Sommer & Maca Industries TTW 366 User manual

TILT TOP HD GLASS

WASHING MACHINES

OPERATION AND MAINTENANCE

MANUAL

Sommer & Maca Industries, Inc.

5501 West Ogden Avenue

Cicero, Illinois 60804

Tel: (708) 863-5446 / (773) 242-2871

Fax: (708) 863-5462

ATLANTA / CHICAGO / DALLAS / MOONACHIE / LOS ANGELES / SANTA CLARA

TABLE OF CONTENTS

SECTION PAGE

1 – SAFETY

GENERAL SAFETY INFORMATION 1

Introduction 1

Safe Operating Considerations 1

Care Exercised During Installation 1

Quality and Frequency of Inspection and Maintenance 1

Common Sense Approach to Operation 1

NOTES, CAUTIONS and WARNINGS 1

Notes 1

Cautions 1

Warnings 1

GENERAL PRECAUTIONS 2

Special Warning: OSHA, safety devices, guards and covers 2

2 – DESCRIPTION

GENERAL DESCRIPTION 3

Model TTW 366, 6 Brush Washer 3

Model TTW 486, 6 Brush Washer 4

Model TTW 606, 6 Brush Washer 5

Model TTW 726-½, 6 Brush Washer 6

Model TTW 726-¾, 6 Brush Washer 7

Model TTW 846, 6 Brush Washer 8

Model TTW 966, 6 Brush Washer 9

3–RECEIVING

UNCRATING 10

InspectingCrate 10

Notification 10

Removing Crate 10

SECTION PAGE

4–INSTALLATION

FACILITIES REQUIREMENTS 11

FloorSpace 11

CompressedAir 11

Electrical Requirements 11

Plumbing 12

Water Requirements 12

5 – OPERATING INSTRUCTIONS

STARTINGTHEWASHER 13

Cleaning Action Quality 14

TEMPERATURE CONTROLLER 14

SetpointAdjustment 14

Auto-TuningProcedure 15

6 – MAINTENANCE

MAINTENANCE CONCEPT 16

DAILY INSPECTION 16

DAILY MAINTENANCE 16

WaterTank(s) 16

WEEKLY MAINTENANCE 16

Blower Intake Air Filter(s) 16

Conveyor Chain 16

MONTHLY MAINTENANCE 17

SprayPipes 17

Washer Surfaces and Pans 17

SECTION PAGE

6 – MAINTENANCE (continued)

BRUSH ADJUSTMENT 17

Brush Adjustment for Wear 17

LowerBrushAdjustment 17

Upper Brush Adjustment 17

Glass Thickness Adjustment 18

Conveyor Chain Idler 18

DriveChain 18

Blower Tube (Air Knife) Adjustment 18

BeltAdjustment 18

ControlPanel 18

7 – TROUBLESHOOTING

PROBLEM/CAUSE/POSSIBLE SOLUTION 19, 20

TEMPERATURE CONTROLLER 21

Tuning the FUJI Temperature Controller 21

8 – PART LOCATIONS

CONTROLS 22

PANEL 23

CLEANING & DRYING 24

BELTS; REMOVING BEFORE RAISING UPPER SECTION 25

BRUSHSECTION 26

RAPID THICKNESS ADJUSTMENT; QUICK BRUSH ADJUSTMENT 27

BRUSH BELT; CONVEYOR CHAIN 28

DISCHARGE END VIEWS 29

GUARD REMOVAL 30

GENERAL PART LIST 31

RIGHTSIDEVIEW 32

LEFTSIDEVIEW 33

WARRANTY STATEMENT 34

SECTION 1

SAFETY

FAILURE TO OBSERVE THE WARNINGS, CAUTIONS AND INSTRUCTIONS LISTED IN

THIS MANUAL AND ON THE DECALS ATTACHED TO THW GLASS WASHING MACHINE

COULD CAUSE SERIOUS INJURY TO PERSONNEL OR DAMAGE TO EQUIPMENT.

GENERAL SAFETY INFORMATION

Introduction

This manual contains instructions and operating and

maintenance procedures for Somaca Glass Washing

Machines (herein called “Washer”). The machines

must always be operated and maintained in

accordance with the instructions and procedures

contained in this manual. Only qualified personnel

thoroughly familiar with the operating and

maintenance instructions should operate and maintain

this equipment.

Safe Operating Considerations

Safety must be observed through all facets of

operation and maintenance. Proper tools and

operating procedures must always be used to prevent

accidents that could cause injury to personnel or

damage to equipment. Safe, reliable operation and

long service are dependent on three important

considerations:

1. Care exercised during installation

The most important single factor of installation is

the alignment and leveling of one to three

sections (large machine) that comprise the

Washer. These must be installed properly on a

solid floor to maintain critical alignments.

2. Quality and frequency of inspection and

maintenance

Frequent inspection and recommended

lubrication procedures must be performed to

ensure safe and trouble-free operation and

machine longevity.

3. Common sense approach to operation

The Washer is not necessarily a complex device

due to its functionality and the flexibility it

offers; however, there is no witchcraft involved

in its operation. Patience and time spent in

acquiring familiarity with the aspects of

operation will reveal most of its secrets. The

most important rule is:

DON’T TAKE CHANCES!

NOTES, CAUTIONS AND WARNINGS

1. Notes

The notes contained throughout this manual

provide additional information to carry out the

operating and maintenance procedures. Any

particular note is listed just prior to the

procedural step to which it applies. This is an

example of a NOTE format.

2. Cautions

The cautions in this manual contain

instructions and information concerning

operation and maintenance procedures that, if

not followed, could cause damage to

equipment, parts and facilities. Like notes,

cautions are listed just prior to the steps to

which they apply. This is an example of a

CAUTION format.

3. Warnings

The warnings in this manual contain

instructions and information concerning

operation and maintenance procedures that, if

not followed, could cause injury to personnel.

Warnings also are listed just prior to the steps

to which they apply. This is an example of a

WARNING format.

GLASS WASHING MACHINES 1

SECTION 1

GENERAL PRECAUTIONS

The precautions listed below are in general; however,

failure to practice them could result in personal injury

or damage to property. These precautions are not all-

inclusive. Specific cautions and warnings are listed

throughout this manual. They may address issues that

are peculiar to a specific operation or industry. In

addition, employers are subject to the federal

Occupational Safety and Health Act (OSHA) of

1970, as amended, that requires an employer to keep

abreast of the regulations that are continually released

under its authority.

GLASS WASHING MACHINES 2

1. ALWAYS operate and maintain the Washer

in accordance with the instructions and

procedures of this manual.

2. ALWAYS load glass onto the entry conveyor

and allow the rollers to drive the glass into the

machine. DO NOT feed glass directly into the

main washing section by hand. DO NOT wear

loose fitting clothing that could get caught in

the moving parts of the machine. DO NOT

exceed the capacity of the Washer.

3. DO NOT open inspection doors, covers or

guards while the unit is in operation except in

special circumstances that are addressed later

in this manual. NEVER work on the Washer

or related components unless the electrical

power and motor drive have been locked out

and tagged. The National Electrical Code

requires a manually operated disconnect

switch located within sight of the machine or

other means by which the conductors of the

circuit can be disconnected from their source

of supply (Parts F and I of Article 230).

4. DO NOT use the Washer for any purpose for

which it was not designed. It is to be used only

to wash flat float, plate, tempered, specialized

glass and mirror. All tags, stickers or tape

should be removed prior to washing.

5. DO NOT poke or prod into the openings of the

Washer with a rod, bar or stick.

6. ALWAYS have a clear view of the loading and

unloading points and all safety devices of the

Washer. Be aware of all the locations of the

emergency stop switches.

7. KEEP the area around the Washer free of

debris and obstacles. This includes the

electrical control cabinet, detergent and rinse

tanks, and entry and exit conveyors.

8. NEVER operate the Washer without guards

and all safety devices in position and

functioning.

9. ALWAYS allow the Washer to stop naturally

by ramping down. DO NOT attempt to

artificially brake or slow the movement of the

Washer or any of its components.

10. ALWAYS wear safety glasses, proper clothes

and other necessary safety equipment while

operating and maintaining the Washer. When

in doubt, consult with the shop safety

representative(s).

11. ALWAYS wear safety glasses, proper clothes

and other necessary safety equipment while

handling glass. When in doubt, consult with

the shop safety representative(s).

Many of the photographs used to illustrate this manual were taken of partially assembled machines or of

machines with guards removed for clarity. This should not be construed as a safe method of operation when

running this machine. NEVER operate the Washer unless all interlocks, safety devices and guards are

operating properly and properly installed. Failure to do so could result in injury or death.

GLASS WASHING MACHINES 3

SECTION 2

DESCRIPTION

GENERAL DESCRIPTION

All Somaca Glass Washing Machines operate in

basically the same way. The glass is scrubbed clean

(sometimes with a pre-wash) by cylindrical bristle

brushes as it is conveyed through the machine on

rubber covered rollers. Spray pipes apply detergent

water followed by rinse water to the top and bottom

of the glass. After this process, the glass is dried by

internal air dryers that remove the water from both

surfaces, leaving the glass thoroughly dry.

Four brush models can be used with regular plant

water to remove such contaminants as fingerprints,

shop dust or glass grindings. Cold water is

satisfactory in most cases; however, warm water is

preferred.

Six brush models with the recirculating detergent

system are recommended for cutting oil, grease and

heavier contaminants.

Four and six brush Washers use the same air blast

method. However, six brush Washers typically have

more air knives for drying with a larger blower.

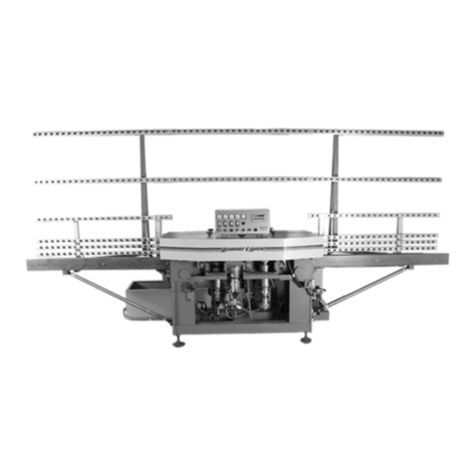

36 inch GLASS WASHING MACHINE

Model TTW 366, 6 Brush Washer

Capacity - The Washer accepts 5½ inch glass circles

up to full width sheets from single strength to ¼ inch

thicknesses. The line speed is variable from 0 to 35

feet per minute.

Brushes - The cylindrical bristle brushes are 3½

inches in diameter, mounted on stainless steel cores

and individually adjusted for proper height by raising

the tilt-top. Brushes are V-belt driven by a common

motor.

Drying System - A 10 HP blower with an air intake

filter is connected to four air knives; two knives

above the glass and two knives underneath the glass.

Rollers - The feed and pinch rollers are 2½ inches in

diameter, made with stainless steel journals and

heavy steel tubing with a precision ground Nitrile

covering. The rollers are driven by a ⅛HP DC gear

motor using chain and sprockets.

Bearings - The brushes are supported on ball

bearings. The upper pinch rollers are mounted on

pivoting brackets. The rotating action of the pivots

smoothes the movement of the thicker pieces of glass

through the machine.

Frame - The frame is a one piece steel weldment

with machined upper sidebars. The infeed and

unloading conveyors are two feet long each. All

sections that become wet through normal operation

are either plated, coated or made from a corrosion

resistant material.

Electrical - The control panel is mounted on the

machine with conduit wiring. All electrical circuitry

is built to NEMA 12 specifications to meet OSHA

requirements. Every panel is UL approved.

The power requirements are 3 phase, 60 cycle,

208/230/460 volts. The electrical panel name plate

specifies the full load amperage.

Water - A water/detergent solution is applied

through spray pipes; one on either side of the glass

per brush. Threaded plugs on the spray pipe ends

allow for easy cleaning. The water usage is about 4½

gallons per minute without the Aqua-Miser rinse;

about 1½ gallons per minute with. There will be

minimal (zero) consumption (due to drag out and

evaporation) when used with the Aqua-Miser ready

option.

Options - The recirculating detergent system, miser

rinse system, Aqua-Miser ready (zero water), auto

glass thickness adjustments, power brush adjustment

and hydraulic power tilt-top are all options. A wetted

parts package constructed out of stainless steel for

use with a de-ionized water system is also an option.

MODEL

NUMBER STYLE BRUSH MOTORS WIDTH LENGTH HEIGHT

BLOWER

HP HEATER

TTW 366 36 inch 6 brush one 2 HP

one ⅛HP

4 feet

6 inches

6 feet

4 inches

3 feet

6 inches 10 5 kW

SECTION 2

48 inch GLASS WASHING MACHINE

Model TTW 486, 6 Brush Washer

Capacity - The Washer accepts single strength to ½

inch thick glass, from 11 inches wide 14 inches long

to full width sheets. The line speed is variable from 0

to 35 feet per minute.

Brushes - The spiral-wound brushes in “dense-fill”

construction are 6 inches in diameter, mounted on

stainless steel cores and individually adjusted for

proper height. Brushes are V-belt driven by a

common motor and can be individually adjusted, to

compensate for wear, by raising the tilt-top.

Drying System - A 15 HP blower with an air intake

filter is connected to four air knives; two knives

above the glass and two knives underneath the glass.

A baffled enclosure covers the drying system and

reduces the noise to acceptable levels.

Rollers - The feed and pinch rollers are 2½ inches in

diameter, made with stainless steel journals and

heavy steel tubing with a precision ground Nitrile

covering. The rollers are driven by a ⅛HP DC gear

motor using chain and sprockets.

Bearings - The brushes are supported on ball

bearings. The upper pinch rollers are mounted on

pivoting brackets. The rotating action of the pivots

smoothes the movement of the thicker pieces of glass

through the machine.

Frame - The frame is a one piece steel weldment

with machined upper sidebars. The infeed and

unloading conveyors are two feet long each. All

sections that become wet through normal operation

are either plated, coated or made from a corrosion

resistant material. Plumbing, tanks, detergent/rinse

cabins, pans and covers are constructed from

stainless steel.

Electrical - The control panel is mounted on the

machine with conduit wiring. All electrical circuitry

is built to NEMA 12 specifications to meet OSHA

requirements. Every panel is UL approved.

The power requirements are 3 phase, 60 cycle,

208/230/460 volts. The electrical panel name plate

specifies the full load amperage.

Water - A water/detergent solution is applied

through spray pipes; one on either side of the glass

per brush. Threaded plugs on the spray pipe ends

allow for easy cleaning. The water usage is about 6

gallons per minute without the Aqua-Miser rinse;

about 2 gallons per minute with. There will be

minimal (zero) consumption (due to drag out and

evaporation) when used with the Aqua-Miser ready

option.

Options - The recirculating detergent system, miser

rinse system, Aqua-Miser ready (zero water), auto

glass thickness adjustments, power brush adjustment

and hydraulic power tilt-top are all options. A wetted

parts package constructed out of stainless steel for

use with a de-ionized water system is also an option.

MODEL

NUMBER STYLE BRUSH MOTORS WIDTH LENGTH HEIGHT

BLOWER

HP HEATER

TTW 486 48 inch one 3 HP

one ⅛HP

6 feet

4 inches 9 feet 3 feet

8 inches 15

6 brush 10 kW

GLASS WASHING MACHINES 4

SECTION 2

60 inch GLASS WASHING MACHINE

Model TTW 606, 6 Brush Washer

Capacity - The Washer accepts single strength to ½

inch thick glass, from 11 inches wide 14 inches long

to full width sheets. The line speed is variable from 0

to 35 feet per minute.

Brushes - The spiral-wound brushes in “dense-fill”

construction are 6 inches in diameter, mounted on

stainless steel cores and individually adjusted for

proper height. Brushes are V-belt driven by a

common motor and can be individually adjusted, to

compensate for wear, by raising the tilt-top.

Drying System - In the 6 brush Washer, a 15 HP

blower with an air intake filter is connected to four

air knives; two knives above the glass and two knives

underneath the glass. An insulated enclosure covers

the drying system and reduces the noise to acceptable

levels.

Rollers - The feed and pinch rollers are 2½ inches in

diameter, made with stainless steel journals and

heavy steel tubing with a precision ground Nitrile

covering. The rollers are driven by a ¼ HP DC gear

motor using chain and sprockets.

Bearings - The brushes are supported on ball

bearings. The upper pinch rollers are mounted on

pivoting brackets. The rotating action of the pivots

smoothes the movement of the thicker pieces of glass

through the machine.

Frame - The frame is a one piece steel weldment

with machined upper sidebars. The infeed and

unloading conveyors are two feet long each. All

sections that become wet through normal operation

are either plated, coated or made from a corrosion

resistant material. Plumbing, tanks, detergent/rinse

cabins, pans and covers are constructed from

stainless steel.

Electrical - The control panel is mounted on the

machine with conduit wiring. All electrical circuitry

is built to NEMA 12 specifications to meet OSHA

requirements. Every panel is UL approved.

The power requirements are 3 phase, 60 cycle,

208/230/460 volts. The electrical panel name plate

specifies the full load amperage.

Water - A water/detergent solution is applied

through spray pipes; one on either side of the glass

per brush. Threaded plugs on the spray pipe ends

allow for easy cleaning. The water usage is about 7½

gallons per minute without the Aqua-Miser rinse;

about 2½ gallons per minute with. There will be

minimal (zero) consumption (due to drag out and

evaporation) when used with the Aqua-Miser ready

option.

Options - The recirculating detergent system, miser

rinse system, Aqua-Miser ready (zero water), auto

glass thickness adjustments, power brush adjustment

and hydraulic power tilt-top are all options. A wetted

parts package constructed out of stainless steel for

use with a de-ionized water system is also an option.

MODEL

NUMBER STYLE BRUSH MOTORS WIDTH LENGTH HEIGHT

BLOWER

HP HEATER

TTW 606 60 inch one 3 HP

one ⅛HP

6 feet

9 inches

10 feet

3 inches

3 feet

8 inches 15

6 brush 15 kW

GLASS WASHING MACHINES 5

SECTION 2

72 inch GLASS WASHING MACHINE

Model TTW 726-½, 6 Brush Washer

Capacity - The Washer accepts single strength to ½

inch thick glass, from 13 inches wide 16 inches long

to full width sheets. The line speed is variable from 0

to 35 feet per minute.

Brushes - The spiral-wound brushes in “dense-fill”

construction are 6 inches in diameter, mounted on

stainless steel cores and individually adjusted for

proper height. Brushes are V-belt driven by a

common motor and can be individually adjusted, to

compensate for wear, by raising the tilt-top.

Drying System - In the 6 brush Washer, a 20 HP

blower with an air intake filter is connected to four

air knives; two knives above the glass and two knives

underneath the glass. An insulated enclosure covers

the drying system and reduces the noise to acceptable

levels.

Rollers - The feed and pinch rollers are 3 ⅞inches in

diameter, made from heavy steel tubing with a solid

neoprene covering. The conveyor rollers are ring

type and driven by a ⅛HP DC gear motor using

chain and sprockets.

Bearings - The brushes are supported on ball

bearings. The upper pinch rollers are mounted on

pivoting brackets. The rotating action of the pivots

smoothes the movement of the thicker pieces of glass

through the machine.

GLASS WASHING MACHINES 6

Frame - The frame is a three part steel weldment

with machined upper sidebars. The infeed and

unloading conveyors are 3 feet 2½ inches long each.

All sections that become wet through normal

operation are either plated, coated or made from a

corrosion resistant material.

Electrical - The control panel is mounted on the

machine with conduit wiring. All electrical circuitry

is built to NEMA 12 specifications to meet OSHA

requirements. Every panel is UL approved.

The power requirements are 3 phase, 60 cycle,

208/230/460 volts. The electrical panel name plate

specifies the full load amperage.

Water - A water/detergent solution is applied

through spray pipes; one on either side of the glass

per brush. Threaded plugs on the spray pipe ends

allow for easy cleaning. The water usage is about 9

gallons per minute without the Aqua-Miser rinse;

about 3 gallons per minute with. There will be

minimal (zero) consumption (due to drag out and

evaporation) when used with the Aqua-Miser ready

option.

Options - The recirculating detergent system, miser

rinse system, Aqua-Miser ready (zero water), auto

glass thickness adjustments, power brush adjustment

and hydraulic power tilt-top are all options. A wetted

parts package constructed out of stainless steel for

use with a de-ionized water system is also an option.

MODEL

NUMBER STYLE BRUSH MOTORS WIDTH LENGTH HEIGHT

BLOWER

HP HEATER

TTW 726-½ 72 inch 6 brush one 5 HP

one ⅛HP

8 feet

2 inches 14 feet 4 feet

4 inches 20 10 kW

SECTION 2

72 inch GLASS WASHING MACHINE

Model TTW 726-¾, 6 Brush Washer

Capacity - The Washer accepts single strength to ¾

inch thick glass, from 13 inches wide 16 inches long

to full width sheets. The line speed is variable from 0

to 35 feet per minute.

Brushes - The spiral-wound brushes in “dense-fill”

construction are 6 inches in diameter, mounted on

stainless steel cores and individually adjusted for

proper height. Brushes are V-belt driven by a

common motor and can be individually adjusted, to

compensate for wear, by raising the tilt-top.

Drying System - In the 6 brush Washer, a 20 HP

blower with an air intake filter is connected to four

air knives; two knives above the glass and two knives

underneath the glass. An insulated enclosure covers

the drying system and reduces the noise to acceptable

levels.

Rollers - The feed and pinch rollers are 3 ⅞inches in

diameter, made from heavy steel tubing with a solid

neoprene covering. The conveyor rollers are ring

type and driven by a ⅛HP DC gear motor using

chain and sprockets.

Bearings - The brushes are supported on ball

bearings. The upper pinch rollers are mounted on

pivoting brackets. The rotating action of the pivots

smoothes the movement of the thicker pieces of glass

through the machine.

GLASS WASHING MACHINES 7

Frame - The frame is a three part steel weldment

with machined upper sidebars. The infeed and

unloading conveyors are 3 feet 2½ inches long each.

All sections that become wet through normal

operation are either plated, coated or made from a

corrosion resistant material.

Electrical - The control panel is mounted on the

machine with conduit wiring. All electrical circuitry

is built to NEMA 12 specifications to meet OSHA

requirements. Every panel is UL approved.

The power requirements are 3 phase, 60 cycle,

208/230/460 volts. The electrical panel name plate

specifies the full load amperage.

Water - A water/detergent solution is applied

through spray pipes; one on either side of the glass

per brush. Threaded plugs on the spray pipe ends

allow for easy cleaning. The water usage is about 9

gallons per minute without the Aqua-Miser rinse;

about 3 gallons per minute with. There will be

minimal (zero) consumption (due to drag out and

evaporation) when used with the Aqua-Miser ready

option.

Options - The recirculating detergent system, miser

rinse system, Aqua-Miser ready (zero water), auto

glass thickness adjustments, power brush adjustment

and hydraulic power tilt-top are all options. A wetted

parts package constructed out of stainless steel for

use with a de-ionized water system is also an option.

MODEL

NUMBER STYLE BRUSH MOTORS WIDTH LENGTH HEIGHT

BLOWER

HP HEATER

TTW 726-¾ 72 inch one 5 HP

one ⅛HP

8 feet

2 inches 14 feet 4 feet

4 inches 20

6 brush 10 kW

SECTION 2

84 inch GLASS WASHING MACHINE

Model TTW 846, 6 Brush Washer

Capacity - The Washer accepts single strength to ¾

inch thick glass, from 13 inches wide 16 inches long

to full width sheets. The line speed is variable from 0

to 35 feet per minute.

Brushes - The spiral-wound brushes in “dense-fill”

construction are 6 inches in diameter, mounted on

stainless steel cores and individually adjusted for

proper height. Brushes are V-belt driven by a

common motor and can be individually adjusted, to

compensate for wear, by raising the tilt-top.

Drying System - In the 6 brush Washer, a 25 HP

blower with an air intake filter is connected to four

air knives; two knives above the glass and two knives

underneath the glass. An insulated enclosure covers

the drying system and reduces the noise to acceptable

levels.

Rollers - The feed and pinch rollers are 3 ⅞inches in

diameter, made from heavy steel tubing with a solid

neoprene covering. The conveyor rollers are ring

type and driven by a ⅛HP DC gear motor using

chain and sprockets.

Bearings - The brushes are supported on ball

bearings. The upper pinch rollers are mounted on

pivoting brackets. The rotating action of the pivots

smoothes the movement of the thicker pieces of glass

through the machine.

GLASS WASHING MACHINES 8

Frame - The frame is a three part steel weldment

with machined upper sidebars. The infeed and

unloading conveyors are 3 feet 2½ inches long each.

All sections that become wet through normal

operation are either plated, coated or made from a

corrosion resistant material.

Electrical - The control panel is mounted on the

machine with conduit wiring. All electrical circuitry

is built to NEMA 12 specifications to meet OSHA

requirements. Every panel is UL approved.

The power requirements are 3 phase, 60 cycle,

208/230/460 volts. The electrical panel name plate

specifies the full load amperage.

Water - A water/detergent solution is applied

through spray pipes; one on either side of the glass

per brush. Threaded plugs on the spray pipe ends

allow for easy cleaning. The water usage is about

10½ gallons per minute without the Aqua-Miser

rinse; about 3½ gallons per minute with. There will

be minimal (zero) consumption (due to drag out and

evaporation) when used with the Aqua-Miser ready

option.

Options - The recirculating detergent system, miser

rinse system, Aqua-Miser ready (zero water), auto

glass thickness adjustments, power brush adjustment

and hydraulic power tilt-top are all options. A wetted

parts package constructed out of stainless steel for

use with a de-ionized water system is also an option.

MODEL

NUMBER STYLE BRUSH MOTORS WIDTH LENGTH HEIGHT

BLOWER

HP HEATER

TTW 846 84 inch one 5 HP

one ⅛HP

9 feet

2 inches 14 feet 4 feet

4 inches 25

6 brush 12 kW

SECTION 2

96 inch GLASS WASHING MACHINE

Model TTW 966, 6 Brush Washer

Capacity - The Washer accepts single strength to ¾

inch thick glass, from 13 inches wide 16 inches long

to full width sheets. The line speed is variable from 0

to 35 feet per minute.

Brushes - The spiral-wound brushes in “dense-fill”

construction are 6 inches in diameter, mounted on

stainless steel cores and individually adjusted for

proper height. Brushes are V-belt driven by a

common motor and can be individually adjusted, to

compensate for wear, by raising the tilt-top.

Drying System - In the 6 brush Washer, a 25 HP

blower with an air intake filter is connected to four

air knives; two knives above the glass and two knives

underneath the glass. An insulated enclosure covers

the drying system and reduces the noise to acceptable

levels.

Rollers - The feed and pinch rollers are 3 ⅞inches in

diameter, made from heavy steel tubing with a solid

neoprene covering. The conveyor rollers are ring

type and driven by a ⅛HP DC gear motor using

chain and sprockets.

Bearings - The brushes are supported on ball

bearings. The upper pinch rollers are mounted on

pivoting brackets. The rotating action of the pivots

smoothes the movement of the thicker pieces of glass

through the machine.

GLASS WASHING MACHINES 9

Frame - The frame is a three part steel weldment

with machined upper sidebars. The infeed and

unloading conveyors are 3 feet 2½ inches long each.

All sections that become wet through normal

operation are either plated, coated or made from a

corrosion resistant material.

Electrical - The control panel is mounted on the

machine with conduit wiring. All electrical circuitry

is built to NEMA 12 specifications to meet OSHA

requirements. Every panel is UL approved.

The power requirements are 3 phase, 60 cycle,

208/230/460 volts. The electrical panel name plate

specifies the full load amperage.

Water - A water/detergent solution is applied

through spray pipes; one on either side of the glass

per brush. Threaded plugs on the spray pipe ends

allow for easy cleaning. The water usage is about 12

gallons per minute without the Aqua-Miser rinse;

about 4 gallons per minute with. There will be

minimal (zero) consumption (due to drag out and

evaporation) when used with the Aqua-Miser ready

option.

Options - The recirculating detergent system, miser

rinse system, Aqua-Miser ready (zero water), auto

glass thickness adjustments, power brush adjustment

and hydraulic power tilt-top are all options. A wetted

parts package constructed out of stainless steel for

use with a de-ionized water system is also an option.

MODEL

NUMBER STYLE BRUSH MOTORS WIDTH LENGTH HEIGHT

BLOWER

HP HEATER

TTW 966 96 inch one 5 HP

one ⅛HP

10 feet

2 inches 14 feet 4 feet

4 inches 25

6 brush 12 kW

SECTION 3

RECEIVING

UNCRATING

Every Washer is tested and adjusted to work

perfectly before shipment. Every component is

tested in actual conditions to guarantee proper

operation before shipment. It is essential that the

Washer is received and handled properly before

installation to ensure that it was received in exactly

the same condition as it was when it left the factory

and that it reaches the site where it will be set up for

operation without damage.

GLASS WASHING MACHINES 10

The crate with the Washer, dependant on the

machine size, will weight between 2,000 to 4,000

pounds and requires adequate lifting devices to

move the crate and components.

Inspecting the Crate

Crate damage could indicate that the shipment has

been mishandled and that the machine could be

damaged. It is very important that the machine be

inspected for exterior damage immediately upon

receipt. Use the following procedure for inspection:

Check all surfaces of the crate for gouges, tears or

holes that could have been made by the forks of a

forklift or some other lifting device.

Check for crushed corners, edges or framing

members that could indicate that the crate was

dropped.

Check for broken crate straps and breaks or

distortion in the framing of the crate.

Inspect the plastic wrappings that cover the

components and assemblies. Carefully note any

damage to the wrappings.

Remove the framing and plastic wrappings as

necessary to inspect the machine, especially in the

areas of obvious visible damage.

Notification

Document any and all damage to any part of the

Washer or ancillary equipment. Notify the carrier

and Sommer and Maca Industries, Inc. immediately

upon detection of any damage.

Removing the Crate

Cut any straps and remove the crate from the skid.

Note that the frame of the Washer is bolted to the

wooden skid.

Check the machine for damage, especially in an

area that has evident crate damage that was

noticed in the inspection procedure described

previously.

Use a proper lifting device and lift slings to raise

the machine off of the mounting skid. It is

recommended that the machine be in the desired

location, if possible, so that handling of the

machine is kept to a minimum.

SECTION 4

INSTALLATION

FACILITIES REQUIREMENTS

GLASS WASHING MACHINES 11

Floor Space

The Washer requires a location with an adequate area

to permit easy access around the machine with no

obstructions. The detergent and rinse tanks require

an additional space, equal to the width of the Washer,

from the center section on the control panel side of

the machine. This is necessary if the tanks are to be

removed for cleaning or maintenance. The floor area

must be clean and free from grease, oil and water.

When installing the machine, consideration should be

given to the size of glass to be used to ensure proper

clearance of the infeed and unloading conveyor

sections of the machine when loading and unloading

the glass.

Compressed Air

If an optional power lift for the height adjustment is

used, an air supply is required capable of delivering

100 PSI at 5 CFM. The air supply connection is

located at the control panel side at the infeed

conveyor of the Washer main body.

Electrical Requirements

The power requirements are 3 phase, 60 cycle,

208/230/460 volts. The electrical panel name plate

specifies the full load amperage (other power sources

can be accommodated on special order). The power

source must also have a safety disconnect switch for

servicing the Washer. Local electrical codes may

require this switch. All wiring must meet local

electrical codes.

Ensure that the Washer is wired for the SAME

VOLTAGE as the voltage supplied to the machine.

Remember, 208 volt IS NOT 230 volt!

Ensure that electrical connections and lines do not

contact water.

The EMERGENCY STOP slap switches DO NOT

disconnect power from all components of the

machine.

The main power source safety disconnect switch

controlling the main power to the machine must

be in sight of personnel at the machine or must be

capable of being locked OFF.

After Washer has been connected to power press the

“ON” button. Open the detergent compartment cover

and see if the upper brush rotates against the glass

flow through the machine. If it is moving with the

glass travel, change any of the two main wire leads

that feed the main control panel.

Never change the wires to any motor directly. The

wiring has been properly done at the factory and

should not be altered.

A second check is to observe the rotation of the

blower motor. This will also indicate if the main

power supply to the machine needs to be rewired to

achieve the correct rotation.

Properly ground the machine to reduce static

charges.

If the Washer’s starters or heaters kick out, check for

loose connections and for a low voltage supply.

Always check one motor to make sure that the

Washer is properly wired for your applied voltage.

SECTION 4

Plumbing

GLASS WASHING MACHINES 12

Before connecting the water supply lines, clean all

pipes or any other connectors to remove chips,

pipe dope and other debris. The spray pipe holes

can be easily clogged.

A water supply line and accessible drain will be

required for filling, cleaning and draining the

detergent and rinse tanks and pumps. Ideally, a floor

drain should be located close to the Washer for run-

off and cleaning.

The supply line should feed the last rinse section with

80ºF to 110ºF water. Cold water can be used, but

under high humidity conditions, glass may not dry

adequately.

The Washer should be piped so that one shut-off

valve will turn off all the water to the Washer. If a

temperature control valve is used, a hot and a cold

line should be connected to the correct side of that

valve. If there is a separate shut-off valve for each

hot and cold line, a setting for each can be set to

achieve 100ºF. Adjust the temperature by metering

the hot and cold flow. A separate shut-off valve

should control a hose to clean the Washer and fill the

tanks.

Most Washers use a recirculating water system.

Water from the fresh rinse collects in the

recirculating tank. The tank has an overflow that

must be connected to a drain. The drain lines from

the drain pan and recirculating tank should be

adequately sized to prevent water from building up in

the pan or the tank.

Both the detergent tank and the recirculating tank

should be connected from the bottom coupling to a

floor drain. Install a shutoff valve to maintain the

water level of the tank. The level should be within ½

inch of the overflow coupling.

Fill the tanks with water through the pumps

(turned OFF) by pressure to eliminate trapped air

that may result in pump seal failure.

If the overflow coupling has a direct connection to

the drain, no shutoff valve is required. Do not

interconnect the overflows from the two tanks; this

will result in one tank draining into the other. A

union on each tank should be used to connect to the

drain. This will facilitate easy removal of the tank

for cleaning or other service functions.

Water Requirements

If the Washer uses de-ionized water, it is

preferable to use stainless steel or PVC pipes for

most plant water or well water. All connections

should be watertight to prevent any leakage.

If de-ionized water is used without installing

stainless steel or PVC piping, excessive corrosion

on the wetted parts of the Washer will result. This

will severely shorten the life of the machine.

If softened water is used in the Washer, excessive

corrosion on the wetted parts of the Washer will

result. This will severely shorten the life of the

machine.

Softened water will not improve the washing process.

Softened water replaces the metal ions in the water

with sodium ions, leaving salt spots and films on the

glass. This reaction may not be visible immediately,

but may appear on the glass later. This is most likely

to result on the inside of insulated glass units after the

desiccant has absorbed all the moisture from the

inside surfaces of the glass.

Reverse osmosis is an ultra-filtration process that

removes suspended compounds in the water, such as

hard salts and calcium. Although this treatment will

not remove dissolved ions, it may improve the water

quality without the risk of damage to the Washer.

SECTION 5

OPERATING INSTRUCTIONS

GLASS WASHING MACHINES 13

Do not wash rubber-covered rollers with products

that contain high levels of petroleum based

compounds.

If the Washer has a water heater, verify that the

heating element is totally submerged in the water

before turning the machine “ON”. Frequent

checks of the water level during operation are

highly recommended.

STARTING THE WASHER

Verify proper electrical grounding of the Washer.

Turn the main power switch on the electrical

control panel to “ON”.

Start the conveyor and adjust the speed to suit the

operating conditions. Generally, the speed

between 10 to 12 feet per minute (about ⅓full

speed) is a good start.

Adjust the brushes. For instructions see Section

6: Maintenance.

The glass thickness adjustment is made on the

upper frame only. To adjust for thicker glass,

loosen the upper nut(s) on the upper frame support

and turn the lower nut(s) to raise the frame. To

adjust for thinner glass, loosen the upper nut(s) on

the upper frame support and turn the lower nut(s)

to lower the frame. When the adjustment is

completed, retighten the upper nut(s) to secure the

frame.

Some Washer models have the optional patented

Somaca air-activated glass thickness adjustment

system. The clearance bars a factory-set to

prevent the insertion of glass that is too thick.

If the Washer uses a detergent tank, ensure that

the water level is above the pump intake. Push

the “SPRAY CHECK” button on the operator

console to start the pumps. Add enough

detergent, according to the detergent

manufacturer’s recommendations, to clean the

glass. In some applications, detergent may not be

necessary to produce clean glass.

Strong solutions can damage rubber-covered

rollers. Use only a detergent at the

manufacturer’s recommended level.

If the Washer has a water heater, set the

thermostat to maintain a temperature of 120º-

130ºF. Higher temperatures may result in

“steaming”. In any case, DO NOT exceed

170ºF. Higher temperatures will damage the

rubber rollers.

Check the water level in each tank for correct

volume.

With the “SPRAY CHECK” button on, adjust the

flow of the rinse water. A “fine stream” will help

reduce fresh water consumption. A mixing valve

or hot and cold shutoffs should feed the rinse

section with water at 80º to 110ºF.

Too much water can cause poor drying.

Push the “SPRAY CHECK” button again to turn

the pumps off. Push the machine “START”

button to begin running a rest piece of glass. Push

the conveyor “START” button. Run the sample

piece of glass through the Washer and inspect.

Make any necessary adjustments.

SECTION 5

Cleaning Action Quality

The quality of the cleaning action depends primarily

on these factors:

No detergent or too much detergent

Conveyor speed

Brush adjustment

Cleanliness of the Washer and the water

Proper detergent solution flow to the brushes

Proper rinse water flow to the brushes

The operator can vary the cleaning action of the

Washer by increasing brush pressure on the glass,

changing the conveyor speed, changing the detergent

concentration or changing the temperature of the

detergent solution. The Washer should have

approximately a ¾ inch of contact with the glass

surface on each brush.

To make a brush adjustment, loosen the stop nuts at

both ends of the brush. Turn the adjusting nut to

raise or lower the brush. Retighten the stop nuts

when completed.

GLASS WASHING MACHINES 14

The slower the conveyor speed is, the longer the

brushes can scrub the glass. It is better to slow the

conveyors rather than to increase the amount of

detergent or raise the water temperature.

TEMPERATURE CONTROLLER

On Washers equipped with the detergent option, the

temperature of the detergent solution is regulated by

a temperature controller. This is located on the

operator control panel and displays the detergent

solution temperature whenever the electrical power to

the machine is on.

To heat the detergent solution to the setpoint

temperature, the “DETERGENT HEATER”

pushbutton must be on. Normal temperature control

variation is ±4ºF. when he Washer is running. If

the pumps and conveyors are off, the control is

much closer.

Setpoint Adjustment

The controller setpoint is adjusted to 130ºF at the

factory. To change the temperature controller

setpoint:

OPERATION DISPLAY

Power ON Detergent Solution Temperature

Press SEL key Setpoint Value: “SV” lamp is lit

Press UP or DOWN key Setpoint value changes accordingly

Press SEL key to return to operational mode Detergent solution temperature: SV lamp is off

SECTION 5

Auto-Tuning Procedure

GLASS WASHING MACHINES 15

The controller has been factory tuned at the time of

machine assembly. In the event that it is necessary

to retune, verify the proper water level in the tank(s)

and follow these steps:

Auto-Tuning is not necessary when the setpoint has

been adjusted.

Auto-Tuning may require as long as 1½ hours

because of the high thermal inertia of the water.

For more detailed information, refer to the manual

of the manufacturer of the controller.

OPERATION DISPLAY

Power ON Detergent temperature

Turn on DETERGENT HEATER;

turn on SPRAY CHECK Detergent temperature: pushbutton illuminated

Set the setpoint for 130ºF using the Setpoint

Adjustment above

Allow one (1) hour for detergent temperature to stabilize

at 130ºF

Press SEL key for three (3) seconds ALM light blinks

Press SEL key until Auto-Tune parameter is reached AT appears (as “A7”)

If a “1” does not appear next to AT, press UP key 1(appears as “A7 1”) Auto-Tune at 100% setpoint

Press SEL key Auto-Tune indication lamp at lower right blinks

(Auto-Tune running)

Auto-Tune stops blinking Displays temperature and Auto-Tune indication stops

Controller automatically returns to operating mode

SECTION 6

MAINTENANCE

MAINTENANCE CONCEPT

This section is divided into four main parts:

Daily maintenance

Weekly maintenance

Monthly maintenance

Less frequent maintenance

This section will include information on

frequency and type of lubrication, adjustments to

specific areas and minor repairs.

DAILY INSPECTION

A clean, well-maintained Washer will always give

cleaner, better results. Follow these steps every day:

Turn on the SPRAY CHECK and inspect the

fresh water spray pipe. Clean if necessary.

After all of the spray pipes have been inspected,

remove the covers over the air knives.

Run a piece of clean glass through the Washer

that is wide enough to span the width of the roller.

Inspect the air knives for blockage on the air exit

side. If an air knife is blocked, a streak of water

will be visible on the top or bottom of the glass.

The daily inspection routine is especially important if

you are washing glass prior to manufacturing

insulated glass units.

DAILY MAINTENANCE

Water Tank(s)

Inspect the water tank(s) every day. If the glass is

excessively dirty or is powder coated, clean the

tank(s) once a day or, if necessary, more often.

Follow these steps for routine daily maintenance:

Drain the water from the tank(s) by grasping the

pin on the top of the standpipe in the tank(s) and

removing.

Sponge the remaining water from the bottom of

the tank(s) and wipe the inside clean.

Clean any debris from the return water tank’s

screen.

Clean the pump’s discharge strainer.

Refill the tank(s).

Turn on the SPRAY CHECK and inspect the

spray pipes. Clean any clogged holes or nozzles.

Check the return water tank’s screen for debris

and clean.

Keep the Washer covered whenever it is practical,

especially the discharge conveyor rollers.

WEEKLY MAINTENANCE

Blower Intake Air Filter(s)

Replace the air filter(s) immediately if damage is

evident.

Check the air filter(s) for dirt build-up. When the

filter needs cleaning, remove and clean it with a

vacuum. Do not use oiled filter units. The oil will

eventually transfer to the glass through the drying

system. A good practice is to keep a spare filter on

hand to use while the dirty one is being cleaned.

Conveyor Chain

Lubricate all pinch roller bearings. Lubricate all

conveyor roller bearings (if there are grease fittings).

Add waterproof general purpose grease slowly with a

grease gun until the grease begins to ooze from the

bearing seals. Do not over grease!

For bearings that have bronze bushings, use a high

quality moly spray lubricant that will wick into the

bushing.

GLASS WASHING MACHINES 16

This manual suits for next models

6

Table of contents

Other Sommer & Maca Industries Industrial Equipment manuals