Sonardyne 8142-000-01 User manual

UM-8142/8182

Revision Number: Initial Issue

Prepared by: Edmund Ceurstemont

Authorised by: Darryl Newborough

Issue Date: 20/12/2010

Commercial in Confidence

This document contains Sonardyne

Technical information and is issued

Commercial in Confidence.

The contents of this document must not

be divulged to any third party without

Sonardyne’s written permission

User Manual for:

Type 8142-000-01/02 USBL Transceivers

Type 8182-000-01 Modem/transceiver

Sonardyne Wideband2®

6 Generation (6G®)

Issuing Office

Sonardyne International Limited T. +44 (0) 1252 872288

Blackbushe Business Park F. +44 (0) 1252 876100

GU46 6GD United Kingdom Sonardyne International Ltd.

Initial Issue

Issue Date 25/06/2010

User Manual: 8142/8182 Transceivers

Table of Contents 0-1

Page 1of 5

TABLE OF CONTENTS 0-1

Section Subject

01 Preliminaries

Table of Contents 0-1

Customer Change Request Form (CCRF) 0-2

Record of Revisions 0-3

Introduction 0-4

1 - General

2 - Observance of the User Manual

3 - Warranty

4 - How to Use this User Manual

5 – Units of Measurement

6 - Verification

7 – Glossary of Terms

8 – General Safety Precautions

9 – Hazard Appreciation

10 – General Handling of Equipment

11 – Dismantling Sub-sea equipment

11.1 Instruments fitted with Sprung vent Valves

11.2 Precautions (Instrument Fully Functioning)

11.3 Precautions (Instrument known or suspected of being Pressurised)

12 – Instrument Load Bearing Capacity

13 – Floatation Equipment

Head Office

Sonardyne International Limited

Blackbushe Business Park,

Yateley, Hampshire,

GU46 6GD, UK

T. +44 (0) 1252 872288

F. +44 (0) 1252 876100

www.sonardyne.com

Initial Issue

Issue Date 25/06/2010

User Manual: 8142/8182 Transceivers

Table of Contents 0-1

Page 2of 5

02 Technical and Functional Description

1 - General

2 – System Description

2.1 Type 8142 Transceiver

2.2 Type 8182 Transceiver

3 – Acoustic Processing Principles

3.1 Positioning

3.2 Sonardyne Wideband®2 Signals

3.3 Data Exchange

4 – USBL

4.1 ROV/Tow Fish Tracking

4.2 Dynamic Positioning

5 - LUSBL

5.1 Dynamic Positioning

5.2 Underwater Positioning

5.3 Marine Riser Angle Monitoring

03 Technical Data

1 – 8142-000-01 Transceiver and 8182-000-01 Transceiver

1.1 Mechanical

1.2 Electrical

1.3 Acoustics

1.4 Environmental

2 – 8142-000-02 Transceiver

2.1 Mechanical

2.2 Electrical

2.3 Acoustics

2.4 Environmental

04 Operating Instructions

1 – 8142 Transceiver

1.1 Operating Instructions

Initial Issue

Issue Date 25/06/2010

User Manual: 8142/8182 Transceivers

Table of Contents 0-1

Page 3of 5

05 Maintenance and Storage

1 – 8142 Transceivers Clean, Examine and Store

1.1 Tools

1.2 Consumable Materials

1.3 Preparation

1.4 Clean and Examine the Transceiver

1.5 Storage

1.6 Post Task Procedures

2 – Recommended Lubricants

3 - Maintenance Codes and Schedule

06 Fault Finding

1 – No Communication From Transceiver

1.1 Check the Wiring and the Power

1.2 Check AGP Connector

1.3 Check Continuity of RS485 Connection

07 Removal

1 – Removal Transceivers 8142-000-001/2

1.1 Tools and Equipment

1.2 Equipment Weights

1.3 Preparation

1.4 The Method, for removing the transducer from through deck pole or over-

side mount.

08 Operational Test

1 - Testing the Transceiver

09 Repair

1 – No Authorised Repairs

10 Battery Safety

1 – Battery Safety

Initial Issue

Issue Date 25/06/2010

User Manual: 8142/8182 Transceivers

Table of Contents 0-1

Page 4of 5

11 Upgrading Firmware

1 – Upgrade HPT Firmware via Marksman or Ranger 2

2 - Upgrade HPT Firmware via HPT Terminal

12 Installation

1 – Installation Transceivers 8142-000-001/2

1.1 Tools and Equipment

1.2 Equipment Weights

1.3 Consumable Materials

1.4 Preparation

2 – Installation

2.1 Mounting the Transceiver

2.2 Transceiver Interconnections

13 Acoustic Navigation Principle

1 – Acoustic Navigation System Principles

1.1 Long Base Line Principles

1.2 Short Base Line Principles

1..3 Ultra Short Base Line Principles

1.4 Long Ultra Short Base Line Principles

14 Recommended Spares

1 – How to Order Spares

2 – Recommended Spares

2.1 Transceiver 8142-000-001/2

2.2 Assemblies

2.3 Cables

15 Drawings

1 – AGP Tail Stripping Detail

2 – 8 Pin Lemo to Flylead

3 – HPT Outline – 8142-000-01

4 – Serial I/O cable Assembly

5 – HPT Outline – 8142-000-02

Initial Issue

Issue Date 25/06/2010

User Manual: 8142/8182 Transceivers

Table of Contents 0-1

Page 5of 5

16 Deployment

1 – 8142 transceiver Deployment

1.1 Preparation

1.2 Deployment From Ship

17 Equipment Log Book

1 – Deployment and Recovery

2 – Repairs

3 - Servicing

4 – Sea State Table

Initial Issue

Issue Date 25/06/2010

User manual: 8142/8182 Transceivers

Customer Change Request Form 0-2

Page 1of 1

CUSTOMER CHANGE REQUEST FORM 0-2

Use this form to tell Sonardyne Int Ltd of any errors or omissions that you find when you use this manual. Your

request will be acknowledged and Sonardyne Int Ltd will inform you of any action to be taken.

To:Sonardyne Int Ltd

Blackbushe Business Park

Yateley

Hampshire Fax (0) 1252 876100

Publication: Type 8142 USBL Transceivers and Type 8182 transceivers - User Manual

Publication No.: UM 8142/8182

Page Block:_______ Section Title:_________________________ Revision:_____

From: Company: ________________________ Department: ______________________

Name: ___________________________ Title: ____________________________

Address: ______________________________________________________________

______________________________________________________________

Telephone: ________________ Fax: _______________ E-mail: _________________

Comments:

Head Office

Sonardyne International Limited

Blackbushe Business Park,

Yateley, Hampshire,

GU46 6GD, UK

T. +44 (0) 1252 872288

F. +44 (0) 1252 876100

www.sonardyne.com

Initial Issue

Issue Date 25/06/2010

User manual: 8142/8182 Transceivers

Record of Revision 0-3

Page 1of 1

RECORD OF REVISION 0-3

Rev No. Description Page/ Date Inserted By Date

Initial Issue Complete Issue All Sonardyne Int Ltd 20/12/2010

Head Office

Sonardyne International Limited

Blackbushe Business Park,

Yateley, Hampshire,

GU46 6GD, UK

T. +44 (0) 1252 872288

F. +44 (0) 1252 876100

www.sonardyne.com

User Manual: Generic Section

Section: Introduction 0-4

Revision: 00

Page 1 of 21

INTRODUCTION 0-4

Contents

1GENERAL

2OBSERVANCE OF THE USER MANUAL

3WARRANTY

4HOW TO USE THIS USER MANUAL

5UNITS OF MEASUREMENT

6VERIFICATION

7GLOSSARY OF TERMS

8GENERAL SAFETY PRECAUTIONS

9HAZARD APPRECIATION

10 GENERAL HANDLING OF EQUIPMENT

11 DISMANTLING SUB-SEA EQUIPMENT

11.1 INSTRUMENTS FITTED WITH SPRUNG VENT PLUGS

11.2 PRECAUTIONS (INSTRUMENT FULLY FUNCTIONING)

11.3

PRECAUTIONS (INSTRUMENT KNOWN OR SUSPECTED TO BE

PRESSURISED)

12 INSTRUMENT LOAD BEARING CAPABILITY

13 FLOATATION EQUIPMENT

Head Office

Sonardyne International Limited

Blackbushe Business Park,

Yateley, Hampshire,

GU46 6GD, UK

T. +44 (0) 1252 872288

F. +44 (0) 1252 876100

www.sonardyne.com

User Manual: Generic Section

Section: Introduction 0-4

Revision: 00

Page 2 of 21

1 GENERAL

This User Manual is issued by Sonardyne International Limited.

This User Manual contains all the information necessary to operate and maintain the equipment in an

operational environment.

This User Manual contains the technical data, operating instructions, maintenance schedules, maintenance

procedures, spares information and all applicable drawings and parts lists.

This User Manual is divided into the sections that follow:

01 Preliminaries:

Table of Contents 0.1

Customer Change Request Form (CCRF) 0.2

Record of Revisions 0.3

Introduction 0.4

02 Technical and Functional Description

03 Technical Data

04 Operating Instructions

05 Maintenance

06 Fault Finding and Testing

07 Removal

08 Operational Test

09 Repair

10 Battery Safety

11 Upgrading Firmware

12 Installation

13 Acoustic Navigation Principle

14 Spares

15 Drawings and Parts Lists

16 Deployment

17 Equipment Log Book

User Manual: Generic Section

Section: Introduction 0-4

Revision: 00

Page 3 of 21

2 OBSERVANCE OF THE USER MANUAL

This User Manual must only be used by trained and qualified maintenance personnel that are familiar with

the equipment included in this User Manual.

It is the responsibility of the customer, to make sure that all operation and maintenance personnel that will

operate and maintain the equipment included in this User Manual are correctly trained and qualified.

Before you operate or do any work on the equipment you must read and obey all sections of this User

Manual.

You must keep the Equipment Log Book up to date and current.

The procedures and instructions in this User Manual have been provided to maintain the integrity and

serviceability of this equipment only.

You must follow all procedures and instructions in this User Manual as they are given. If you do not follow

the procedures / instructions correctly, you can cause damage to the equipment, its assemblies, components

or parts.

Only the procedures and instructions given in this User Manual have the approval of Sonardyne International

Limited. If a necessary procedure or instruction is not given in this User Manual, before you continue you

must contact Sonardyne International Limited.

Only the parts given in this User Manual have the approval of Sonardyne International Limited.

You must read and obey all WARNINGS and CAUTIONS given in this User Manual.

For all consumable materials you must also read and obey the manufacturers’ health and safety instructions.

If the WARNINGS and CAUTIONS given in this User Manual are different to those given by the

manufacturer, you must obey those given by the manufacturer.

All operations and work done on this equipment must be done in accordance with the local health and safety

and environmental regulations and the safe working practices of the applicable site, installation or

operational environment.

User Manual: Generic Section

Section: Introduction 0-4

Revision: 00

Page 4 of 21

3 WARRANTY

Sonardyne International Ltd warrants, subject to the following conditions, upon the return of the goods to its

works or with prior approval to a local agent, carriage paid, to examine it or them and should any fault due to

defective design, material or workmanship be found, to repair the defective part or parts or, at its own

discretion, to supply a new part or parts in place of the same free-of-charge.

Any claim under this warranty must be lodged in writing with Sonardyne within twelve months and the part or

parts returned to Sonardyne within thirteen months of the commencement of the warranty. The warranty will

commence upon the commissioning or putting into service of the equipment or one month from shipment

from Sonardyne, whichever is the sooner.

No claim can be accepted for damage due to fair wear and tear, misuse, neglect, dirt, accident, overloading,

or other similar causes, and Sonardyne International Ltd judgement in all matters relating to claim shall be

final and conclusive and the buyer agrees to accept Sonardyne International Ltd decision on all questions as

to defects and as to the exchange of any part or parts.

Goods supplied to buyer's drawings or designs are not warranted by Sonardyne International Ltd to be fit for

any particular purpose.

The foregoing warranty is rendered void in any of the following circumstances:

a) If any seal, safety device, identification, or instruction plates are deliberately broken or removed

from the goods.

b) If any pressure housing has been opened.

c) If the goods are worked beyond their rated capacity.

d) If any parts or accessories other than those approved by Sonardyne International Ltd, have

been fitted to the goods.

These contractual warranties are in addition to and shall not be construed to modify or limit in any manner

any rights or actions which the buyer may otherwise have against Sonardyne by law or statue, or in equity.

In the event that agreement cannot be reached the matter will be placed in the hands of an independent

arbitrator appointed by the London Chamber of Commerce whose decision shall be binding on both parties.

User Manual: Generic Section

Section: Introduction 0-4

Revision: 00

Page 5 of 21

4 HOW TO USE THIS USER MANUAL

Look on the Title page. Make sure this User Manual is applicable to the equipment that you will operate and

do work on.

Use the Table of Contents (TOC) to find the applicable section of the User Manual.

Use the applicable sections of this User Manual to do the necessary task.

Before you start a task, read and obey the applicable WARNINGS and CAUTIONS.

To find the applicable part of an assembly or component, refer to Section 14 – Spares.

This User Manual is designed so that you can remove separate sections to make a copy to help you do the

task. You must make sure that you return any section or part of the User Manual that you remove.

You must keep this User Manual clean, readable and complete.

You must tell Sonardyne International Limited of any errors that you find when you use this User Manual.

The content of each section of the User Manual is described in the following paragraphs:

Technical and Functional Description Para.3.1

Technical Data Para.3.2

Operating Instructions Para.3.3

Maintenance Para.3.4

Fault Finding and Testing Para.3.5

Removal Para.3.6

Repairs Para.3.7

Installation Para.3.8

Spares Para.3.9

Drawings and Parts Lists Para.3.10

Appendices Para.3.11

User Manual: Generic Section

Section: Introduction 0-4

Revision: 00

Page 6 of 21

3.1 Technical and Functional Description

Description of the assemblies that make up the equipment and how they operate.

3.2 Technical data

All the equipment Specifications included in the User Manual.

3.3 Operating instructions

This section gives the information necessary to operate the equipment.

3.4 Maintenance

This section gives all the necessary information to maintain the equipment. It includes the

recommended lubricants, maintenance codes, schedules and maintenance tasks. The maintenance

section also includes any applicable inspections or adjustments. The maintenance tasks do not

include any schedule or frequency information.

3.5 Fault Finding and Testing

This section gives the necessary information for the purpose of identifying faults with the equipment. It

also includes any necessary functional tests of equipment with test equipment.

3.6 Removal

This section gives the necessary procedures to remove the equipment, assemblies, sub-assemblies or

components for the purpose of maintaining the equipment.

3.7 Repairs

This section includes any applicable repair procedures necessary to return the equipment to a

serviceable condition.

3.8 Installation

This section gives the necessary procedures to install the components,

sub-assemblies, assemblies and equipment, for the purpose of maintaining the equipment.

3.9 Spares

This section gives the recommended spares necessary to operate the equipment in addition to a

detailed list of all the replaceable parts installed on the equipment.

3.10 Drawings and Parts Lists

This section gives all the drawings and Parts Lists applicable to the equipment.

3.11 Appendices

This section gives any additional information that is a supplement to the User Manual, but may be

necessary to operate and maintain the equipment.

User Manual: Generic Section

Section: Introduction 0-4

Revision: 00

Page 7 of 21

5 UNITS OF MEASUREMENT

All dimensions, weights, pressure, torque values, etc. in the User Manual are normally given in metric units.

But, when required they will be followed by imperial units in parentheses.

6 VERIFICATION

All technical data, descriptive, operational and procedural information given in this User Manual has been

approved by Sonardyne International Limited.

7 GLOSSARY OF TERMS

NOTE: The terms that follow are general and are not specific to this User Manual.

NOTE: The table that follows contains User Operator Terms, Sonardyne Systems, Signal Processing and

Communication Terms and General Terms.

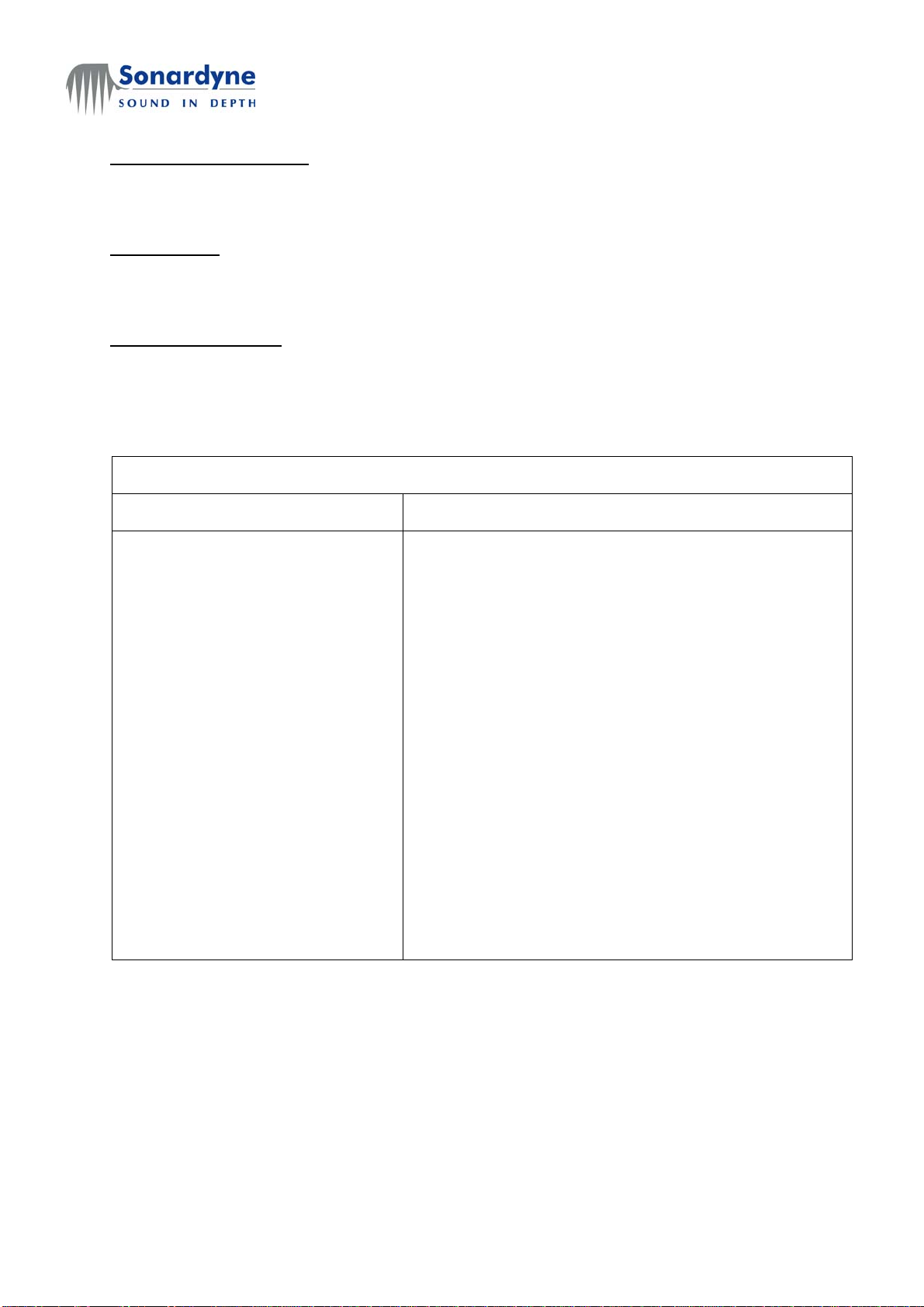

User Operator Terms

Term Definition

Acoustic Transceiver An instrument that emits acoustic signals and receive acoustic

signals and extract information from them. Transceivers can

measure the time it takes a signal to travel from its transducer

to a transponder and return. Some can encode and send data

in a message and extract digital data from a message

(Acoustic Telemetry). Used on a surface vessel or to mark a

point on the seabed, or fixed to a mobile for tracking or

positioning.

Acoustic Transponder An instrument that emits an acoustic signal when it detects an

interrogating acoustic signal.

Acoustic Responder An instrument that emits an acoustic signal in response to an

electrical signal carried to it by cable

Acoustic Synchronous/ Precision Pinger An instrument that emits signals regularly without an

interrogating signal. A SYNCHRONOUS Pinger can be

synchronised to an external master signal.

A PRECISION Pinger has an accurate internal time standard

Acoustic Transducer A device that converts electrical signals into acoustic signals

and vice-versa

User Manual: Generic Section

Section: Introduction 0-4

Revision: 00

Page 8 of 21

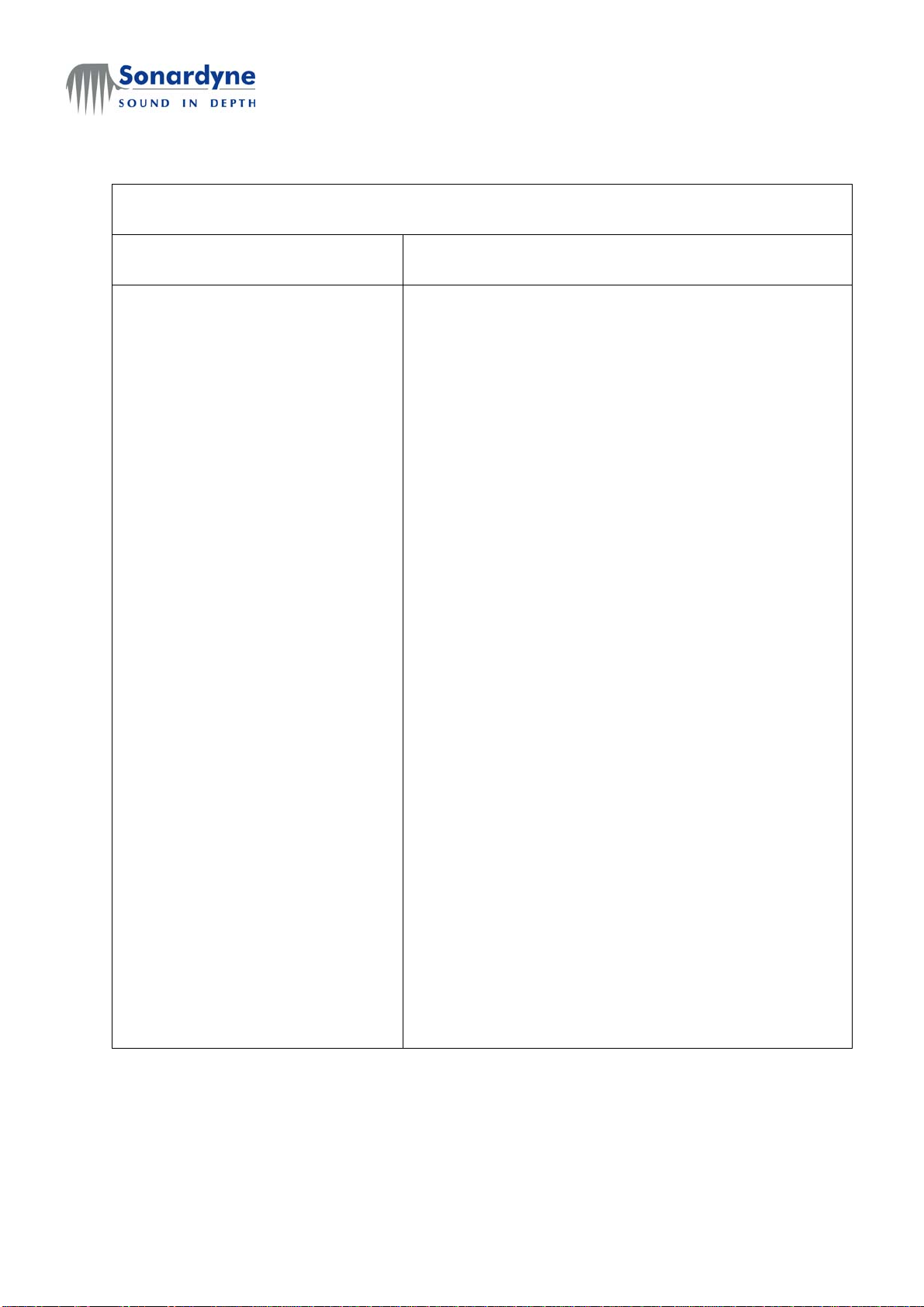

User Operator Terms

Term Definition

Acoustic Transponder (Intelligent

Transponder)

A type of transponder that is managed by a micro-controller.

Examples include the COMPATT (COMPuting And Telemetry

Transponder) and the WMT (Wideband Mini Transponder).

Depending on supported functionality it can:

Decode acoustic telemetered commands from a transceiver

and can send telemetered data to the transceiver. It can

measure the distance between itself and other transponders

and then telemeter the data to a transceiver. It can be capable

of measuring its depth and the temperature of the water.

It can be used to measure a variety of underwater parameters

and telemeter these back to the surface. It can be used, as an

intelligent angle-measuring device, in a Riser Angle Monitoring

System.

It can be fitted with a release mechanism so it can return, on

command, back to the surface e.g. if battery power is low.

Acoustic Signal Information carried by sound pressure waves through water.

The Sonardyne acoustic signal has a finite length

Common Reply Signal (CRS) A reply signal common to a complete family of addressed

transponders.

COMPATT COMPuting And Telemetry Transponder (see Acoustic

Intelligent Transponder).

Data Acquisition Sub-Assembly (DAS) A micro – controlled data acquisition and logging sub assembly

located within a transponder.

Database A body of data stored in a computer memory, magnetic disc

media e.g. embedded hard disc or portable floppy disc

Data Fusion Engine (DFE) Acts as the system controller, generates the display signals for

the monitor, processes the data from the transceiver for the

display to the operator and output to a DP system and talks to

various "attitude" sensors and other navigation systems

Differential Global Positioning System

(DGPS)

A 24 hour, world-wide radio navigation system. GPS receivers

track and decode the data from satellites and calculate the

position and speed of a vehicle.

User Manual: Generic Section

Section: Introduction 0-4

Revision: 00

Page 9 of 21

User Operator Terms

Term Definition

Digital Signal Processing (DSP) The representation of signals by a sequence of numbers or

symbols and the processing of these signals. DSP includes

subfields like: audio and speech signal processing, sonar and

radar signal processing, sensor array processing.

Dynamic Positioning System (DPS) Automatically maintains a vessel with a constant heading, and

in a fixed position without an anchor and provides more

flexibility in operation

Dynamic Positioning reference (DP

Reference)

Several position inputs e.g. GPS receivers, taut wire sensors,

LBL, SBL or USBL acoustic positioning sensors, wind speed

indicators etc

Dynamic Positioning telegram (DP

Telegram)

The report an acoustic positioning system sends to a DP

system over a serial interface

Geodetic Co-ordinates The position of any point on or near the earth surface is defined

by an angle of latitude and an angle of longitude.

For a point on earth P:

Latitude is defined as the angle between the normal plane at P

and the plane of the earth’s equator.

Longitude is defined as the angles between the meridians

plane through P and the defined zero meridian plane or

"Greenwich" plane.

(Ref. Geodesy, fourth edition, Bomford, Oxford, sections 2.03

and 4.10(d)).

Gyro Compass A gyro compass is similar to a gyroscope. It is a compass that

finds true north by using an (electrically powered) fast-spinning

wheel and friction forces in order to exploit the rotation of the

Earth. Gyro compasses are widely used on ships. They have

two main advantages over magnetic compasses:

They find true north, i.e., the direction of Earth's rotational axis,

as opposed to magnetic north.

They are far less susceptible to external magnetic fields, e.g.

those created by ferrous metal in a ship's hull.

Inclinometer An analogue device, which measures the angle of the

transponder.

Individual Interrogation Signal (IIS) Signal used to uniquely address a transponder, based on the

transponders acoustic address.

Individual Reply Signal (IRS) Signal used to uniquely identify a reply from a transponder.

Mobile An object that can move freely between the seabed and the

sea surface.

User Manual: Generic Section

Section: Introduction 0-4

Revision: 00

Page 10 of 21

User Operator Terms

Term Definition

Monitor/Keypad A monitor contains a 12 inch colour graphics display and has a

keypad for operator input.

A later version of this unit has a 17 inch high resolution

monitor. The monitor and keypad are split into two separate

units. Both are designed for 19 inch rack mounting

Marine Riser Angle Monitoring System

(MRAMS)

Used for measuring the angle between the Blow-Out Preventer

(BOP) on the seabed and the Riser.

Navigation Sensor Hub (NSH) The NSH is the interface between the in-water acoustic

instruments, sensors and the Navigation Computer which runs

the acoustics positioning software.

Remotely Operated Vehicle (ROV) A vehicle controlled and powered by a cable connection so it

can travel between the sea surface and the seabed

Heading, Roll and Pitch (HRP) Is a compensated vessel frame. This is a frame sharing the

same origin as the vessel frame but with the z axis vertical and

the y axis parallel with a meridian passing through the origin

(points true north)

Seabed The surface of the earth covered by sea water. The seabed is

considered stationary

Spread Spectrum (SS) Spread-spectrum techniques are methods by which a signal

(e.g. an electrical, electromagnetic, or acoustic signal)

generated in a particular bandwidth is deliberately spread in the

frequency domain, resulting in a signal with a wider bandwidth.

These techniques are used for a variety of reasons, including

the establishment of secure communications, increasing

resistance to natural interference and jamming, to prevent

detection, and to limit power flux density.

Unit Identification Number (UID) Each product produced by Sonardyne Int Ltd contains a unique

24bit address. It is denoted by 6 hexadecimal characters.

Wideband Test Terminal (WTT) PC software for testing 6G transponders and transceivers.

Sonardyne Wideband®2 6G® transponders and transceivers use Sonardyne

Wideband® 2 which has ultra-wide bandwidth signals giving a

faster and robust transmission of data, more precise ranging

and mitigation from multipath in shallow water and amongst

steel structures in deepwater.

6 Generation (6G®) 6G® technology gives a better performance, easier to use,

more functions, equipment flexibility and compatibility with

aided inertial technologies.

User Manual: Generic Section

Section: Introduction 0-4

Revision: 00

Page 11 of 21

Sonardyne Systems

Term Definition

Long-Base-Line (LBL) System A system where two or more transponders are on the seabed.

The positions of the transponders are established by a

calibration process in a seabed frame.

The distances from a transducer to each transponder are

measured using a transceiver.

The position of the transducer can be computed in the seabed

frame.

The name comes from the "baselines" joining each

transponder. It is can be to as a range-range system

Short-Base-Line (SBL) System A system where three or more transducers are fixed to a vessel

and connected to a single transceiver.

The position of each transducer is measured and co-ordinated

in the vessel frame. By measuring the time of arrival of the

signal from a transceiver at each transducer the position of the

transceiver in the vessel frame can be computed.

Ultra-Short-Base-Line (USBL) System A system similar to an SBL system except the system uses

three or more elements in a single transducer array.

The measurements it makes are the differences in "time-

phase" of the signals from each element.

The co-ordinate frame is fixed to the transducer array which

must be oriented in the vessel frame to be equivalent to the

SBL system.

Long-Ultra-Short-Base-Line (LUSBL)

system

A hybrid of an LBL and a USBL system. It utilises USBL

equipment in an LBL configuration.

Dual-Redundant LUSBL System Two complete sets of LUSBL equipment working in tandem on

a master/slave basis.

The two sub-systems are cross-linked so that, in the event of a

failure of any major elements, system operation will continue

without the need for operator intervention.

Operation of the dual-redundant version is identical to that of

the standard version.

EHF Extra-High Frequency (50-110kHz)

HF High Frequency (35-55kHz)

LF Low Frequency (7.5-15kHz)

LMF Low-Medium Frequency (13-17kHz)

MF Medium Frequency (18-36kHz)

Sound Speed If seawater is at a constant temperature, salinity and pressure

the speed at which sound travels in seawater is constant.

Sound speed can be derived from values of conductivity,

temperature and depth, or it can be measured directly using

time-of-flight instruments.

User Manual: Generic Section

Section: Introduction 0-4

Revision: 00

Page 12 of 21

Sonardyne Systems

Term Definition

Sound Speed Profile At different depths the temperature, salinity and pressure vary,

so the local sound speed varies.

Depth cannot be measured directly. So pressure

measurements are taken, and the depth calculated, using

knowledge of density and local gravity. Derivation of density

requires knowledge of temperature and salinity. Salinity cannot

be measured directly but conductivity can be measured.

A method of measuring the sound speed profile is from a

profile of pressure, temperature and conductivity and a formula

to compute depth and sound speed.

Submersible A vehicle that operates below the seas surface.

It can carry men in a one atmosphere environment with one

man piloting the craft.

It has a supply of air for the crew and a supply power for

propulsion etc. It can operate autonomously form a vessel for

a limited time.

True North The direction of the shortest line that can be drawn, across the

surface of the earth, from the observer and the north pole.

(The north pole is where the north end of the spin axis of the

earth meets the surface.)

Universal Transverse Mercator (UTM) A Projection system that is used to transform Geodetic co-

ordinates into an orthogonal two dimensional system suitable

for representation on a plane such as a chart. The co-ordinates

are called easting and northing which are equivalent to x and y

respectively. The UTM system is a world wide system.

Each projection covers 6 degrees of longitude with the central

meridian at 3, 9 degrees etc east of Greenwich and from 84

degrees north to 80 degrees south. The scale factor on a

central meridian is 0.9996 (with some exceptions).

The projection is orthomorphic this means at a point the scale

in all directions is the same there is no local distortion. NOTE:

Scale factors change with distance from the central meridian.

For points away from the central meridian grid north and true

north diverge. The difference is called the CONVERGENCE

which is positive when grid north is east of true north. The point

where the central meridian meets the spheroid equator is given

a false easting of 500,000 m. Many countries’ mapping

systems are based on the same system but use a particular

reference spheroid.

This manual suits for next models

2

Table of contents

Other Sonardyne Transceiver manuals

Popular Transceiver manuals by other brands

Technisonic Industries Limited

Technisonic Industries Limited TiL-91-DE/8.33 Installation and operating instructions

Kenwood

Kenwood NX-1200NE2 user manual

Allied Telesis

Allied Telesis CentreCOM AT-200 Series user manual

Kenwood

Kenwood TM-V71E Service manual

Standard Horizon

Standard Horizon HX260S owner's manual

WAGO

WAGO I/O-SYSTEM 750 manual