Sony UVW-1800P User manual

Other Sony VCR System manuals

Sony

Sony SLV-SE50EE User manual

Sony

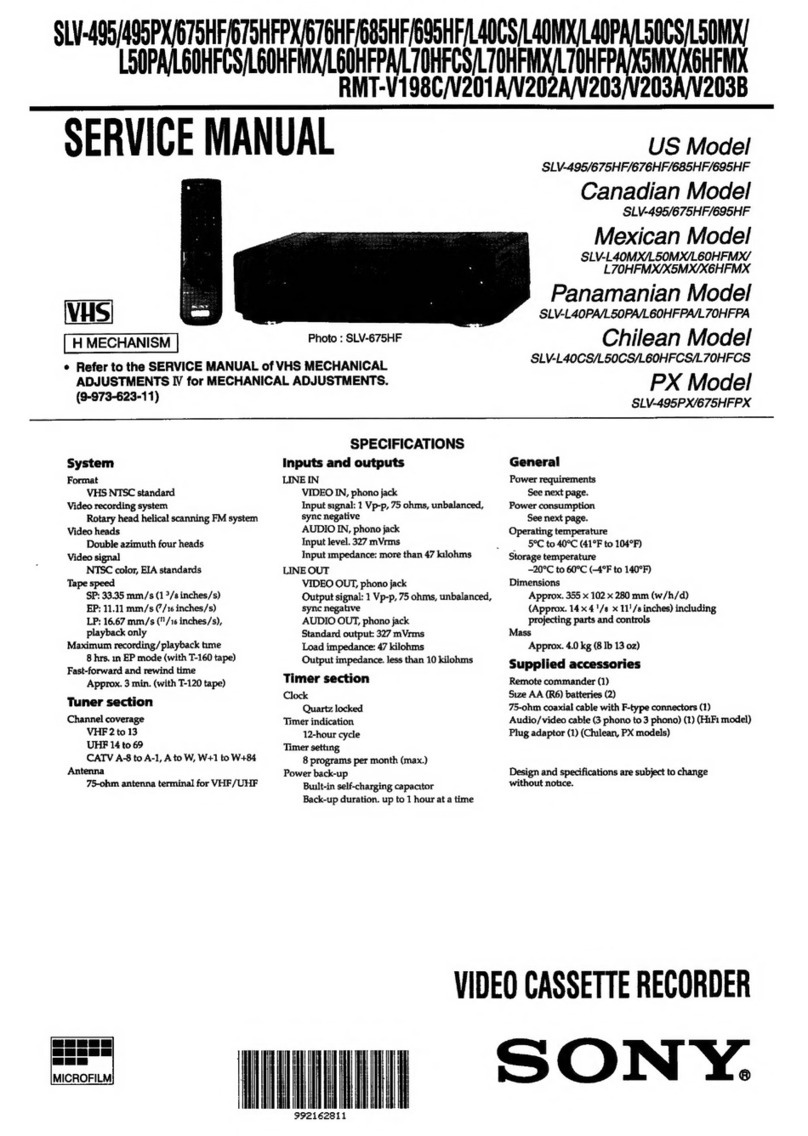

Sony SLV-495 User manual

Sony

Sony EV-C100 User manual

Sony

Sony GV-D300 Operating Instructions (primary... User manual

Sony

Sony SLV-662HF Operating Instructions (SLV-662HF / 679HF / 679HF PX... User manual

Sony

Sony SLV-N99 - Video Cassette Recorder User manual

Sony

Sony SLV-669HF Operator's manual

Sony

Sony Digital Betacam DVW-2000P User manual

Sony

Sony PVW-2800 User manual

Sony

Sony SLV-AV100 User manual

Sony

Sony HVR-M25N User manual

Sony

Sony SLV-AX20 - Video Cassette Recorder User manual

Sony

Sony SLV-M91HF - Video Cassette Recorder Manual

Sony

Sony SLV-575UC User manual

Sony

Sony HVR-M15AU - Professional Video Cassete... User manual

Sony

Sony SLV-L56AR User manual

Sony

Sony SLV-998HF CS User manual

Sony

Sony SLV-N700 - Video Cassette Recorder User manual

Sony

Sony SLV-AV100C User manual

Sony

Sony Walkman GV-8 User manual