 dBA to 63 dBA @ 1m

This manual suits for next models

2

Table of contents

Other Solid State Cooling Systems Chiller manuals

Popular Chiller manuals by other brands

oxford diffraction

oxford diffraction KMW150CCD user manual

MTA

MTA TAEevo015 Maintenance and operating manual

Midea

Midea MC-SU30-RN1L Owners & installation manual

Carrier

Carrier PACKAGED AIR COOLED FLOTRONIC 30GB060 Advance product data

Carrier

Carrier 30GT 015 installation instructions

Carrier

Carrier AQUAFORCE 30XW150-400 Operation & service manual