Solo Tele Style DIY Electric Double Neck Guitar Kit

Copyright © 2011 Solo Music Gear. All rights reserved | v1.02

hex-bushing on the front using a socket wrench or a hex-wrench. Do this for all 18 tuners on the 6 and 12

string headstocks. Both necks of the DCTK-1 are 'tilt-back' headstocks so there will not be any string

retainers required.

STEP 2 –Install the necks. Now, you can attach the necks to the body using the 8 neck screws, the neck plates

and the neck plate cushions. Remember, when you are holding the guitar in playing position, the upper neck is

the 12 string neck. Once again organize all the required parts to make sure you have everything and that they

fit properly. Make sure the necks fit snugly in the neck pockets and that they are neither loose, nor so tight

that you have to force it in. The factory fit should be satisfactory! Rubbing a little bees wax on the screws will

make this job easier, and will not compromise the holding power of the screws. Install a screw through the

neck-plate and cushion, through the appropriate hole in the body and start to thread it into the correct hole in

the back of the neck....screw it in just far enough that it holds, and then repeat for the remaining screws of the

first neck. Now, tighten the screws enough that the neck holds in place... do not tighten completely until you

have made sure the neck aligns with the holes for the bridge (take two straight edged and hold them against

the sides of the neck and make sure the holes for the bridge are centered between your straight edges. You

may want to use a piece of painters tape to protect the top of the body while doing this) When you are

satisfied that the neck is correctly aligned, finish tightening the screws, and repeat the process for the second

neck.

STEP 3 –Install the bridges. Assemble all the parts for the 6 and 12 string bridges and ensure you have

everything required. Your bridge pickups are already fastened to the bridges so you only have to make

sure that you include the ground wire that must contact the under-surface of the bridge, and then be

soldered to one of the pots. Strip about 3/8" - 1/2" of the insulation from the ground wire and insert the

wire through the hole which goes from the guitar surface to the bridge pickup cavity, leaving only the

stripped wire on the surface of the guitar. Now, thread both the ground wire and the pickup wire through

the supplied hole, into the control cavity and start to install the bridge screws. Make sure the bridge sits

flat and that it's position conforms with your neck alignment....finish tightening the bridge screws and

repeat for the second bridge. Note that the 12 string bridge has 6 strings that thread through the back of

the plate, and 6 strings that thread through the body....you can install the 6 string ferrules into the back of

the body at this time as well.

STEP 4 –Install the pickguard. Before you start this process, 'dry fit' the pick-guard to the body to ensure

the cut-outs for the necks align properly...you may have to make some small adjustments with a file to

the pick-guard in order for it to fit 100%. There are no pilot holes for the pick-guard screws, so once you

are satisfied with the location and fit of the pick-guard, use some painters tape to hold the pick-guard in

place, and mark/pre-drill the pick-guard screw holes. Now, you will have to install both neck pickups

and the 3-way switch into the pick-guard with the supplied screws before installing the pick-guard itself,

ensuring that you insert all the wires through the appropriate holes into either the control cavity or the

3-way switch cavity before you install the pick-guard screws. (Make sure you mark the wires as they

come through the cavities, so there is no confusion as to which wire belongs to which pick-up!) You will

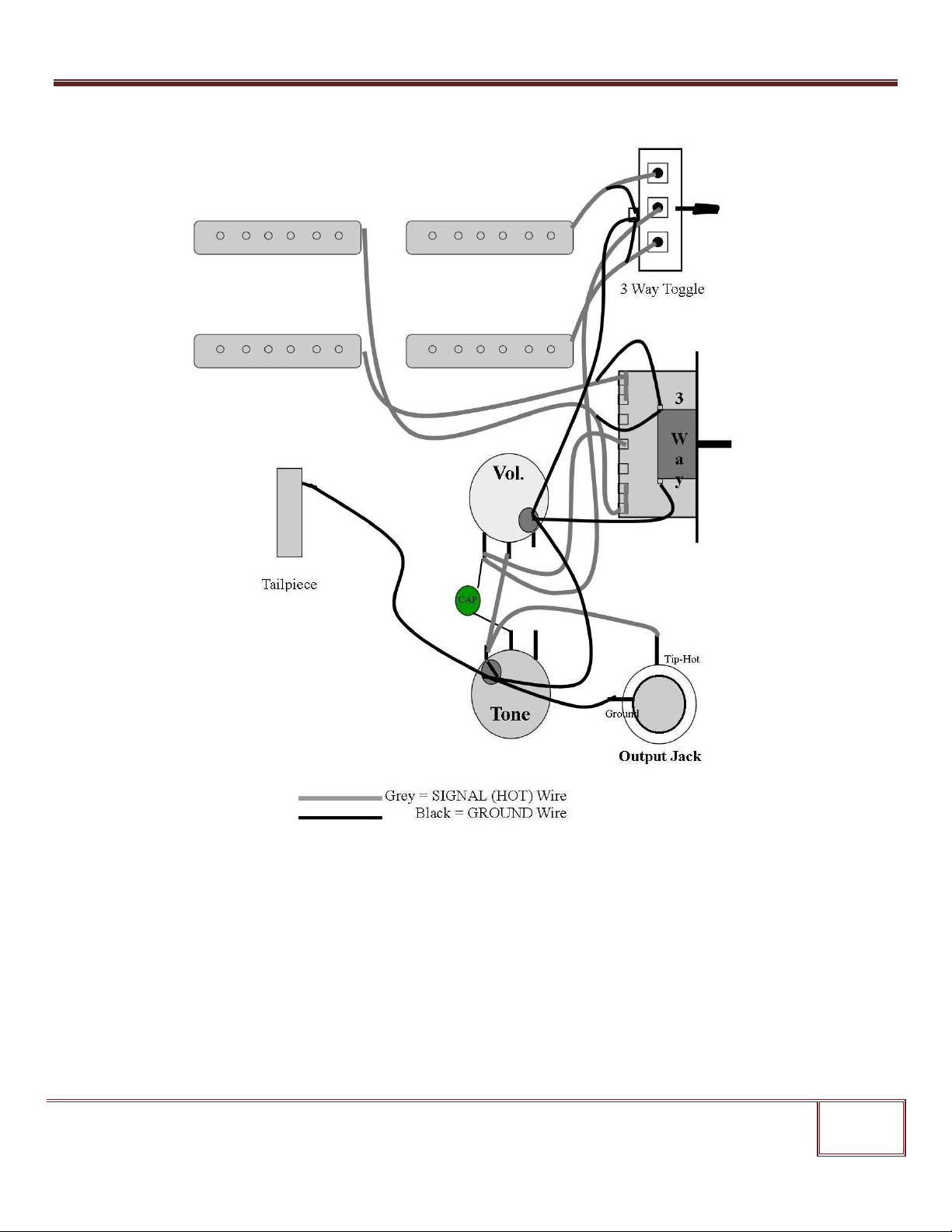

have to refer to your wiring diagram to make sure your pick-up wires are correctly located. When you

are satisfied that everything is properly located, install the pick-guard with the supplied screws.