4.ADJUSTABLE PRESET PARAMETERS

*Caution: very light doors may require a lower speed setting

The chart below shows all the adjustable parameters for version 2 software.

Follow the procedure outlined in step 9 to make any necessary changes.

**In versions 2.06 & prior, d1 and d2 adjust from 1-199 seconds.

**Beginning with version 2.07, these parameters may be set to 1-8, 10, 12,14, 16, 20, 25,

30 or 60 seconds.

-A double dash (--) is a reserved parameter that is not implemented.

CODE

-The display will show the current value or setting of

the parameter.

-When the SET button is released, the display will show

the parameter that was just changed. Another parameter

may be changed, or the toggle circuit turned on to check the

changes just made. In versions 2.12 and up the SET button

may be double clicked to exit the menu (toggle must be on).

-With the display reading 2d or da press and HOLD the

SET button until dS (data save) is displayed. All of the

changes are now stored in the control's memory.

This step must be performed or the control will revert to

the default settings after a power failure.

-Set the reversing sensitivity as required using R10. Do not

leave this adjustment at minimum. Horton recommends setting

the sensitivity so the door will reverse at 28 ft.lb. or less.

-When all adjustments have been made and checked, be

sure the toggle circuit is on.

10th Step -Saving new settings

-While holding the SET button,

press the UP or DOWN button to modify the setting.

2.190d1

R

+100

UP

UP

+100

R

+100

DOWN

SET

DOWN

SET

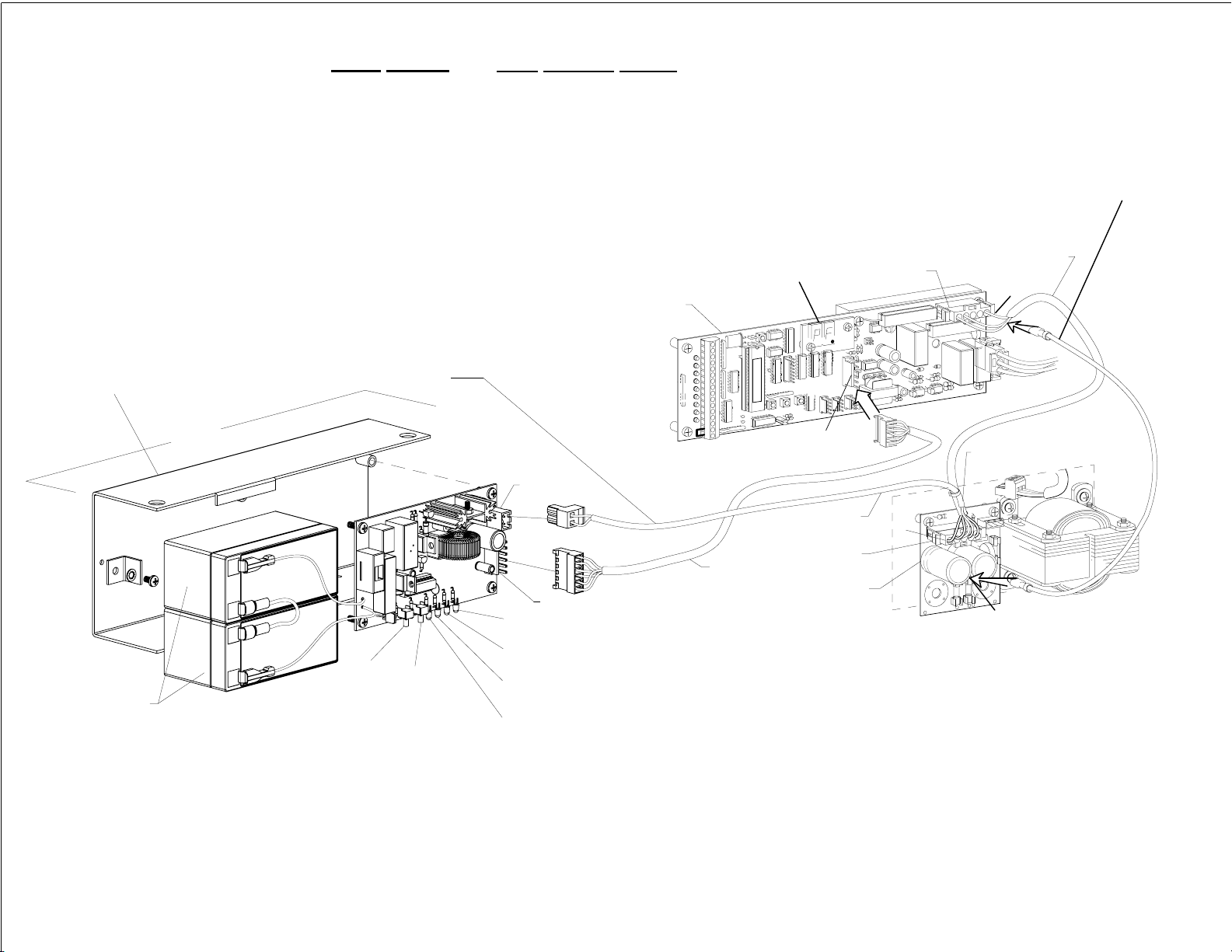

-Refer to the chart in section 4 for a list of codes for

adjustable parameters.

-Scroll through the parameter list using the UP and

DOWN buttons until the parameter to be changed is

found.

-When the parameter to be changed is found, press

and hold the SET button.

-The display will switch to the menu of adjustable parameters

-In versions 2.10 and up, the right decimal point will be blinking

-Turn the toggle switch OFF

Or for versions 2.12 and up, leave the toggle ON and

double click the SET button.

A chart of preset values is shown to the right.

If any speeds or other settings need to be changed, follow this procedure:

9th Step - Changing parameter settings

3. ADJUSTING PARAMETERS

UP

UP

R

+100

SET

R

DOWN

DOWN SET

UP

R

+100

SET

DOWN

OP (power fail OPen)

H202.4

OP/CLPower Fail

oF

3 (factory set - most senistive - 0 off)

on (version 2.13 & up only)

on (version 2.07 & up only)

oF (version 2.03 and up only)

oF (version 2.05 and up only)

oF(if lock stays unlocked in day mode)

oF (All open speeds)

on (version 2.07 & up only)

1 (Set during initialization)

oF (Never used)

oF (on)(Version 2.03 & up only)

oF(fail-secure) (on fail-safe)

oF (monitored lock)

oF (on if Horton lock is present)

oF (on)(Version 2.03 & up only)

oF (version 2.03 & up only)

on (version 2.06 and up only)

OBstruction

no Adjustment permitted

Sidelite Protection

TYpe

Jam Sensing

reverse on encoder Pulse

Unmonitored Lock

daytime 1-way Lock

daytime Lock

Close braking

Lock present

brake on recycles

fail-SAfe lock

Power fail Night mode

SLow

Bistable Lock

APex

1-2-3

oF/on

oF/on

oF/on

oF/on

0-3

oF/on

oF/on

oF/on

oF/on

oF/on

oF/on

oF/on

oF/on

oF/on

oF/on

oF/on

75% of stroke

4

4

oF (no)

oF (no)

(as determined by learn cycle)

oF (no)

12*

10

on (yes)

8" (adjustable in inches)

3 (factory set - do not change)

3 (factory set - do not change)

1 (factory set - do not change)

1 sec

FACTORY PRESET VALUE

1 sec

3

3

Partial Open position

Auto Seal

cycle test

total Stroke

open Check Point

Stop OKon first run

delay time 2 (partial open)

Heavy-duty door/motor

PARAMETER

CloseCheck

Open Check

Open Speed

Open cUshion

delay time 1 (full open)

Close cUshion

Close Speed

oF/on

12-199"

8"-ts

50-90% ts

1-60**

oF/on

oF/on

oF/on

0-15

0-15

0-15

ADJUSTS

0-15

1-60**

0-15

0-15