II.Working with VRZ 740/780

By deciding upon counter VRZ 7401780,

you have purchased a unit which, due to

the practical design, makes positioning

easier, quicker and more economical.

This counter offers the possibility of

setting several datum points. Furthermore,

it is possible to position with “target”

counting whereby the tool radius can be

simultaneously taken into account.

Re-establishing the correlation between

datum points and reference marks of the

LS system is “automated”.

Traversing over the reference marks once

is sufficient to calibrate the counter in all

axes. (Previous determination of the

position value for the datum point is not

required.)

In addition to these advantages, the

counters are provided with keyboard entry

(keyboard display), selectable display step,

mm/inch converter, dimmer, direction

switch and pulse evaluation selector.

When reading the following explanations,

it is recommended to refer to the

illustration of the operating panel on

page 20. The encircled figures (0, 0,

0.. .) of a 3 axes counter are explained in

this illustration.

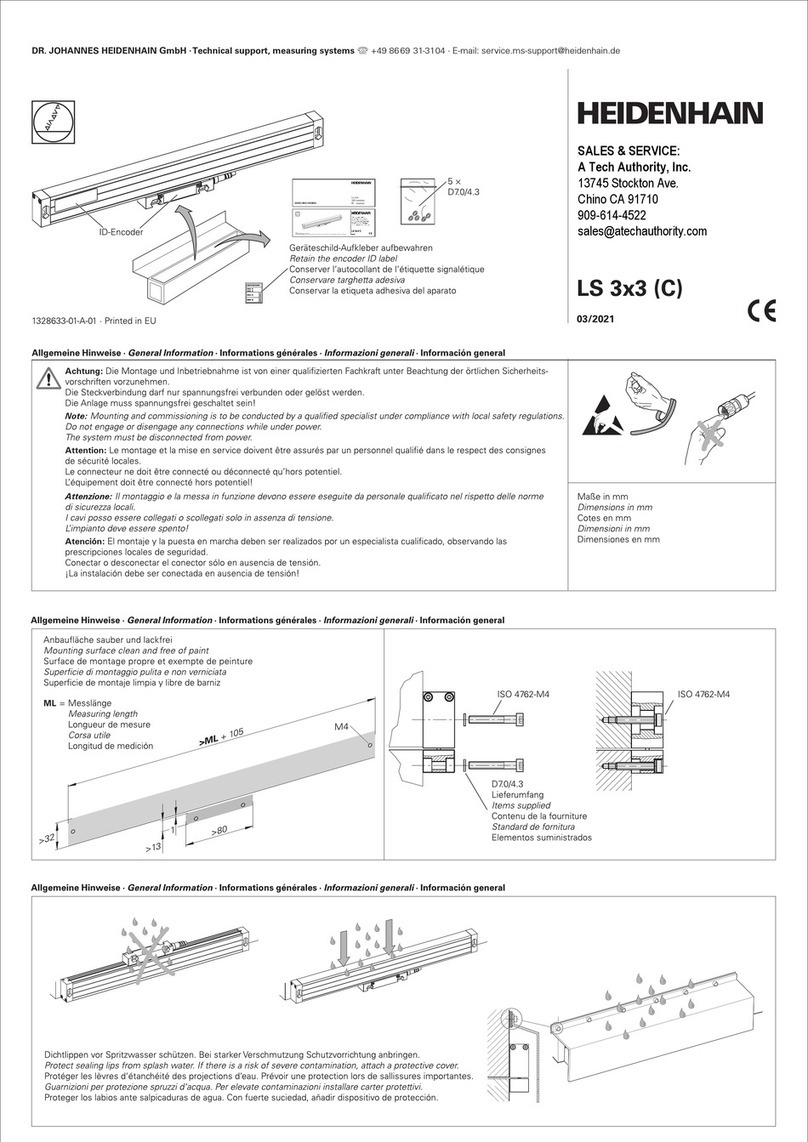

1.1 1.2

Absolute mode and incremental mode

In the absolute mode all measurements

refer to the “absolute” datum point, whilst

in incremental mode each immediately

preceding position serves as datum point.

Absolute mode

Example:

The left upper corner is the “absolute

datum point” for the measurements

Instructions for key-in of position

values or dimensions

Entry errors can be cleared by means of the

q @.

Values are entered in “mm” or “inch”,

whereby key-in of trailing zeroes is not

required.

An entered value remains within the

keyboard memory until it is overwritten by

a new value or cleared with the

q

button @ The finest decade of the key-

board display is rounded off to digital step

0.002 mm inoperating mode “metric”2 pm,

and to 0.00005 inch in “imperial” operating

mode 0.00005.

An entry value can be preset into the

position displays @or can be repeated

any number of times as an incremental

dimension -in any axis and with changing

sign (see item 2.2).

Only negative sign “-‘I is displayed. Each

actuation of the sign change key

q

will

change the sign of the value in the

keyboard memory. For entry of negative

values, the following is applicable: first

enter value, then negative sign.

If the entered value in the kevboard disolav

, ,

The machine is to be positioned to

a certain dimension. is too large (> 5079.999 mm or

199.99995 inches), then each numeral in

the keyboard display will illuminate with

Incremental mode

Example: decimal point.

Measurements are carried out-starting 1.3

from the left upper corner - in increments Traversing over reference marks when

first setting up

After initial connection of transducers, all

REF-memories of the counter must be

“activated”.

”

press REF key @:

reference mark indicators @ in the

position displays illuminate.

Traverse over reference marks in all axes;

referencemarkindicatorsareextinguished.

1.4

The machine is to be traversed by

a certain distance. Gilure signal

Failure of a transducer, cable defects etc.

are indicated by flashing of the appropriate

position display @.

Switch off counter, remedy the fault and

re-active counter. Alternatively, the failure

signal can be cancelled by pressing the

REF key (repeat, if reqd.).

IO