– 2 –

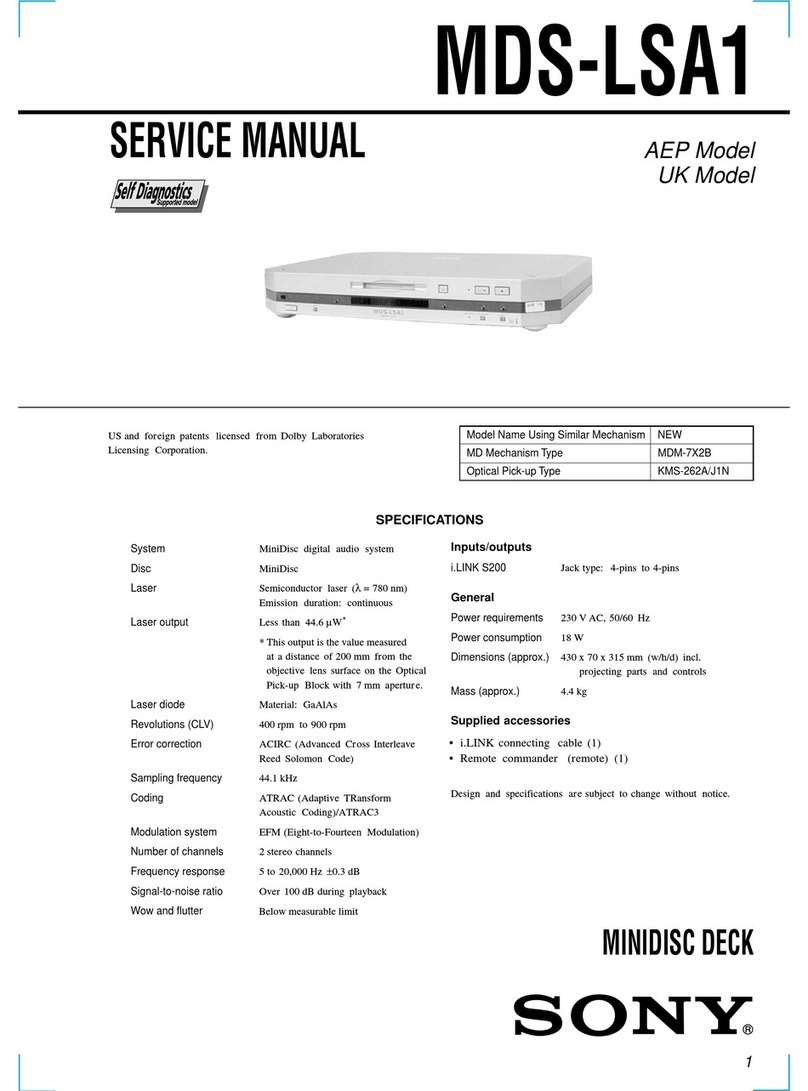

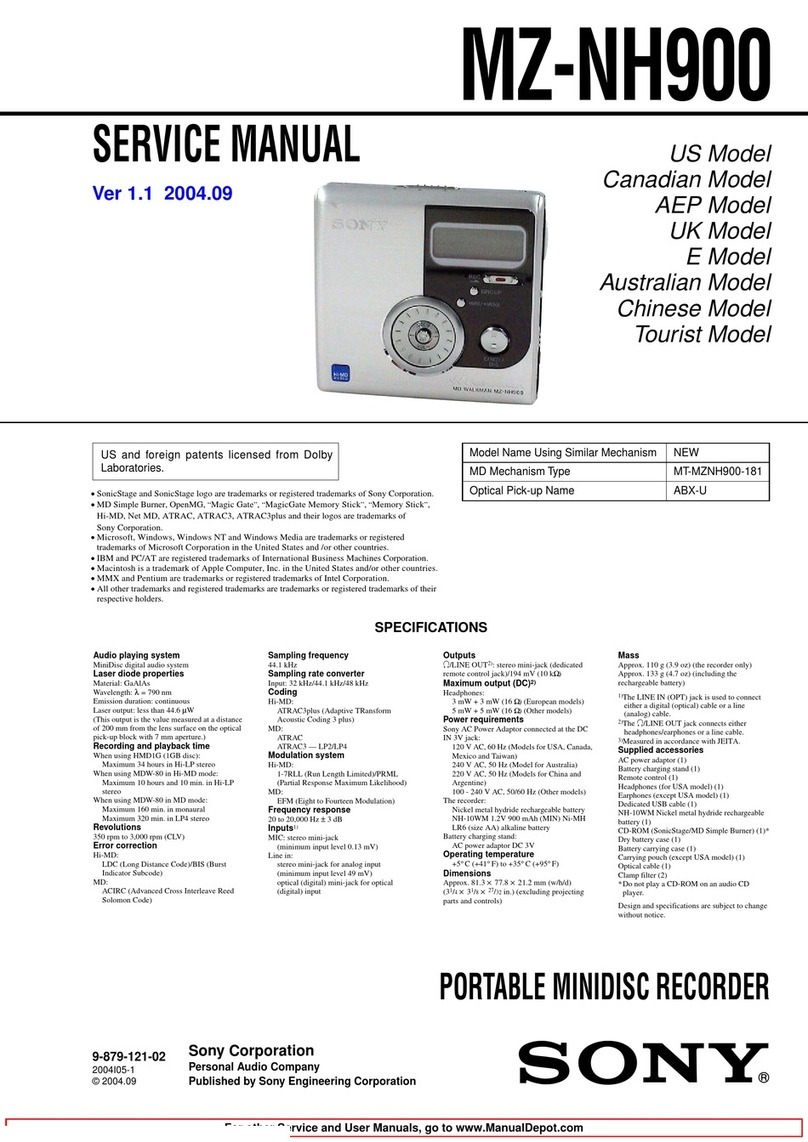

Specifications ........................................................................... 1

1. SERVICE NOTE........................................................... 3

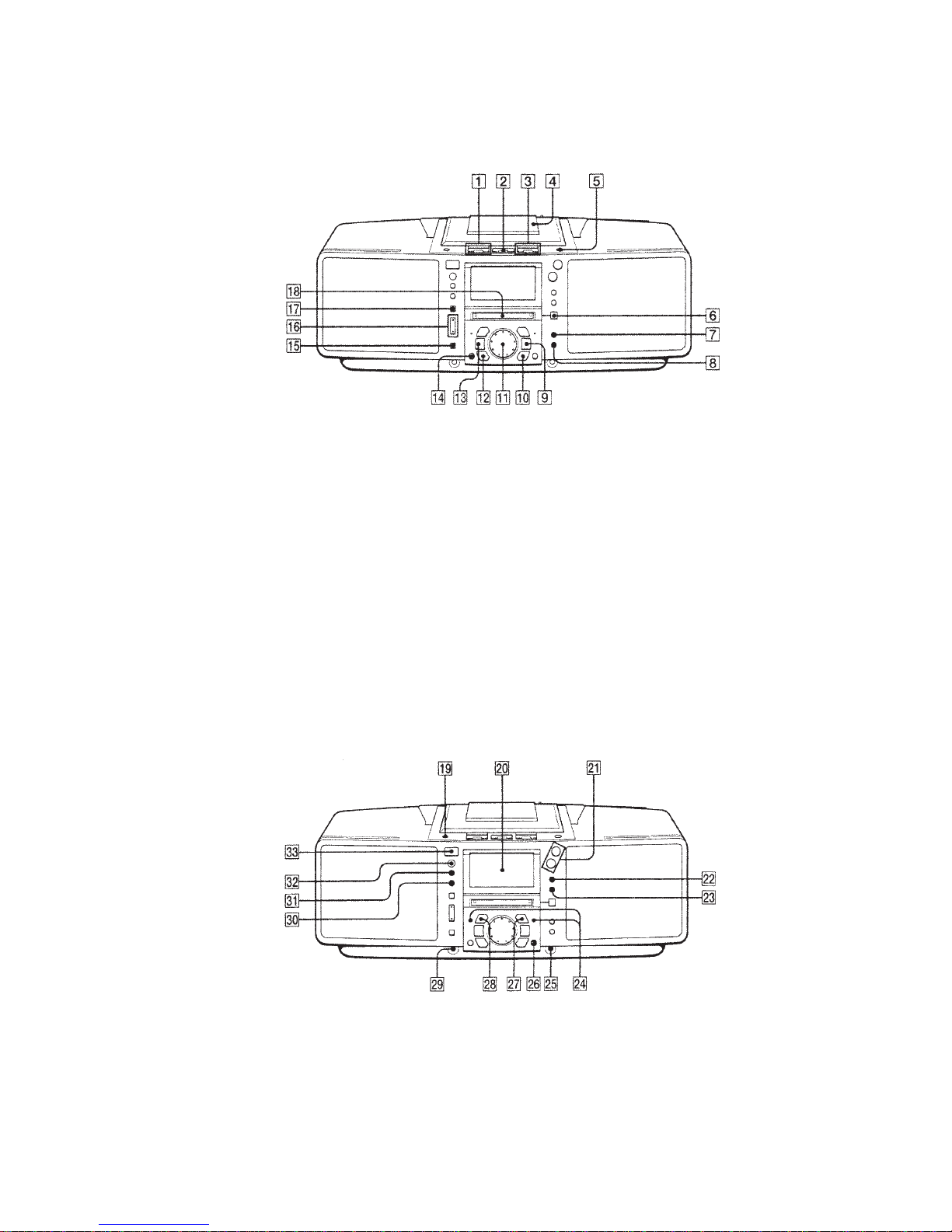

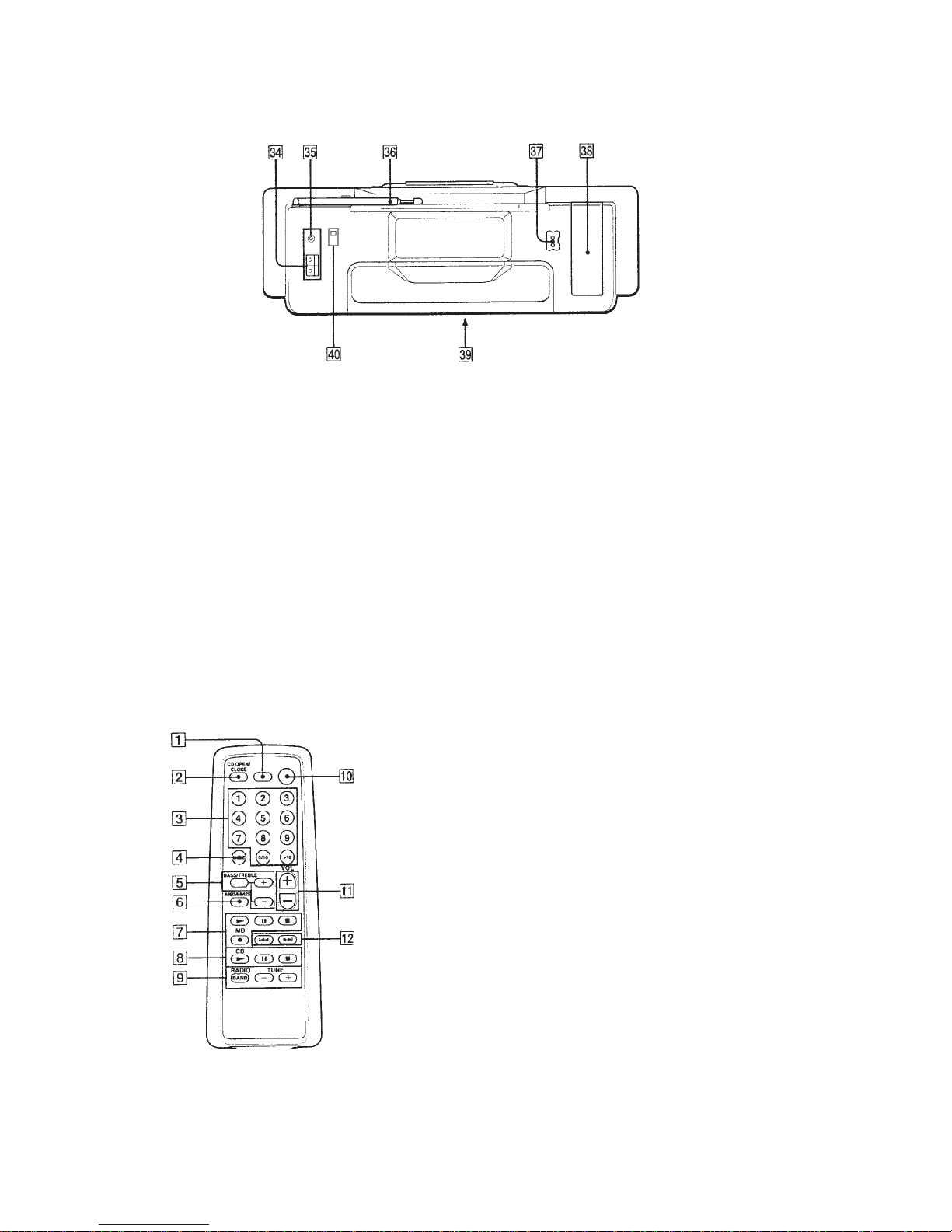

2. GENERAL...................................................................... 5

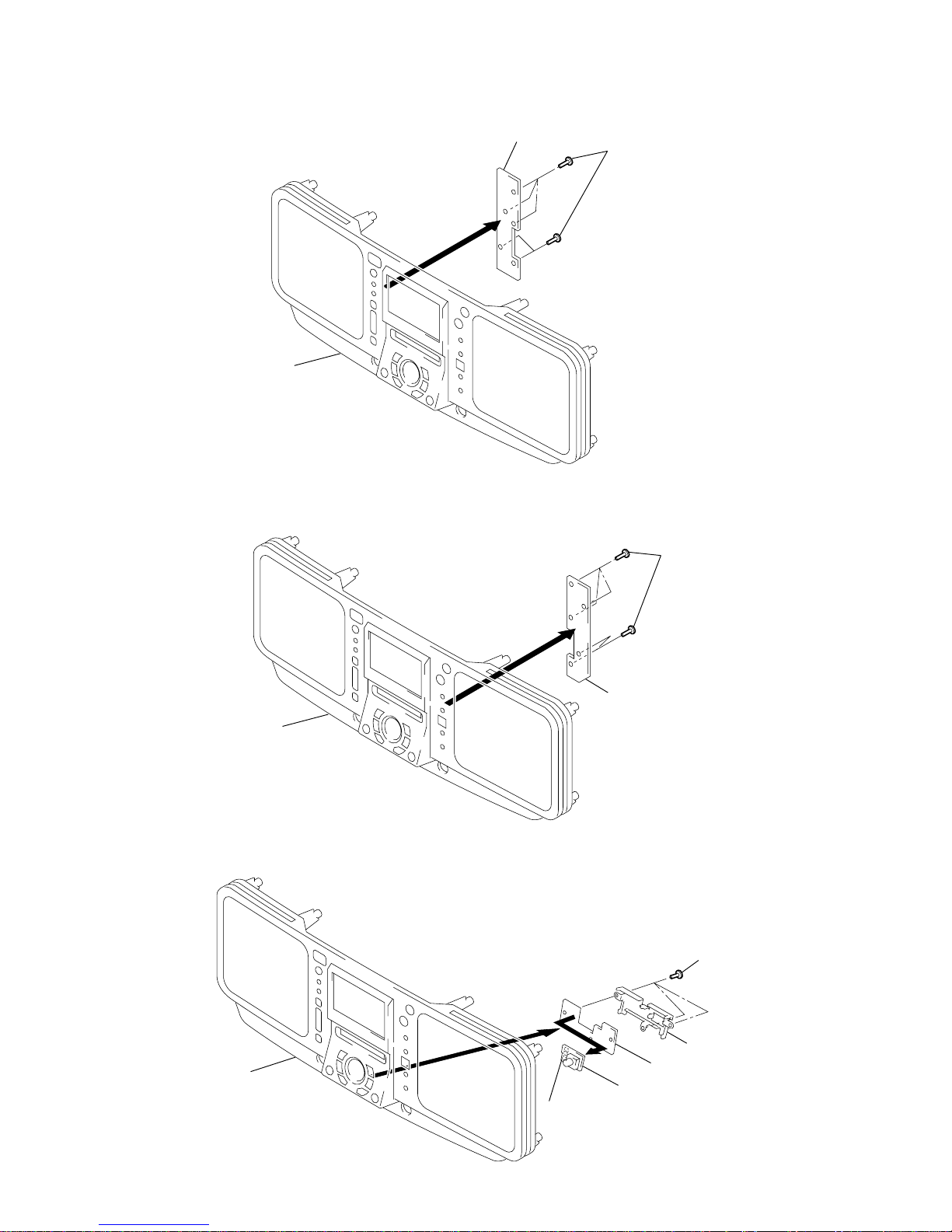

3. DISASSEMBLY

3-1. Cabinet (Front) Sub ASSY,

Cabinet (Rear) Sub ASSY ......................................... 7

3-2. Control (L) Board...................................................... 8

3-3. Control (R) Board ..................................................... 8

3-4. Control (F) Board, JOG Board.................................. 8

3-5. BATT Board .............................................................. 9

3-6. Power Board.............................................................. 9

3-7. Tuner Board, Antenna SW Board ............................. 9

3-8. Center Block Section .............................................. 10

3-9. Cabinet (Upper), Chassis (Main) ............................ 10

3-10.Optical Pick-up ASSY, CD Motor Board.................11

3-11.Control SW Board....................................................11

3-12.Motor Board, Belt, Motor (M703) ...........................11

3-13.LCD Board, BL Board ............................................ 12

3-14.Audio Board ............................................................ 12

3-15.Line Board............................................................... 13

3-16.Main Board ............................................................. 13

3-17.MD Block ASSY..................................................... 14

3-18.DG Board ................................................................ 14

3-19.Chassis (MD) .......................................................... 15

3-20.BD Board ................................................................ 15

3-21.Sub Chassis ASSY, MD Mechanism Deck ............. 16

3-22.Shutter ASSY .......................................................... 16

3-23.SW Board ................................................................ 17

3-24.“Head, Over Write”, Slider ASSY .......................... 17

3-25.MD Optical Pick-up Block ..................................... 18

4. TEST MODE

4-1. Caution When Using the Test Mode......................... 19

4-2. Test Mode Settings ................................................... 19

4-3. Releasing the Test Mode........................................... 19

4-4. Basic Operations of the Test Mode........................... 19

4-5. Selecting the Test Mode............................................ 19

4-6. Functions of Other Buttons ...................................... 20

4-7. Test Mode Display .................................................... 20

TABLE OF CONTENTS

5. ADJUSTMENTS

MD Section ...................................................................... 21

CD Section ....................................................................... 24

Display Section ................................................................ 25

Tuner Section ................................................................... 26

6. DIAGRAMS

6-1. Explanation of IC Terminals ................................... 28

6-2. Block Diagram (Main Section) ............................... 35

6-3. Block Diagram (MD Section) ................................. 39

6-4. Printed Wiring Boards –Main Section – ................. 43

6-5. Schematic Diagram –Main Section (1/3) – ............. 47

6-6. Schematic Diagram –Main Section (2/3) – ............. 51

6-7. Schematic Diagram –Main Section (3/3) – ............. 55

6-8. Printed Wiring Boards –Audio Section –................ 58

6-9. Schematic Diagram –Audio Section – .................... 61

6-10.Schematic Diagram –DG Section – ........................ 66

6-11.Printed Wiring Boards –DG Section – .................... 71

6-12.Printed Wiring Boards –Tuner Section – ................ 73

6-13.Schematic Diagram –Tuner Section –..................... 75

6-14.Schematic Diagram –Control Section – .................. 78

6-15.Printed Wiring Boards –Control Section – ............. 81

6-16.Printed Wiring Boards –BD Section – .................... 83

6-17.Schematic Diagram –BD Section – ........................ 85

7. EXPLODED VIEWS

7-1. Rear Cabinet Section ................................................ 95

7-2. Front Cabinet Section ............................................... 96

7-3. Center Block Section ................................................ 97

7-4. Upper Cabinet Section.............................................. 98

7-5. MD Section (1) ......................................................... 99

7-6. MD Section (2) ....................................................... 100

7-7. CD Optical Pick-up Section ................................... 101

8. ELECTRICAL PARTS LIST................................. 102