Solstice Xopax PX Series User manual

USER MANUAL AND PRODUCT GUIDE

and

series

table of

contents

01

PAGE CONTENTS

02 specs

03 components

04 warranty & support

05 set up

06 measuring for lm

07 how much overlap?

08 cube wrapping

09 narrow end wrapping

Distributed by Solstice Technologies

specs

MACHINE SPECS

02

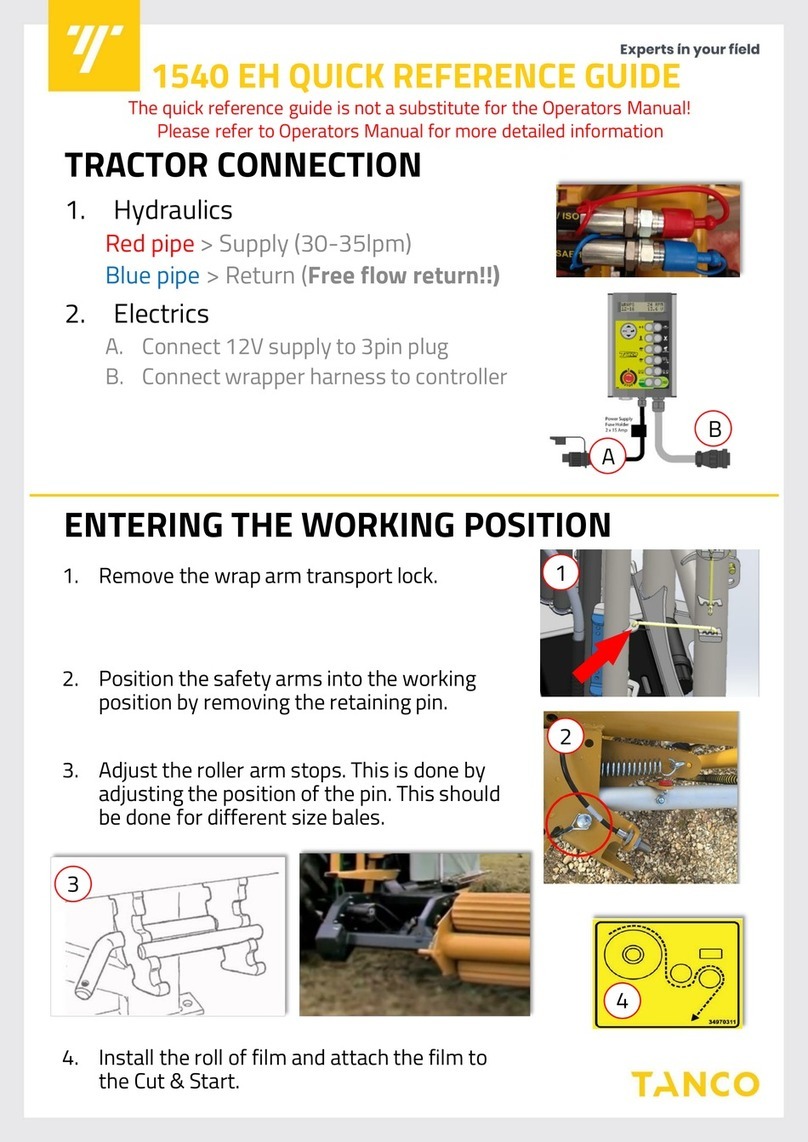

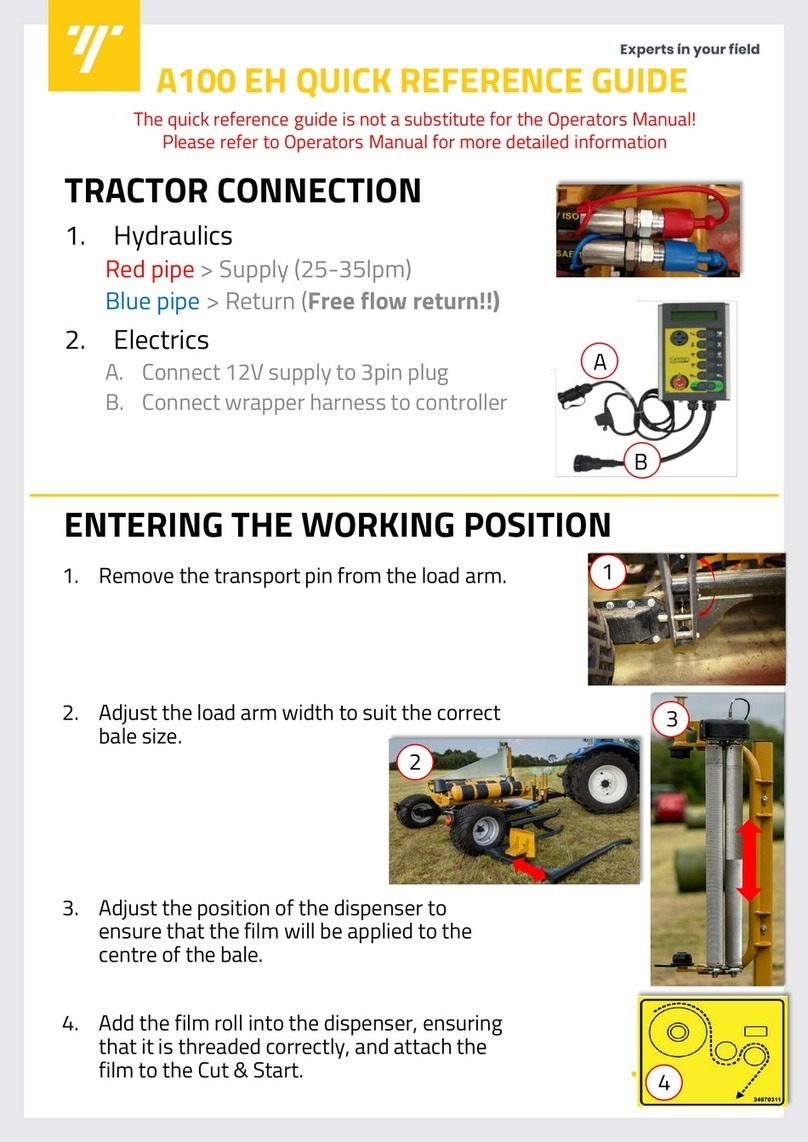

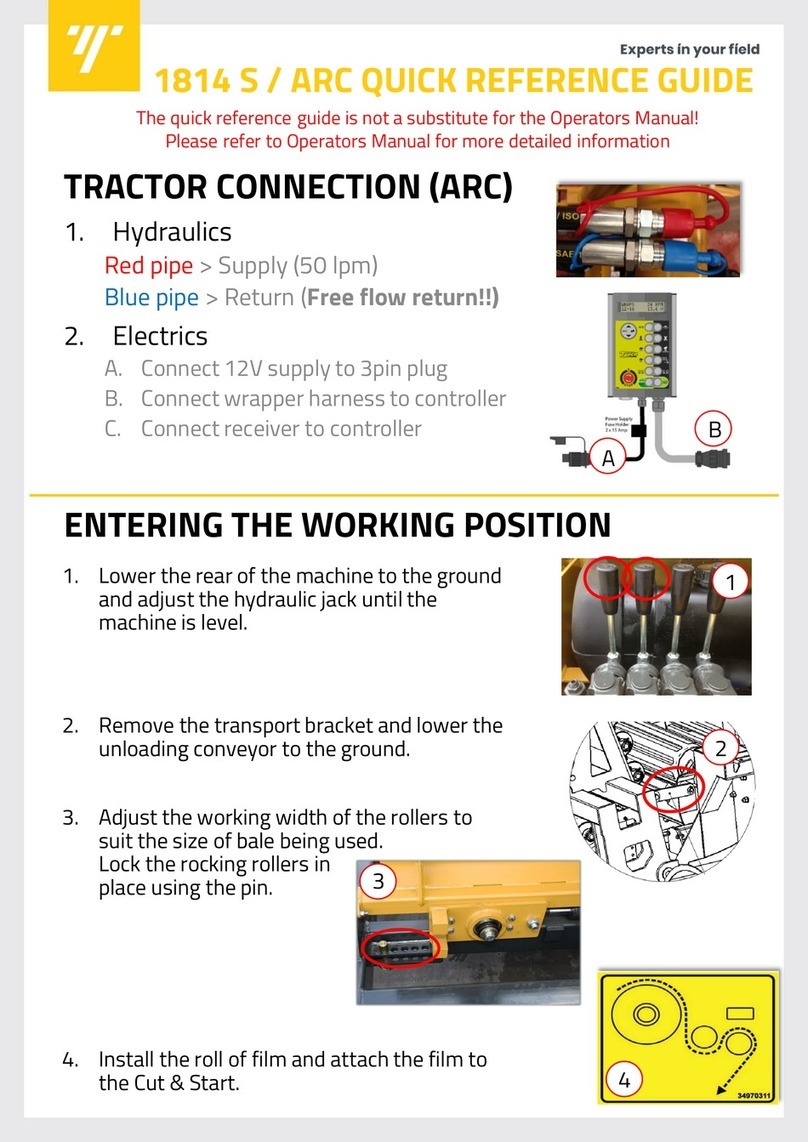

Dimensions: PX(C)12 : 14”W X 17.3/4”D X 7 1/8”H

PX(C)20: 22”W X 17?3/4”D X 7 1/8”H

Weight: PX(C)12: 27 lbs

PX(C)20: 40 lbs

Maximum Film Width: PX(C)12: 12”

PX(C)20: 20”

Maximum Film Roll Diameter: PX(C)12: 12”

PX(C)20: 20”

Electrical: 120 VAC or 240VAC (power cord not included with 240VAC)

Cutting Wire: 28 gauge Nicrome wire

Warranty: 100% Parts and Labor.

Term: One Year for PX Series and Three Year for PXC Series

FILM SPECS

Material: Bi Oriented Polypropylene (BOPP)

Thickness: 1 mil standard (other thickness available with custom rolls)

Roll Length:

.7 mil = 7,000 ft.

.8 mil = 6,300 ft.

1 mil = 5,000 ft. (standard)

1.2 mil = 4,200 ft.

1.4 mil = 3,600 ft.

1.6 mil = 3,100 ft.

2 mil = 2,500 ft.

Custom sized and non-standard thickness rolls

can be special ordered for $10 per linear inch

of lm width + $20 per roll.

components

03

Xopax shipping box with

specialty foam inserts.

DO NOT THROW AWAY

BOX AND FOAM INSERTS!

USER MANUAL AND PRODUCT GUIDE

and

series

User Manual and

Product Guide

Replacement

Wire Pack

3/16” allen wrench,

and 2 spare

5 amp fuses

Xopax Unit

Xopax User

Tips Video

Power Cord

(120V)

warranty

& support

warranty

& support

04

Term: One Year for PX Series and Three Years for PXC Series

Warranty: Begins from the date of sale and continues until the term has been

completed. 100% of all parts and labor will be covered by this warranty when repairs

are completed by an Authorized Xopax Repair Center. Shipping costs to and from

Repair Center are not covered under this warranty but shall be the sole expense of

the customer. Please note most repairs are simple and can be completed by the

end user with replacement parts provided by Xopax and will therefore save time and

shipping expenses.

Items not covered: Abusive use or damage from liquids or exposure to outdoor

elements. The machine is intended to be used in an indoor environment

Requirements for receiving repair:

Fill out the Technical Support request on the Contact page.

Return Merchandise Agreements are required for all repair requests. Do not ship

machines without an RMA #.

Machines MUST be shipped back in original shipping box and foam packing. If you do

not keep your packaging a replacement box and foam will be sent to you at a cost

of $65.00 plus shipping fees.

Return Policy: Xopax accepts returns up to thirty days from date of sale if returned

unopened or in new condition. Returns are subject to a 20% restocking fee. All returns

must be shipped in original box with foam supports and must have approved RMA

# on outside of box. Any returns without an approved RMA # will be refused and

returned to shipper at shippers expense.

Media should

come off the top of

the roll, rather than

under. The stand-

ard media path is

to feed over the

top bar and under

the bottom bar as

seen in the picture

at left. The bottom

bar can be lowered

and raised to adjust

tension.

05

set up

Use the supplied

allen wrench to

loosen hub lock

on bar. Slide one

hub off, load roll,

replace hub and

tighten hub lock.

Don’t press the

hubs too tightly

against the

media roll,

it needs to spin

in place.

Install your power

cord into the

back of your

machine, just

under the on/

off switch. 120V

machines are

supplied with a

power cord.

Be sure the washer

is on the outer side

of the blue wall

when you install

your media bar.

Tighten the black

handles snugly.

The bar should not

spin during usage.

For particularly heavy rolls, an

alternative lm path is recommended.

Try feeding it between the two rolls

rather than directing it around the

bars. You’ll want to raise the lower bar

close to the top bar to prevent the lm

from slipping out of place. As your roll

gets lighter, simply re-route the media

to the standard feed path.

Standard

Feed

Heavier

Rolls

settings

06

measuring

for lm

Measuring your box to determine the needed lm size can be confusing.

You need to consider HOW you want your box to be wrapped. For the neatest

wraps, you’ll want the folded edges to occur on the shorter or smaller sides. These

sides where the folds will occur are the “ends.” The distance between these two

“ends” is the “span.” Start by nding the measurement of your span. This is the

distance between the two ends.

span

span

span

span

The lm needs to lay across the span to the edge and then fold over more than

half way down the ends. If the lm doesn’t go more than half way down, there

won’t be any overlap to accomodate the seal. Let’s start this step by measuring

the depth of one end.

end

depth

end

depth end

depth

end

depth

span + end depth + amount of overlap = lm width

Now you’ll need to determine how much overlap you want for the ends. If you

want .25” of overlap, add .25” to the equation. For .5” of overlap, add .5” to the

equation and so forth. For boxes with long, shallow ends, we recommend adding

the full depth again.

For a 3”x3”x3” box with .5” desired overlap, the formula would be:

3 + 3 + .5 = 6.5” roll

For a 5”x1”x3” box with .75” desired overlap, the formula would be:

5 + 1 + .75 = 6.75” roll

span + end depth + amount of overlap

= your lm width

07

how much

overlap?

Determining overlap on cubes and approximate cube shaped boxes:

The left example shows a quarter inch overlap. The right example shows an

inch and a quarter overlap. For cubes, we recommend a smaller overlap.

You’ll need to use more caution to make sure the box is centered as you

wrap, but there will fewer layers of lm and a neater appearance.

Determining overlap on shallow end boxes:

With less depth on the ends, the amount of overlap is a bit different than

with square shaped ends. If you allow very little overlap (see the top exam-

ple above) the ends look more cluttered. We recommend a full end over-

lap (as in the lower example). You achieve this by adding the span + end

depth + end depth again. The ends will look neater and you won’t have to

be as cautious to perfectly center your box.

TEST YOUR SIZE BEFORE ORDERING:

Before you place your custom roll order, cut some paper to the desired

width. Wrap this around your box and tape in place. This is the best way to

determine if what you think you need is REALLY what you need.

08

cube

wrapping

For instructional videos, please go to

www.solstice-inc.com/Xopax.htm.

narrow end

wrapping

For instructional videos, please go to

www.solstice-inc.com/Xopax.htm

09

This manual suits for next models

1

Table of contents