2 OM-BLAST CHILLER

INSTALLATION

SELECTING A LOCATION FOR YOUR NEW UNIT

The following conditions should be considered when selecting a location for

your unit:

1. Floor Load: The area on which the unit will rest must be level, free of vibration,

and suitably strong enough to support the combined weights of the unit plus

the maximum product load weight. All casters or legs must be in contact with

the floor to support the weight. Legs have adjustable feet that can be raised

or lowered. Casters may require shims in order for the caster to be in contact

with the floor. NOTE: If there is a question pertaining to weight load limits,

consult the factory at 1-888-994-7636.

2. Ventilation: The air-cooled self-contained unit requires a sufficient amount

of cool clean air. Avoid surrounding your blast chiller around other heat

generating equipment and out of direct sunlight. Also, avoid locating in

an unheated room or where the room temperature may drop below 55° F

(13°C) or above 86°F (32°C).

3. Clearance: There must be a combined total of at least 3” clearance on all

sides of the unit.

INSTALLATION CHECKLIST

After the final location has been determined, refer to the following checklist prior

to start-up:

1. Check all exposed refrigeration lines to ensure that they are not kinked,

dented, or rubbing together.

2. Check that the condenser and evaporator fans rotate freely without striking

any stationary members.

3. Turn on control once unit has been plugged in or properly wired direct (see

page 15)

4. Allow unit time to cool down to holding temperature. (See page 10 for Unit

Operation).

5. Refer to the front of this manual for serial number location. Please record

this information in your manual on page 3 now. It will be necessary when

ordering replacement parts or requesting warranty service.

6. Confirm that the unit is holding temperature.

7. Allow your unit to operate for approximately 30 minutes before putting in

food to allow interior of unit to cool down to storage temperature.

NOTE: All motors are oiled and sealed.

NOTE:FAILURE TO FOLLOW INSTALLATION GUIDELINESAND RECOMMENDATIONS

MAY VOID THE WARRANTY ON YOUR UNIT.

ELECTRICAL SUPPLY

The wiring should be done by a qualified electrician in accordance with local

electrical codes. A properly wired and grounded outlet will assure proper

operation. Please consult the data tag attached to the compressor to ascertain

the correct electrical requirements. Supply voltage and amperage requirements

are located on the serial number tag located on the rear interior wall.

NOTE: It is important that a voltage reading be made at the compressor

motor electrical connections, while the unit is in operation to verify the correct

voltage required by the compressor is being supplied. Low or high voltage can

detrimentally affect operation and thereby void its warranty.

NOTE: It is important that your unit has its own dedicated line. Condensing

units are designed to operate with a voltage fluctuation of plus or minus 10% of

the voltage indicated on the unit data tag. Burn out of a condensing unit due to

exceeding voltage limits will void the warranty.

OPERATION

The Randell BC series blast chillers are designed for rapid chilling through the

danger zone down to 40°F or below in approximately 90 minutes. The exact chill

time will vary depending on product type. The door must be in closed position to

activate switch at top of door before any cooling cycle will begin.

INTRODUCTION

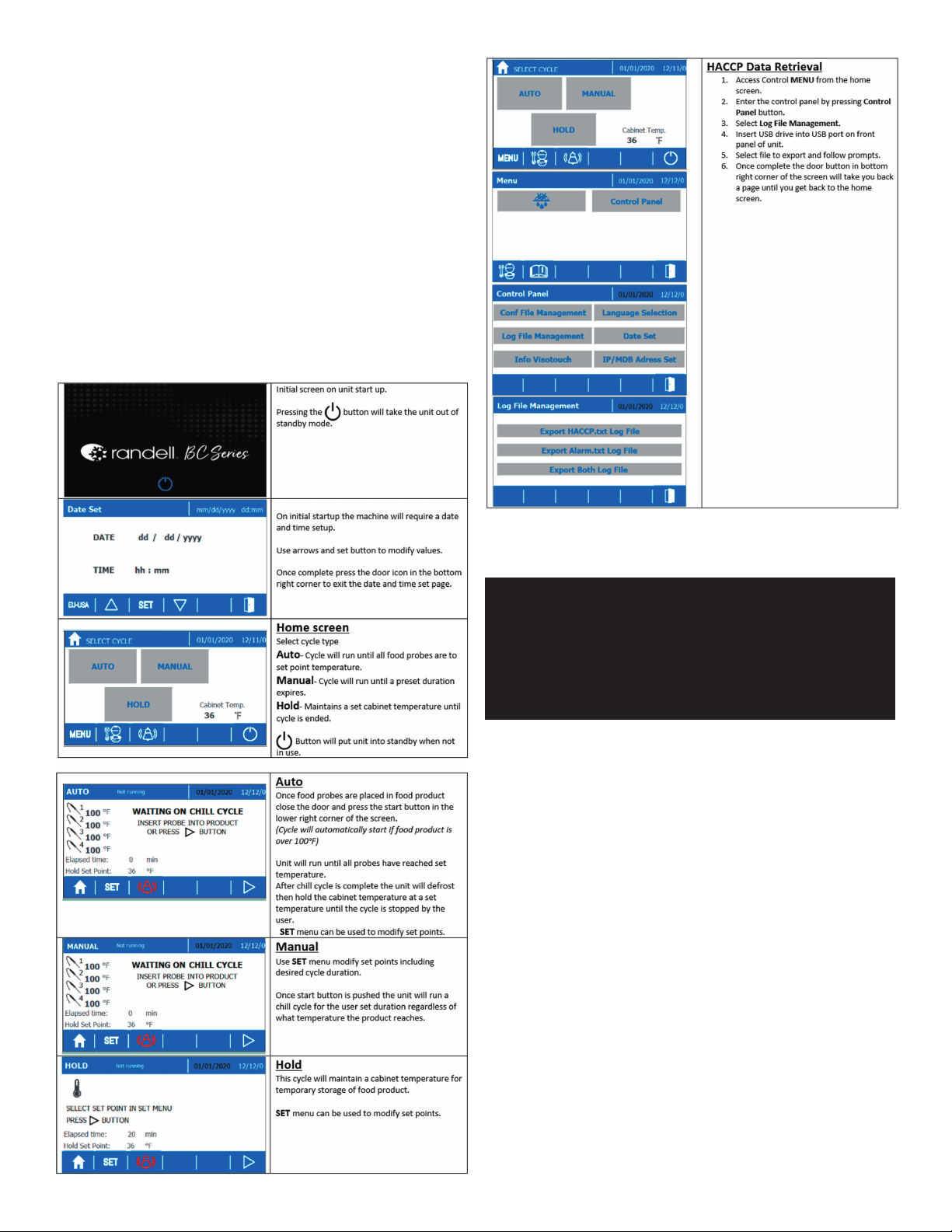

1. The control software for the BC Control Unit is based on a Real-Time Operating

System and is capable of simultaneously running a chiller operation while at

the same time accepting/displaying user information from the control panel

such as chiller preset adjustments. This document provides an overview of the

current controller features.

POWERING UP UNIT

1. Once the unit is connected to AC power the touch screen will display a loading

screen with a progress bar.

2. Once loaded the standby screen will be displayed. Depressing the power key

on initial power up will cause the unit to request setting of the date and time.

Adjust the date and time values by touching the desired value, press the set

button then use arrow buttons to adjust value up or down. After all values have

been set press the return button on the bottom right of the screen to return to

the standby screen.

SETTING THE DATE/TIME

1. Upon turning on the unit for the first time, the controller will prompt the user to

set the current date and time of day.

2. To adjust the date or time after initial power up you must access the Date Set

function. This function can be accessed by entering the menu screen from the

home screen then the control panel.

Menu àControl Panel àDate Set

POWERING DOWN UNIT

The unit may be returned to the low power standby state by depressing the

power button. The display will then return to the standby screen. NOTE: Power

should only be removed from the unit while it is idle on this standby screen.

MODES OF OPERATION

The controller can run one of three possible modes, Auto, Manual, or Hold.

1. Auto Mode - Auto Mode will run a chill cycle until all food probes have reached

a preset set point.

a. Auto can be manually selected by pressing the “AUTO” button on the

home screen.

- The food probe set point can be modified by entering the setting menu

via the “SET” button at the bottom of the auto cycle screen.

b. Auto cycle will start automatically from home screen or while running a

hold cycle if food probes are placed directly into food product and probes

have exceeded 100°F

c. Once an auto cycle has completed the unit will perform a defrost cycle.The

word defrost will display on the cycle screen once the defrost cycle has

activated and will remain until the evaporator coil has properly defrosted.

d. After completion of the defrost cycle the unit will hold the cabinet at the

hold set point until the user removes the product and ends the chill cycle

by pressing the “X” in the lower right-hand corner of the cycle screen.

2. Manual Mode - Manual Mode will run a chill cycle for a user set duration that

is not controlled by food probe temperature. Chill cycle will only end when set

duration has expired or user intervention occurs.

3. Hold Mode - Cabinet temperature will be held at a user defined set point.

This can be used to pre chill the cabinet prior to an auto/manual chill cycle or

temporarily hold food product. Not intended for extended food product storage.