SONIX 10D Installation instructions

ULTRASONIC FLOWMETER

SONIX 10D

INSTRUCTION FOR ASSEMBLY AND OPERATING

SONIX®

Industri l Electronic Devices

ul. Leopold Lis -Kuli 12, 05-270 M rki, Pol nd

phone:+4822-7811133, f x: +4822-7811644

www.sonix.com.pl

Instructions for Assembly nd Oper ting SONIX 10D

Contents

GENERAL INFORMATIONS ON SAFETY................................................................................................. 3

Introduction............................................................................................................................................ 3

Symbols................................................................................................................................................. 3

Discl imer.............................................................................................................................................. 3

INTRODUCTION........................................................................................................................................ 4

Component p rts .................................................................................................................................. 4

List of supplied elements....................................................................................................................... 5

Purpose ................................................................................................................................................ 5

B sic technic l d t .............................................................................................................................. 5

ASSEMBLY........................................................................................................................................... 6

Mech nic l ssembly of the flow sensor ...............................................................................................6

Me surement ex mple of sew ge flow in gr vit tion l pipeline ....................................................6

Length of str ight sections of the pipeline.........................................................................................6

Recommend tions for the flow sensor ssembly..............................................................................7

The producer’s supervision over the ssembly nd st rt-up .................................................................7

Sp ce for the ssembly of ultr sound probes ..................................................................................7

User’s prep r tion for ssembly ...................................................................................................... 8

Assembly of the me suring tr nsducer.................................................................................................. 8

Electric l connections ...................................................................................................................... 9

Probe's c ble correct ending.......................................................................................................... 10

Gener l Inform tion ............................................................................................................................ 10

Descriptions of the menu..................................................................................................................... 10

E0 Flow Volume.............................................................................................................................. 11

E1 Upper threshold Lower threshold...............................................................................................11

E2 Di gnostic screen...................................................................................................................... 11

E3 Working time Time of correct work............................................................................................11

E4 SONIX...................................................................................................................................... 11

User’s functions................................................................................................................................... 11

Neg tive volume............................................................................................................................. 11

P ssword ch nge........................................................................................................................... 12

St rting the b cklight...................................................................................................................... 12

Ch nge of current nd r nge.......................................................................................................... 12

Setting the thresholds..................................................................................................................... 12

Ch nge of displ y precision ........................................................................................................... 12

Ch nge of the const nt of time, c libr tion of the current output ...................................................12

P r meters of the RS485 output.................................................................................................... 12

Exiting user’s functions................................................................................................................... 12

Tempor ry volume.......................................................................................................................... 12

Servicing ............................................................................................................................................. 12

ERRORS.................................................................................................................................................. 13

Gener l inform tion............................................................................................................................. 13

Di gnostic mess ges........................................................................................................................... 13

THE SERIES RS485 OUTPUT................................................................................................................. 14

Protocol description............................................................................................................................. 14

Electric l connections.......................................................................................................................... 14

Unit ch nge volume/m ss .................................................................................................................. 14

List of registers.................................................................................................................................... 15

DECLARATION OF CONFORMITY.........................................................................................................16

GUARANTEE CERTIFICATE .................................................................................................................. 17

©SONIX 2010 Act. 13.08.2010

2

Instructions for Assembly nd Oper ting SONIX 10D

GENERAL INFORMATIONS ON SAFETY

3

Introduction

Symbols

Disclaimer

The symbols used in this m nu l or pl ced on the flowmeter h ve the

following me ning:

Attention: Risk of electric l shock

PROTECTIVE EARTH TERMINAL

Attention: Identify conditions th t could result in

injury or loss of life nd lso could result in

flowmeter d m ge. In e ch c se the expl n tion is

in this m nu l.

- Assembly nd oper ting of the flowmeter is not llowed without re ding,

underst nding nd following the inform tions in this m nu l

- Sevice of the flowmeter performs SONIX only

- For power supply of the flowmeter use 1-ph se m ins with protective e rth

- Do not use the flowmeter with removed cover

- The recommend tions nd w rnings cont ined in this m nu l nd pl ced

on the flowmeter should be followed

- Using the flowmeter in w y or in conditions incomp tible with this m nu l

m y result in flowmeter d m ge, loss of w rr nty or reducing protection

provided by the flowmeter

- SONIX reserves the right to ch nge the product in order to incre se its

utility v lues or djust it to current regul tions. Such ch nges m y not be

t ken into ccount in the current version of the m nu l. SONIX is not

responsible for consequences it imply.

- The purch ser is responsible for the selection of suit ble flowmeter

- W rr nty is given in ccord nce with terms specified in Gu r ntee

Certific te

Instructions for Assembly nd Oper ting SONIX 10D

INTROD CTION

4

Component

parts

The SONIX 10D flowmeter consists of flow sensor nd me suring

tr nsducer connected together with probes c bles. The flow sensor is

v il ble in three versions:

1. An U-sh ped section ended with fl nges or screw thre d

(DN15...40)

2. A section ended with fl nges (DN50...200)

3. An existing section of pipeline (DN250...2000)

Addition l equipment:

- Flow simul tor SONIX S5l

- Probes exch nge ble under pressure for versions 2 nd 3 (from DN250)

Instructions for Assembly nd Oper ting SONIX 10D

5

Purpose Me surement of flow intensity nd summing the volume of flowing liquids in

closed, fully filled pipelines.

Flow tr nsducer for he t meter.

Cold w ter meter.

Univers l flowmeter for industri l us ge

Basic technical

data

Flow tr nsducer

for he t meter

Cold w ter meter Flow meter not

requiring

verific tion

Authentic tion

type -Decision No ZT

295/2006 -

M rk of

uthentic tion

type

- PLT 06268 -

Di meter r nge

of pipelines (mm) 50 ÷ 600 50 ÷ 300 15 ÷ 2000

Liquid speed

r nge (m/s) 0,038 ÷ 5 0,038 ÷ 4 0 ÷ 15

Liquid

temper ture

r nge (

°C

)

0 ÷ 130 0 ÷ 30

0 ÷ 150

tempor rily to

180

Ambient

temper ture of

the me suring

tr nsducer

+5 ÷ +55 +5 ÷ +55 +5 ÷ +55

Liquid re ction

(pH) 3 ÷ 11 3 ÷ 11 3 ÷ 11

Working pressure

(MP ) 0,03 ÷ 2,5 0,03 ÷ 2,5 0,03 ÷ 2,5 (4)

B sic

me surement

error (% w.m.)

σ=±0.5 σ=±0.5 σ=±0.5

Method of

c libr tion or

verific tion

C libr tion in the

flow st nd of the

SONIX comp ny.

Verific tion on

the flow st nd in

the verific tion

premises

C libr tion in the

flow st nd of the

SONIX comp ny.

Flowmeters

ssembled on n

existing pipeline-

theoretic lly

c libr ted in

ccord nce with

the Polish PN/M-

42370 Norm

List of supplied

elements

The following elements constitute the flowmeter set:

- me suring tr nsducer

- flow sensor with two or four ultr sound probes including c bles

- Instructions for Assembly nd Oper ting nd Gu r ntee Certific te

- C libr tion certific te for the flowmeters c libr ted in the SONIX comp ny

flow st nd

Instructions for Assembly nd Oper ting SONIX 10D

ASSEMBLY

6

Mechanical

assembly of the

flow sensor

The choice of location and manner of the assembly of the flow sensor

decides on the metrological properties of the device.

The following conditions must be met in order to provide correct

me surement:

1. L ck of er tion of the liquid

2. 100% filling of the pipeline

3. Sm ll ttenu tion of the ultr sound w ve

3. St bilized nd symmetric l profile of liquid speed

The U-sh ped sensor must be ssembled horizont lly or t the 45° ngle

m x. The ssembly position of the rem ining type of sensor depends on the

choice of the user. The probes must be loc ted in the horizont l surf ce i.e.

t both sides of the pipeline nd not below nd bove it. The ccept ble

devi tion from the level equ ls 25°.

Length of

straight

sections of the

pipeline

Measurement

example of

sewage flow in

a gravitational

pipeline

In the m jority of c ses, str ight sections of the following lengths re

sufficient:

- Inlet: 10D

- Outlet: 3D

Two- or more surf ce sp ti l configur tions of the pipeline, the pump, not

entirely closed v lves, side inlets etc. require ppropri te elong tion of the

str ight sections before nd behind the me suring spot. The U-sh ped flow

sensor does not require str ight sections.

10D

15D

20D

3D

Swelling w ter se l

h=50cm

3D

10D

SONIX 10D

Open de er ting t nk with bulkhe d

Liquid level

Access eye for removing solid impurities

The elements of the me suring system shown on the following figure provide

the conditions necess ry for the correct me surement:

- De er tion of the inflowing sew ge

- 100% filling of the pipeline

- L ck of ccumul ting deposit in the flow sensor

- Symmetric l profile of liquid speed

Instructions for Assembly nd Oper ting SONIX 10D

7

Recommendations

for the flow sensor

assembly

The producer’s

supervision over the

assembly and start-

up (refers to

assembly on an

existing pipeline

DN250...DN2000)

Space for the

assembly of

ultrasound

probes

➢ Choose the longest v il ble str ight section of the pipeline. Inst ll the

sensor with probes on the 3/4 of its length st rting from the inflow.

➢ M ke sure th t in the selected spot the liquid will not be er ted nd ir or

solid impurities will not ccumul te there.

➢ The inside di meter of the pipeline nd the sensor should be the s me.

➢ Inst ll the sensor in such w y so the rrow on it is on top nd shows the

flow direction.

➢ The probes should be loc ted horizont lly on both sides of the pipeline

(never vertic lly).

➢ The se ls of the fl nge connections c nnot protrude into the inside of the

pipeline (protruding se ls c n c use the incre se of me surement error

from ± 5 to even ± 40%)

➢ Do not hit the flow sensor with h mmer or other devices. It m y d m ge

the probes.

➢ The f ctory numbers of the me suring tr nsducer nd the sensor must

be identic l.

➢ Pl ce the me suring tr nsducer in pl ce ppropri te for re dings from

the displ y nd ccessible for servicing te m.

➢ Run the sign l nd supply c bles in sep r te, own ch nnels nd tt ch

them to the termin l strip of the flowmeter in ccord nce with the m rkings

nd colours.

➢ The length of the c ble between the PE termin l of the flowmeter nd the

grounding vertic l should not exceed few metres.

0.5m 0.5m

0.5m

D

1,8 D

min 1,2 m

The following ctivities m ke up the ssembly nd the st rt-up of the

flowmeter:

- Tr cing points on the pipeline

- M king 4 holes of pprox. 25mm di meter in the w ll of the pipeline

( cetylene cutting in steel pipeline, drilling in c st iron one)

- Electric l welding of tt ching sleeves to the steel pipeline or screwing

them to c st iron one

- Assembly of ultr sound probes

- Assembly of the me suring tr nsducer

- Connecting the me suring tr nsducer to the ultr sound probes with

tr nsmission c bles

- St rt-up of the flowmeter

- Setting to zero in the c se of stopped flow

Instructions for Assembly nd Oper ting SONIX 10D

8

Assembly of the

measuring

transducer

Protection c tegory of the me suring tr nsducer: IP54 It is ccept ble to

ssembly the device in the open ir in he ted protective c binet. Due to

temper ture r nge of +5..+55 C during the summer months, the c binet

should be loc ted in the sh dow.

180

135

230

178

3 otwory 8mm

68

8

ser’s

preparation for

assembly

➢ Choice of the me suring spot on the pipeline nd choice of me suring

tr nsducer loc tion. The st nd rd length of probes c bles is 4 x 5m. In

c se of doubts, it is recommended to consult SONIX represent tive.

➢ Prep r tion of the pipeline for ssembly:

- cle ning the surf ce of the pipeline from rust, insol tion etc on the whole

of its surf ce on the length of 1.8D

- emptying the pipeline for welding nd probe ssembly. The tent tive

emptying time equ ls pprox. 2 hours for steel pipeline nd pprox. 6

hours for c st iron one.

- filling the pipeline in order to st rt-up the flow meter. After the filling, it is

recommended to stop the flow for pprox. 10 min in order to set the

flowmeter to zero.

➢ Acetylene cutting of the holes of pprox. 25mm di meters nd electric l

welding for steel pipeline.

➢ Prep r tion of possible bushings, tubes, ducts etc. for probes c bles: four

c bles of the pprox. 6mm di meter.

➢ Arr ngement of the 230V AC supply nd sign l c bles connected to the

me suring tr nsducer.

Instructions for Assembly nd Oper ting SONIX 10D

9

Electrical connections

Power supply conection

- Protective e rth conductor up to 2.5mm

- Protective e rth conductor up to 2.5mm

- Protective e rth conductor up to 2.5mm

2 (13 AWG) h s to be connected to

termin l of the flowmeter

termin l of the flowmeter

- Perm nent connection to them ins 230V AC +10..-15% 50Hz 10VA

- Perm nent connection to them ins 230V AC +10..-15% 50Hz 10VA

- Perm nent connection to them ins 230V AC +10..-15% 50Hz 10VA

- The power supply should h ve pplied reli ble limiters decre sing surge

to level which does not couse d nger

- Protective e rth c ble lenght should not exceed few meters

- It is forbidden connecting to protective e rth termin l ny other c ble th n

protective e rth conductor

- Power supply c ble should h ve di meter 5..6mm nd its c ble gl nd

should be ssembled properly

Instructions for Assembly nd Oper ting SONIX 10D

OPERATING

10

General

Information

The user communic tes with the device vi the LCD 2 x 1 6 ch r cters

displ y using two push buttons for choice of functions or p r meters. The

principle of oper ting is s follows:

-The left one 'L': choice of function or digit

-The right one 'P': ch nge of function or v lue

-Left nd right one t the s me time 'O': ccept nce the ch nge

The menu consists of 5 b sic m in screens nd sever l screens of user’s

nd servicing functions.

Descriptions of

the menu

Probe's cable correct

ending

55 mm

25 mm

USERS FUNCTIONS

OUTPUT CURRENT

SETTING

THRESHOLDS

DISPLAY

PRECISION

TIME CONSTANT

CURRENT OUTPUT

CALIBRATION

RS485 OUTPUT

SETTING

EXIT

USER FUNCTIONS

TEMPORARY

VOLUME

L

E3

SONIX F ctory number

E4

Phone number Time of corr. work

Working time

NEGATIVE FLOW

TOTALIZER

CHANGE

PASSWORD

BACKLIGHT

ON/OFF

FLOW RANGE

L P

E0

O

E1

FLOW RATE

TOTALIZER

Upper threshold

Lower threshold

PASSWORD

ACCESS

SERVICE FUNCTIONS

P

E2

screen

Di gnostic

Instructions for Assembly nd Oper ting SONIX 10D

11

E3

Working time

Time of correct

work

E1

pper threshold

Lower threshold

E2

Diagnostic screen

E4

SONIX

The current flow in m3/h (or t/h) nd the counted tot l volume in m3(or t).

For positive flow counts the b sic volume counter.

For neg tive flow counts sep r te neg tive volume counter v il ble in the

user’s functions.

Power f ilure does not c use deletion of volume counters d t or the loss of

other d t nd p r meters.

It is possible for the user to progr m the number (0...3) of displ yed

decim ls.

Threshold progr mming is v il ble in the user’s functions.

On E1 screen re only displyed the progr mmed flow thresholds bove nd

below which short circuit of ppropri te tr nsistors in tr nsoptor outputs

t kes pl ce.

Upper line, from left:

-Flow speed in m/s

-Type nd v lue of enh ncing djustment: r-m nu l djusting, - utom tic

djusting

-Mode of work: 0 – l ck of liquid

1– two p th me surement, work only on the AB p th

2– two p th me surement, work only on the CD p th

3– two p th me surement, work on both p ths

4– one p th me surement - AB

5– one p th me surement - CD

- the percent ge of interferences m rking the r tio of the number of incorrect

flow me surements to ll me surements done within unit of time.

V lues below 25% re s tisf ctory. V lues between 25...50%

show excessive electric l interferences or liquid er tion. V lues bove

50% re tre ted s group I errors requiring servicing.

Di gnostic mess ges re displ yed in the lower line:

‘Me surement OK’

‘Empty pipe’ – empty pipeline or disconnected probes

‘Low sign l AB' – decre sing of the sign l from the AB p ir of probes

‘Low sign l CD' – decre sing of the sign l from the CD p ir of probes CD

'Out of I r nge' – flow exceeding the current r nge of flowmeter

'Out of v r nge' – too high liquid speed

'Disturb nces' – more th n 50% of interfered me surements

'Wrong p r meter' – incorrect p r meter v lue progr mmed

'AB tr ns. trouble' – d m ge of one or both probes of the AB p ir

‘CD tr ns. trouble' – d m ge of one or both probes of the CD p ir

'M in trouble' – d m ge of the digit l p rt of the flowmeter

'Temper ture?' – l ck of temper ture record (in the c se of tone displ y)

Working time me ns the number of hours the supply of the meter w s on.

Time of correct work me ns the number of hours without sign ling errors of

group I or II.

ser’s functions

Neg tive flow tot l volume counter.

Negative volume

Using the user’s functions does not influence flow me surement nd volume

counting done t the s me time by the flowmeter. The impulse output

rem ins free from interference s well.

E0

Flow

Volume

Logo of the SONIX comp ny. F ctory number of the flowmeter. Phone

number of SONIX’s service.

Instructions for Assembly nd Oper ting SONIX 10D

12

5 digit ccess p ssword to user’s functions. Def ult p ssword: 11111

Service of the flowmeter is performed only by the SONIX servicing te m.

Password

change

Starting the

backlight

Change of

current and

range

Setting the

thresholds

Change of

display precision

Change of the

constant of time,

calibration of the

current output

Parameters of the

RS485 output

Exiting user’s

functions

The LCD displ y is illumin ted for 15s fter pressing ny push button.

Progr mming of the lower nd upper flow threshold in m3/h or t/h.

Progr mming from 0 to 3 decim ls for tempor ry flow nd the tot lized

volume.

Ch nge of the me surement’s time const nt: 0...9 corresponds to pprox.

0.5...30s. Forcing the 0, 4, 10, 15 or 20mA current in order to chieve

c libr tion of the device connected to the current output of the flowmeter.

Progr mming p rity control: Odd, Even, None, ddress of the device: 01H...FFH

nd tr nsmission speed: 1200B/s...9600B/s.

Exiting user’s functions is done by pressing both push buttons.

Servicing

The function llows dosing the liquid. The tempor ry liquid counter is set to

zero nd initi ted with the left push button nd stopped with the right one.

The counter m y lso be oper ted by the RS485 series link (see Protocol of

series tr nsmission).

Temporary

volume

Ch nge of output current: 0-20mA or 4-20mA

Progr mming of r nge flow in m3/h or t/h.

Progr mming the ch r cteristics of the current output:

+ the output works symmetric lly for the neg tive nd positive flows

- the output work only for the positive flow

Instructions for Assembly nd Oper ting SONIX 10D

ERRORS

13

General

information

Diagnostic

messages

Oper ting flowmeters errors re divided into two groups:

I. Errors c using incorrect me surement nd requiring immedi te servicing.

The occurrence of such error is sign led by periodic l bl nking of the

displ y every 0.3s. All outputs return to non- ctive st tes. Volume

counting nd the counter of correct work re blocked. The description of

the error is displ yed on the di gnostic screen.

II. Errors of lesser import nce which do not signific nt influence on the

ccur cy of me surement but require servicing within few weeks or

months. The occurrence of such error is sign led by periodic l bl nking

of the displ y every 4s. All functions nd outputs rem in ctive. The

description of the error is displ yed in the di gnostic screen.

Me surement OK - the me surements re done correctly.

Errors:

Group I – errors of high import nce (bl nking of the displ y every 0.3s)

-d m ge of the me suring tr nsducer

-d m ge of the probes or c bles except for d m ge of one p ir of probes in

two-p th work. When this occurs the flowmeter then switches over to the

functioning p ir of probes nd n error of group II is sign led

-too high speed of the liquid

-pipeline not fully filled

-too m ny interferences

-progr mming of n incorrect v lue of p r meter

Group II – errors of lesser import nce (bl nking of the displ y every 2s)

-low ultr sound sign l

-flow outside the current r nge

-d m ge of one p ir of probes in two-p th work

-l ck of temper ture records by the RS485 link when tones re the

progr mmed unit. Cubic meters then rem ins the unit nd n error is

sign led.

Instructions for Assembly nd Oper ting SONIX 10D

THE SERIES RS485 O TP T

14

Protocol

description

Electrical

connections

The MODBUS RTU protocol of series tr nsmission is compli nt with the

current specific tion v il ble t www.modbus.org Tr nsmission speeds:

1200, 2400, 4800 or 9600 B/s. Addresses of the devices: 1 ...255.

Ch r cter form t:

-1 st rt bit

-8 d t bits

-1 p rity control bit (progr mm ble: Odd, Even, None)

-1 stop bit (or 2 stop bits when progr mmed to None).

Two functions re v il ble:

03 or 04 – re ding of the content of the flowmeter’s register group

06 – recording d t in the flowmeter register

Examples of frames for the device of the 02 H address

1. Re ding of 2 registers beginning from register no 10 of the following

content:

register no 10: 057FH register no 11: 9D1AH

Order: 02,03,00,09,00,02,14,3A

Response: 02,03,04,05,7F,9D,1A,11,7C

2. Setting to zero nd st rting the tempor ry volume counter:

Order: 02,06,00,1E,00,01,28,3F

Response: 02,06,00,1E,00,01,28,3F

3. Stopping the tempor ry volume counter:

Order: 02,06,00,1E,00,00,E9,FF

Response: 02,06,00,1E,00,00,E9,FF

4. Record of the 94°C temper ture in register no 32:

Order: 02,06,00,1F,00,5E,39,C7

Response: 02,06,00,1F,00,5E,39,C7

The pplied isol ted interf ce is compli nt with the EIA RS-485 st nd rd. The

tr nsmission line must be connected in ccord nce with l bels on the printed

pl te: RA – higher potenti l, RB – lower potenti l. In the c se of severe

electric l interferences or if the length of the c bles exceed 300m, p ired

twisted 120Ω c ble c t.4 w ve resist nce should be used.

If the flowmeter is loc ted t the end of tr nsmission line exceeding 300m,

line termin tion should be initi ted by tt ching the 2 jumpers (next to the

fuse on the printed pl te). Simult neously with the termin tion, the line is lso

pol rized with the pprox 2.5V volt ge. (see electric l connections of the

flowmeter). The flowmeter is supplied with jumpers tt ched.

nit change

volume/mass

The SONIX 10D flowmeter en bles re dings of tempor ry v lues of the flow

nd the content of counters in m ss units (t/h, t nd kg). In order to chieve

this, one should:

1. Progr m the desired option in the servicing functions (done by the SONIX

servicing te m)

2. Record in register no. 32 the current temper ture v lue in the ch r. Form t

vi the RS485 interf ce. Av il ble temper ture r nge: 1 ...255°C

Rem rks:

-Temper ture records must be done not less frequently th n every 100s. If

this is not done, the device will return to displ ying in volume units nd

sign ls n error. The content of the volume counters will not be deleted.

-The ch nge over into m ss units does not pply to the impulse output of the

flowmeter.

Instructions for Assembly nd Oper ting SONIX 10D

15

List of registers

N me of the v ri ble

1 flo t LO Flow m3/h ( t/h)

2 HI

3 long int HI Positive volume m3(t)

4 LO

5 int Positive volume l(kg)

6 flo t LO

Liquid speed m/s7 HI

8 bit errors 1... 16

9 reserved

10 reserved

11 long int HI

Working time s12 LO

13 long int HI Time of correct work s

14 LO

15 long int HI Tempor ry volume l(kg)

16 LO

17 long int HI Neg tive volume m3(t)

18 LO

19 int Neg tive volume l(kg)

20 flo t LO

5 min ver ge of the flow21 HI

22 flo t LO

Hour ver ge of the flow m3(t)23 HI

24 Reserved

25 Reserved

26 Reserved

27 Reserved

28 Reserved

29 Reserved

30 Reserved

31 bit Op. with temp. vol. counter

32 ch r Temper ture oC

Register

no

V ri ble

type

Rem rks:

16 bit registers, ch r, int, long int – v ri ble without sign

Register no 8 (errors), 1 in given position me ns:

15 - reserved

14 - reserved

13 - reserved

12 - reserved

11 - reserved

10 - l ck of temper ture record to register no 32

9 - low sign l from the CD p ir of probes

8 - outside the r nge of ccept ble liquid speed

7- d m ge of the digit l p rt of the flowmeter

6 - the flow exceeds the progr mmed current r nge v lue

5 - excessive number of electric l interferences or er tion of the liquid

4 - d m ge of probe in the CD p ir

3 - d m ge of probe in the AB p ir

2 - incorrect v lue of p r meter progr mmed

1 - l ck of liquid in the pipeline, d m ged probe c bles, d m ge of the

n logue p rt of the flowmeter

0 - low sign l from the AB p ir of probes

Instructions for Assembly nd Oper ting SONIX 10D

16

DECLARATION OF

CONFORMITY The m nuf cturer:

SONIX® Industri l Electronic Devices

ul. Leopold Lis -Kuli 12, 05-270 M rki

decl res th t the following described product:

Ultr sonic Flowmeter type SONIX10D

is compli nt with the requirements of the Europe n Counsil directives no

73/23/ECC, 89/336/ECC, 97/23/EC

nd is compli nt with the princip l requirements cont ined in the following

norms:

PN-EN 61000-4-2:1999; PN-EN 61000-4-3:2002; PN-EN 61000-4-4:1999;

PN-EN 61000-4-5:1998; PN-EN 61000-4-8:1998; PN-EN 61000-4-11:1997;

PN-EN 55022:2000; PN-EN 1434-1:1997; PN-EN 1434-4:2001; PN-EN

60068-2-2; PN-EN 60068-2-1; PN-EN 1708-1:2002; PN-EN 1779:2002; PN-

EN1289:2000; PN-EN 1011-1; IEC 68-2-30: Test Db,v ri nt 1; PN-M-42370

Compli nce with the princip l requirements w s confirmed by ccredited

l bor tories nd offices:

Polskie Centrum B d ń i Certyfik cji S.A. [Polish Centre for Testing

nd Certific tion] , ul. Kłobuck 23A, 02-699W rs w, Pol nd

Przemysłowy Instytut Elektroniki [Institute of Industri l Electronics], ul. Dług

44/50, 00-241 W rs w, Pol nd

Główny Urząd Mi r Jednostk Certyfikując [Centr l Office of Me sures,

Certific ting Unit], ul.Elektor ln 2, 00-950 W rs w, Pol nd

W rsz w , 13.08.2010

Krzysztof Kolodziej

M n ging Director

_____________________

Instructions for Assembly nd Oper ting SONIX 10D

SONIX® Industri l Electronic Devices

ul. Leopold Lis -Kuli 12

05-270 M rki, Pol nd

phone +4822-7811133

f x +4822-7811644

sonix@sonix.com.pl

G ARANTEE CERTIFICATE

1. The producer gu r ntees good qu lity of the product nd its meeting the p r meters

defined in the Instruction for Assembly nd Oper ting.

2. The gu r ntee period covers 72 months from the d te of s les.

3. The free of ch rge gu r ntee rep ir sh ll be done within 48 hours from delivering the

product to the producer’s.

4. The producer undert kes to perform post-gu r ntee rep irs within the d tes specified in

point 3.

5.The gu r ntee sh ll not rem in v lid in the c se of:

- mech nic l d m ge to the product

- interferences to the inside of the product except for the c ses defined in the Instruction for

Assembly nd Oper ting

- oper tion incompli nt with the Instruction for Assembly nd Oper ting

6.The gu r ntee does not cover compl ints rel ting to incorrect working c used by extern l

f ctors or by d m ge of the product (e.g. the probes’ surf ce covering with deposit, presence

of ir in the pipeline, exceeding the llowed temper ture limit for the ultr sound probes etc.).

N me of the product: ULTRASOUND FLOWMETER, type: SONIX 10D

Purch sing comp ny:....................................................................................

F ctory numbers:

The SONIX 10D Flowmeter..............................................................................

D te of s le:.................................................................................................

17

Table of contents

Other SONIX Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Aquametro

Aquametro CONTOIL VZD2 Mounting and operating instructions

ISAFE MOBILE

ISAFE MOBILE SENSEVEN IS-VS1A.1 Quick start manual

Aqualytic

Aqualytic CHECKIT Comparator instruction manual

Unit

Unit UTE9802 user manual

Avonic

Avonic AV-REC200 user manual

ABQINDUSTRIAL

ABQINDUSTRIAL SKIPPER 5 quick start guide

B+K precision

B+K precision 2831E user manual

IKALOGIC

IKALOGIC SP259 Series Datasheet and User Manual

Aqualytic

Aqualytic CHECKIT Comparator D55 instruction manual

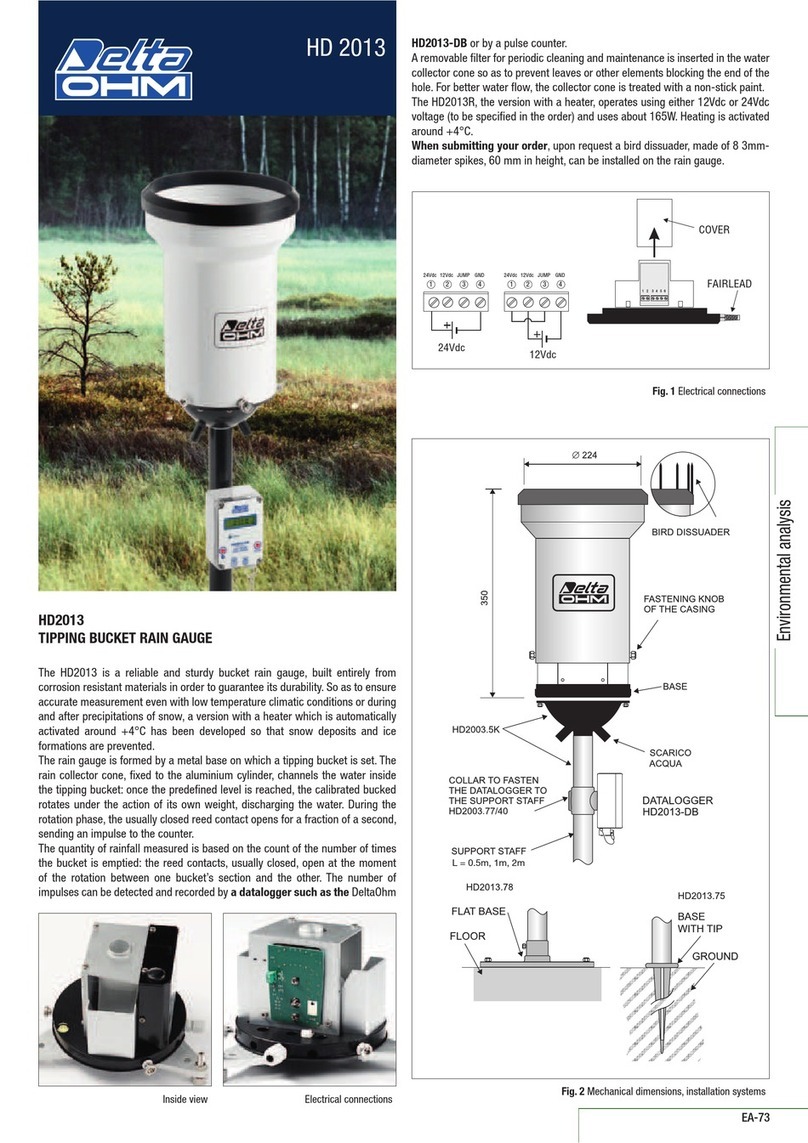

Delta OHM

Delta OHM HD 2013 Series quick start guide

Aqualytic

Aqualytic CHECKIT Comparator instruction manual

Silvercrest

Silvercrest SND 3600 D2 operating instructions