SONIX 30D Installation instructions

ULTRASONIC FLOWMETER

SONIX 30D

INSTRUCTION FOR ASSEMBLY AND OPERATING

SONIX®

Industri l Electronic Devices

ul. Leopold Lis -Kuli 12, 05-270 M rki, Pol nd

phone:+4822-7811133, f x: +4822-7811644

www.sonix.com.pl

Instructions for Assembly nd Oper ting SONIX 30D

Contents

GENERAL INFORMATIONS ON SAFETY................................................................................................. 3

Introduction............................................................................................................................................ 3

Symbols................................................................................................................................................. 3

Discl imer.............................................................................................................................................. 3

INTRODUCTION........................................................................................................................................ 4

Component p rts .................................................................................................................................. 4

List of supplied elements....................................................................................................................... 4

Purpose ................................................................................................................................................ 4

B sic technic l d t .............................................................................................................................. 4

ASSEMBLY................................................................................................................................................. 5

Mech nic l ssembly of the flow sensor ...............................................................................................5

Me surement ex mple of sew ge flow in gr vit tion l pipeline ....................................................5

Length of str ight sections of the pipeline.........................................................................................5

Recommend tions for the flow sensor ssembly..............................................................................6

The producer’s supervision over the ssembly nd st rt-up .................................................................6

Sp ce for the ssembly of ultr sound probes ..................................................................................6

User’s prep r tion for ssembly ...................................................................................................... 7

Assembly of the me suring tr nsducer.................................................................................................. 7

Electric l connections ...................................................................................................................... 8

Probe's c ble correct ending............................................................................................................ 8

OPERATING............................................................................................................................................... 9

Gener l Inform tion .............................................................................................................................. 9

Descriptions of the menu..................................................................................................................... 10

B sic m in screens.............................................................................................................................. 10

E0 Flow Volume.............................................................................................................................. 10

E1 Upper threshold Lower threshold...............................................................................................10

E2 Di gnostic screen...................................................................................................................... 10

E3 Di gnostic mess ges................................................................................................................ 11

E4 Working time Time of correct work............................................................................................11

E5 Seri l number Progr m version Checksums.............................................................................11

E6 SONIX phone number.............................................................................................................. 11

E7 Access code............................................................................................................................. 11

User functions screens........................................................................................................................ 11

F1 R nge flow Qp........................................................................................................................... 11

F2 Setting the thresholds................................................................................................................ 12

F3 Ch nge of the current output properties...................................................................................12

F4 P r meters of the RS485 output............................................................................................... 12

F5 Time const nt............................................................................................................................ 12

F6 Ch nge of displ y precision ...................................................................................................... 12

F7 Access code ch nge ................................................................................................................ 12

F8 Tempor ry volume..................................................................................................................... 12

F9 C libr tion of the current output ................................................................................................ 12

F10 C libr tion of the pulse output ................................................................................................ 12

F11 L ngu ge selection.................................................................................................................. 12

F12 St rting the b cklight............................................................................................................... 12

F13 Pulse unit ch nge.................................................................................................................... 12

F14 Aver ging................................................................................................................................ 12

F15 Amplific tion............................................................................................................................ 12

ERRORS.................................................................................................................................................. 13

Gener l inform tion............................................................................................................................. 13

Di gnostic mess ges........................................................................................................................... 13

Servicing ............................................................................................................................................. 13

THE SERIES RS485 OUTPUT................................................................................................................. 14

Protocol description............................................................................................................................. 14

Electric l connections.......................................................................................................................... 14

List of registers.................................................................................................................................... 15

GUARANTEE CERTIFICATE .................................................................................................................. 16

©SONIX 2016 Act. 17.02.2017

2

Instructions for Assembly nd Oper ting SONIX 30D

GENERAL INFORMATIONS ON SAFETY

3

Introduction

Symbols

Disclaimer

The symbols used in this m nu l or pl ced on the flowmeter h ve the

following me ning:

Attention: Risk of electric l shock

PROTECTIVE EARTH TERMINAL

Attention: Identify conditions th t could result in

injury or loss of life nd lso could result in

flowmeter d m ge. In e ch c se the expl n tion is

in this m nu l.

- Assembly nd oper ting of the flowmeter is not llowed without re ding,

underst nding nd following the inform tions in this m nu l

- Sevice of the flowmeter performs SONIX only

- For power supply of the flowmeter use 1-ph se m ins with protective e rth

- Do not use the flowmeter with removed cover

- Before removing cover switch off power supply

- The recommend tions nd w rnings cont ined in this m nu l nd pl ced

on the flowmeter should be followed

- Using the flowmeter in w y or in conditions incomp tible with this m nu l

m y result in flowmeter d m ge, loss of w rr nty or reducing protection

provided by the flowmeter

- SONIX reserves the right to ch nge the product in order to incre se its

utility v lues or djust it to current regul tions. Such ch nges m y not be

t ken into ccount in the current version of the m nu l. SONIX is not

responsible for consequences it imply.

- The purch ser is responsible for the selection of suit ble flowmeter

- W rr nty is given in ccord nce with terms specified in Gu r ntee

Certific te

Instructions for Assembly nd Oper ting SONIX 30D

INTROD CTION

4

Component

parts

Purpose Me surement of flow intensity nd summing the volume of flowing liquids in

closed, fully filled pipelines in both directions. Me sured v lues re v il ble

on pulse nd current outputs s well s on RS485 output with Modbus RTU

protocol.

Influence of unsymmetric l flow velocity profile on me surement ccur cy is

signific ntly reduced th nks utilising 3 coustic p ths. In ddition, dyn mic

p ths repl cement llow flowmeter to continue oper tion even if one or two

p ths f il.

The device is equipped with n LCD displ y. Oper tion is very simple th nks

to intuitive menu. With 2 buttons, you c n en ble / dis ble e ch function.

Basic technical

data

List of supplied

elements

The following elements constitute the flowmeter set:

- me suring tr nsducer

- flow sensor with two or six ultr sonic probes including c bles

- instructions for Assembly nd Oper ting nd Gu r ntee Certific te

- “wet” c libr tion certific te for the flowmeters c libr ted in the SONIX

comp ny flow st nd or theoretic l c libr tion certific te

The SONIX 30D flowmeter consists of flow sensor with 2 or 6 ultr sonic

probes nd me suring tr nsducer connected together with probes c bles.

The flow sensor is v il ble in three versions:

1. An U-sh ped section ended with fl nges or screw thre d

(DN15...40)

2. A section ended with fl nges (DN50...200)

3. An existing section of pipeline (DN250...2000)

Addition l equipment:

- Flow simul tor SONIX S2

- Probes exch nge ble under pressure for versions 3 (from DN250)

Pipe di meter r nge 15 ÷ 2000mm

Liquid flow velocity r nge 0 ÷ 15m/s

Liquid temper ture r nge 0 ÷ 150 oC moment ry to 180oC

Ambient temper ture r nge +5 ÷ +55 oC

Working pressure 0,03 ÷ 2,5 (4.0) MP

Me surement ccur cy σ=±0.3% m.v.

Me suring tr nsducer protection c tegory IP54

Power supply overvolt ge to Cl ss II wg IEC 60364-4-443

R ted pollution degree 2

Pulse output cl ss OC

Instructions for Assembly nd Oper ting SONIX 30D

ASSEMBLY

5

Mechanical

assembly of the

flow sensor

The choice of location and manner of the assembly of the flow sensor

decides on the metrological properties of the device.

The following conditions must be met in order to provide correct

me surement:

1. L ck of er tion of the liquid

2. 100% filling of the pipeline

3. Sm ll ttenu tion of the ultr sound w ve

3. St bilized nd symmetric l profile of liquid speed

The U-sh ped sensor must be ssembled horizont lly or t the 45° ngle

m x. The ssembly position of the rem ining type of sensor depends on the

choice of the user. The probes must be loc ted in the horizont l surf ce i.e.

t both sides of the pipeline nd not below nd bove it. The ccept ble

devi tion from the level equ ls 25°.

Length of

straight

sections of the

pipeline

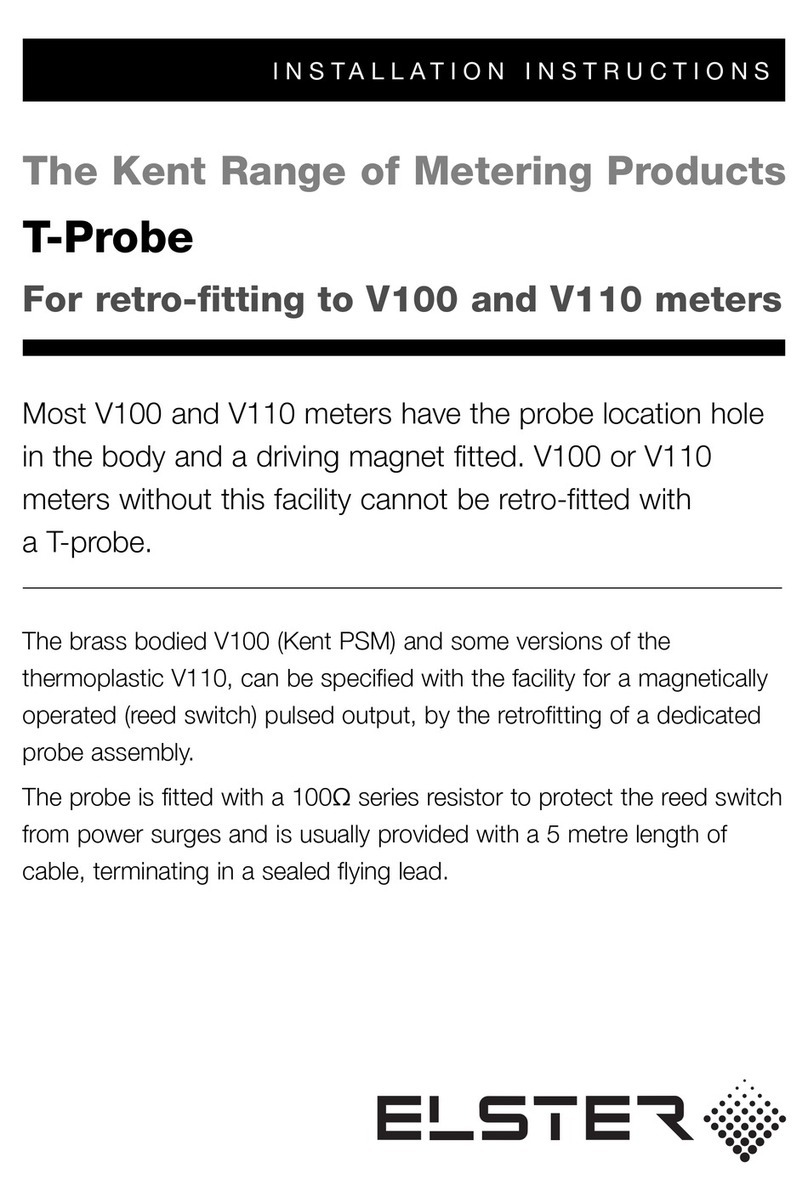

Measurement

example of

sewage flow in

a gravitational

pipeline

In the m jority of c ses, str ight sections of the following lengths re

sufficient:

- Inlet: 10D

- Outlet: 3D

Two- or more surf ce sp ti l configur tions of the pipeline, the pump, not

entirely closed v lves, side inlets etc. require ppropri te elong tion of the

str ight sections before nd behind the me suring spot. The U-sh ped flow

sensor does not require str ight sections.

10D

15D

20D

3D

Swelling w ter se l

h=50cm

3D

10D

SONIX 10D

Open de er ting t nk with bulkhe d

Liquid level

Access eye for removing solid impurities

The elements of the me suring system shown on the following figure provide

the conditions necess ry for the correct me surement:

- De er tion of the inflowing sew ge

- 100% filling of the pipeline

- L ck of ccumul ting deposit in the flow sensor

- Symmetric l profile of liquid speed

Instructions for Assembly nd Oper ting SONIX 30D

6

Recommendations

for the flow sensor

assembly

The producer’s

supervision over the

assembly and start-

up (refers to

assembly on an

existing pipeline

DN250...DN2000)

Space for the

assembly of

ultrasound

probes

➢ Choose the longest v il ble str ight section of the pipeline. Inst ll the

sensor with probes on the 3/4 of its length st rting from the inflow.

➢ M ke sure th t in the selected spot the liquid will not be er ted nd ir or

solid impurities will not ccumul te there.

➢ The inside di meter of the pipeline nd the sensor should be the s me.

➢ Inst ll the sensor in such w y so the rrow on it is on top nd shows the

flow direction.

➢ The probes should be loc ted horizont lly on both sides of the pipeline

(never vertic lly).

➢ Inst ll tions on vertic l pipes is llowed but str ight sections must be

provided

➢ The se ls of the fl nge connections c nnot protrude into the inside of the

pipeline (protruding se ls c n c use the incre se of me surement error

from ± 5 to even ± 40%)

➢ Do not hit the flow sensor with h mmer or other devices. It m y d m ge

the probes.

➢ The f ctory numbers of the me suring tr nsducer nd the sensor must

be identic l.

➢ Pl ce the me suring tr nsducer in pl ce ppropri te for re dings from

the displ y nd ccessible for servicing te m.

➢ Run the sign l nd supply c bles in sep r te, own ch nnels nd tt ch

them to the termin l strip of the flowmeter in ccord nce with the m rkings

nd colours.

➢ The length of the c ble between the PE termin l of the flowmeter nd the

grounding vertic l should not exceed few meters.

The following ctivities m ke up the ssembly nd the st rt-up of the

flowmeter:

- Tr cing points on the pipeline

- M king 6 holes of pprox. 25mm di meter in the w ll of the pipeline,

drilling or cetylene cutting

- Electric l welding of tt ching sleeves to the steel pipeline or screwing

them to c st iron one

- Assembly of ultr sound probes

- Assembly of the me suring tr nsducer

- Connecting the me suring tr nsducer to the ultr sound probes with

tr nsmission c bles

- St rt-up of the flowmeter

- Setting to zero in the c se of stopped flow

0.5m

0.5m

0.5m D

1,8 D

min 1,2 m

Instructions for Assembly nd Oper ting SONIX 30D

7

Assembly of the

measuring

transducer

Protection c tegory of the me suring tr nsducer: IP54. It is ccept ble to

ssembly the device in the open ir in he ted protective c binet. Due to

temper ture r nge of +5..+55 C during the summer months, the c binet

should be loc ted in the sh dow.

ser’s

preparation for

assembly

➢ Choice of the me suring spot on the pipeline nd choice of me suring

tr nsducer loc tion. The st nd rd length of probes c bles is 6 x 5m. In

c se of doubts, it is recommended to consult SONIX represent tive.

➢ Prep r tion of the pipeline for ssembly:

- cle ning the surf ce of the pipeline from rust, insul tion etc on the whole

of its surf ce on the length of 1.8D

- emptying the pipeline for welding nd probe ssembly. The tent tive

emptying time equ ls pprox. 2 hours for steel pipeline nd pprox. 6

hours for c st iron one.

- filling the pipeline in order to st rt-up the flow meter. After the filling, it is

recommended to stop the flow for pprox. 10 min in order to set the

flowmeter to zero.

➢ Drilling or cetylene cutting of the holes of pprox. 25mm di meters nd

electric l welding for steel pipeline.

➢ Prep r tion of possible bushings, tubes, ducts etc. for probes c bles: six

c bles of the pprox. 6mm di meter.

➢ Arr ngement of the 230V AC supply nd sign l c bles connected to the

me suring tr nsducer.

Instructions for Assembly nd Oper ting SONIX 30D

8

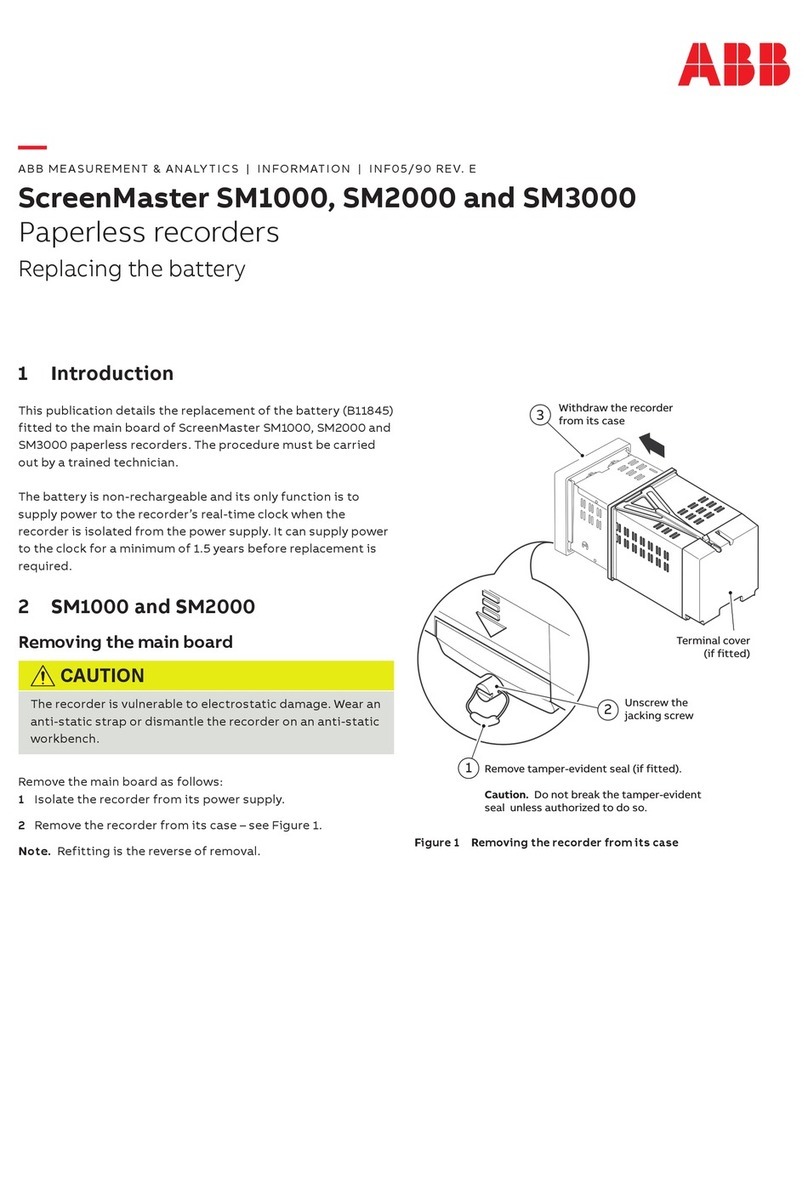

Electrical connections

Power supply conection

- Protective e rth conductor up to 2.5mm

- Protective e rth conductor up to 2.5mm

- Protective e rth conductor up to 2.5mm

2 (13 AWG) h s to be connected to

termin l of the flowmeter

termin l of the flowmeter

- Perm nent connection to the m ins 230V AC +10..-15% 50Hz 10VA

- Perm nent connection to the m ins 230V AC +10..-15% 50Hz 10VA

- Perm nent connection to the m ins 230V AC +10..-15% 50Hz 10VA

- It is dvis ble to provide n extern l overcurrent protection B type with

v lue of 1 A t dist nce of no further th n few meters from the

flowmeter with properly l beled power switch

- The power supply should h ve pplied reli ble limiters decre sing surge

to level which does not couse d nger

- Protective e rth c ble lenght should not exceed few meters

- It is forbidden connecting to protective e rth termin l ny other c ble th n

protective e rth conductor

- Power supply c ble should h ve di meter 5..6mm nd its c ble gl nd

should be ssembled properly

- A fitter of the system is responsible for security of the system comprising

the flowmeter

Probe's cable correct

ending

55 mm

25 mm

Rem rks:

- c ble shields of probes ABC connect to termin l 1

- c ble shields of probes DEF connect to termin l 14

- ddition l OC output is progr m ble from user menu level

Instructions for Assembly nd Oper ting SONIX 30D

OPERATING

9

General

Information

The user communic tes with the device vi the LCD 2 x 1 6 ch r cters

displ y using two push buttons for choice of functions or p r meters. The

principle of oper ting is s follows:

-The left one 'L': choice of function or digit

-The right one 'P': ch nge of function or v lue

-Left nd right one t the s me time 'O': ccept nce the ch nge

The menu consists of 8 b sic m in screens nd 15 screens of user’s

functions. User def ult ccess code: 1111

CABLES SHIELDS PROBES A, B, C

CABLES SHIELDS PROBES D, E, F

PROBE A CABLE

PROBE B CABLE

PROBE C CABLE

PROBE D CABLE

PROBE E CABLE

PROBE F CABLE

AUXILIARY VOLTAGE 15V 0.1A

PULSE OUTPUT OC

CURRENT

OUTPUT

RS485

OUTPUT

Pol ris tion nd termin tion

120om of the RS485 output with

both jumpers inst lled

FUSE T315mA

PULSE AND CURRENT OUTPUTS COMMON GROUND

ultr sonic sign l

oscilloscope ground

oscilloscope trigger

Active output 0/4...20mA

Rm x < 500om

Seri l digit l output RS 485,

protokol MODBUS RTU,

tr nsm. speed 1200...9600B/s

SUPPLY VOLTAGE

230V AC +10.. -15%

50Hz 10VA

ISOLATED OC

OUTPUT

Protective e rth

termin l

SERVICE

CONNECTOR

15

PE

L1

N

-

+

-

C

E

C

E

+

-

24

25

26

5V

1.5k

JP13

1.5k 120

JP14

22

23

16

17

18

19

20

21

+

RS 485

15V

+

-

Flowmeter SONIX 30D

bl ck

white

bl ck

white

bl ck

white

bl ck

white

bl ck

white

bleck

white

11

12

13

14

5

8

7

6

9

10

1

3

2

4

Instructions for Assembly nd Oper ting SONIX 30D

10

E1

pper threshold

Lower threshold

E2

Diagnostic screen

The current flow in m3/h nd the counted tot l volume in m3

For positive flow the volume counter counts up. For neg tive flow the counter

c n stop counting or c n count down.

Power f ilure does not c use deletion of volume counter d t or the loss of

other d t nd p r meters.

It is possible for the user to progr m the number (0...3) of displ yed

decim ls.

Threshold progr mming is v il ble in the user’s functions.

On E1 screen re only displ yed the progr mmed flow thresholds bove nd

below. Only one treshold c n be used t time. It is v il ble on OC output.

Upper line, from left:

-Flow speed in m/s

-Type nd 2 digits v lue of mplific tion djustment: r-m nu l djusting, -

utom tic djusting

-Desired nd current mode of work:

0 – l ck of liquid

1 – works only on the AB p th

2 – works only on the CD p th

3 – works only on the EF p th

4 – work only AB nd CD p ths

5 – work only CD nd EF p ths

6 – work only AB nd EF p ths

7 – 3 p ths me surement

Di gnostic mess ges re displ yed in the lower line:

‘Me surement OK’

‘Empty pipe’ – empty pipeline or disconnected probes

‘Low sign l' – decre sing of the sign l from p ir of probes

'Out of I r nge' – flow exceeding the current r nge of flowmeter

'Out of v r nge' – too high liquid speed

'Disturb nces' – more th n 50% of interfered me surements

'Inconsistency' – mode of work or CRC inconsistency

'Adjustment' – ultr sonic sign ls re djusting

E0

Flow

Volume

Descriptions of the menu

Basic main screens

Nr Button Upper line Bottom line

E0 Current flow Tot l volume

E1 Right Upper threshold Lower threshold

E2 Right Di gnostic d t Di gnostic mess ge

E3 Right Di gnostic mess ges Di gnostic mess ges

E4 Left Working time Time of correct work

E5 Left F ctory number L Progr m version CRC

E6 Left SONIX SONIX phone nymber

E7 Both Access code ****

Instructions for Assembly nd Oper ting SONIX 30D

11

E4

Working time

Time of correct

work

E6 SONIX phone

number

Working time me ns the number of hours the supply of the meter w s on.

Time of correct work me ns the number of hours without sign ling errors.

7 or 8 digits f ctory number, L – checksum s ved fter verific tion

4 digits progr m version, CRC – current checksum

E5

Serial number

Program version

Checksums

Using some of user's functions m y interfere with the current flow

me surements.

15-30s bre ks m y be observed.

Logo of the SONIX comp ny. Phone number of SONIX’s service.

E3

Diagnostic

messsages

Current f ilure condition mess ges re displ yed

E7

Access code

4 digits ccess to user funktions. Def ult v lue: 1111.

F1 Range flow Qp Progr mming of r nge flow in m3/h

ser functions screens

Nr Function

F1 R nge flow Qp

F2 Flow thresholds

F3 Current output

F4 RS485 output

F5 Time const nt

F6 Displ y precision

F7 Access code ch nge

F8 Moment ry volume

F9 Current output c libr tion

F10 Pulse output c libr tion

F11 L ngu ge

F12 LCD b cklight

F13 Pulse output unit

F14 Aver ging

F15 Probes djusting

Instructions for Assembly nd Oper ting SONIX 30D

12

Password chan

F12 Starting the

backlight

F3 Change of the

current output

properties

F2 Setting the

thresholds

F6 Change of

display precision

F9 Calibration of

the current

output

F15

Amplification

Switching on/off the illumin tion of LCD displ y.

Progr mming of the lower nd upper flow threshold in m3/h or t/h.

Progr mming from 0 to 3 decim ls for tempor ry flow nd the tot lized

volume.

Forcing the 0, 4, 10, 15 or 20mA current in order to chieve c libr tion of the

device connected to the current output of the flowmeter.

Six 3-digit numbers re visible on the screen. E ch digit represents the

mplific tion of the sign l from the probe.The sm ller the mplific tion the

stronger sign l from the probe. The correct v lues should be in r nge

100...500. When the mplific tion is gre ter then 750 it me ns th t the sign l

is too sm ll. This m y be due to sediment on the probe's surf ce or d m ge

of the probe.

The function llows dosing the liquid. The tempor ry liquid counter is set to

zero nd initi ted with the left push button nd stopped with the right one.

The counter m y lso be oper ted by the RS485 series link (see Protocol of

series tr nsmission).

F8 Temporary

volume

Ch nge of output current: 0-20mA or 4-20mA

Progr mming the ch r cteristics of the current output:

1 – the output works symmetric lly for the neg tive nd positive flows

0 – the output work only for the positive flow

bottom line:

1 – the current 4..0mA responds to flow 0..-0,25Qp (only for 4..20mA r nge)

F4 Parameters of

the RS485 output

Progr mming p rity control: Odd, Even, None, ddress of the device: 01H...FFH

nd tr nsmission speed: 1200B/s...9600B/s.

F5 Time constant Ch nging 0...9 responds to pp. 0,5...30s time const nt.

Time const nt is sep r ted from ver ging mode (F14).

This funkcion is un ccesible fter verific tion.

F10 Calibration

of the pulse

output

Forcing the pulses in order to chieve c libr tion of the device connected to

the pulse output of the flowmeter.

The number of pulses is in ccord nce with the progr mmed pulse unit (F13)

nd is shown s percent ge of the r nge flow Qp.

This funkcion is un ccesible fter verific tion.

F7 Access code

change

Allows user to ch nge 4 digits ccess code to user funkcions.

Def ult ccess code: 1111

F11 Language

selection

Menu l ngu ge selection. Av il ble re: Polish, English, Swedish

F13 Pulse unit

change

Pulse output unit ch nge in m3. Progr mmed unit must not be less th n the unit

displ yed in bottom line. Pulse unit ch nge is not v il ble fter verific tion.

F14 Averaging Selection of the ver ging method. Sever l methods re v i ble:

- rithmetic me n

- medi n

- extended medi n

- SONIX filter

This funkcion is un ccesible fter verific tion.

Instructions for Assembly nd Oper ting SONIX 30D

ERRORS

13

Service of the flowmeter is performed only by the SONIX servicing te m.

Service includes:

– supervision over the ssembly nd st rt-up of the flowmeter

– dignostic nd me surement error n lysis of existing inst ll tions

– rep ir of flowmeter electronic

– rel cement nd djustment of the ultr sonic probes

– „wet” c libr tion for flowmeters DN≤300

– theoretic l c libr tion cc. to PN/M- 42370 for flowmeters DN>200

Servicing

General

information

The l st 2 digits displ yed on the top line on the dignostic screen E2 should

be the s me. It me ns th t desired nd current mode of work re the s me.

In the c se of work on 3-p ths this digits re 77.

In the c se the digits re not equ l the f ilure is possible. For ex mple digits

71 me n th t the desired mode is working on 3 p ths but flowmeter works on

AB p th only.

In verified flowmeter checksums L nd CRC shown on E5 screen should be

the s me. Furthermore checksum L is printed on meters l bel.

When the checksums re not equ l pulse output is blocked nd the meter

sign ls inconsistency.

Diagnostic

messages

N ekr n ch E2 i E3 wyświetl ne są n stępujące komunik ty:

„me surement OK” – flowmeter me sures with no errors

„ djustment” – mlific tion is beeing djusted

„disturb nces AB, CD or EF” – more th n 50% re disturbed

„low sign l AB, CD or EF” – decre se of the sign ls from the p ir of

probes

„inconsistency” – current nd progr mmed mode of work re different or

checksums re not equ l for verific ted flowmeter

“me surement OK” - the me surements re done correctly.

Instructions for Assembly nd Oper ting SONIX 30D

THE SERIES RS485 O TP T

14

Protocol

description

Electrical

connections

The MODBUS RTU protocol of series tr nsmission is compli nt with the

current specific tion v il ble t www.modbus.org Tr nsmission speeds:

1200, 2400, 4800 or 9600 B/s. Addresses of the devices: 1 ...255.

Ch r cter form t:

-1 st rt bit

-8 d t bits

-1 p rity control bit (progr mm ble: Odd, Even, None)

-1 stop bit (or 2 stop bits when progr mmed to None).

Two functions re v il ble:

03 or 04 – re ding of the content of the flowmeter’s register group

06 – recording d t in the flowmeter register (register nr 31 only)

Examples of frames for the device of the 02 H address

1. Re ding of 2 registers beginning from register no 10 of the following

content:

register no 10: 057FH register no 11: 9D1AH

Order: 02,03,00,09,00,02,14,3A

Response: 02,03,04,05,7F,9D,1A,11,7C

2. Setting to zero nd st rting the tempor ry volume counter:

Order: 02,06,00,1E,00,01,28,3F

Response: 02,06,00,1E,00,01,28,3F

3. Stopping the tempor ry volume counter:

Order: 02,06,00,1E,00,00,E9,FF

Response: 02,06,00,1E,00,00,E9,FF

The pplied isol ted interf ce is compli nt with the EIA RS-485 st nd rd. The

tr nsmission line must be connected in ccord nce with l bels on the printed

pl te: RA – higher potenti l, RB – lower potenti l. In the c se of severe

electric l interferences or if the length of the c bles exceed 300m, p ired

twisted 120Ω c ble c t.4 w ve resist nce should be used.

If the flowmeter is loc ted t the end of tr nsmission line exceeding 300m,

line termin tion should be initi ted by tt ching the 2 jumpers (next to the

fuse on the printed pl te). Simult neously with the termin tion, the line is lso

pol rized with the pprox 2.5V volt ge. (see electric l connections of the

flowmeter). The flowmeter is supplied with jumpers tt ched.

Instructions for Assembly nd Oper ting SONIX 30D

15

List of registers

N me of the v ri ble

1 flo t LO Flow m3/h

2 HI

3 long int HI Positive volume m3

4 LO

5 int Positive volume l

6 flo t LO Liquid speed m/s

7 HI

8 bit errors 1... 16

9 long int HI

10 LO

11 long int HI Working time s

12 LO

13 long int HI Time of correct work s

14 LO

15 long int HI Tempor ry volume liter

16 LO

17 flo t LO Tempor ry volume

18 HI me surement time s

19 int

20 flo t LO 5 min ver ge of the flow

21 HI

22 flo t LO Hour ver ge of the flow m3

23 HI

24 int CRCL

25 Reserved

26 Reserved

27 ch r work mode: desired, current

28 int CRC

29 int

Register

no

V ri ble

type

Flowmeter seri l number

progr m vesion

AB probes dj., ut./m nu l

Rem rks:

16 bit registers, ch r, int, long int – v ri ble without sign

CRCL – checksum s ved fer verific tion

CRC – current checksum c lcul ted every 60s

Register no 8 (errors), 1 in given position me ns:

15 – correct me surement

14 – EF p th sign l djustment

13 – CD p th sign l djustment

12 – AB p th sign l djustment

11 – low sign l from EF p ir of probes

10 – reserved

9 – low sign l from the CD p ir of probes

8 – outside the r nge of ccept ble liquid speed

7 – checksum or mode of work inconsistency

6 – the flow exceeds the progr mmed current r nge v lue

5 – the s me s bit 1

4 – reserved

3 – reserved

2 – flowmeter self test

1 – l ck of liquid in the pipeline, d m ged probe c bles, d m ge of the

n logue p rt of the flowmeter, liquid er tion, electric l interferences

0 – low sign l from the AB p ir of probes

Instructions for Assembly nd Oper ting SONIX 30D

SONIX® Industri l Electronic Devices

ul. Leopold Lis -Kuli 12

05-270 M rki, Pol nd

phone +4822-7811133

f x +4822-7811644

sonix@sonix.com.pl

G ARANTEE CERTIFICATE

1. The producer gu r ntees good qu lity of the product nd its meeting the p r meters

defined in the Instruction for Assembly nd Oper ting.

2. The gu r ntee period covers 36 months from the d te of s les.

3. The free of ch rge gu r ntee rep ir sh ll be done within 48 hours from delivering the

product to the producer’s.

4. The producer undert kes to perform post-gu r ntee rep irs within the d tes specified in

point 3.

5.The gu r ntee sh ll not rem in v lid in the c se of:

- mech nic l d m ge to the product

- interferences to the inside of the product except for the c ses defined in the Instruction for

Assembly nd Oper ting

- oper tion incompli nt with the Instruction for Assembly nd Oper ting

6.The gu r ntee does not cover compl ints rel ting to incorrect working c used by extern l

f ctors or by d m ge of the product (e.g. the probes’ surf ce covering with deposit, presence

of ir in the pipeline, exceeding the llowed temper ture limit for the ultr sound probes etc.).

N me of the product: ULTRASOUND FLOWMETER, type: SONIX 30D

Purch sing comp ny:....................................................................................

F ctory numbers:

The SONIX 30D Flowmeter..............................................................................

D te of s le:.................................................................................................

16

Table of contents

Other SONIX Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Hanna Instruments

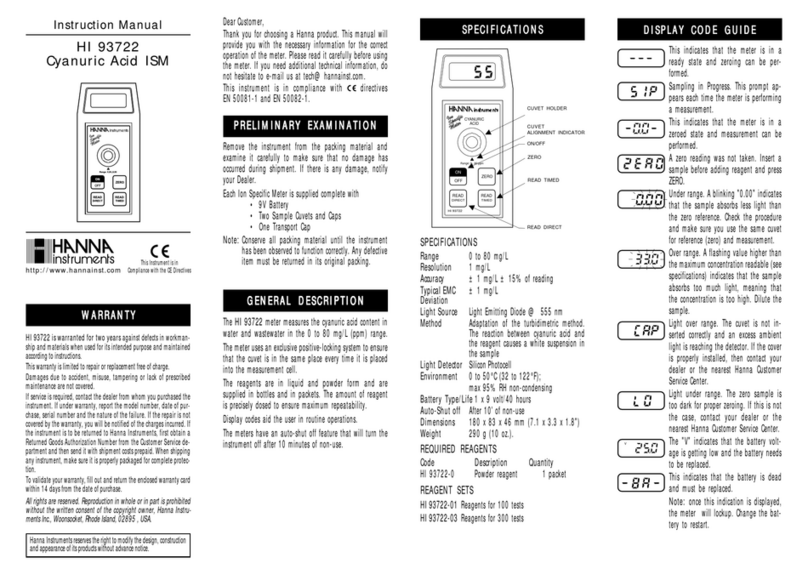

Hanna Instruments HI 93722 instruction manual

LI-COR

LI-COR LI-200R instruction manual

Ridder

Ridder PAR Sensor quick start guide

PCE Health and Fitness

PCE Health and Fitness PCE-G1 manual

Lignomat

Lignomat Ligno-Scanner SD User instructions

HEIDENHAIN

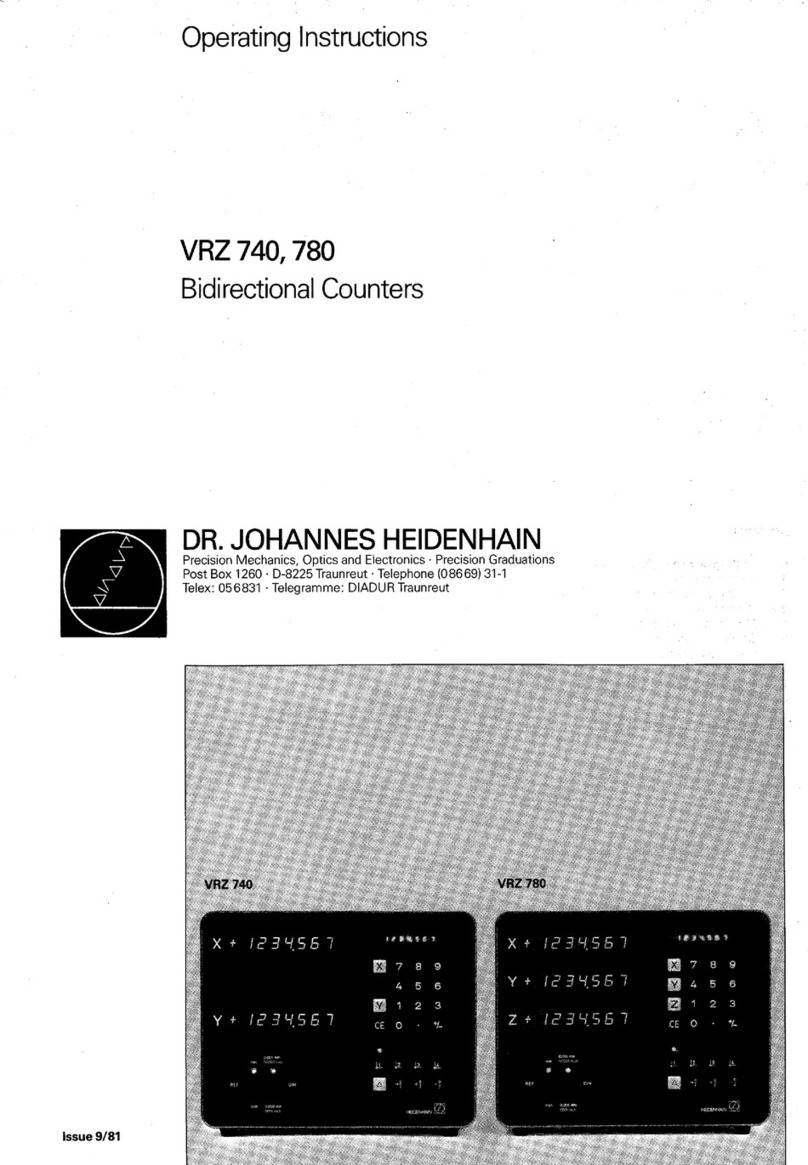

HEIDENHAIN VRZ 780 operating instructions

PCB Piezotronics

PCB Piezotronics 3713F11200G Installation and operating manual

Graco

Graco 234576 Instructions-parts list

Hanna Instruments

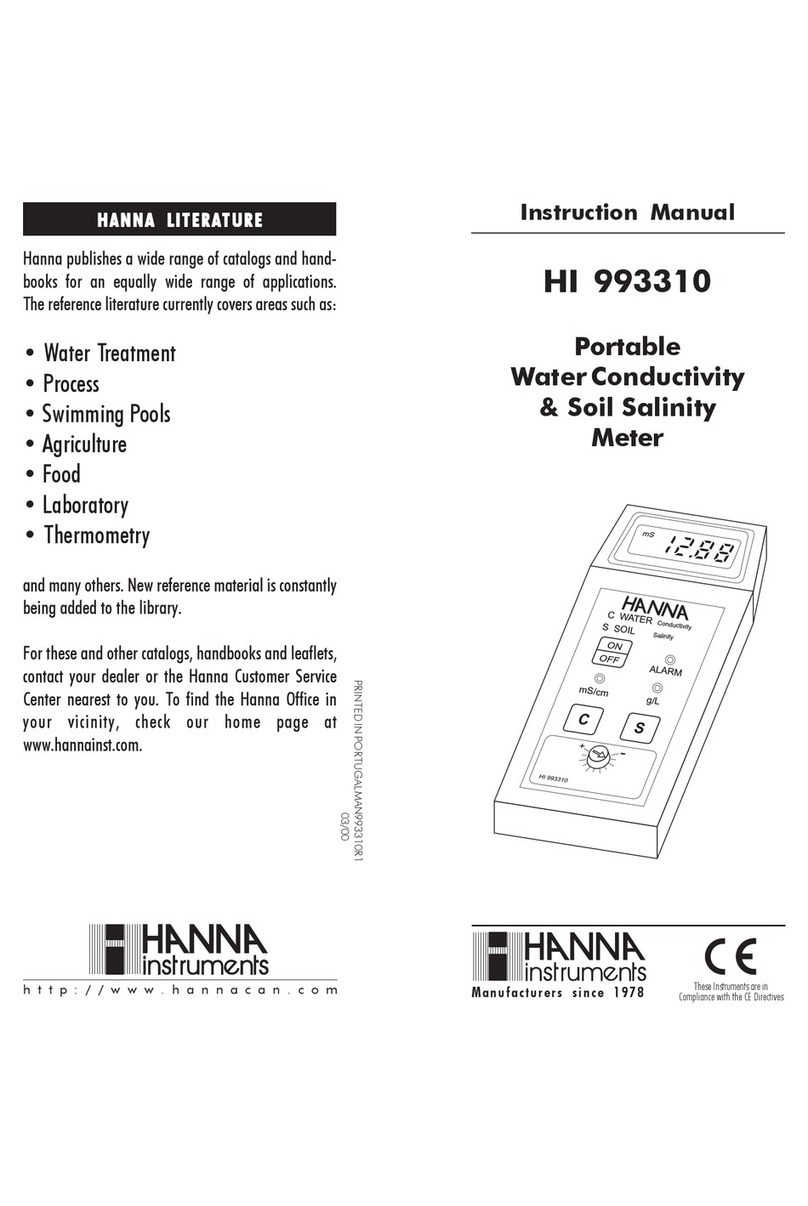

Hanna Instruments HI 993310 instruction manual

RS PRO

RS PRO IM-195 instruction manual

Rice Lake

Rice Lake 820i installation instructions

Agilent Technologies

Agilent Technologies N1913a user guide