DD

Giskersy0)

TABLE

OF

CONTENTS

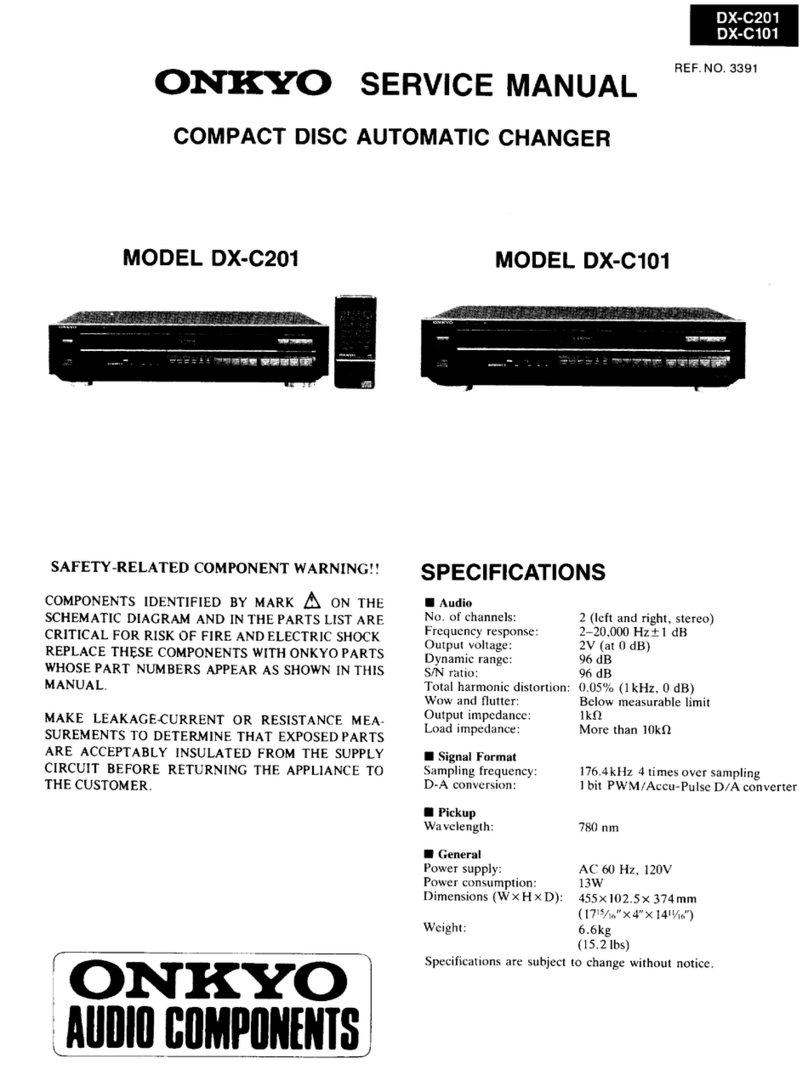

Specifications

oiceu:

scisicses

pavsie

dew

gssaeaewse.secedsereseons

1

Service

procedures

...........ccceeceeeceea

ee

eceeeeeeeeeeneeaes

Note

on

compact

disc

.............eeceeeeeeceeeetee

een

eeeeenens

3

Protection

of

eyes

from

laser

beam

during

servicing

..

4

Laser

warning

label

...............cccceeeeeeceeeeececueeeeneens

4

Caution

on

replacement

of

pickup

.................:eeeeeees

6

Packing

View:

ss

.cssetescd.asaedanssateatanesbyenssaasadnssaartasecs

7

Chassis-exploded

View

.............ccccceceeeeeceeeeeneeneeeeees

8

Parts

St

seas

dnvaccangsyee

wis

tuas

aeyed

oie

taclacncendy

vescavesboeaeases

9

Mechanism-exploded

View

............csceeeeeceeeeeeeeenees

10

Parts:

lISt:

sve.

tsdensCreshevtnes

gitnacdats

ae

etandeeelavdenearscee.

11

Disassembling

procedures

..............ececceeeeeeeeceeeeees

11

LUbricatiOn:

o.3.05

sccpeesscceeantaver

esas

ancedaaweddecaseatneets

12

IC

block

diagram

and

descriptions

..............:..e00e0

13

Adjustment

procedures

............scceceeesceeceeceecneen

ens

22

Printed

circuit

board

view

from

bottom

side

Main:

¢ircuit'sco:.ci.2.eccsscstdvedeile

cavenettvlvavcartexteveds

25

Other

pc

boards

..........

cece

eec

eee

eec

sence

eeeeereeaenees

29

Printed

circuit

board-parts

list

.............cccceeeeeeeee

ees

27

Block

diagram

...........ccecececeeeeeeeeeeeceeeeeeeeeeeeeeneas

31

SERVICE

PROCEDURES

1.

How

to

Release

the

Transport

Lock

To

protect

the

optical

assembly

including

the

laser

pickup

from

vibration

related

damage

during

shipping,

this

unit

is

equipped

with

a

transport

lock

lever

located

on

the

base.

60+

head

screwdriver

Lock

lever

:

Hole

|

@

Usea

screwdriver

to

turn

the

lock

lever

(about

90°)

in

the

round

hole

in

the

direction

of

arrow

(

G

).

®

Before

transporting

the

unit

again,

stand

it

with

its

left

side

facing

down,

and

turn

on

the

power.

Wait

2-3

seconds

and

then

turn

the

lock

lever

in

the

opposite

direction

of

the

arrow.

Fig.

1

2.

Safety-check

out

After

correcting

the

original

service

problem,

perform

the

following

safety

check

before

releasing

the

set

to

the

customer:

Connect

the

insulating-resistance

tester

between

the

plug

of

power

supply

cable

and

chassis.

Specifications:

more

than

10Mohm

at

500V.

~2-

3.

Procedures

for

replacement

of

flat

packaged

ICs

1.

Tools

to

be

used:

(1)

Soldering

iron

....

Grounded

soldering

iron

or

soldering

iron

with

leak

re-

sistance

of

10

Mohms

or

more.

Form

of

soldering

iron’s

tip:

(2)

Magnifying

glass...

for

checking

of

finished

works

(3)

Tweezers........

for

handling

of

IC

forming

of

leads

(4)

Grounding

ring...

.

Countermeasure

for

electro-

static

breakdown

(5)

Nipper

.........

for

removing

defective

IC

(6)

Small

brush

......

for

application

of

flux

and

2.

Work

Procedures:

(1)

Remove

the

defective

IC

Cut

all

leads

of

the

defective

IC

one

by

one

using

a

nipper

and

remove

the

IC.

(2)

Clean

the

pattern

surface

of

the

PC

board.

Get

rid

of

the

remaining

leads

and

solder.

(3)

Check

and

from

the

leads

of

the

new

flat

pack-

aged

IC

to

be

installed.

From

every

lead

on

the

new

IC

using

a

pair

of

tweezers,

so

that

all

of

them

are

aligned

neatly

without

being

risen,

twisted

or

inclined

toward

one

side.

Especially

the

rising

portion

of

every

lead

must

be

formed

with

greatest

care.

IC

ee

;

IC

&

;

Ic

a

(Incliming)

(Rising)

(Twisting)

Fig.

3

(4)

Apply

flux

to

the

PC

board.

Apply

flux

to

the

pattern

surface

of

the

PC

board

which

has

been

cleaned,

as

shown

in

the

illustration.

The

area

to

be

applied

with

flux

is

the

portion

of

about

2.5mm

in

width

where

the

IC’s

leads

are

to

be

soldered.

Be

careful

to

apply

minimum

amount

of

flux

required

so

as

not

to

smear

it

on

unwanted

areas.

About

2.5

mm

Fig.

4