measure and predict with confidence

B04547_02_E00_00 SO-269-1004662_rev01 HBM: public

© HBM, Inc. All rights reserved. All details describe our products in general form only.

They are not to be understood as express warranty and do not constitute any liability whatsoever.

Americas:

HBM, Inc. · 19 Bartlett Street · Marlboro · MA 01752 · USA · Tel.: (800) 578 4260 · Email: in[email protected]Asia: Hottinger Baldwin Measurement (Suzhou) Co., Ltd. · 106 Heng Shan Road · Suzhou 215009 · Jiangsu · China

Free hotline: 4006217621 (only in China) · Tel.: +86 512 682 47776 · Email: hbmchina@hbm.com.cn

Europe: Hottinger Baldwin Messtechnik GmbH · Im Tiefen See 45 · 64293 Darmstadt · Germany

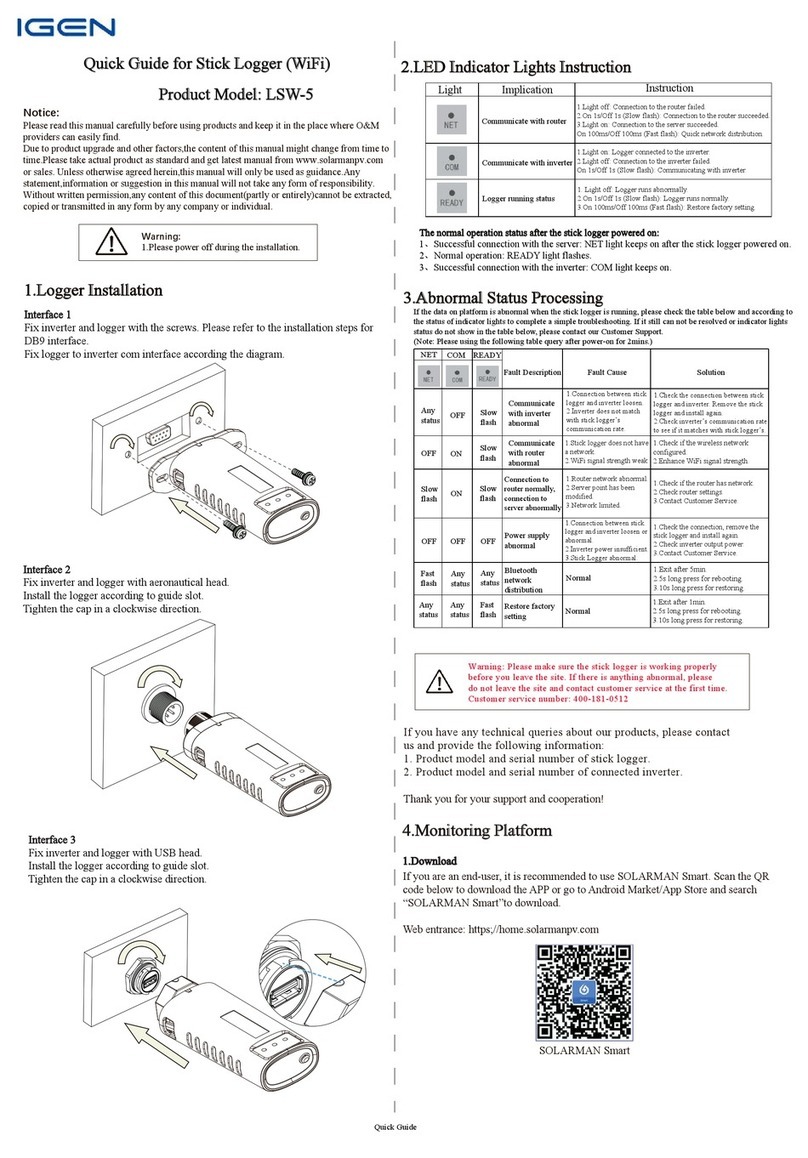

Instructions

Assemble a stack before applying serviceable (blue)

threadlock to Phillips head screws.

1. Apply serviceable (blue) threadlock to the four (4)

M5 set screws (E) in each caselink (D). Use a 2.5

mm hex wrench to turn set screws back in the

caselink before installing the caselink on a

module.

2. Connect two (2) stacked modules by inserting two

(2) caselinks (D) in the slots on each end of the

modules.

3. A set of four (4) caselinks can hold two (2) stacked

modules together.

Kit 1-CASEMOUNT2-2 has 1-CASELINK-RUG-2

for two (2) modules. Kit 1-CASEMOUNT3-2 has

1-CASELINK-RUG-2 for three (3) modules.

4. Connect a bracket (F or G) to the caselinks using

M5 flat screws (A), serviceable (blue) threadlock

and a #2 Phillips screw driver. Apply serviceable

threadlock and tighten each screw until secure

using a #2 Phillips screw driver.

5. Tighten the set screws (E) in each caselink using

a 2.5 mm hex wrench. Tighten the screws to 3.6

N-m (32 in-lbs) torque.

6. Install brackets (F or G) on modules and verify measurements before drilling and tapping holes (M6 18-8 1.0 pitch).

The Mounting diagram below is not at 1:1 scale. The dimensions can be used as a guide to tap the holes. The

mounting holes in the brackets area slightly oversized to allow for assembly tolerances. Apply serviceable threadlock

to M6 screws (B) and install them through the three (3) holes in each bracket (F or G) and into the tapped holes.

Tighten the screws to 6.1 N-m (54 in-lbs) torque.

Installing a UPX kit (1-UPX002-2) Uninterruptible Power Supply

Each UPX kit includes four (4) SO-227-1002109 (M4) screws to install the uninterruptible power

supply on a mounting bracket.

1. Mount a UPX unit (H) on a bracket (F or G) using serviceable (blue) threadlock, four (4) M4

screws (C) and a 3 mm hex wrench.

2. Apply serviceable threadlock and tighten the screws (C) to 1.8 N-m (16 in-lbs) torque or

vibration may loosen screws and damage bracket threads.