Application Note DSDN

Issue Date May 21, 2003

© 2003 Johnson Controls, Inc. 1

Code No. LIT-1201602 www.johnsoncontrols.com

DSDN No Flow Duct Smoke Detector

Description

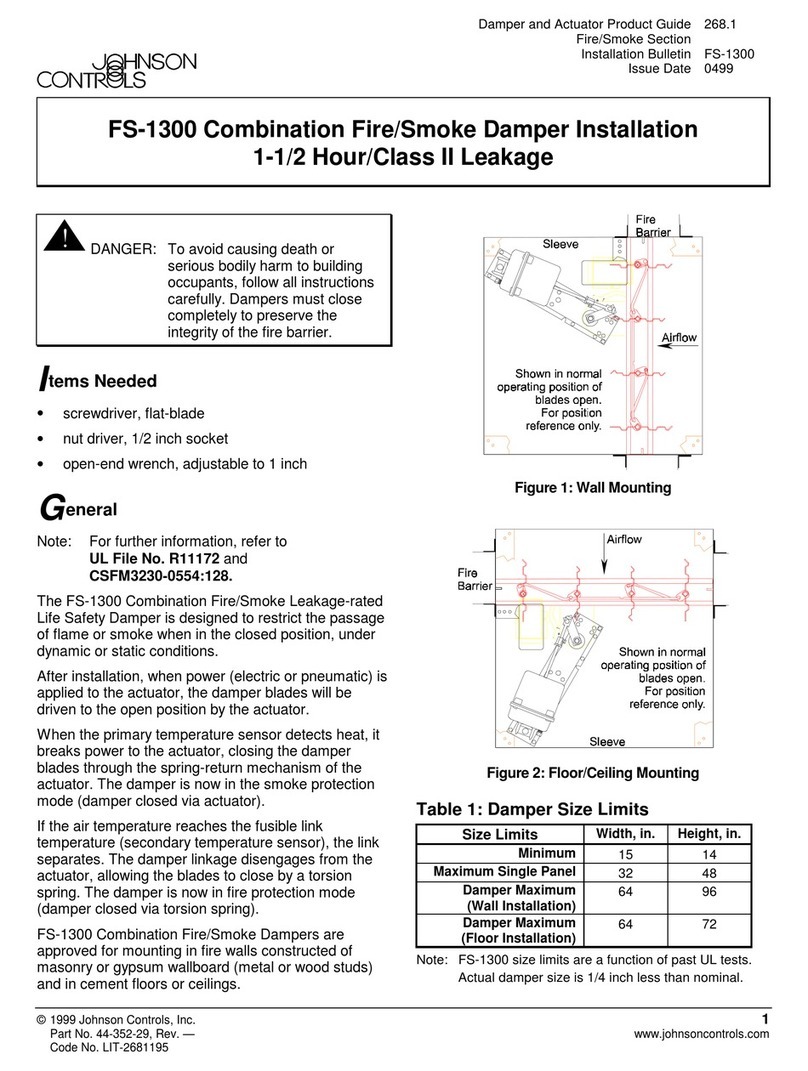

The DSDN No Flow Duct Smoke Detector is designed

for use with Johnson Controls® UL555S classified

smoke dampers. The device detects the presence of

smoke in the airstream of ductwork in Heating,

Ventilating, and Air Conditioning (HVAC) systems

without a minimum operating velocity.

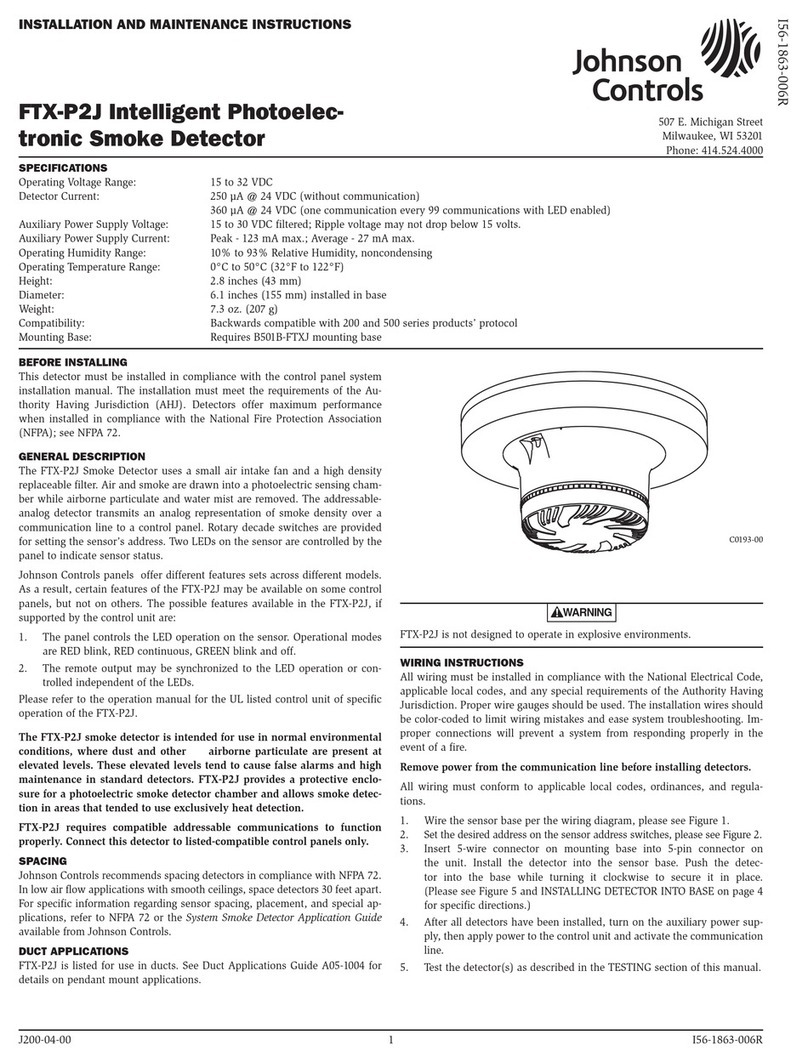

Model: System Sensor® 2151

Type: Photoelectronic

Velocity: 0 to 3,000 fpm.

Dimensions (Dia.): 6.1 in.(155 mm)

Weight: 3.6 oz. (104 g).

Operating Temperature Range: 32° F to 120° F

(0° C to 49° C).

Operating Humidity Range: 10% to 93% Relative

Humidity.

Operating Voltages: 120 VAC operation.

Contact Ratings:

Form A: 2.0A @ 30 VAC/VDC,

Form C: 0.6A @ 110 VDC, 2.0A @ 30 VDC,

1.0A @ 125 VAC, 2.0A @ 20 VAC

Underwriter's Laboratories®, Inc. (UL) does not have a

separate Product Category for factory mounted smoke

detectors. The smoke detector and the damper have

been individually evaluated by their applicable UL

standards. The local authority having jurisdiction

should be consulted prior to installation of the damper

and smoke detector.

•UL Listed: file S911

•standard cubic feet/minute (scfm) Listing:

7272-1209:159

•New York: MEA-205-94-E

•Factory Mutual Approved: OX5A4.AY

Application

National and local safety standards and codes

recognize the ability of air duct systems to transfer

smoke, toxic gases, and flame from area to area.

Smoke can be a serious hazard to life safety unless

blowers are shut down and dampers are actuated.

The primary purpose of duct smoke detection is to

prevent injury, panic, and property damage by

reducing the spread of smoke. Duct smoke detection

can also serve to protect the air conditioning system

itself from fire and smoke damage, and can be used to

assist in equipment protection applications. When the

presence of smoke in the duct is sensed, or when loss

of power occurs, the damper will fail close.

Consult NFPA90A, NFPA72 documents and local

codes to determine where smoke detectors are

required. DSDN No Flow Duct Smoke Detectors are

factory mounted for single point field wiring

connection.

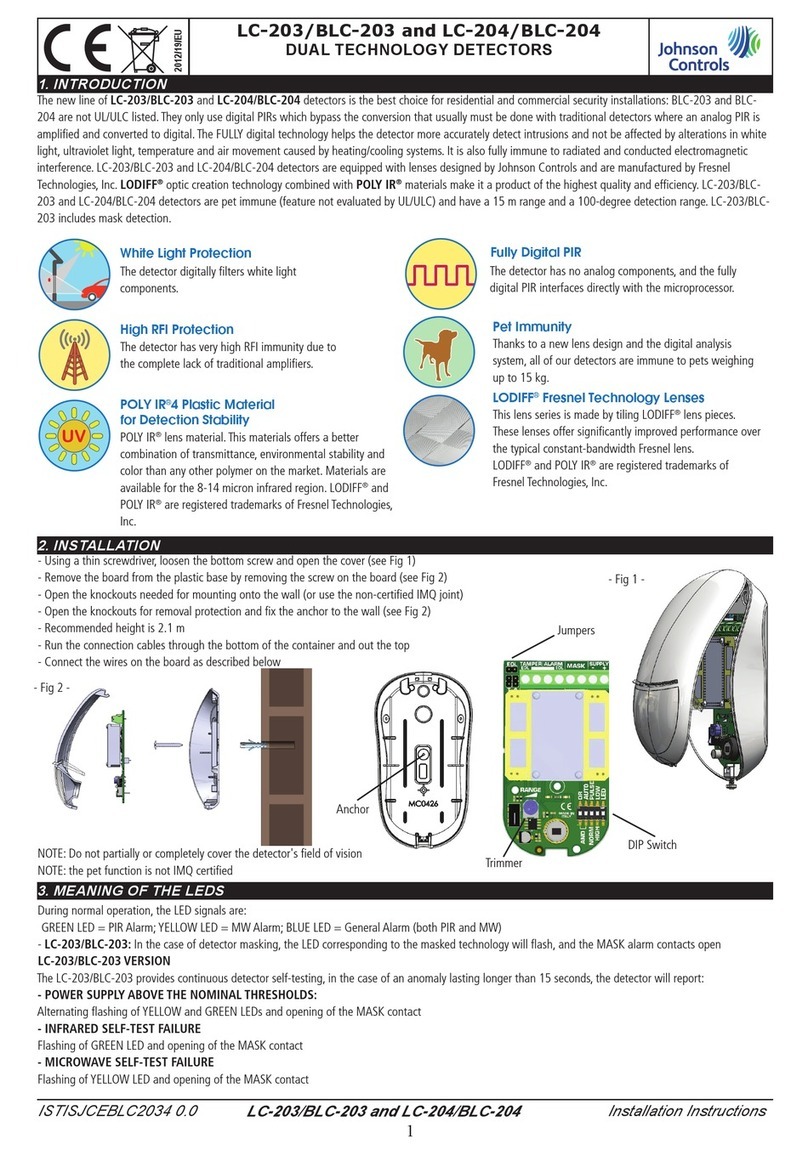

Maintenance and Service of Duct

Detectors

Dust, dirt, and other foreign matter can accumulate

inside a detector and change its sensitivity. Detectors

should be tested and maintained periodically. Routine

maintenance should be performed at least once a year

and more frequently in dirtier environments. Refer to

NFPA90A, NFPA72, and detector manufacturer's

instructions packaged with each detector for specific

maintenance and testing information.