2

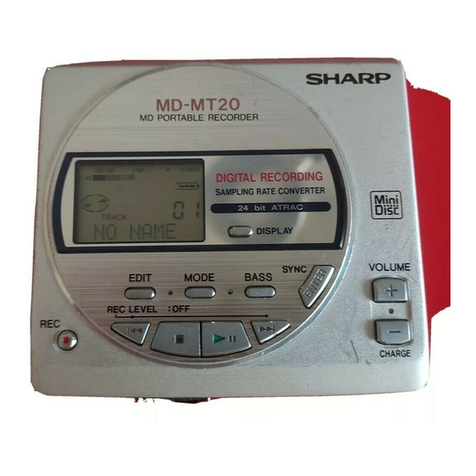

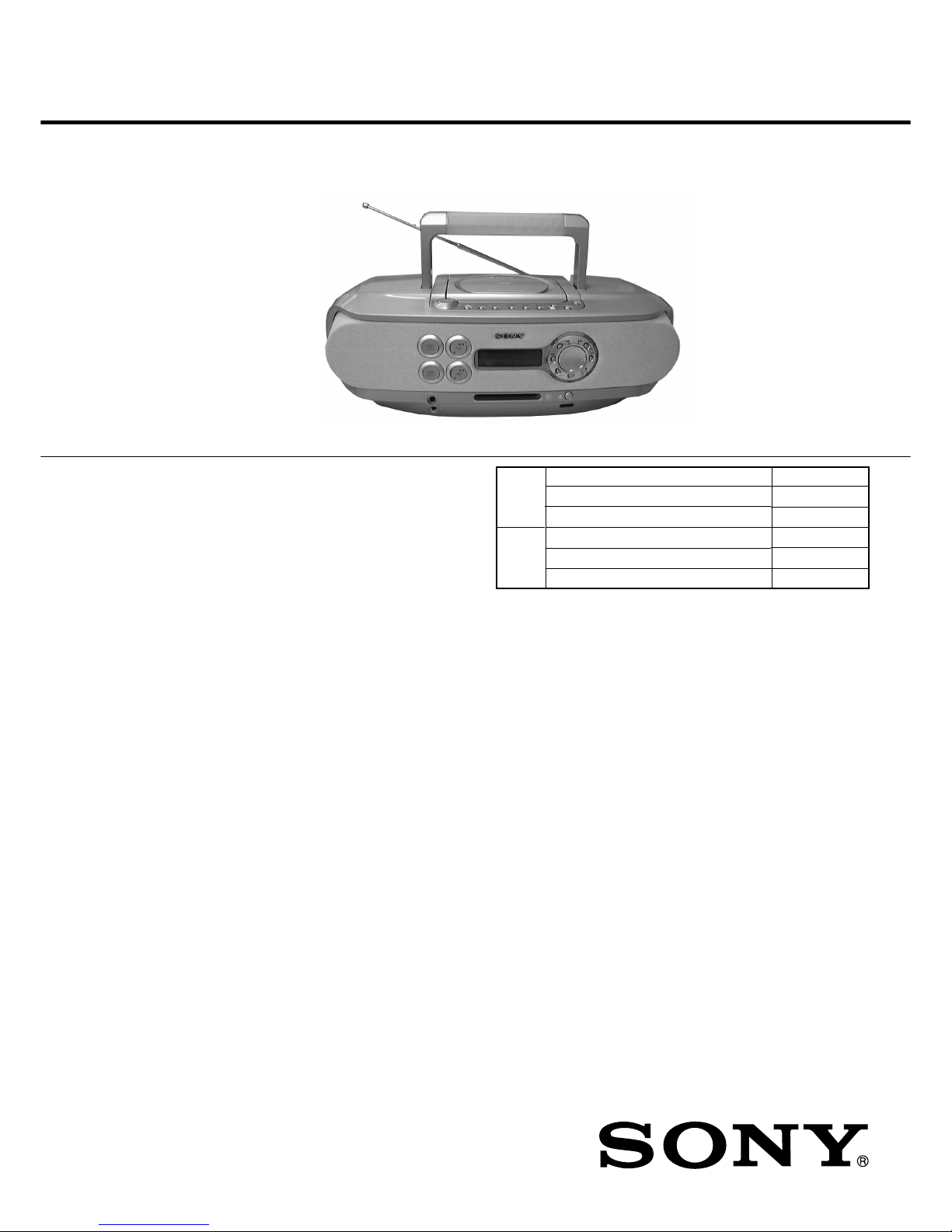

ZS-M30

Modulation system

EFM (Eight-to-Fourteen Modulation)

Number of programme positions

2 stereo programme positions

Frequency response

20 - 20,000 Hz +1/–2 dB

Signal-to-noise ratio

Over 80 dB (during playback)

Wow and flutter

Below measurable limit

General

Speaker

Full-range: 8 cm (3 1 ⁄4 in.) dia., 4 Ωcone type (2)

Panorama sound: 5 cm (2 in.) dia., 12 Ωcone type (2)

Inputs

LINE IN (stereo minijack): Sensitivity 436 mV/870 mV

Outputs

Headphones jack (stereo minijack) (1):

For 32 Ωimpedance headphones

Maximum power output

Full-range: 8 W

Panorama sound: 3.4 W

Specifications ........................................................................... 1

1. SERVICING NOTE

1-1. Notes on Handling the Optical Pick-up Block or

Base Unit ............................................................................ 3

1-2. Notes on Laser Diode Emission Check .............................. 3

1-3. Notes on Chip Component Replacement ........................... 3

1-4. Flexible Circuit Board Repairing ....................................... 3

1-5. Chuck Plate Jig on Repairing ............................................. 3

1-6. Checking the Laser Diode and Focus Search Operation .... 3

1-7. Checks Prior to Parts Replacement and Adjustments

(for MD Section) ............................................................... 4

2. GENERAL

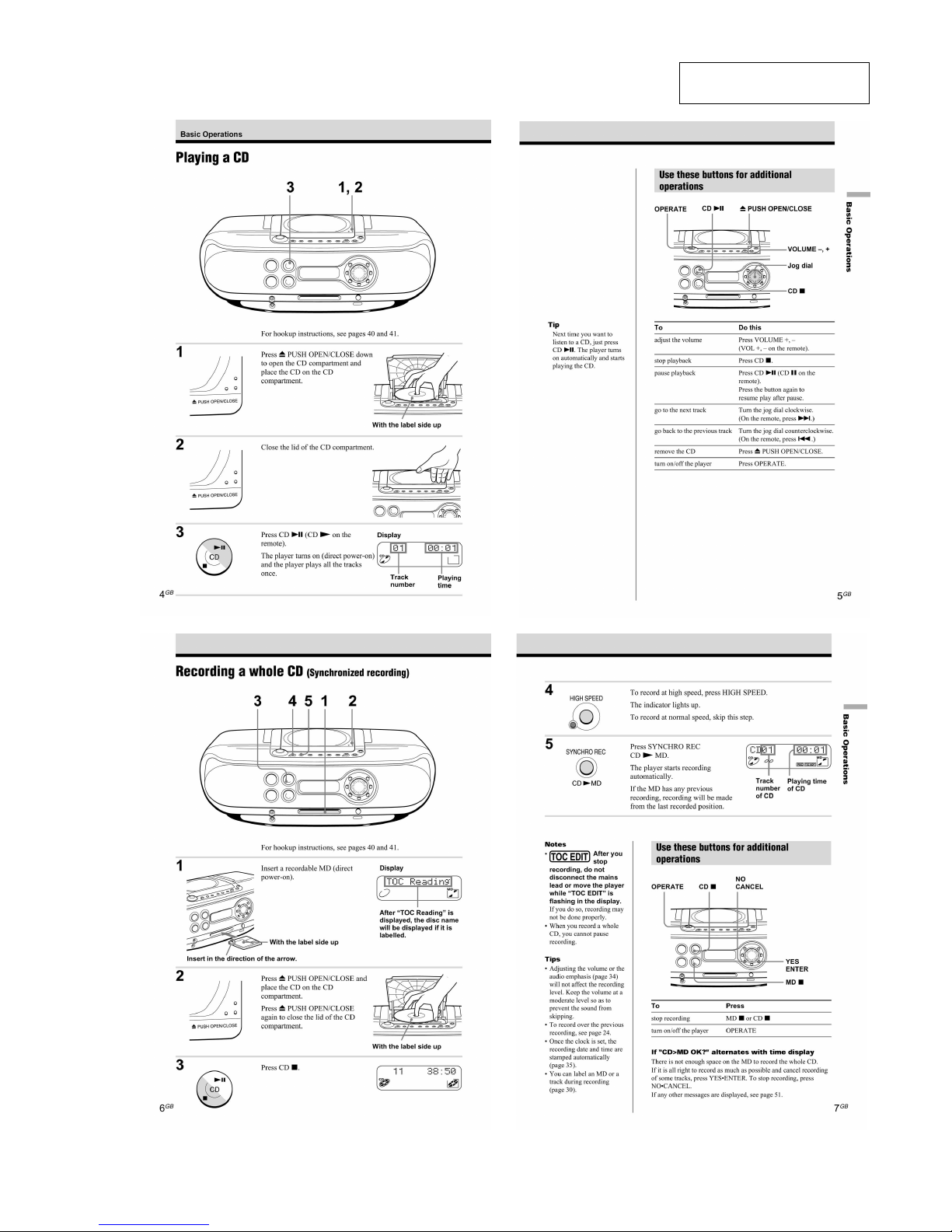

Playing a CD ...................................................................... 5

Recording a Whole CD (Synchronized Recording) ........... 5

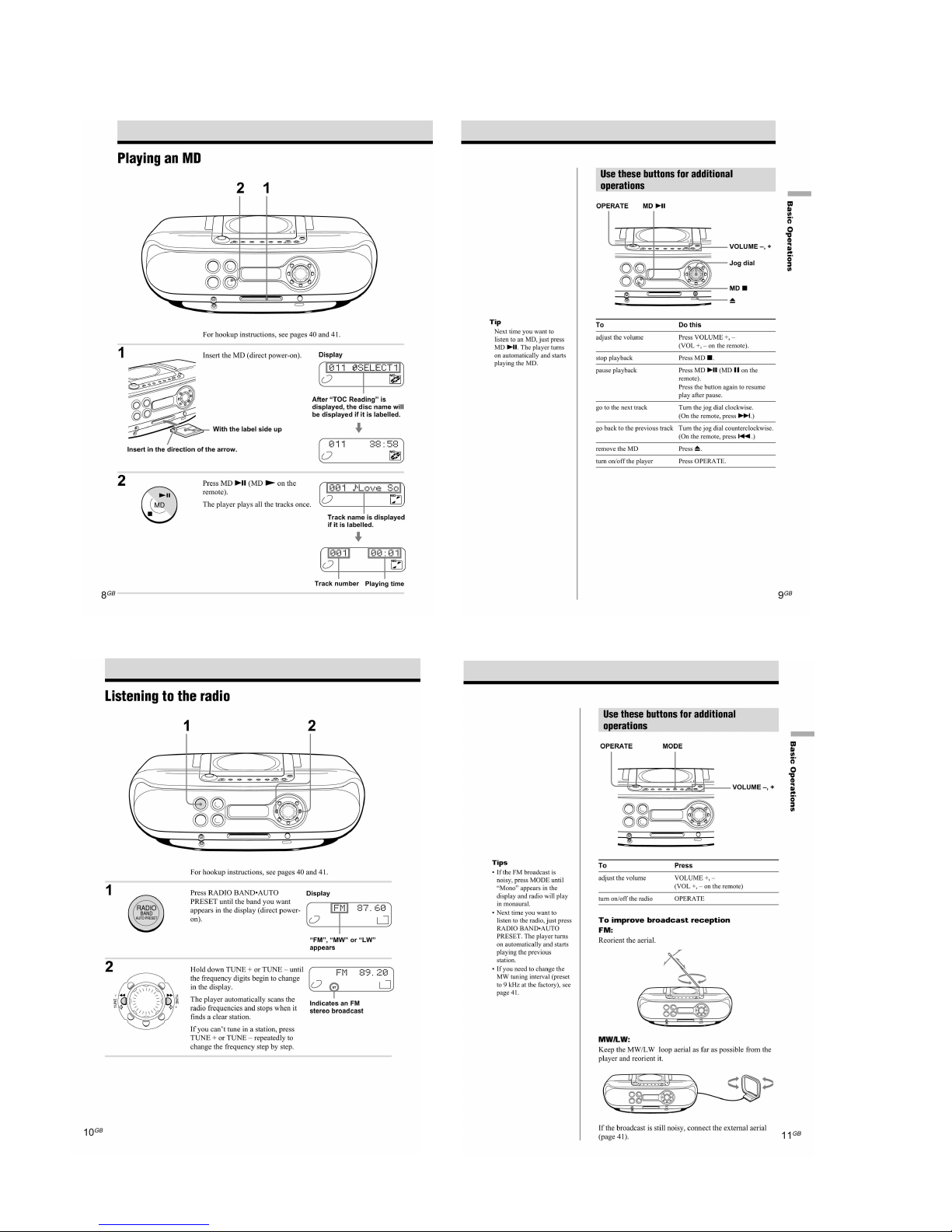

Playing an MD ................................................................... 6

Listening to the Radio ........................................................ 6

3. DISASSEMBLY

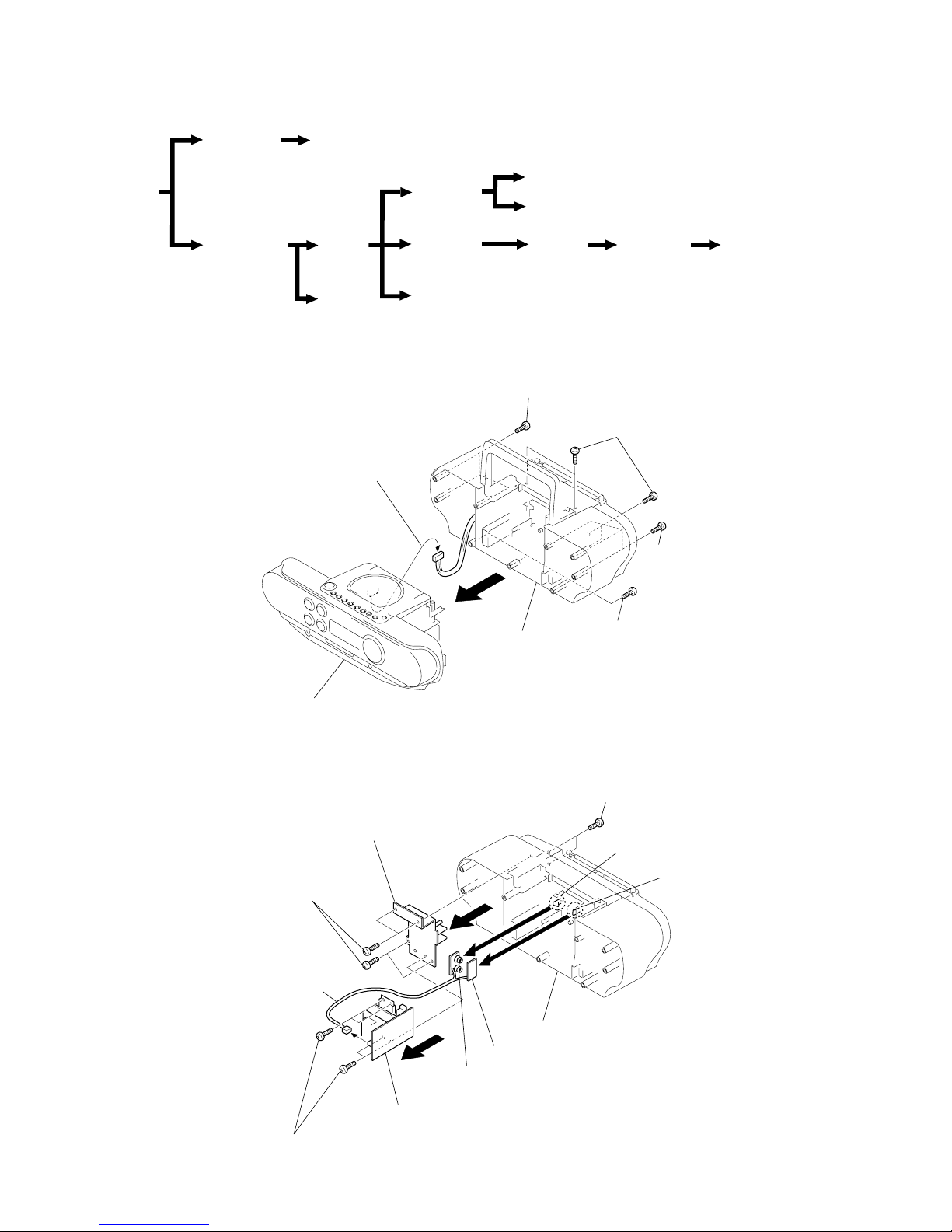

3-1. Cabinet (Rear), Cabinet (Front) ......................................... 7

3-2. BATT (B) Board, BATT (A) Board, Power Board ............. 7

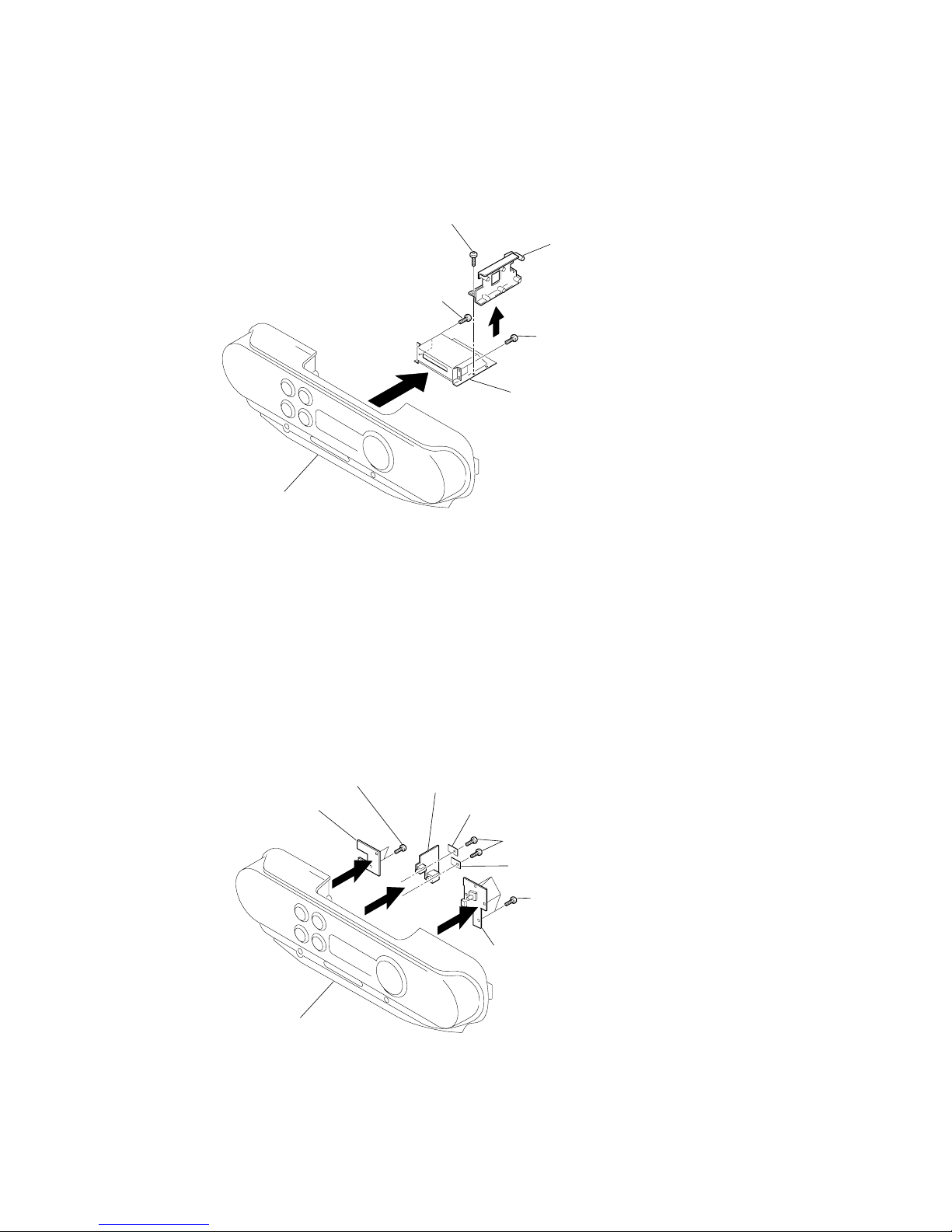

3-3. Cabinet (Upper) ASSY ....................................................... 8

3-4. Main Board, LCD Board .................................................... 8

3-5. CD Board ........................................................................... 9

3-6. Top Board ........................................................................... 9

3-7. Tuner Board ........................................................................ 9

3-8. MD Block ASSY .............................................................. 10

3-9. SW (L) Board, Jack Board, SW (R) Board ...................... 10

3-10. MD Board ...................................................................... 11

3-11. REC Board, DETECT Board ......................................... 11

3-12. Over Write Head (HR901), MD Optical Pick-up,

D SW Board ................................................................... 12

4. TEST MODE

4-1. MD Section ...................................................................... 13

4-2. Section the Test Mode ...................................................... 13

4-3. Releasing the Test Mode .................................................. 13

4-4. Basic Operations of the Test Mode .................................. 13

4-5. Selecting the Test Mode ................................................... 14

4-6. Functions of Other Buttons .............................................. 16

4-7. Test Mode Displays .......................................................... 16

4-8. Meanings of Other Displays............................................. 16

TABLE OF CONTENTS

Power requirements

For personal minidisc system:

230 V AC, 50 Hz

For back-up memory:

4.5 V DC, 3 R6 (size AA) batteries

For remote control:

3 V DC, 2 R6 (size AA) batteries

Power consumption

26 W

Dimensions (incl.projecting parts)

approx. 475 X165.5 X249 mm (w/h/d)

(18 3/4 X6 5 ⁄8 X9 7/8 inches )

Mass

approx. 4.6 kg (10 lb. 2 oz)

Supplied accessories

Mains lead (1)

Remote control (1)

MW/LW loop aerial (1)

AV connecting cord (1)

Audio connecting cord (1)

Design and specifications are subject to change without

notice.

5. ELECTRICAL ADJUSTMENT

5-1. Tuner Section ................................................................... 17

5-2. MD section ....................................................................... 19

5-3. CD section ........................................................................ 25

6. DIAGRAMS

6-1. IC Pin Function Descriptions ........................................... 28

6-2. Block Diagrams (1/4) ....................................................... 37

6-3. Block Diagrams (2/4) ....................................................... 38

6-4. Block Diagrams (3/4) ....................................................... 39

6-5. Block Diagrams (4/4) ....................................................... 40

6-6. Printed Wiring Boards -Main Section- ............................. 41

6-7. Schematic Diagram -Main Section (1/3)- ........................ 42

6-8. Schematic Diagram -Main Section (2/3)- ........................ 43

6-9. Schematic Diagram -Main Section (3/3)- ........................ 44

6-10. Printed Wiring Boards -Power Section- ......................... 45

6-11. Printed Wiring Boards -Tuner Section- .......................... 46

6-12. Schematic Diagram -Tuner Section- .............................. 47

6-13. Printed Wiring Boards -Control Section- ....................... 48

6-14. Schematic Diagram -Control Section- ........................... 49

6-15. Printed Wiring Boards -CD Section- .............................. 50

6-16. Schematic Diagram -CD Section- .................................. 51

6-17. Printed Wiring Boards -MD Section- ............................. 52

6-18. Schematic Diagram -MD Section (1/2)- ........................ 53

6-19. Schematic Diagram -MD Section (2/2)- ........................ 54

7. EXPLODED VIEWS

7-1. Rear Cabinet Section ........................................................ 64

7-2. Front Cabinet Section ....................................................... 65

7-3. Upper Cabinet Section ..................................................... 66

7-4. Optical Pick-up Section.................................................... 67

7-5. MD Section -1 .................................................................. 68

7-6. MD Section -2 .................................................................. 69

8. ELECTRICAL PARTS LIST .................................... 70