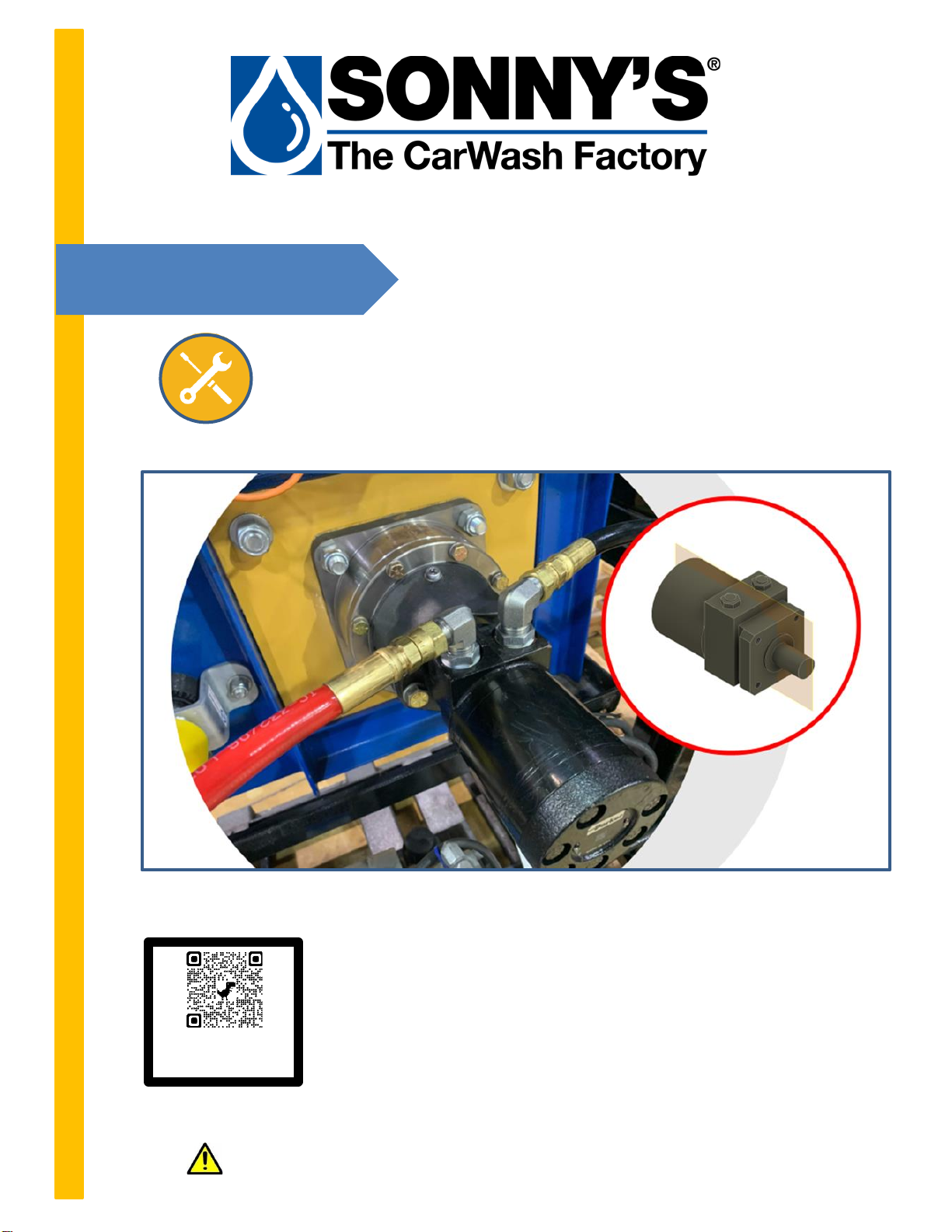

Sonny's Parker TE0230AS User manual

Maintenance Manual

* All maintenance MUST be performed by experienced and trained technicians.

Work Force: 1 Technician*

Maintenance Time: Varies

Parker®Motor

for Sonny’s Over/Under Conveyor

Scan QR Code

For Manuals

Replacement Parts

Parker Motor Maintenance Manual

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

© 2021 SONNY’S The CarWash Factory®. All Rights Reserved. SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed, or published without prior written consent.

Content, prices, and availability subject to change without notice.

Manual-M, Parker Motor Maintenance –Part # 10014125-B

Page 1 of 14

Sonny’s and Sonny’s The CarWash Factory are Registered trademarks of Sonny’s Enterprises LLC

Make CarWashing Easy is a trademark of Sonny’s Enterprises LLC

Products mentioned herein are for identification purposes only and may be registered trademarks of their respective companies. All

other brand names, trademarks or registered trademarks are the property of their respective owners.

Parker Motor Maintenance Manual

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

© 2021 SONNY’S The CarWash Factory®. All Rights Reserved. SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed, or published without prior written consent.

Content, prices, and availability subject to change without notice.

Manual-M, Parker Motor Maintenance –Part # 10014125-B

Page 2 of 14

TABLE OF CONTENTS

READ ALL INSTRUCTIONS PRIOR TO MAINTENANCE

3

IMPORTANT SAFEGUARDS AND WARNINGS

3 - 5

INTRODUCTION

6

SAFETY WEAR REQUIRED FOR ALL PERSONNEL

7

TOOLS REQUIRED FOR MAINTENANCE

7

PARKER MOTOR OIL CHANGE

8

INSTALLATION INSTRUCTIONS

8

MAINTENANCE

9

WEAR ITEMS AND REPLACEMENT PARTS

10 - 11

TECHNICAL SUPPORT

12

EMERGENCY CONTACTS

13

WARRANTY

14

REGISTER YOUR WARRANTY

14

Parker Motor Maintenance Manual

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

© 2021 SONNY’S The CarWash Factory®. All Rights Reserved. SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed, or published without prior written consent.

Content, prices, and availability subject to change without notice.

Manual-M, Parker Motor Maintenance –Part # 10014125-B

Page 3 of 14

•These instructions are a comprehensive step-by-step instruction guide on how to perform

maintenance on the Parker Motor and order replacement parts. To review other manuals go online

to SonnysDirect.com under Support Tab.

•Make sure to read, understand and follow all these instructions.

•To address any questions relating to installation, ordering parts, operations, troubleshooting,

maintenance, service or anything else, contact Sonny’s Technical Support Team at 1-800-327-

8723, Ext: 234.

•All deviations and alterations from these instructions MUST be reported to both your supervisor and

Sonny’s The CarWash Factory.

•WARNING: Do not perform any maintenance or work on equipment unless you first perform

Lock-Out Safety Precautions. All electrically powered equipment MUST have manually

operated disconnects capable of being locked in the “OFF” position. Equipment that has

been “locked out” for any reason must be restarted ONLY by the person who performed the

“lock out” operation. These procedures MUST be followed to avoid personal injury, death

and/or dismemberment.

•All parts and components MUST be installed by experienced and trained technicians.

•No unauthorized personnel should ever be permitted in the wash tunnel or near the equipment at

any time.

•Hardhat, safety glasses with side shields, closed steel toe shoes, anti-impact and cut resistant

gloves, dust mask, and earplugs if operating power tools, MUST be worn.

•When cutting or grinding any metal, safety glasses, earplugs, and dust mask MUST be worn.

•Do NOT leave a ladder or any other items such as wash down hoses or tools in the wash

tunnel while equipment is running. Vehicle damage and injury, including death, can occur.

•Do NOT wear loose fitting clothing or jewelry around moving equipment. Do not allow any

part of your body or other objects (including ladders, hoses, or tools) to come in contact

with moving equipment. Entanglement may result causing injury, death, or dismemberment.

•Always exercise caution when walking (never run) through the wash tunnel as there may be

slippery conditions. Be careful so you do not bump into or trip over equipment.

READ ALL INSTRUCTIONS PRIOR TO MAINTENANCE

IMPORTANT SAFEGUARDS AND WARNINGS

Parker Motor Maintenance Manual

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

© 2021 SONNY’S The CarWash Factory®. All Rights Reserved. SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed, or published without prior written consent.

Content, prices, and availability subject to change without notice.

Manual-M, Parker Motor Maintenance –Part # 10014125-B

Page 4 of 14

•Electrical connections and repairs MUST ONLY be performed by a Licensed Electrician.

•Plumbing connections and repairs MUST ONLY be performed by a Licensed Plumber.

•When working on any equipment that is higher than your shoulders, always use a fiberglass ladder

that is in good condition.

•Use proper lifting technique. Team lifts are required for items over 50 lbs.

•Do NOT alter or modify parts in any way and do NOT interchange or substitute any components

without the authorization of your supervisor and Sonny’s The CarWash Factory.

•Do NOT install any parts or components into faulty materials.

•All damages and defects MUST be reported to both your supervisor and Sonny’s The CarWash

Factory.

•If there are any malfunctions with the Parker Motor; or if any questions arise regarding the

equipment operations, immediately contact your supervisor or Sonny’s The CarWash Factory.

•Only use approved hardware, parts, and components with the Parker Motor, or any other

equipment.

•Protect your body parts against sharp corners and edges at all times.

•Keep loose articles of clothing and jewelry away from the removal, installation, or operation of all

equipment.

•The personnel performing maintenance on the Parker Motor are responsible for making sure it still

works after maintenance. To address any questions, contact Sonny’s Technical Support Team at

1-800-327-8723, Ext: 234.

•Always remove ladders, tools, parts, etc, from the wash tunnel when finished.

•All personnel MUST be trained in the safe operation of all equipment, wash tunnel operations,

safety regulations, emergency shutdown and maintenance practices to avoid any accidents.

•Only personnel specifically instructed and trained are permitted to enter the wash tunnel to perform

inspections or maintenance. At least two qualified maintenance personnel MUST be present when

performing equipment repairs or preventive maintenance.

•IMPORTANT: Call Technical Support to adjust wash cycle when new equipment is installed.

•WARNING: All hydraulic and electrical systems in the wash tunnel equipped with a torque relief or

overload should be checked and set to the minimum amount that will allow for proper functionality

under normal washing conditions.

IMPORTANT SAFEGUARDS AND WARNINGS

Parker Motor Maintenance Manual

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

© 2021 SONNY’S The CarWash Factory®. All Rights Reserved. SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed, or published without prior written consent.

Content, prices, and availability subject to change without notice.

Manual-M, Parker Motor Maintenance –Part # 10014125-B

Page 5 of 14

•WARNING: Possible wet floors and slippery conditions! To avoid an accident that might

result in personal injury, death or dismemberment, all personnel MUST proceed with

Caution.

•WARNING: Do NOT enter the wash tunnel when the equipment is operating. Personal injury,

death and/or dismemberment may occur.

•WARNING: Make sure the proper Chemistry (Brush Lubrication) is being used in the Car

Wash Tunnel to prevent vehicle and/or equipment damage.

•WARNING: If the Equipment Installation Dimensions at the time of installation are NOT

measured correctly, it may result in equipment damage and/or failure. Dimensions MUST be

verified if equipment is already installed. Contact Sonny’s Technical Support Team at 1-800-

327-8723, Ext: 234 for any Installation questions.

•WARNING: All connections and repairs MUST ONLY be performed by Licensed Professionals.

Perform all trade work in compliance with all applicable local and national codes.

•WARNING: Although building codes have been considered in developing all drawings, verification

of site-specific conditions and compliance with federal, state, and local building codes is the

exclusive responsibility of the customer and/or architect and engineer.

•WARNING: Do NOT attempt to repair or adjust any pressurized liquid or pneumatic part, hose,

pipe, or fitting while that equipment is in operation.

•WARNING: Do NOT operate any equipment that requires safety covers with those covers removed

or improperly installed. Do NOT operate any equipment if any component of that equipment is

suspected to be defective or malfunctioning.

•WARNING: Store all cleaning, washing solutions and oils in a well-ventilated area. Clean up

fluid spills immediately to prevent hazardous safety conditions. Be certain to follow all

safety procedures on SDS Sheets for each chemical product used.

•WARNING: When a piece of equipment must be in operation during inspection or

maintenance, one qualified technician must stay at the power disconnect switch while

another qualified technician performs the inspection or maintenance.

•WARNING: All Equipment MUST be given regular maintenance to prevent equipment

damage and/or failure that will VOID the warranty.

SAVE THESE INSTRUCTIONS

IMPORTANT SAFEGUARDS AND WARNINGS

Parker Motor Maintenance Manual

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

© 2021 SONNY’S The CarWash Factory®. All Rights Reserved. SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed, or published without prior written consent.

Content, prices, and availability subject to change without notice.

Manual-M, Parker Motor Maintenance –Part # 10014125-B

Page 6 of 14

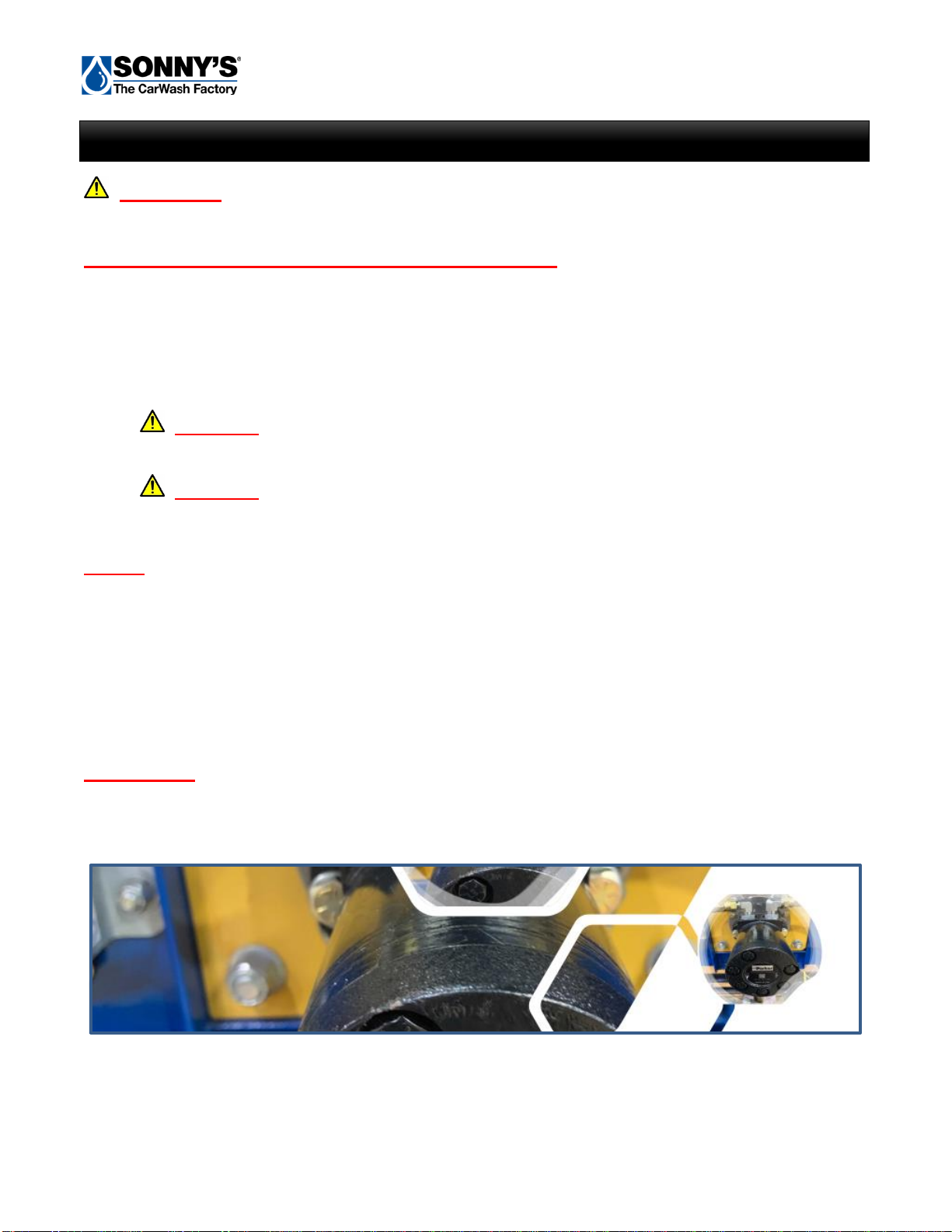

INTRODUCTION

Parker Motor Maintenance Manual

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

© 2021 SONNY’S The CarWash Factory®. All Rights Reserved. SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed, or published without prior written consent.

Content, prices, and availability subject to change without notice.

Manual-M, Parker Motor Maintenance –Part # 10014125-B

Page 7 of 14

WARNING: Make sure to follow Local and State Safety Wear Required Regulations

to ensure the safety of all personnel. Failure to follow Safety Regulations may result in

personal injury, death and/or dismemberment.

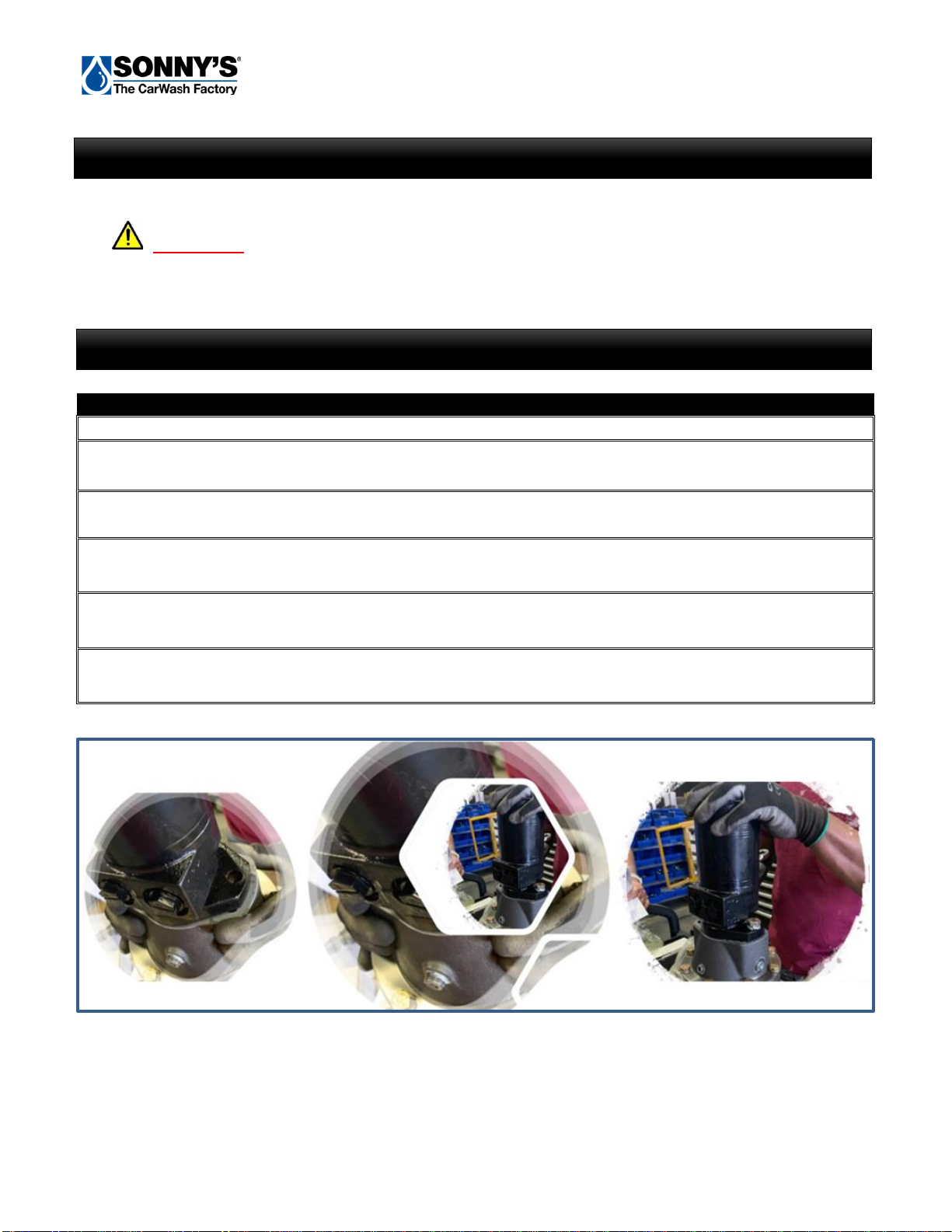

Tools

Not Included

Allen Key Set

9/16” Wrench

3/4” Wrench

15/16” Wrench

1” Wrench

SAFETY WEAR REQUIRED FOR ALL PERSONNEL

TOOLS REQUIRED FOR MAINTENANCE

Parker Motor Maintenance Manual

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

© 2021 SONNY’S The CarWash Factory®. All Rights Reserved. SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed, or published without prior written consent.

Content, prices, and availability subject to change without notice.

Manual-M, Parker Motor Maintenance –Part # 10014125-B

Page 8 of 14

Recommended: Unit should be cleaned with Flushing Oil, NO Solvents. If the maximum

oil operating temperature is exceeded, change the oil immediately!

WARNING: Make sure to dispose of Gear Oil according to local and state regulations.

Go online to SonnysDirect.com under Support Tab and look for:

Parker Motor Replacement Installation Instructions

PARKER MOTOR OIL CHANGE

INSTALLATION INSTRUCTIONS

Parker Motor Maintenance Manual

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

© 2021 SONNY’S The CarWash Factory®. All Rights Reserved. SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed, or published without prior written consent.

Content, prices, and availability subject to change without notice.

Manual-M, Parker Motor Maintenance –Part # 10014125-B

Page 9 of 14

IMPORTANT: FOR THE FIRST MONTH OF OPERATION CHECK ALL HARDWARE AND

FITTINGS FOR TIGHTNESS EACH WEEK!

Preventative Maintenance for Parker Motor Setup

1. The gear oil in the HECO gearbox should be cleaned after the first 50 hours of operation, 100

hours, and every 1,000 hours thereafter.

2. Oil should be drained while the unit is at operating temperature. The unit should be cleaned with

flushing oil (use of solvents should be avoided).

WARNING: If the maximum oil operating temperature is exceeded, change the oil

immediately.

WARNING: DO NOT connect a case drain to the HECO motor to avoid mixing hydraulic

fluid and gear oil.

DAILY

1. Before Opening:

a. Check for leaks around hoses and fittings

b. Repair any hydraulic leaks immediately

2. General Examination of Operation:

a. Listen for any unusual noises

b. Observe the operation of the conveyor and power pack

ANNUALLY

1. Drain, flush, and refill the hydraulic power pack with new, non-foaming, non-detergent hydraulic

fluid (ISO #46).

MAINTENANCE

Parker Motor Maintenance Manual

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

© 2021 SONNY’S The CarWash Factory®. All Rights Reserved. SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed, or published without prior written consent.

Content, prices, and availability subject to change without notice.

Manual-M, Parker Motor Maintenance –Part # 10014125-B

Page 10 of 14

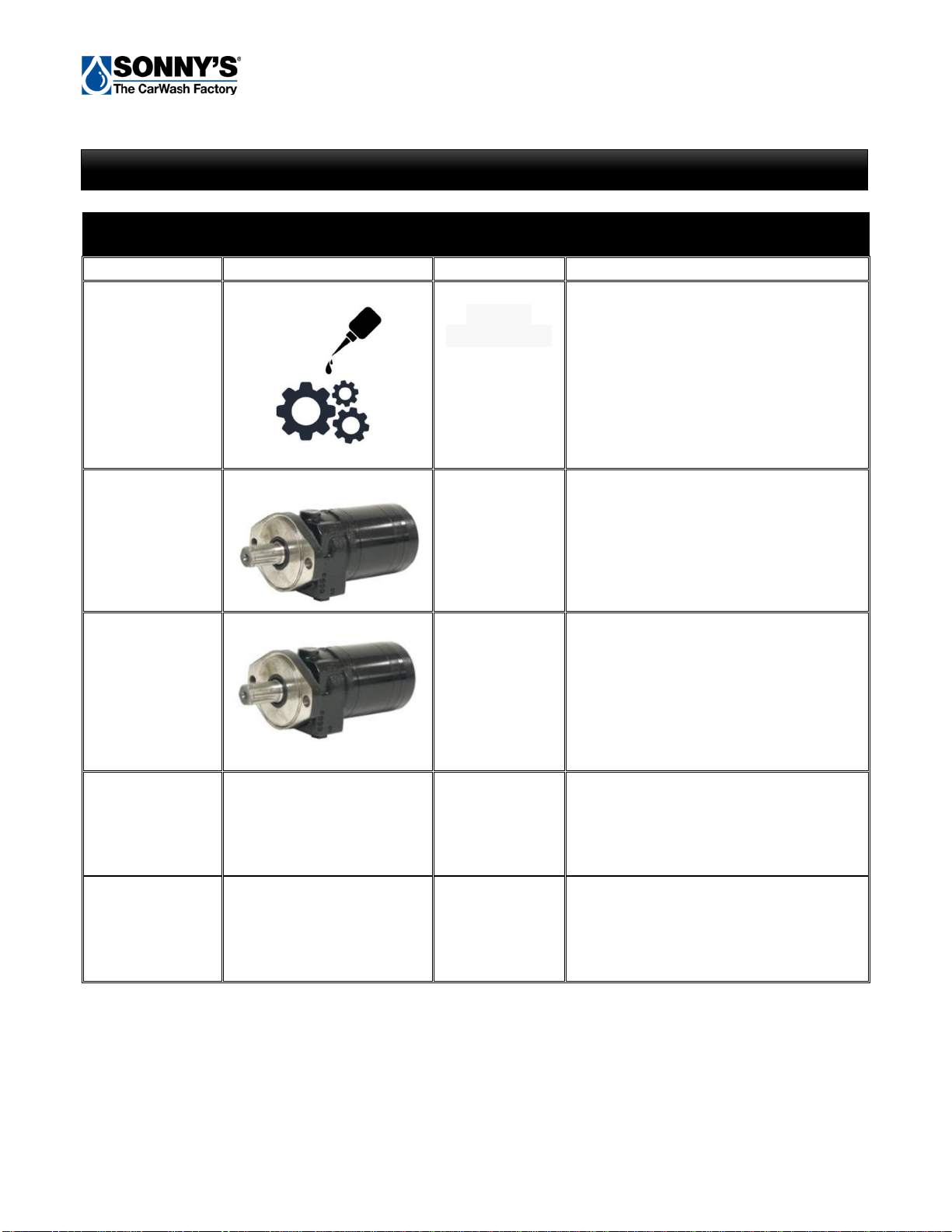

Part Number

Image

Quantity Per

Parker Motor

Description

16oz or

Half a Quart

75W Gear Oil

10008835

1

Motor Hydraulic Parker, 2-Bolt

TE0230AS 13.9 Cu In

10008155

1

Motor Hydraulic Parker, 2-Bolt

TE0295AS 17.9 Cu In

10014110

N/A

1

HECO 2 Bolt Gearbox

No Pulse w/ Sungear

10014111

N/A

1

HECO 2 Bolt Gearbox w/

Pulse w/ Sungear

WEAR ITEMS AND REPLACEMENT PARTS

Parker Motor Maintenance Manual

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

© 2021 SONNY’S The CarWash Factory®. All Rights Reserved. SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed, or published without prior written consent.

Content, prices, and availability subject to change without notice.

Manual-M, Parker Motor Maintenance –Part # 10014125-B

Page 11 of 14

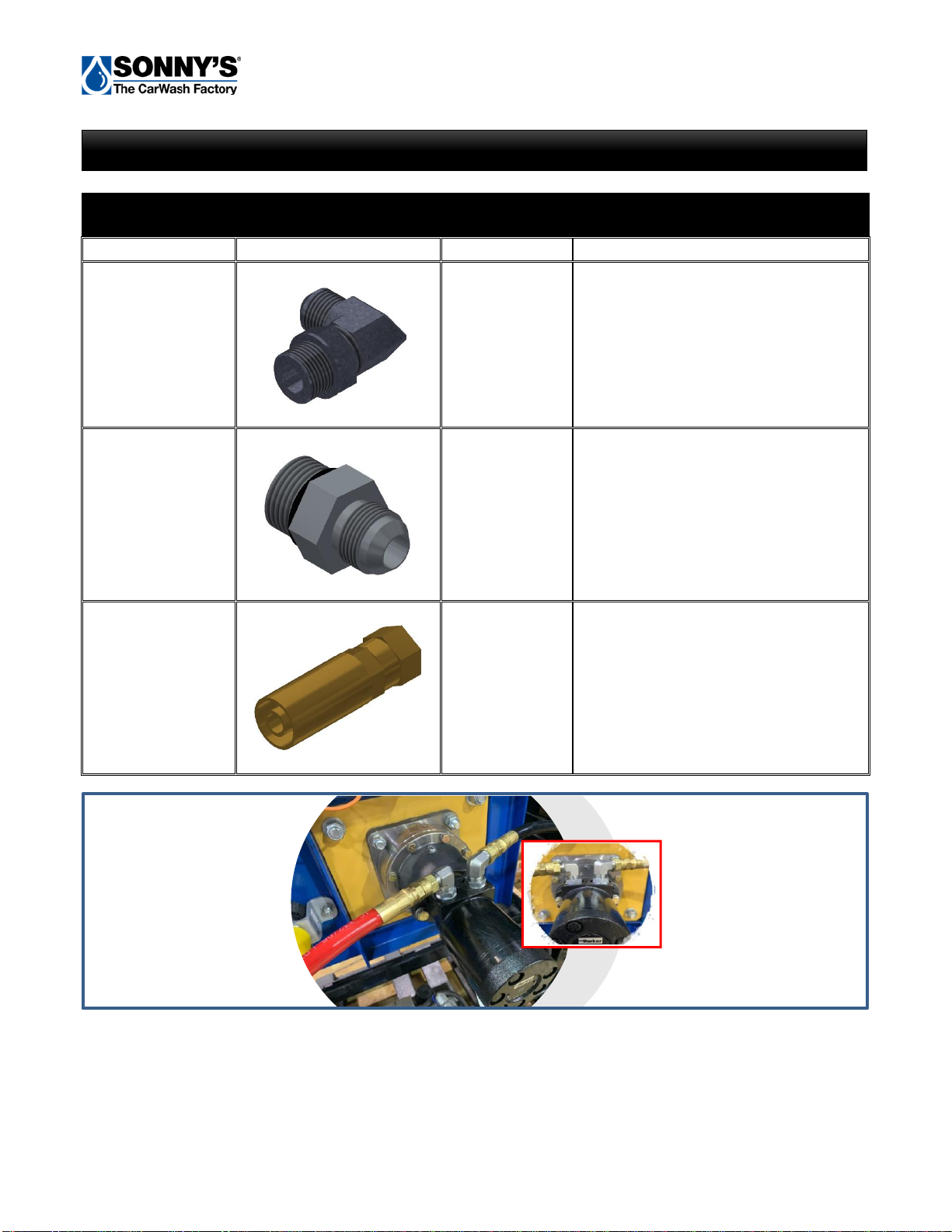

Part Number

Image

Quantity Per

Parker Motor

Description

10001762

2

Elbow 6801-8-10 M JIC

½” x 7/8-14”

10000961

2

Connector 6400-8-10 JIC

½” x 5/8” O-Ring

10003154

2

Swage Fitting, Brass

½” F JIC Swivel

WEAR ITEMS AND REPLACEMENT PARTS

Parker Motor Maintenance Manual

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

© 2021 SONNY’S The CarWash Factory®. All Rights Reserved. SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed, or published without prior written consent.

Content, prices, and availability subject to change without notice.

Manual-M, Parker Motor Maintenance –Part # 10014125-B

Page 12 of 14

Need more help?

For questions regarding installation, operational issues, settings, or servicing of this

equipment please contact Sonny’s Tech Support at extension 234 or email at

To order replacement parts, contact Customer Service at ext. 200, email us at

Toll Free Main Line 800-327-8723 Office: Monday –Friday 8:00 AM –5:30 PM ET

Fax Number 800-495-4049

Local Number 954-720-4100

Customer Service Option 3 Customer Service: Monday –Friday 8 AM –8 PM ET

Parts Option 3

Equipment Sales Option 4

Technical Support Option 5

SONNY’S ENTERPRISES INC.

5605 Hiatus Road

TAMARAC, FLORIDA 33321

You are part of the solution; we are here to support you!

From all of us here at

TECHNICAL SUPPORT

Parker Motor Maintenance Manual

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

© 2021 SONNY’S The CarWash Factory®. All Rights Reserved. SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed, or published without prior written consent.

Content, prices, and availability subject to change without notice.

Manual-M, Parker Motor Maintenance –Part # 10014125-B

Page 13 of 14

Scan QR Code

Emergency

CarWash Equipment

Tunnel Equipment

CarWash Parts & Supplies

CarWash Controls

CarWash College

CarWash Chemistry

CarWash Signage

Corporate

New Investors

EMERGENCY CONTACTS

Parker Motor Maintenance Manual

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

© 2021 SONNY’S The CarWash Factory®. All Rights Reserved. SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed, or published without prior written consent.

Content, prices, and availability subject to change without notice.

Manual-M, Parker Motor Maintenance –Part # 10014125-B

Page 14 of 14

Register Your Warranty Online: SonnysDirect.com (Support tab) Scan QR Code

SONNY’S ENTERPRISES, INC.

FACTORY LIMITED

LIFETIME WARRANTY

Equipment manufactured by SONNY’S ENTERPRISES LLC is warranted to be free from defect

in material and workmanship. Welded metal framework and other non-moving, non-wearable fabricated

metal components manufactured by Sonny’s are warranted for the life of the equipment to the original

purchaser. Fabricated metal wearable surface and moving components manufactured by Sonny’s are

warranted for a period of one (1) year to the original purchaser of the equipment.

All components assembled to Sonny’s equipment that are manufactured by others are warranted

by the appropriate manufacturer and subject to that manufacturer’s limited warranty. Contact Sonny’s for

the specific information on other component manufacturer’s warranty terms. All new cloth shipped with

new Sonny’s equipment is warranted for a period of one (1) year or 80,000, whichever occurs first.

This warranty is not assignable or transferable. The warranty period begins the first day

following installation or 30 days from the original invoice date, whichever occurs first. The Seller’s liability

shall be limited to repair or replacement of materials found to be defective within the warranty period. In

the event of repair or replacement this limited warranty is noncumulative. The Purchaser must supply the

Seller with immediate written notice when any defects are found. The Seller shall have the option of

requiring the return of defective material to establish the Purchaser’s claim. Neither labor nor

transportation charges are included in this warranty. Transportation damage claims are to be submitted

to the carrier of the damaged materials.

This warranty is based upon the Purchaser’s reasonable care and maintenance of the warranted

equipment. It does not apply to any equipment which has been subject to misuse, including neglect,

accident or exposure to harsh chemicals or chemicals that react violently with water, organic acids (e.g.,

acetic acid), inorganic acids (e.g., hydrofluoric acid), oxidizing agents (e.g., peroxides), and metals (e.g.,

aluminum). Chemicals corrosive to aluminum alloys, carbon steel, and other metals. Nor does it apply to

any equipment which has been repaired or altered by anyone not so authorized by Sonny’s. Further, the

equipment must be properly installed with proper accuracy of all specified plumbing, electrical, and

mechanical requirements. This warranty does not apply to normal wear and tear or routine maintenance

components.

EXCEPT AS EXPRESSLY STATED HEREIN, SONNY’S SHALL NOT BE LIABLE FOR

DAMAGES OF ANY KIND IN CONNECTION WITH THE PURCHASE, MAINTENANCE, OR USE OF

THIS EQUIPMENT INCLUDING LOSS OF PROFITS AND ALL CLAIMS FOR CONSEQUENTIAL

DAMAGES. THE LIMITED WARRANTY EXPRESSED HEREIN IS IN LIEU OF ALL OTHER

WARRANTIES EXPRESSED OR IMPLIED. SONNY’S NEITHER ASSUMES NOR AUTHORIZES ANY

PERSON TO ASSUME FOR IT ANY OTHER OBLIGATION OR LIABILITY IN CONNECTION

HEREWITH.

WARRANTY

This manual suits for next models

3

Table of contents

Popular Engine manuals by other brands

Stobag

Stobag MOVENO DWIRE-V Installation and use instructions and warnings

MTU

MTU 20V4000L63 operating instructions

Kohler

Kohler Courage XT-6 Service manual

Cub Cadet

Cub Cadet 195 cc OHV Operator's manual

Toshiba

Toshiba Stainless Steel Washdown Duty Motor Toshwash... Brochure & specs

Hacker

Hacker SKALAR 8 manual

GEIGER

GEIGER GJ5606-DuoDrive Original assembly and operating instructions

Hydro-Gear

Hydro-Gear HGM-C Service and repair manual

ESI

ESI M50Q 230VAC Series Quick setup

Rail King

Rail King Y6b 2-8-8-2 operating instructions

Hyundai Seasall

Hyundai Seasall G7 Series Installation & operation manual

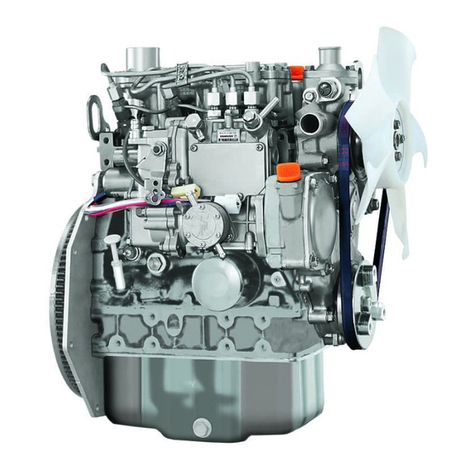

Yanmar

Yanmar 3TNM68 Service manual