Somati system OGS Guide

Somati system s.r.o., Jihlavská 510/2c, 664 41 Troubsko

IČ: 29260159, DIČ: CZ29260159

tel: +420 547 427 011, www.somati-system.cz

3/2019

Installation manual

OGS

Somati system s.r.o., Jihlavská 510/2c, 664 41 Troubsko

IČ: 29260159, DIČ: CZ29260159

tel: +420 547 427 011, www.somati-system.cz

3/2019

1. NOTICE BEFORE INSTALLATION.................................................................. 1

2. CHECK OF DELIVERY .................................................................................... 2

3. TYPES OF OGS ............................................................................................ 10

4. CHECK OF CONSTRUCTION READINESS ACCORDING TO THE DRAWING 12

5. INSTALLATION OF GUIDES ........................................................................ 13

6. INSTALLATION OF BRACKETS.................................................................... 14

6.1 OGS STANDARD AND HIGH-LIFT...................................................................... 14

6.2 OGS VERTICAL................................................................................................ 14

6.3 OGS LOW-LIFT................................................................................................ 15

7. INSTALLATIOn OF ROLLER ........................................................................ 19

7.1 OGS STANDARD, VERTICAL AND HIGH-LIFT..................................................... 19

7.2 OGS LOW-LIFT................................................................................................ 21

8. INSTALLATION OF CURVED TRACK............................................................ 22

9. HORIZONTAL STIFFENERS.........................................................................24

10. HORIZONTAL LATHING ..............................................................................25

11. INSTALLATION OF SECTIONS .................................................................... 26

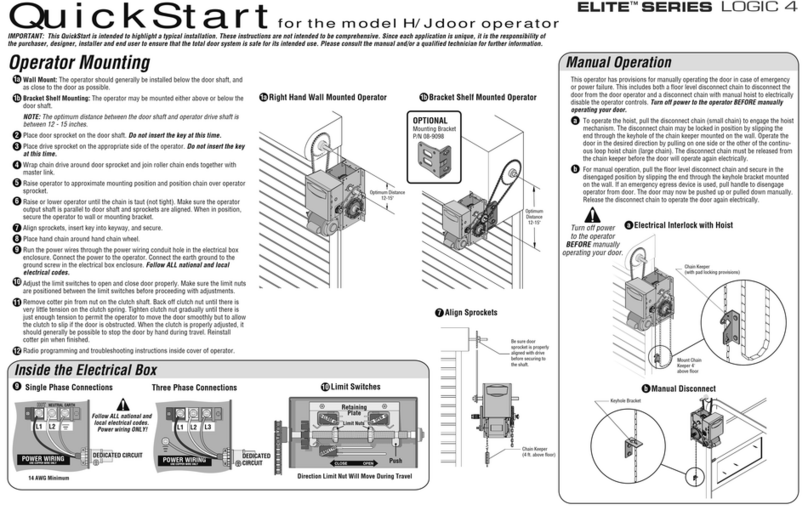

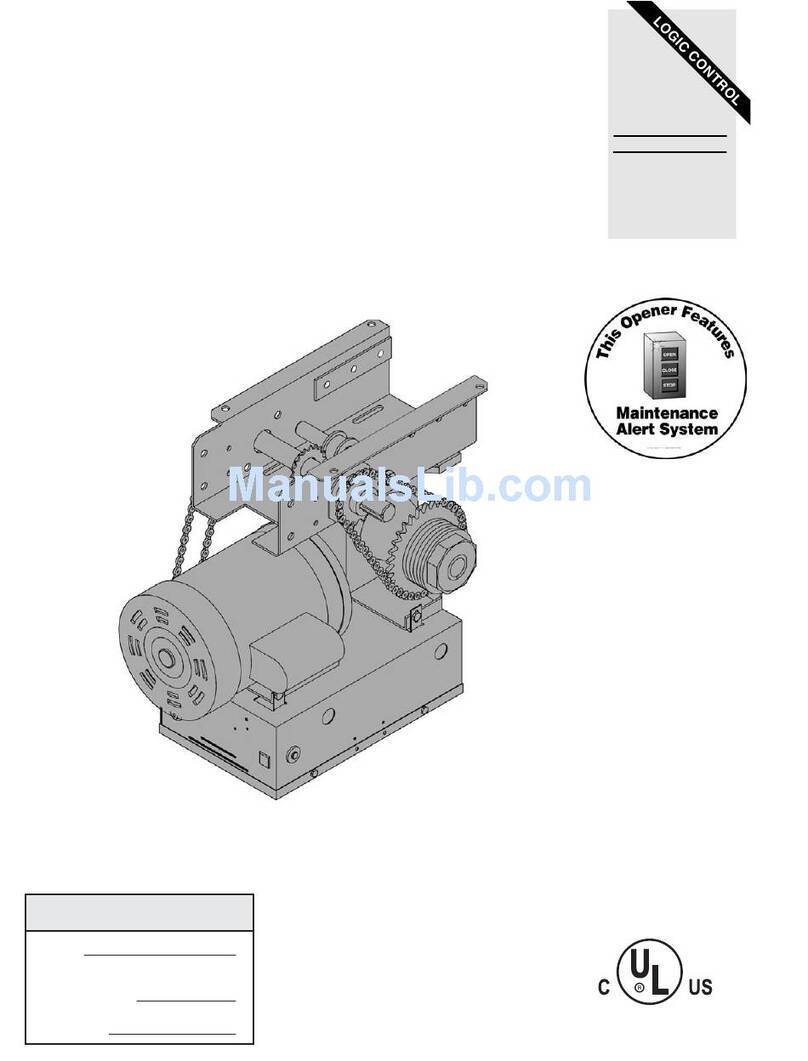

12. INSTALLATION OF MOTOR......................................................................... 30

13. ASSEMBLY OF CARRYING ROPES AND THEIR ADJUSTMENT ....................31

14. COMPLETION OF THE INSTALLATION........................................................ 32

Somati system s.r.o., Jihlavská 510/2c, 664 41 Troubsko

IČ: 29260159, DIČ: CZ29260159

tel: +420 547 427 011, www.somati-system.cz

1

1. NOTICE BEFORE INSTALLATION

Dear customers,

we are pleased, you have decided for sectional fire gates from the company Somati

system s.r.o.

Please, read the instructions carefully and follow them step by step. You will obtain

important information on the safe installation and operation of your gates and proper

maintenance and repairs.

Professional use and proper maintenance significantly influence the performance and

serviceability of the gate system. Errors in operating and improper maintenance lead to

operating malfunctions, which can be normally avoided. Your satisfaction and long-term

operational safety is ensured only in case of professional use and proper maintenance.

Important guidelines:

•Follow instructions mentioned in this manual.

•Improper installation or maintenance of the gate can lead to life-threatening injuries.

For your own safety, have the installation done by a qualified company.

•Transport gate leaves only on a special pallet. During transportation without pallet

you can damage the gate surface.

•These gates open and close vertically. For this reason, make sure that during the

operation of the gate there are no persons in the area of the gate movement –

especially children –and no objects blocking movement of the gate.

•Use gate system only if it is in perfect technical condition. Malfunction of the gate system

can lead to life-threatening injuries.

•Make sure that during all inspections, repairs and cleaning, the gate system is not

controlled by a third party.

•Do not change or remove any functional parts! This way you can put important safety

components out of order.

•Do not install any additional structural parts. All structural parts are tailor-made and

fit exactly to each other. Additionally mounted parts can overload the gate structure and

lead to life-threatening injuries.

Work equipment:

•Use only tools suitable for installation of gate system and appropriate equipment

Gather all the following work equipment:

•Appropriate lifting equipment (forklift truck, crane) for lifting roller and

placing it on the brackets (watch out for the total weight of the roller men-

tioned at the installation drawings)

•Appropriate lifting platform or scaffolding

•Drill

•Grinder

•Set of spanners

•Optical levelling devices

•ACCU screwdriver

•Screw taps (in case of installation on steel structure)

Somati system s.r.o., Jihlavská 510/2c, 664 41 Troubsko

IČ: 29260159, DIČ: CZ29260159

tel: +420 547 427 011, www.somati-system.cz

2

2. CHECK OF DELIVERY

Before starting the installation, remove the technical drawing and pacing list from the pack-

aging and make sure that the delivery corresponds to the packing list.

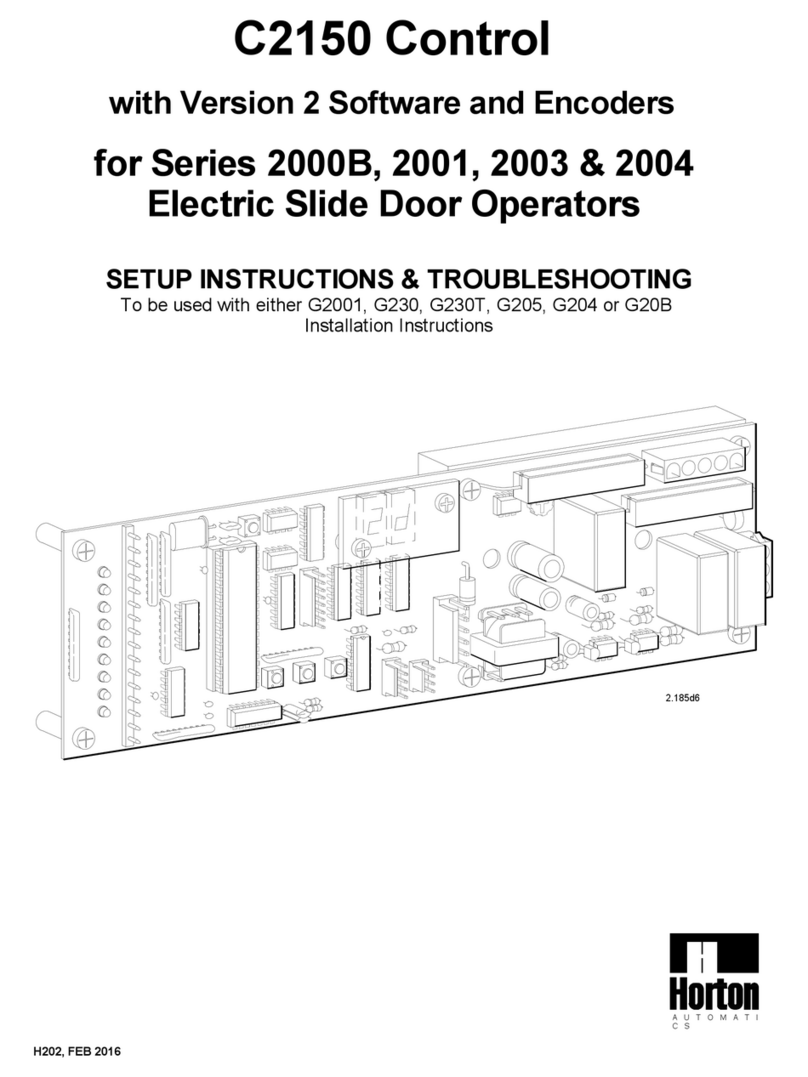

SET OF MOTOR

1.1

motor bracket

1.2

motor (SI, FS, MDF)

1.3

winding roller bracket (2 pcs) (not applicable for low lintel)

1.4

winding roller including drums

1.5

flanged bearing UCFL

Somati system s.r.o., Jihlavská 510/2c, 664 41 Troubsko

IČ: 29260159, DIČ: CZ29260159

tel: +420 547 427 011, www.somati-system.cz

3

1.6

steel wire rope with pressed eyelet

1.7

fasteners

GUIDES

2.1

side guide with vertical rail (1 pair)

2.2

curved rail (1 pair) –not used for vertical OGS

2.3

strut - not used for vertical OGS

Somati system s.r.o., Jihlavská 510/2c, 664 41 Troubsko

IČ: 29260159, DIČ: CZ29260159

tel: +420 547 427 011, www.somati-system.cz

4

2.4

reinforcement (number according to the length of horizontal guidance (not applica-

ble for vertical OGS)

a –for gate of width < 4 m

b - for gate of width ≥ 4 m

2.5

wind bracing - not applicable for vertical OGS

2.6

fasteners

HORIZONTAL LATHING

3.1

horizontal lathing

3.2

fasteners

GATE SECTION

4.1

section without passage door

4.2

section with passage door

Somati system s.r.o., Jihlavská 510/2c, 664 41 Troubsko

IČ: 29260159, DIČ: CZ29260159

tel: +420 547 427 011, www.somati-system.cz

5

4.3

side edges (number of edges = 2x number of sections)

4.4

upper edge profile

4.5

bottom profile (only for gates with passage door)

4.6

upper hinge with pulley

4.7

side hinge with pulley

Somati system s.r.o., Jihlavská 510/2c, 664 41 Troubsko

IČ: 29260159, DIČ: CZ29260159

tel: +420 547 427 011, www.somati-system.cz

6

4.8

centre hinge

4.9

safety brake with pulley

4.10

fasteners

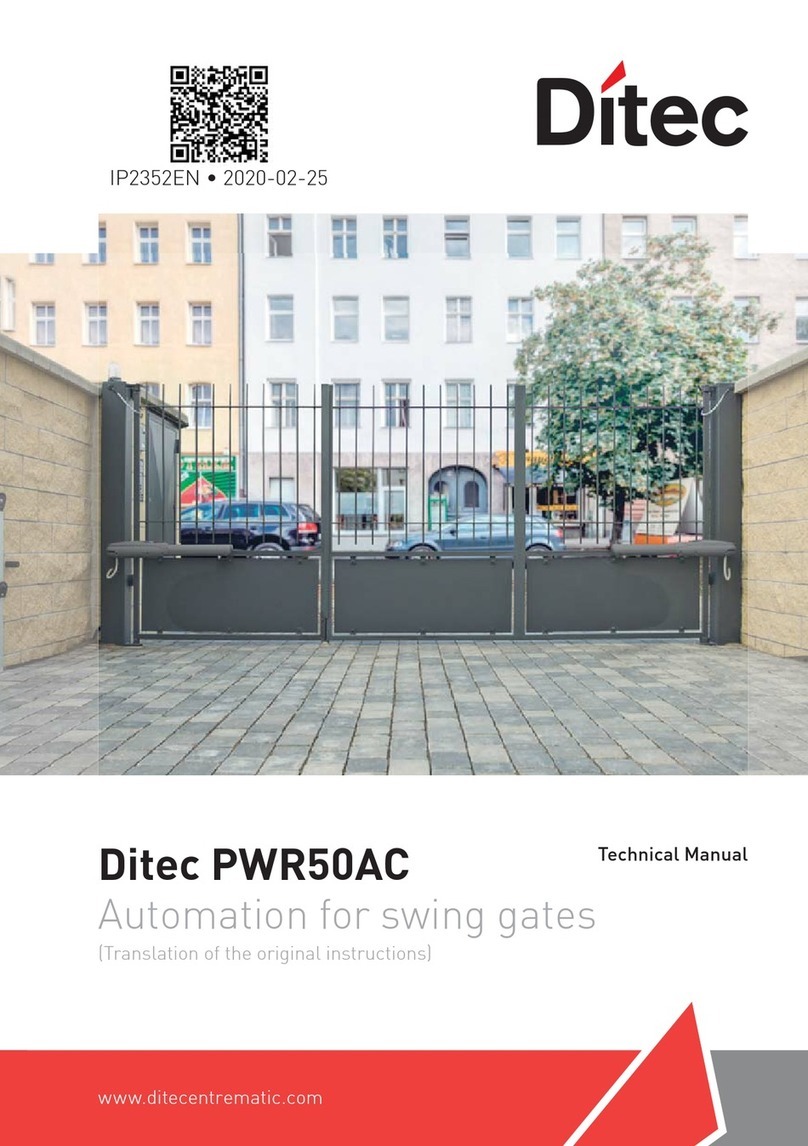

CONTROL

6.1

control box + installation manual

FSTRONIC 24

FSTRONIC DES-FI

TS 970

6.2

cable of motor

ACCESSORIES FOR GATES WITH LOW LINTEL

7.1

shaft with pulleys

a –for gates of width ≤ 3 m

b - for gates of width > 3 m (2 pcs)

Somati system s.r.o., Jihlavská 510/2c, 664 41 Troubsko

IČ: 29260159, DIČ: CZ29260159

tel: +420 547 427 011, www.somati-system.cz

7

7.2

winding roller bracket –ceiling part (2 pcs)

7.3

winding roller bracket –side part (2 pcs)

7.4

motor bracket - fixing

7.5

inserting bracket - J-profile

7.6

flanged bearing UCFL (only for gates of width ≤ 3 m) (2 pcs)

Somati system s.r.o., Jihlavská 510/2c, 664 41 Troubsko

IČ: 29260159, DIČ: CZ29260159

tel: +420 547 427 011, www.somati-system.cz

8

7.7

reduction for the shaft mounting (only for gates of width > 3 m) (2 pcs)

7.8

additional part of J-profile (only for gates of width > 3 m) (2 pcs)

7.9

fasteners

Somati system s.r.o., Jihlavská 510/2c, 664 41 Troubsko

IČ: 29260159, DIČ: CZ29260159

tel: +420 547 427 011, www.somati-system.cz

9

OTHER

8.1

additional accessories –according to the order specification

8.2

installation material –standard delivery does not include bolts for installation into

supporting structure –possible to order according to the type of supporting structure

(wall, steel structure)

recommended anchor material

wall material

brackets

guides

lathing

concrete

anchor to concrete

M12x110

(e.g. Hilti HSA)

wall plug (e.g. Fisher

SX) 8x65 mm +

buttonhead screw

6x80 mm

wall plug (e.g.

Fisher SX) 8x65 mm

+ countersunk

screw 6x80 mm

steel structure

screw M12x min. 30

TEX 6,3x45 mm with

hexagon head

TEX 5,5x45 mm

with countersunk

head

ceramic wall

(Porotherm)

anchoring with

threaded rod M12

through wall +

spreading plates

wall plug (e.g. Fisher

SX) 8x65 mm +

countersunk screw

6x80 mm

wall plug (e.g.

Fisher SX) 8x65 mm

+ countersunk

screw 6x80 mm

gas-silicate (Ytong)

wall from solid

bricks

threaded rod M12 +

chemical anchor

example of optional electrical accessories

8.3

optional battery module for FSTRONIC DES-FS

8.4

connection box with spiral cable for optical safety edge OSE, including grommet

Somati system s.r.o., Jihlavská 510/2c, 664 41 Troubsko

IČ: 29260159, DIČ: CZ29260159

tel: +420 547 427 011, www.somati-system.cz

10

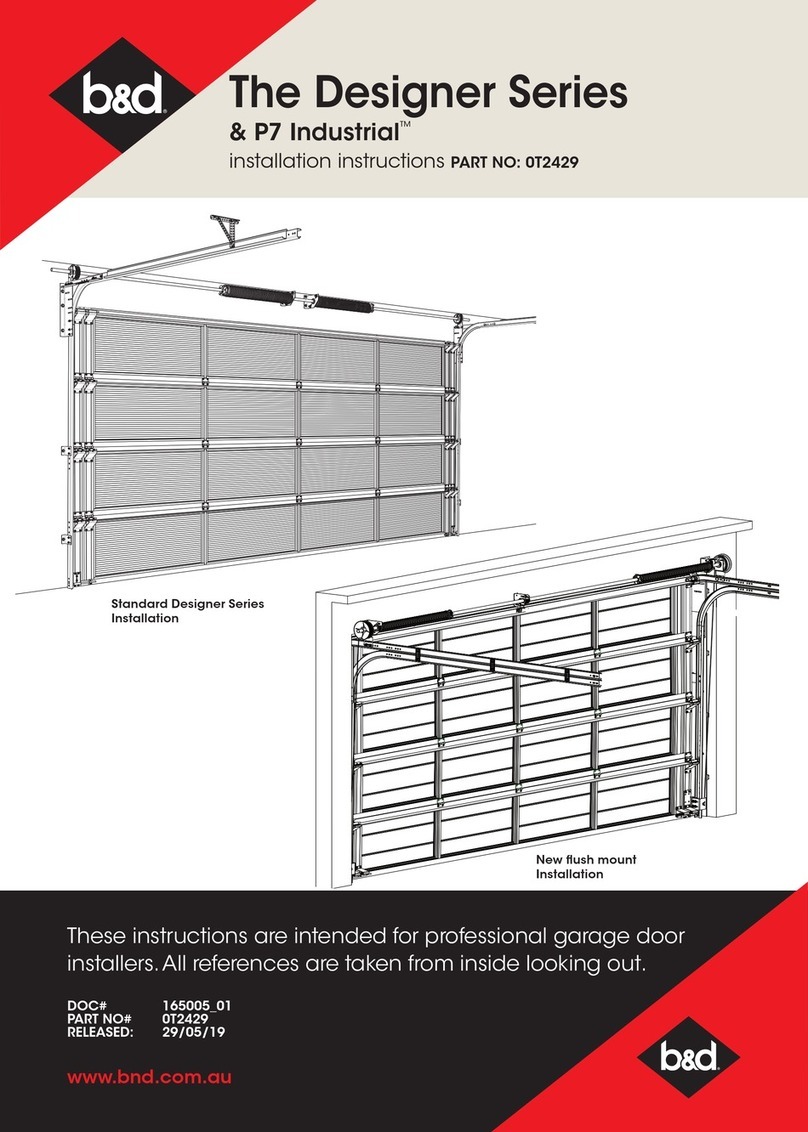

3. TYPES OF OGS

W–opening width

H–opening height

N- lintel

standard

N = 900 mm

vertical

N = H + 500 mm

Somati system s.r.o., Jihlavská 510/2c, 664 41 Troubsko

IČ: 29260159, DIČ: CZ29260159

tel: +420 547 427 011, www.somati-system.cz

11

high-lift lintel

900mm > N < (H + 500 mm)

low-lift lintel

N = 750 mm

All variants can be designed with passage door or without passage door. Passage door must

always open to the wall.

Somati system s.r.o., Jihlavská 510/2c, 664 41 Troubsko

IČ: 29260159, DIČ: CZ29260159

tel: +420 547 427 011, www.somati-system.cz

12

4. CHECK OF CONSTRUCTION READINESS ACCORDING TO THE

DRAWING

W–opening width

H–opening height

N- lintel

P–floor level

Picture 1

•See dimensions in the enclosed drawings.

•Mark centre of the opening.

•Make a level line on the wall (horizontal line at height 1m above clear floor level).

•If any of the dimensions are bigger than in the documentation, it is not possible to

install the gate.

Somati system s.r.o., Jihlavská 510/2c, 664 41 Troubsko

IČ: 29260159, DIČ: CZ29260159

tel: +420 547 427 011, www.somati-system.cz

13

5. INSTALLATION OF GUIDES

Side guides are delivered in a set with vertical lathing. Right and left guide install according

to the provided drawings. Standardly the load-bearing structure is anchored through each

second pre-prepared hole and always through the highest and lowest holes. After the

installation put Palusol on the vertical lathing.

Standard distance of guide anchoring from the edge of opening

Picture 2

A –guide

B –vertical lathing

C –rail, mounted on the guide

D –Palusol, glued on the guide after the

installation (e.g. with glue Colgel, Mamut

Glue)

Picture 3

1. Mark on the guides distance 1m from

the bottom edge.

2. Mount left and right guide on the

wall at a distance from the edge of

the opening, indicated in the installa-

tion drawing. Vertical pitch of the an-

chor points must be max. 1 m.

3. Check the correct distance of the

guides by inserting horizontal lathing

between the guides. The lathing

should be tightly attached to the

guides on both sides.

4. Align the guides into the vertical

plane and tighten the anchor mate-

rial.

Somati system s.r.o., Jihlavská 510/2c, 664 41 Troubsko

IČ: 29260159, DIČ: CZ29260159

tel: +420 547 427 011, www.somati-system.cz

14

6. INSTALLATION OF BRACKETS

6.1 OGS STANDARD AND HIGH-LIFT

standard:

high-lift:

N = 900 mm

900mm > N < (H + 500 mm)

Picture 4

The bracket pitch is shown in the en-

closed installation drawing.

Standard bracket distance [1.3] from the

inner edge of the track is 25 mm. The

bracket is mounted just above the guide

[2.1] - standardly: V = 530 mm

- high-lift lintel: V = N - 370 mm

6.2 OGS VERTICAL

N = H + 500 mm

Picture 5

The bracket pitch is shown in the en-

closed installation drawing.

Standard bracket distance [1.3] from the

edge of the track is 25 mm. The bracket

is mounted just above the guide [2.1].

Somati system s.r.o., Jihlavská 510/2c, 664 41 Troubsko

IČ: 29260159, DIČ: CZ29260159

tel: +420 547 427 011, www.somati-system.cz

15

6.3 OGS LOW-LIFT

width W ≤ 3 m

N = 750 mm

Picture 6

For low-lift gates are used guides [2.1] with

cut-out. The inserting bracket [7.5] for

transfer pulley is placed at the top of the

guides. The inserting bracket is anchored to

the wall through the holes in the guide.

Insert shaft with pair of pulleys [7.1a] into

the cut-out of the bracket. The setting

screws on the pulley can be loosened and

the pulley moved so that the bearing [7.6]

can be mounted using two screws with nut

and spring washer. Fix the pulleys in the

correct position in the later stage of the in-

stallation.

Picture 7

Picture 8

Somati system s.r.o., Jihlavská 510/2c, 664 41 Troubsko

IČ: 29260159, DIČ: CZ29260159

tel: +420 547 427 011, www.somati-system.cz

16

width W > 3 m

N = 750 mm

Picture 9

On inserting bracket [7.5] is mounted addi-

tional part [7.8] and reduction for shaft fix-

ing [7.7] by using screws M12x30. Place

the shaft through the reduction hole, put

on it a short spacer tube, pulley (with bear-

ing) [7.1b], long spacer tube and on the

outside of the additional part [7.8] secure

the shaft with a safety ring.

Picture 11

Picture 10

Somati system s.r.o., Jihlavská 510/2c, 664 41 Troubsko

IČ: 29260159, DIČ: CZ29260159

tel: +420 547 427 011, www.somati-system.cz

17

Picture 12

On the ceiling, mark the position of the ceiling parts of the winding roller brackets

[7.2]. Distance X from the wall is shown in the installation drawing for the particular

gate. The inner edge of the bracket is standardly in plane with the edge of the open-

ing; the pitch of the brackets is standardly equal to the width of the opening W. Verify

alignment of diagonals Y (see pic. 12). After anchoring of the brackets [7.2] mount side

profiles [7.3] (see pic. 13 - 14) on them using screws and nuts with indentation.

Somati system s.r.o., Jihlavská 510/2c, 664 41 Troubsko

IČ: 29260159, DIČ: CZ29260159

tel: +420 547 427 011, www.somati-system.cz

18

Picture 13

Picture 14

Table of contents

Popular Garage Door Opener manuals by other brands

TOPP

TOPP T240 Instructions for installation and use

Genie

Genie Series GCG manual

Nice

Nice AVIO500 Instructions and warnings for installation and use

SkyLink

SkyLink ATOMS ATR Series instruction manual

DoorHan

DoorHan SLIDING-1300 Installation and operation manual

Chamberlain

Chamberlain HJ quick start guide

ALSE

ALSE Stocco 5000 user manual

Beninca

Beninca KEN3 Operating instructions and spare parts catalogue

Vimar

Vimar Elvox EF01.1 Installation and operation manual

Chamberlain

Chamberlain GT owner's manual

Force

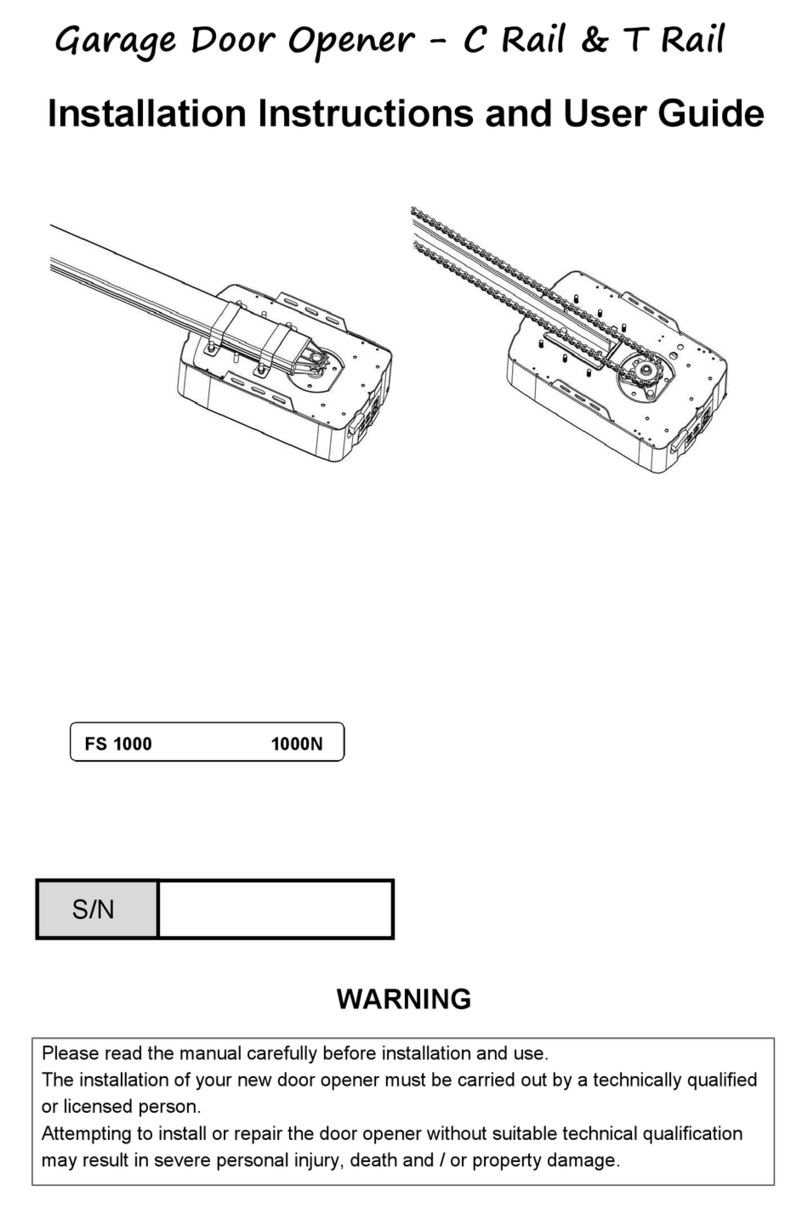

Force FS 1000 Installation instructions and user guide

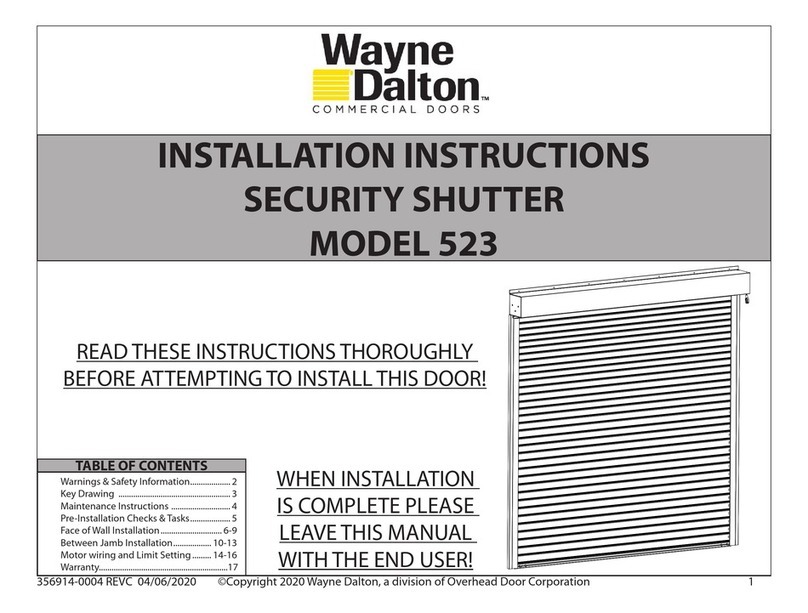

Wayne-Dalton

Wayne-Dalton 523 installation instructions