Find Settings for Composite and Engineered Boards

Follow steps 1 and 2 to find settings for products not listed on the species card.

For best results, the test sample should be acclimated to a uniform moisture content.

1:Determine the moisture content (MC value) of the test sample using 1a) or 1b).

1a) If the top layer is wood, find the MC value by taking readings. Set the meter to the

wood species of the top layer at 1/4” depth, even if the top layer is thinner than 1/4”.

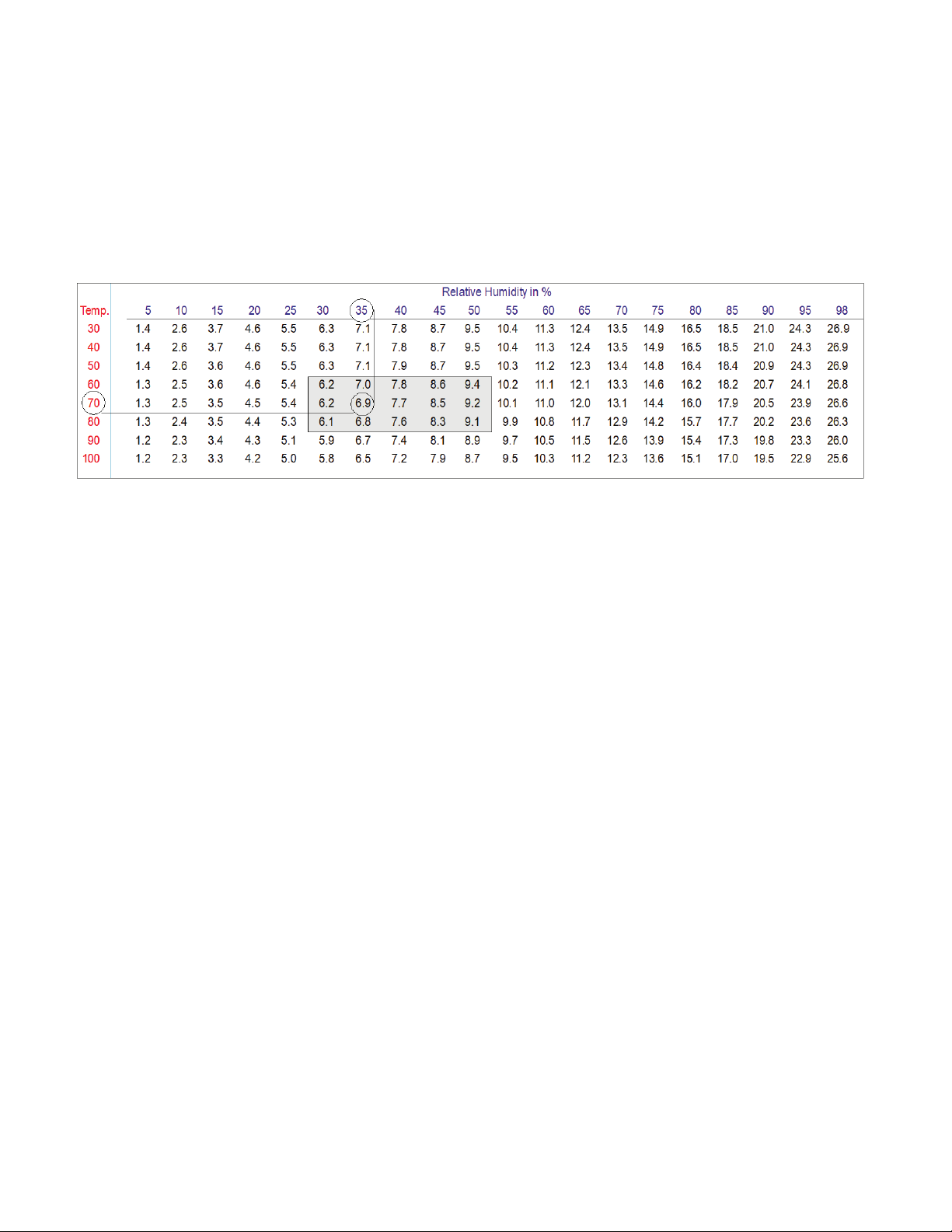

1b) If the top layer is not wood or the product is less than 1/4” thick (veneer), the test

sample has to be well acclimated in a known relative humidity. Then you can find the

MC value in the EMC chart. Moisture measurements with the meter are not needed.

Look up the relative humidity and find the corresponding EMC value. For a test sample accli-

mated in 40-50% rel. humidity, the MC value is 8.5% . Page 10.

2:Determine the new setting using the MC value found in step 1. Take a measurement with

setting # 50 and 3/4” depth. Use depth 1/4” for a test sample less than 3/4” thick.

--If the reading is lower than the MC value found in step 1, choose a setting lower than 50.

--If the reading is higher than the MC value found in step 1, choose a setting higher than 50

Then, take another measurement. Change the setting, until you get a reading close to the

MC value determined in step 1.

The new-found setting can be used in the future for the same type of boards.50.

If the reading is higher than the MC value found in step 1, choose a setting higher than 50.

Then, take another measurement. Change the setting, until you get a reading close to the

MC value determined in step 1.

The new-found setting can be used in the future for the same type of boards.

9

Specific gravity can be found on the Internet by entering <specific gravity ....> followed

by the wood species. Specific gravity can be calculated by dividing:

Dry Weight x 1.73 enter Dry Weight in ounces

Length x Width x Heights enter Length, Width and Heights in inches

Dry Weight enter Dry Weight in grams

Length x Width x Heights enter Length, Width, Heights in centimeters

If the specific gravity is 0.42, the Ligno-Scanner SDM should be set to #42 in pinless

mode. For unlisted species or new products call customer service at 800-227-2105. If

no listing is available, Lignomat offers testing to determine the correct setting.

Calculating Specific Gravity