— 2 —

TABLE OF CONTENTS

SERVICING NOTE

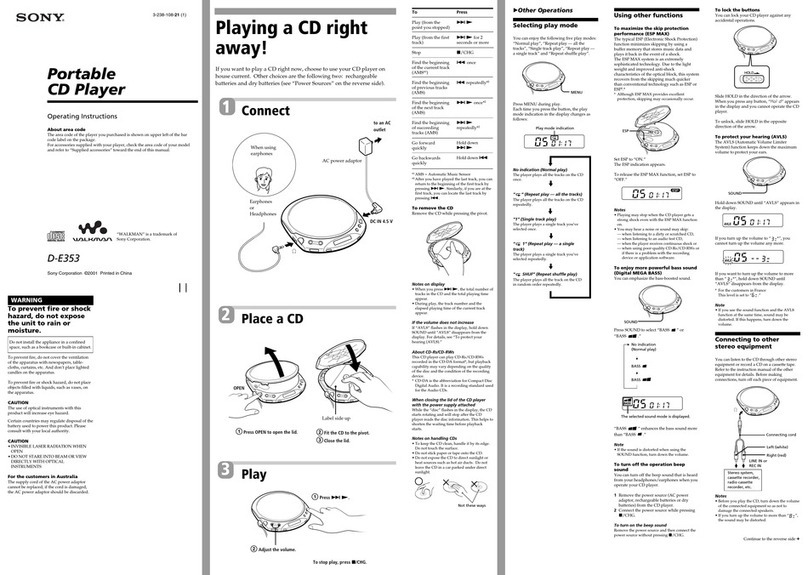

• Supplying power during servicing

This equipment cannot operate without using a separate power supply. Connect to the STR-W550/W770AV when performing service

work.

To apply power set the SYSTEM POWER switch on the Tuner/Amp to ON.

When other units are not available use the PFJ-1 power supply jig.

When using the PFJ-1, simultaneously press the CD STOP button and the DECK A )(fast rightward) button to turn on the power.

[Connection Diagram]

PFJ-1

(Power Supply Jig)

POWER SW

FH-E939,838,737,

MHC-6600,5600,

CDP/TC

Connector Cable 17P

(Supplied with set)

Set

CNB108 17P

SYSTEM CONTROL

Conversion Board

(J-2501-138-A)

1. GENERAL ······································································ 3

2. DISASSEMBLY

2-1. Back Panel, CD Block Removal········································· 4

2-2. Cassette Lid (A)/(B) Assy, Mechanism Deck Removal ···· 4

2-3. Main Board, Resistor Board, Front Panel Assy Removal ·· 5

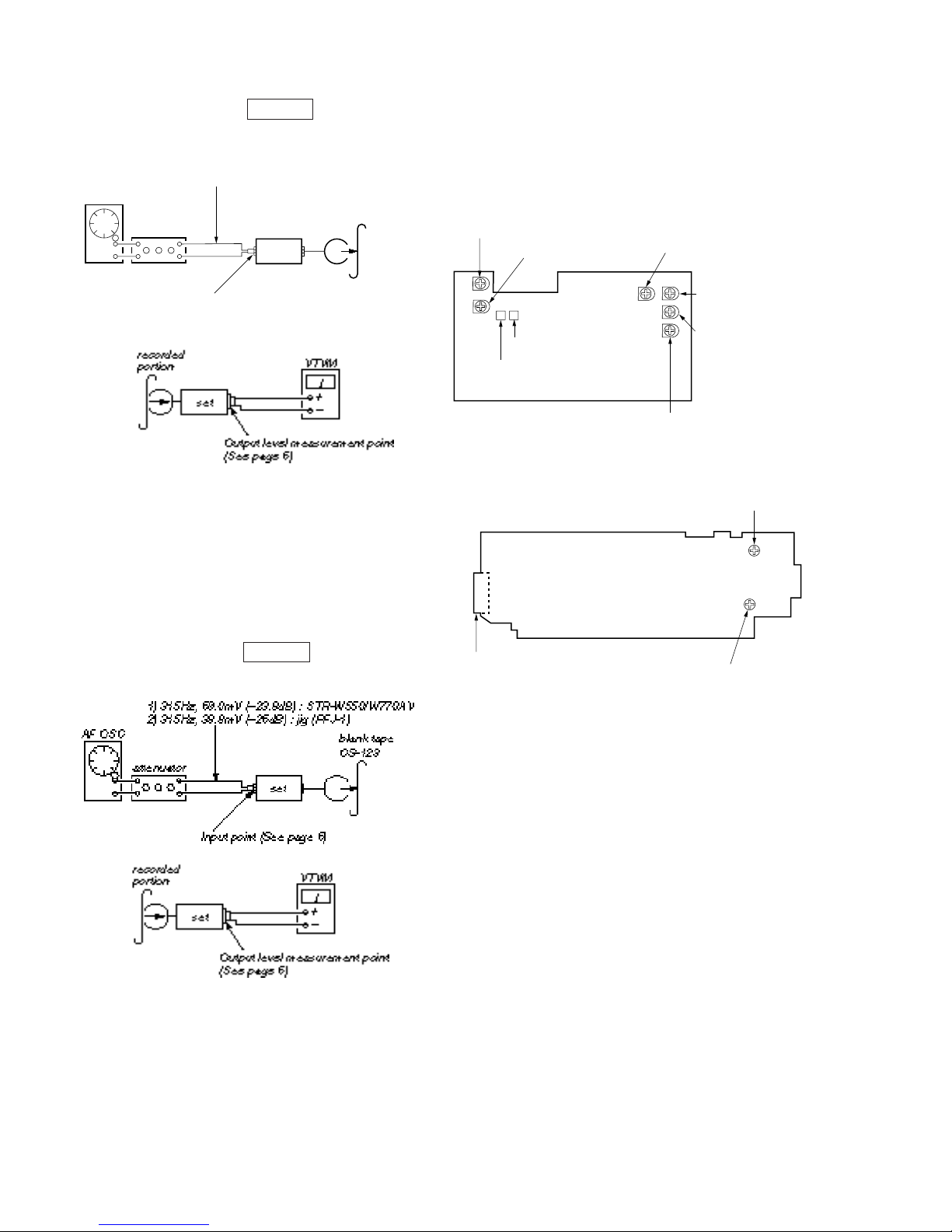

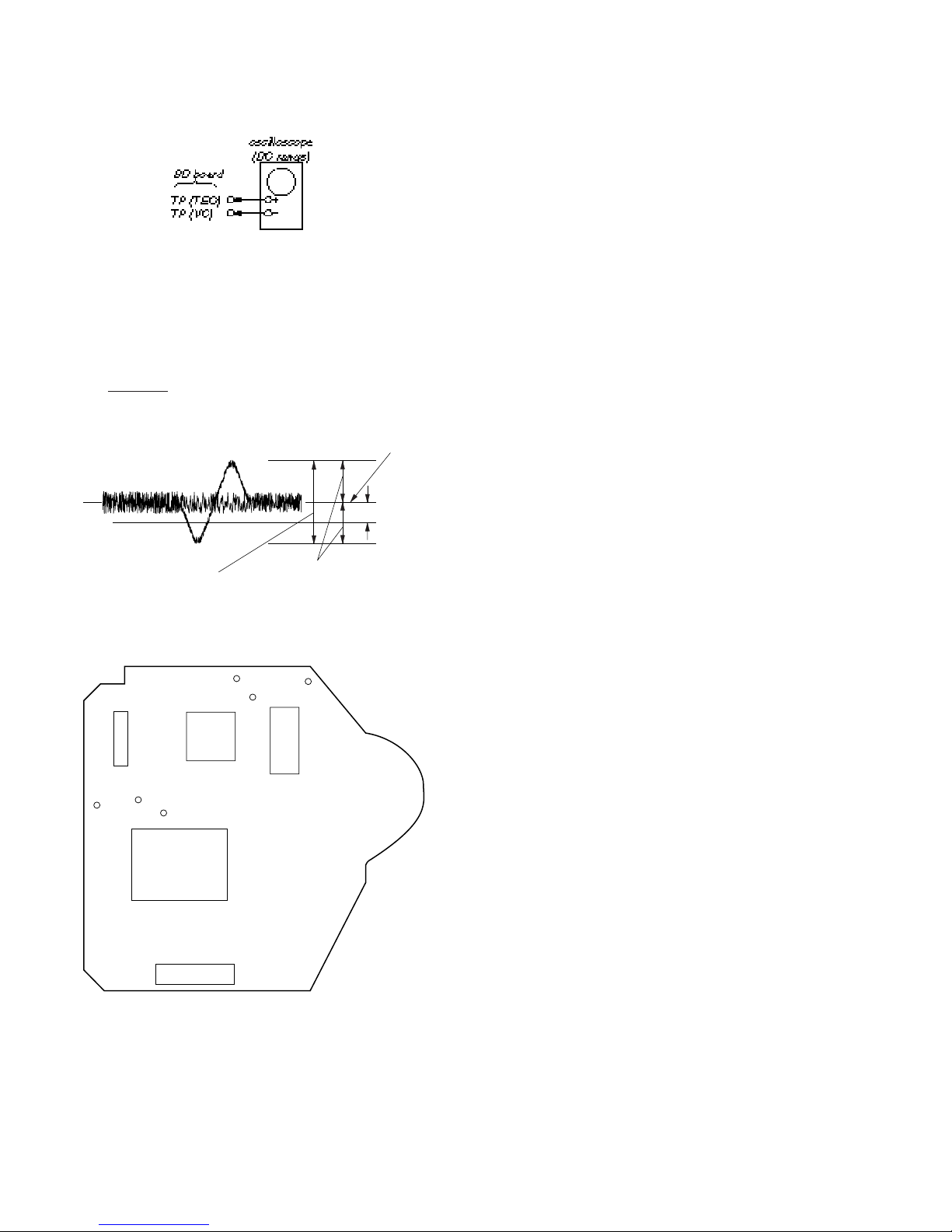

3. ADJUSTMENTS

3-1. Mechanical Adjustment ······················································ 6

3-2. Electrical Adjustment ························································· 6

4. DIAGRAMS

4-1. Block Diagram ································································· 11

4-2. Circuit Boards Location ··················································· 13

4-3. Schematic Diagram — Audio Section —························· 14

4-4. Printed Wiring Board — Audio Section — ······················ 17

4-5. Printed Wiring Board — BD Section — ·························· 19

4-6. Schematic Diagram — BD Section — ····························· 21

4-7. Printed Wiring Board — Motor Section —······················ 23

4-8. Schematic Diagram — Motor Section — ························ 25

4-9. Schematic Diagram — Panel Section — ························· 27

4-10. Printed Wiring Board — Panel Section —······················· 29

4-11. Printed Wiring Board — Main Section — ······················· 32

4-12. Schematic Diagram — Main Section — ··························35

4-13. IC Block Diagrams ···························································38

4-14. IC Pin Function ································································ 40

5. EXPLODED VIEWS

5-1. Main Section····································································· 42

5-2. Front Panel Section ·························································· 43

5-3. CD Mechanism Deck Section-1 (CDM38-5BD29A) ····· 44

5-4. CD Mechanism Deck Section-2 (CDM38-5BD29A) ····· 45

5-5. Base Unit Section (BU-5BD29A) ···································· 46

5-6. Tape Mechanism Deck Section-1 (TCM-220WR2E) ······ 47

5-7. Tape Mechanism Deck Section-2 (TCM-220WR2E) ······ 48

6. ELECTRICAL PARTS LIST ··································· 49