2/8

Form 916 (08.12) ©2012 SOR Inc.

Electrical Power should be disconnected before the cover is removed. Failure to

do so could result in severe personal injury or substantial property damage.

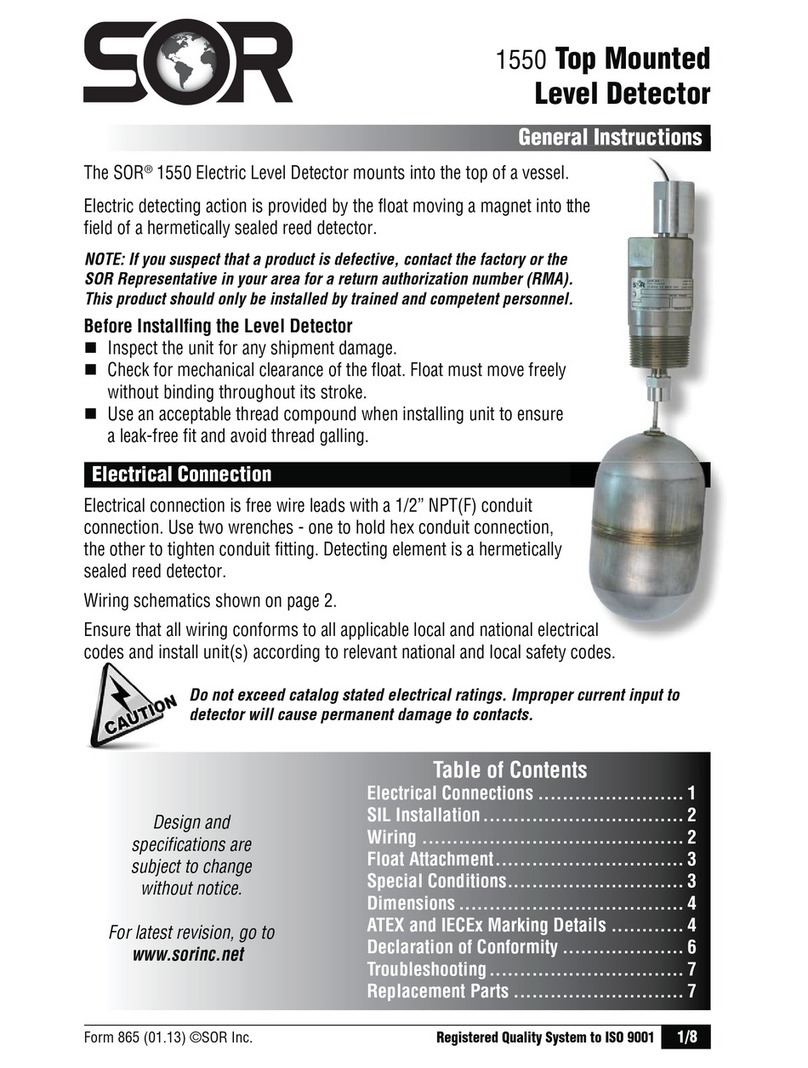

Electrical Connection

Ensure that all wiring conforms to all applicable local and national electrical codes and

install unit(s) according to relevant national and local safety codes.

Verify that obstructions are not present in the application that would prevent free float

movement throughout the entire range of motion.

Assure that the mounting provides a horizontal alignment of the detector.

Thread a one-foot long pipe into the 3/4”NPT electrical connection for a handle, or use a pipe

wrench on the main body. Tighten the unit onto the process connection by rotating clockwise.

To ensure proper operation, the unit must be mounted with the nameplate at 12 o’clock

(pointing up) and the conduit connection at the 6 o’clock position (pointing down). (See

)

Detector actuation cannot be reversed by rotating the unit 180°.

Calibration is provided by SOR. Field adjustments are not recommended.

Any of the following process connections may be provided with the 1710.

a. 2” NPT full coupling

b. Optional flanged mounting

c. Optional external chamber (See )

Counterbalance area must be free from metallic particles that may attract to

magnetic components in the 1710 model.

Remove the end cover with a spanner wrench to gain access to the terminal block and

detector mechanism.

Pull detecting wires into the detector cavity through the electrical connection. Wire to the

terminal block(s) as shown in . (Select wires which are compatible with temperature

and electrical load required by the application.)

Connect the ground wire to the green ground screw located on the outside of the housing.

Replace the detector cover and tighten. Tighten the cover lock screw to prevent accidental

removal.

Seal the conduit connection with a suitable pipe joint compound to prevent entrance of

atmospheric contaminants.

Test the detector action by varying the liquid level in the tank.

Safety Integrity Level (SIL) Installation Requirements

The SOR pressure detectors have been evaluated as Type-A safety related hardware.

To meet the necessary installation requirements for the SIL system, the following

information must be utilized:

Proof Test Interval shall be one year.

Units may only be installed for use in Low Demand Mode.

Products have a HFT (Hardware Fault Tolerance) of 0, and were evaluated in a

1oo1 (one out of one) configuration. Form 1538 (03.12) ©2012 SOR Inc.