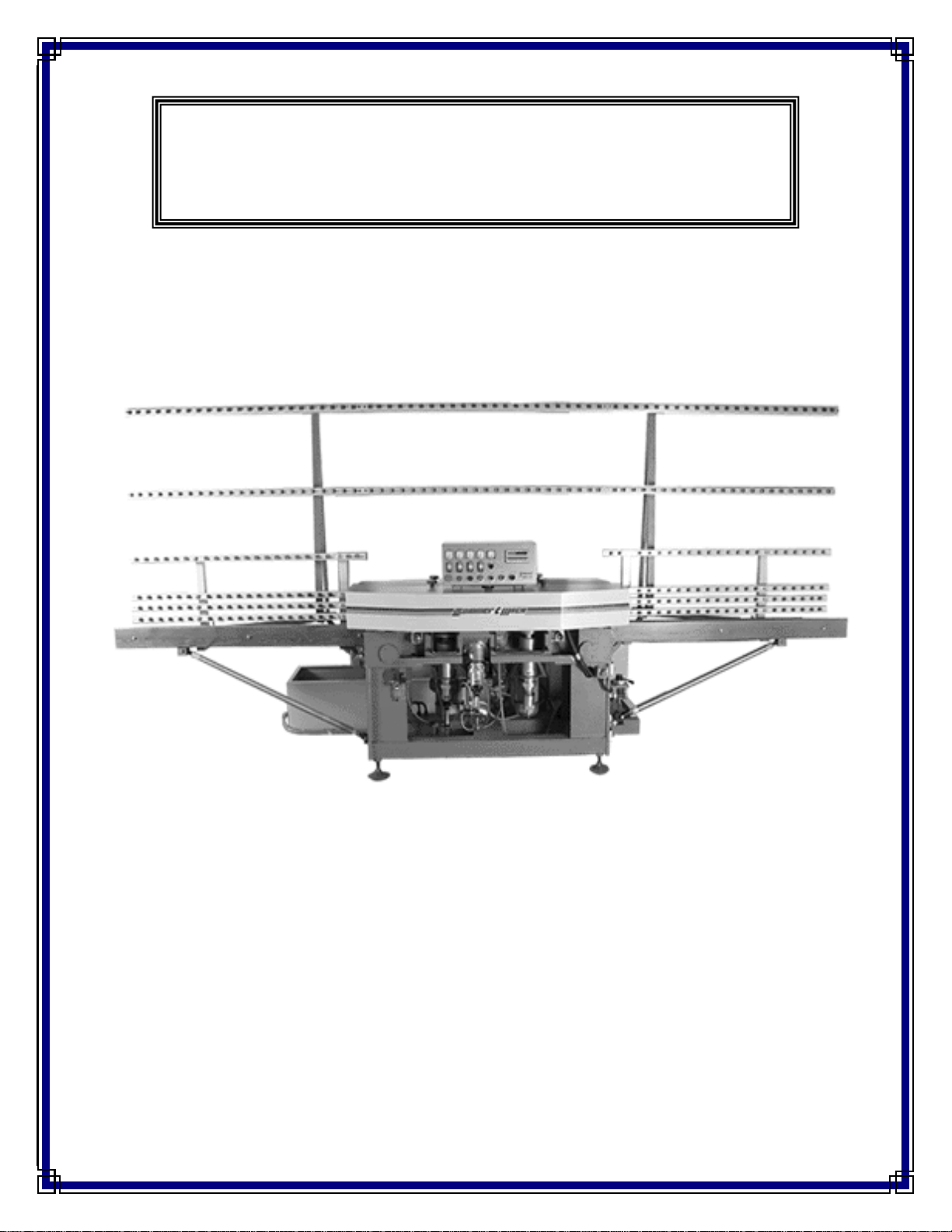

Sommer & Maca Industries VFE-4 User manual

VFE-4

FOUR-CUP FLAT EDGER

5501 West Ogden Avenue

Cicero, Illinois 60804

Tel: (708). 863.5446 / (773). 242.2871

Fax: (708). 863.5462

ATLANTA / CICERO / COMMERCE / DALLAS / MOONACHIE/ SANTA CLARA

Sommer & Maca Industries, Inc.

WARRANTY STATEMENT

SOMMER & MACA Industries, Inc. (Seller) warrants products of its manufacture to be free from defects in

materials and workmanship in normal use for six months from the date of shipment unless a shorter period is

provided elsewhere in this document. Seller’s obligation and Buyer’s exclusive remedy shall be limited to the

repair or replacement at Seller’s option, of defective parts within warranty period, provided Buyer gives Seller

immediate written notice of such alleged defects, and if requested by Seller, returns the defective parts to

Seller’s factory for Seller’ inspection.

The warranties contained herein are in lieu of any other warranty expressed or implied, including any warranty

of MERCHANTABILITY OR FITNESS FOR PURPOSE.

In the case of equipment furnished by Seller but not of Seller’s manufacturer, Seller’s liability to Buyer

hereunder. Adjustment at the manufacturer thereof makes to Seller. Seller shall in no event be liable for

consequential damages.

Warranties hereunder shall not apply to any equipment that shall have been damaged by misuse, neglect, failure

to perform maintenance or accident after the shipment thereof by Seller. In addition thereto, this warranty shall

be null and void if:

1. Machine is used in a manner contrary to instruction or after malfunction is noticed.

2. Buyer does not honor terms of payment.

3. Machine is modified or altered without the agreement of Seller.

PREFIX

We suggest to carefully follow the instructions in this manual and to regularly follow procedures of

maintenance, which will allow you to obtain a higher degree of reliability, safety and durability of the product.

This manual contains several advises and precautions for safety. We urge you to read them carefully.

In this way you will avoid danger, injuries and eventual damage to the machine.

Exclusively trained personnel must do maintenance and repairs.

INDEX

1.) Technical features

1.1) Machine dimensions

1.2) Electrical and pneumatic requirements

1.3) Machine performance description

2.) Safety rules

2.1) General safety rules

3.) Shipping, movement and storage

3.1) Machine shipping and crating

3.2) Packing and unpacking

3.3) Storage until installation

4.) Installations and connections

4.1) Environmental working conditions

4.2) Space requirements

4.3) Machine installation requirements

4.4) Electrical connection

4.5) Pneumatic connection

5.) Equipment description

6.) Main assemblies

7.) Operation cycle: commands, functions and settings

7.1) Wheel replacement procedure

7.2) Necessary spacing between glass pieces

8.) Machine circuits

8.1) Electrical circuit

8.2) Electrical specifications

A. General electrical characteristics

B. Motors

8.3) Pneumatic arrangement

9.) Maintenance

9.1) Preventive maintenance

9.2) Fuse list

10.) Troubleshooting solutions

11.) Annexes

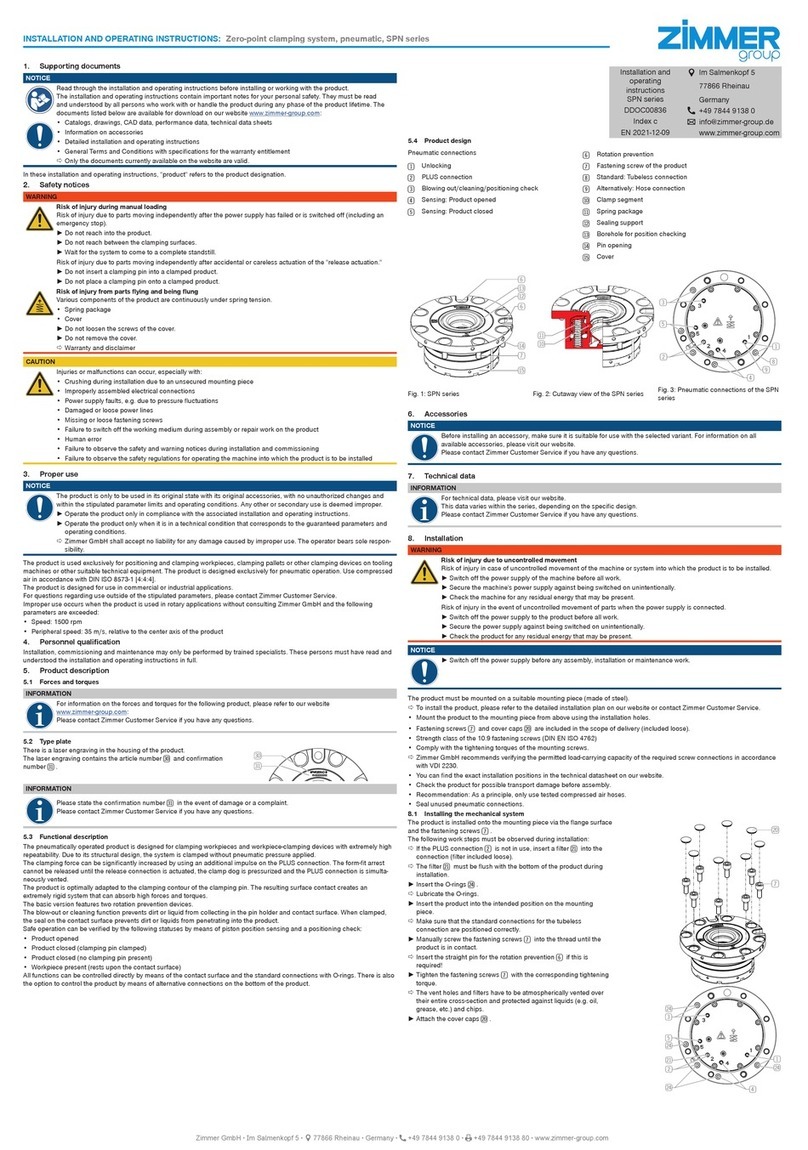

1.)

TECHNICAL FEATURES

1.1)

Machine dimensions

Length : 5000 mm (196.5”)

Width : 1300 mm (51”)

Total height : 2400 mm (94.5”)

Worktop height : 850 mm (33.5”)

Weight : 1300 Kg (2866.5 lbs)

1.2)

Electrical and pneumatic requirements

Voltage : 3-Phase/230Volts +/- 10%

Frequency : 60 Hz. +/-5%

Auxiliary service voltage : 24Volts/60Hz.

Pneumatic supply : 6 Bars (87 psi).

Installed power : 12 kW (16) hp +/- 10%

1.3)

Machine performance description

Workable thickness : 3 – 20 mm (1/8” - 3/4”)

Working speed : 0 – 3 m/min (0-9.84 ft/mn)

Adjustable removal : 0 – 2.5 mm (0 – 0.098”)

Coolant system : Closed circuit

2.)

SAFETY RULES

The machine is provided with all devices of protection both mechanical (chain guard, shelters, etc.) and

electrical (sensors, stops, etc.) in order to avoid any contact with moving parts by the operator.

It is absolutely prohibited for anyone to alter or remove any safety devices mentioned above with the

power on!!

Any kind of verification, control, cleaning, maintenance, change or substitution of parts must be done

with the power off and the main disconnect locked out. (see section 9)

The machine is moreover designed in conformity to CE as per the enclosed statement.

The manufacturer declines any and every responsibility for lack of following safety rules and of injury

prevention described below. He moreover declines every responsibility of damages caused by an improper use

of the equipment or changes made without authorization. It is also necessary for personal safety that no one

beside the operator remains in proximity of the equipment when in use.

2.1) General safety rules

When operating electric equipment, it is necessary to adopt the appropriate safety precautions to minimize the

risk of electrical shock or injuries. Before operating the machine, read the manual carefully and memorize the

following safety rules and save this booklet for future reference:

♦Keep the work area clean and orderly, as unorganized work areas encourage accidents.

♦Before starting, verify the condition of the machine. Check the standard operation and for broken and or

damaged parts. Replace all broken or damaged parts by a competent and authorized service person.

♦All repairs performed by unauthorized service personnel will void the warranty and will constitute operating

the equipment in an unsafe manner leading to potential danger.

♦It is absolutely prohibited to let children, outsiders, untrained, or people in poor health to touch or use this

equipment.

♦Verify that the electrical power source conforms to the electrical specifications before operating this

machine.

♦When installing the electrical power source, make sure that the machine is properly grounded.

♦Check the outlet to be appropriate and compatible with the automatic protection switch in the machine.

♦The extension cord if used must have a grounded receptacle, plug and cable as per code.

♦Never stop the machine by disconnecting the power.

♦Check periodically the condition of the cable and replace it should it become cut or frayed. This work is to

be performed only by qualified personnel.

♦Do not allow any personnel to come in contact with this cable.

♦Do not ignore these advices. Such an act will constitute an unsafe use of this equipment and will create a

potential danger.

♦Personnel authorized by the manufacturer must make repairs.

♦The manufacturer is available for immediate technical assistance to insure optimum performance and the

maximum production of the machine.

3.)

SHIPPING, MOVEMENT AND STORAGE

Specialized and competent personnel must perform all shipping operations of the machine.

3.1) The crated machine is easily transportable by a crane or a forklift with a minimum capacity of (3) tons

and lifting eyes as shown on the machine assembly drawing in the Annex 0 section of this manual.

Machine shipping and crating

In the act of moving be very careful to avoid bumping or dropping the machine or causing excessive

vibration to avoid damaging components.

3.2) After unpacking, make sure of the condition of the machine while checking to see if there is any visible

damage.

Packing and unpacking

If in doubt, do not use the machine and call the manufacturer’s customer’s service.

3.3) It is okay to store the machine in its original container providing that it is not stored in a place of high

humidity.

Storage until installation

In the case of a long or extended idle period or a period of nonuse after the machine has been used, it is

necessary to disconnect the power source and provide protection to the machine with a plastic cover to

avoid dust. Grease all parts that can be damaged by oxidation or moisture.

4.)

INSTALLATION AND CONNECTIONS

4.1) The machine can work at temperatures between 41 and 113 degrees Fahrenheit.

Environmental working conditions.

4.2) Make sure that the clearance provided around the machine is sufficient to be able to open all doors

completely and to perform all operations of maintenance.

Space requirements

4.3) Before placing the machine in its final location, proceed with the following checklist:

Machine installation requirements.

Check the ability of the floor to support the weight of the machine and its accessories.

Check the lighting around the machine. It should be free from shaded areas, inconvenient high

beams and or stroboscopic lights that could create dangerous conditions.

Check the condition of the machine for damage as a result of transportation.

Check to see that all feet of the machine are uniformly positioned on the floor.

After the machine has been placed in its working position, it must be correctly leveled using the

adjustable feet.

4.4) Work performed on electrical parts, electrical safety of this equipment is assured only when it is

correctly connected and properly grounded as per federal, state, and local codes concerning the same.

Electrical connection

It is mandatory to verify these basic safety requirements and when in doubt, ask for a check of the

electrical circuit by professionally trained personnel.

The manufacturer is not responsible for damages caused by an improperly connected machine.

WARNING: Interruption capacity of main circuit breaker: < 6 kA

Verify that the short circuit capacity of the supply is compatible

With the main circuit breaker.

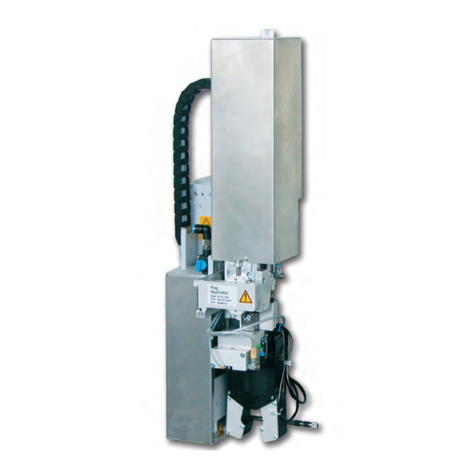

4.5) Compressed air is required and must be connected to the FRL (filter, regulator and lubricator) on the

outside of the machine.

Pneumatic connection

A shut off valve should be placed ahead of the FRL.

After pressurizing the pneumatic circuit, set the air pressure on the pressure gauge of the regulator to 6

bars which is approximately 90-psi minimum. Adjust the knob on the regulator to achieve the above

value.

5.)

EQUIPMENT DESCRIPTION

There are four spindles equipped with:

•1st

•2

diamond grinding wheel – 150 mm dia. (M1)

nd

•3

grinding wheel for rear arris – 100 mm dia. (M2)

rd

•4

grinding wheel for front arris – 100 mm dia. (M3)

th

polishing wheel for flat edge – 150 mm dia. (M4)

The diamond grinding wheel spindle M1 have a locknut and a knurled knob (see enclosed drawing MMD on

annex 4). One complete turn of the knob #3 on the drawing MMD will raise or lower the grinding wheel by 2

mm or approximately .079”. This knob has 40 grades; each grade is equal to variation of height of .002”.

The spindles for the arris edges and the flat polishing wheels work pneumatically, and are controlled

electronically to engage and disengage the operation of the electrovalves relative to every wheel.

6.)

MAIN ASSEMBLIES

1) Lever to regulate glass removal

2) Dial indicator for reading of quantity to be removed

3) Adjustable feet to level the machine

4) Knurled knob for diamond grinding wheel adjustment

5) Diamond grinding wheel motor M1

6) Rear arris grinding wheel motor M2

7) Front arris grinding wheel motor M3

8) Polish wheel motor M4

9) Pneumatic cylinder

10) FRL group (filter, regulator and lubricator)

11) Base

12) Conveyor motor to advance glass

13) Anchors to lift and move the machine

14) Support structure

15) Control panel (see annex. #1)

7.)

OPERATION CYCLE: COMMANDS AND FUNCTIONS

The machine operator is advised to do the following:

Warning:

Always make sure the pump is ON, before you run glass. Otherwise a major damage could be caused

to the machine.

The switching on of the spindles must be done progressively as follows:

1. Turn motor M1 on (diamond grinding wheel).

2. Turn motor M2 on (rear arris grinding wheel)

Note: The pump will be turned on automatically when you turn on M1

3. Turn motor M3 on (front arris grinding wheel)

4. Turn motor M4 on (regular flat polishing wheel)

WHEELS GRIT PART#

M1 140-170 (.025inch DEEP) 3-97302-01

M2 3-97301-02

M3 3-97301-02

M4 3-97300-01

AB 280 CUP

10S40

TYPE

FOUR CUP MACHINE WHEELS ARRANGEMENT

FLAT EDGE CUP (DIAMOND)

AB 280 CUP

The adjustment of the amount of glass to be removed is located under the infeed glass conveyor side and is

changed by operating the lever (0 – 0.4”) as seen on the decimal dial indicator.

NOTE THAT MAXIMUM

MATERIAL REMOVAL IS 0.098” (3/32”)

For optimum machine output, it is recommended to use these settings.

mm 4 TO 8 8 TO 12 12 TO 20

inches 1/8 TO 5/16 5/16 TO 1/2 1/2 TO 3/4

bars 2 2 2

psi 29 29 29

bars 3.5 3.5 TO 4.5 4.5 TO 5

psi 51 51 TO 66 66 TO 73

m/mn 1.4 TO 1.8 1.3 TO 1.6 0.5 TO 0.8

ft/mn 4.6 TO 5.9 4.26 TO 5.25 1.64 TO 2.62

CONVEYOR SPEED

SPINDLE 2 & 3

AIR CYLINDER PRESSURE

GLASS THICKNESS

WHEELS #2, #3 & #4 SETTING

SPINDLE 4

AIR CYLINDER PRESSURE

NOTES:

1- ONLY METRIC CONVEYOR SPEED CAN BE ENTERED INTO CONTROL PANEL

2-MINIMUM PRESSURE ON ALL CYLINDERS SHOULD BE 2 BARS

3- LOWER PRESSURE ON M4 WHEN POLISHING SMALL TAIL STOCK

7.1)

Wheel replacement procedure

When replacing grinding or polish wheels, insert spindle-locking wrench over the flats on the spindle hub. Place

30mm box wrench or 8mm Allen wrench on the spindle locking screw, hold firm and rotate the spindle

clockwise. This will loosen locking screw. Reverse hub rotation to tighten locking screw.

In the event you must replace the diamond grinding, proceed as follows:

•Lower the diamond-grinding wheel via the knurled knob as far as possible while leaving the locknut in its

previous position.

•Remove the old wheel as mentioned above

•Install the new wheel

•Turn water on

•Turn motor M1 on if you working on spindle 1

•Adjust conveyor speed to minimum level

•Load a piece of glass into the machine

•Set the conveyor direction switch to forward

•Press the conveyor start button

•Wait until glass passes the grinding wheel, and set the conveyor direction switch to forward

•Remove glass and measure the amount of glass removed

•Raise the knurled knob until the desired amount of glass is removed and retighten locknut

•Gradually increase the glass conveyor speed to its desired level

In the event of glass breakage, press the emergency stop button

•Decrease speed control setting and remove the glass from the machine by reversing the glass travel

direction.

•Correct the problem causing the breakage and resume operation.

7.2)

Necessary spacing between glass pieces

•Leave 1 inch in between glass pieces of same thickness, so you can put your fingers between the two glass

pieces to remove it from glass conveyor.

•Leave 8 inches in between glass pieces of different thickness, because that is the necessary distance for

arris and polish spindle to retract and engage.

8.)

MACHINE CIRCUITS

8.1)

♦Schematic and components annex #2

Electric circuit

♦Control panel annex #1

8.2)

Electrical specification

A) General electrical characteristics

Machine voltage : 3 phase/230 volts +/-10%

Frequency of operation : 60 Hz +/-5%

Auxiliary service voltage : 24 volts/60 Hz

Pneumatic service voltage : 24 volts/60 Hz

B) Motors

Motor M1 : 2 pole/380 volts/60 Hz/3 hp

Motor M2 : 2 pole/380 volts/60 Hz/2 hp

Motor M3 : 2 pole/380 volts/60 Hz/2 hp

Motor M4 : 2 pole/380 volts/60 Hz/3 hp

Pump motor : 2 pole/380 volts/60 Hz/0.5 hp

Conveyor motor : 4 pole/380 volts/60 Hz/0.5 hp

Complete with 160:1 reducer

8.3)

♦Pneumatic circuit outline Annex #3

Pneumatic arrangement

9.)

MAINTENANCE

WARNING!

Any kind of verification, cleaning, maintenance, replacement and substitution of parts must be performed

with the power off and the main disconnect locked out. (see section 2)

9-1.) Preventive maintenance

•When switching the machine on, check the air pressure. It must be at or above 6 bars / 90psi.

•It is necessary to keep the machine clean from glass grindings regularly to prevent premature wear.

•It is also necessary to keep the machine inside of the spindle tub clean from broken glass to prevent damage

to the water delivery system.

•It is necessary to continually check the condition of the grinding and polishing wheels and replace them as

required.

•Every 40 hours of operation drain the condensation from the FRL group. Replenish oil reservoir with a good

grade of Air Tool Oil (Mobil Almo 525 or equivalent). P/N 299-0148-0

•Every 200 hours of operation lubricate all of the ball bearing units with a NLGI #2 wheel bearing grease.

9-2.) Fuse list

Somaca

VFE 4

Vendor

Part Number

Fuse ID

Description

Vendor

Part Number

Qty

4700302002

4FU1

FUSE 1A 400V 10x38mm 120ka

Shawmut

16011-G

2

4700330102

4FU2

FUSE 6A 500V 10x38mm 120ka

Shawmut

16523-G

1

4700302001

3FU1

FUSE 4A 400V 10x38mm 120ka

Shawmut

16019-G

2

4700330103

1FU1

FUSE 32A 400V 10.3x38mm 100ka

Shawmut

16043-G

3

4700302004

1FUG

FUSE 50A 400V 14x51mm 100ka

Shawmut

17551-G

3

OSHA 29 CFR 1910.147 standard requires the placement of a

lockout on energy stored equipment in a manner that will

render them safe to work on and prevent the inadvertent start

up of such equipment, in accordance with an established

procedure, and ensure that the energy-isolating device and

the equipment being controlled cannot be operated, while it

is being serviced or maintained, until the lockout device is

removed.

10.)

TROUBLE SHOOTING SOLUTIONS

PROBLEM CAUSE

SOLUTION

Motors do not spin Burnt fuse Replace

Thermal out Reset

Electrical interruption Verify

No pneumatic movement Not enough air pressure Verify pressure

At 6 bars / 90 psi. Minimum

Solenoid valve broken Check and replace

or defective

Water pump not working Burnt fuse Replace

Thermal out Reset

Electrical interruption Verify

11.)

ANNEXES

Main Assembly Annex#0

Control panel Annex #1

Electrical circuit outline Annex #2

Pneumatic circuit outline Annex #3

Assemblies Annex #4

Programming of “Mini-Job” Controller Annex #5

ANNEX #0

ANNEX #1

Table of contents

Other Sommer & Maca Industries Industrial Equipment manuals