Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau ● Germany ●+49 7844 9138 0 ● +49 7844 9138 80 ● www.zimmer-group.com

INSTALLATION AND OPERATING INSTRUCTIONS: Zero-point clamping system, pneumatic, SPN series

Installation and Im Salmenkopf 5

operating

instructions 77866 Rheinau

SPN series Germany

DDOC00836 +49 7844 9138 0

EN 2021-12-09 www.zimmer-group.com

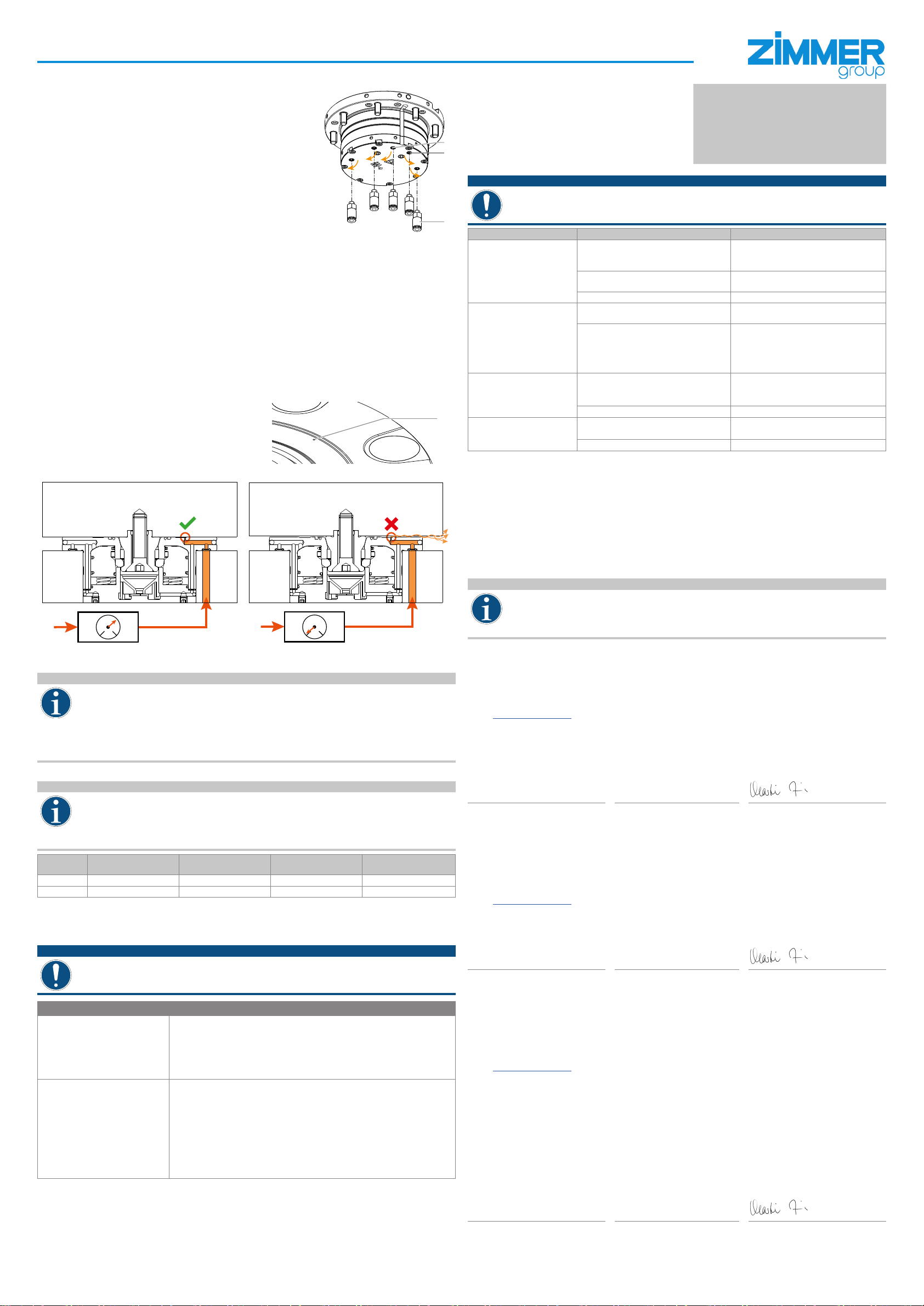

8.2 Installing alternative hose connections

The following work steps must be observed when installing the power

supplies:

►Unscrew the grub screws cn.

►Insert the O-rings cp.

ÖLubricate the O-rings.

►Screw the pneumatic connections co into the alternative

connections.

ÖIf the PLUS connection2 is not in use, insert a lter cm into the

connection (lter included loose).

ÖThe lter cm must be ush with the bottom of the product during

installation.

ÖIf the standard connections are to replace the alternative

connections, the alternative connections must be tightly sealed.

co

cn

cm

8.3 Checking operational readiness

After the product has been properly installed, the following properties must be checked to verify that it is ready to be operated:

• Check pneumatic connections for leaks by looking and listening

• Check all fastening screws for their prescribed tightening torque

• Check the product for leaks while it is pressurized by looking and listening

8.4 Disassembly

Removal is carried out in the reverse order of that described in Section „Montage Mechanik“.

9. Operation

During machining, the entire contact surface of the zero-point clamping system must be covered so that no dirt can penetrate.

►Before any clamping, thoroughly clean the contact surfaces between the zero-point clamping system, the clamping pin and

the material to be clamped.

►Protect the pin hole from dirt when the product is not in use.

►To do this, use accessories such as the sealing pin or automatic seal.

►During operation, secure the zero-point clamping system against unintentional loosening.

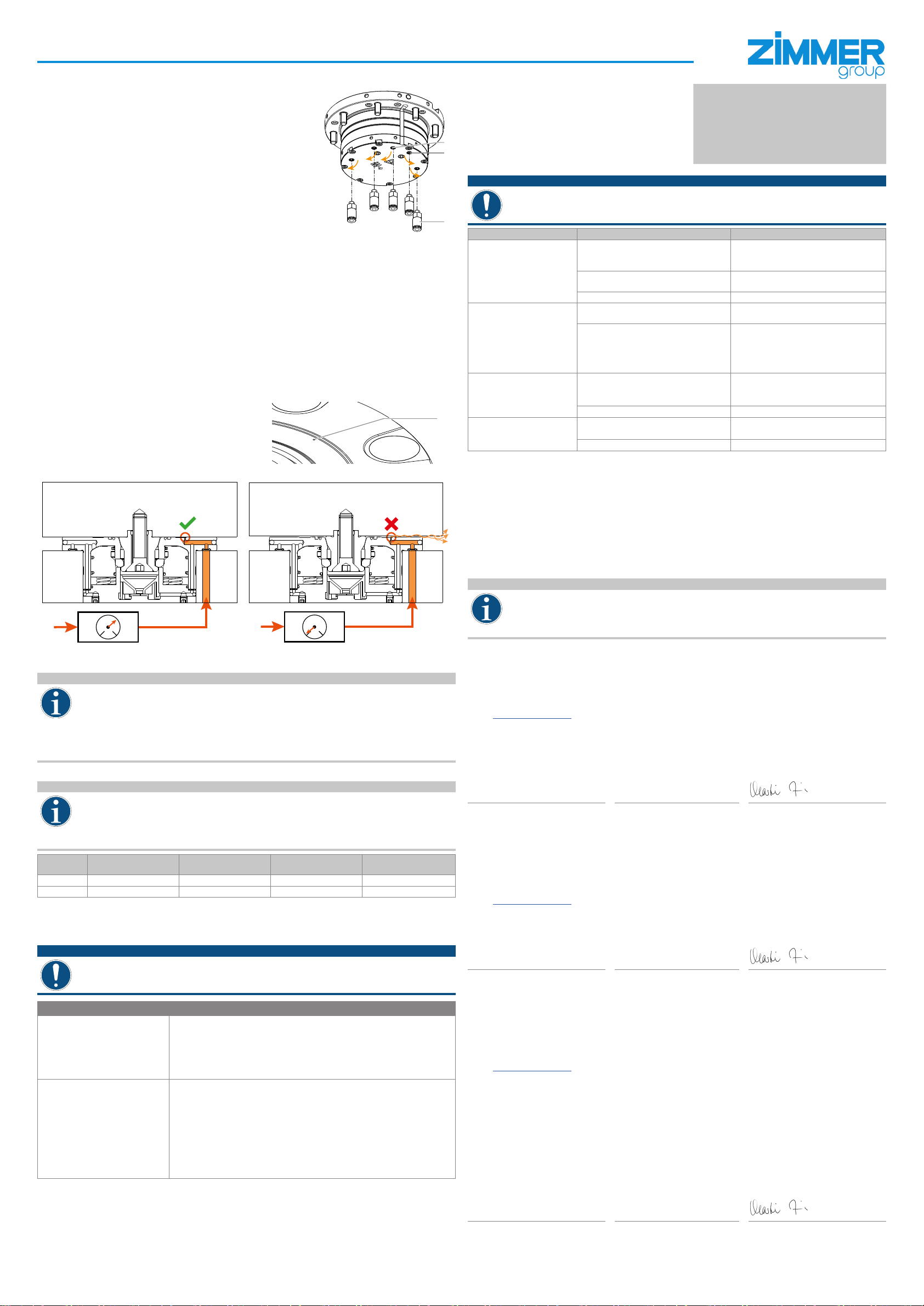

9.1 Positioning check

The product enables the testing or monitoring of the support using an

externally connected ow meter or dynamic pressure indicator.

This inspection veries that the workpiece or clamping plate is

correctly supported on the product.

The ow or dynamic pressure is measured by means of the

designated borehole boin the housing.

bo

ÖThe following illustrations depict an example of dynamic pressure sensing.

P

0 10

bar

P

0 10

bar

The clamped product is resting correctly on the contact surface.

ÖThis generates dynamic pressure.

The clamped product is not resting correctly on the contact

surface.

ÖNo dynamic pressure is generated (leakage).

INFORMATION

The operator of the product has sole responsibility for the positioning check. Sensing for the positioning check

is performed by means of an external ow meter or dynamic pressure indicator. The entire contact surface of the

product must be covered to ensure correct sensing during the positioning check.

Operating pressure for the positioning check: 1.5 bar

To use this function, an adjustable pressure switch must be connected upstream. This reduces the operating

pressure to the required 1.5 bar.

ÖThe power supply line is for blowing out, cleaning and the positioning check.

Please contact Zimmer Customer Service if you have any questions.

9.2 Piston position sensor

INFORMATION

The operator of the product has sole responsibility for piston position sensing. Sensing is performed by means of an

external ow meter or dynamic pressure indicator.

The entire contact surface of the product must be covered to ensure correct sensing during the piston position

sensing.

Operating pressure for piston position sensing: 1.5 bar

Please contact Zimmer Customer Service if you have any questions.

Connection Operating pressure [bar] Product unlocked Pin clamped Product closed/no pin

present

4 1 to 1.5 0 1 1

5 1 to 1.5 1 0 1

0 = dynamic pressure 1 = ow

10. Maintenance

The maintenance interval depends on the respective application. The higher the strain, the more frequently maintenance must

be carried out.

NOTICE

In case of visible damage or signs of malfunction, the zero-point clamping system must be taken out of operation

immediately. Do not start the product again until the damage has been repaired.

►Replace any worn components.

Interval Maintenance work

After 10,000 cycles or every 3 weeks Visual inspection

The visual inspection merely involves visually inspecting component parts and their

function. If any irregularities or damage are identied during the visual inspection, a

more detailed check of the component parts must be carried out.

►Carry out a visual inspection.

►Clean the product if it is dirty.

After 50,000 cycles or every year Measure the clamping force

►Measure the clamping force.

• Suitable devices for measuring the clamping force are available as

accessories.

ÖClamping force undershot by less than 15%

• Further use at the customer's discretion.

• Or have Zimmer GmbH perform the check.

ÖClamping force undershot by more than 15%

• Have Zimmer GmbH perform the check.

Dismantling and reassembling the product without authorization may result in complications, as special installation equipment is

required in some cases. Zimmer GmbH accepts no liability for any resulting malfunctions or damage.

11. Troubleshooting

NOTICE

For error-free function of the product, it is necessary that the contact surface is always completely covered.

►This prevents dirt from penetrating the system and causing malfunctions.

Error/fault Possible cause Measure

Product does not open

• Operating pressure is too low

• Leakage/blockage/pinching of the power

supply lines

►Increase operating pressure (4 to 6 bar)

►Check power supply lines

• Excess force is acting upon the centering

pin

►Reduce the tensile load or compressive

load on the product.

• Clamp dog does not move ►Vent the PLUS connection

Long response time (too little

air is fed in)

• Valve is too small (product opens after a

delay) ►Choose a larger valve accordingly

• Power supply lines from the valve to the

product are too long (product opens after

a delay)

►Shorten the power supply lines (keep the

distance from the product to the valve as

short as possible).

►Enlarge the cross-section of the power

supply lines.

Air leak or blow-off noise

• Housing parts are leaky (O-rings not tted

correctly)

• Installation error

►Align/mount the product again.

►Check the O-rings.

►Open/close the product several times.

• Connecting cables are leaky. ►Check power supply lines.

Dimensional deviations/chatter

marks

• Centering pin is not correctly retracted.

• Contamination of the product ►Clean the product.

• Product worn ►Completely replace the product.

12. Transportation/storage/preservation

►The product must be transported and stored only in the original packaging.

►If the product has already been installed on the superordinate machine unit, care must be taken during transport to ensure

that no unintentional movements can occur. Before commissioning and after transport, check all power connections and all

mechanical connections.

►If the product is stored for an extended period, the following points are to be observed:

ÖKeep the storage location as dust-free and dry as possible.

►Clean all components. There must be no dirt left on the components.

►Seal pneumatic connections by using suitable covers.

►Observe the required temperature.

13. Decommissioning and disposal

INFORMATION

When the product reaches the end of its operational phase, it can be completely disassembled and disposed of.

Completely disconnect the product from the power supply. The product can be disassembled and properly disposed

of according to material groups.

When disposing of them, observe the locally applicable environmental regulations and codes and regulations for

disposal.

14. RoHS declaration

In terms of the EU Directive 2011/65/EU

Name and address of the manufacturer:

Zimmer GmbH

Im Salmenkopf 5, 77866 Rheinau, Germany

+49 7844 9138 0

+49 7844 9138 80

www.zimmer-group.com

We hereby declare that the incomplete machine described below

Product designation: Zero-point clamping system, pneumatic

Type designation: SPN series

conforms to the requirements of the directive in its design and the version we put on the market.

Michael Hoch Rheinau, Germany, 2020-03-31

Authorized representative for compiling

the relevant technical documents

(Place and date of issue) Martin Zimmer

(Legally binding signature)

Managing Partner

15. REACH declaration

In terms of the EU Regulation 1907/2006

Name and address of the manufacturer:

Zimmer GmbH

Im Salmenkopf 5, 77866 Rheinau, Germany

+49 7844 9138 0

+49 7844 9138 80

www.zimmer-group.com

REACH stands for Registration, Evaluation, Authorisation and Restriction of Chemicals.

A full declaration of REACH can be obtained from the manufacturer due to the duty to notify in accordance with Art. 33 of the

REACH regulation ("Duty to communicate information on substances in articles").

Michael Hoch Rheinau, Germany, 2020-03-31

Authorized representative for compiling

the relevant technical documents

(Place and date of issue) Martin Zimmer

(Legally binding signature)

Managing Partner

16. Declaration of Conformity

In terms of the EU Machinery Directive 2006/42/EC (Annex II 1 A)

Name and address of the manufacturer:

Zimmer GmbH

Im Salmenkopf 5, 77866 Rheinau, Germany

+49 7844 9138 0

+49 7844 9138 80

www.zimmer-group.com

We hereby declare that the following, identically constructed safety components

Product designation: Zero-point clamping system, pneumatic

Type designation: SPN series

conform to the requirements of the 2006/42/EC directive in their design and the version we put on the market.

The following harmonized standards have been used:

Basic health and safety requirements:

DIN EN ISO 12100:2011-03 Safety of machinery – General principles for design – Risk assessment and risk reduction

DIN EN ISO 13849-1/-2 Safety of machinery – Safety-related parts of control systems

EN 349:1993+A1:2008 Safety of machinery – Minimum gaps to avoid crushing of parts of the human body

A full list of applied standards can be obtained from the manufacturer.

Clemens Kimmig Rheinau, Germany, 4/30/2021

Authorized representative for compiling

the relevant technical documents

(Place and date of issue) Martin Zimmer

(Legally binding signature)

Managing Partner