Sound Skulptor PSL1 User manual

www.soundskulptor.com

Document revision 1.1 – Last modification : 21/04/08

P L1 Assembly guide

afety warning

THI KIT I NOT FOR BEGINNER !

This kit is main powered and use potentially lethal voltages. Under no circumstance should someone undertake the

realisation of this kit unless he has full knowledge about safely handling main powered devices.

Please read the “DIY guide” before beginning.

Print or open the following documents :

•P L1 chematic

•P L1 Components layout

•P L1 Parts list

•P L1 etup guide

Follow this guide from item number 1 till the end, in this order. The assembly order is based on components height, from

low to high profile, in order to ease the soldering process : The component you are soldering is always taller than the

previously assembled ones and it is pressing nicely against the work area foam.

P L1 Assembly guide

1. Diodes

Add D1 to D4, D6 to D8, D10 to D13. Use a lead forming tool to cleanly bend the leads at 0.4”

except for D11 which is bent at 0,5".

Warning : Make sure to respect the direction of the diodes which is marked by a ring on the component

and a double line on the PCB marking.

2. Resistors

Add R1 to R9. Control the resistor values with a digital multimeter. Bend the leads at 0.4” with a lead

forming tool.

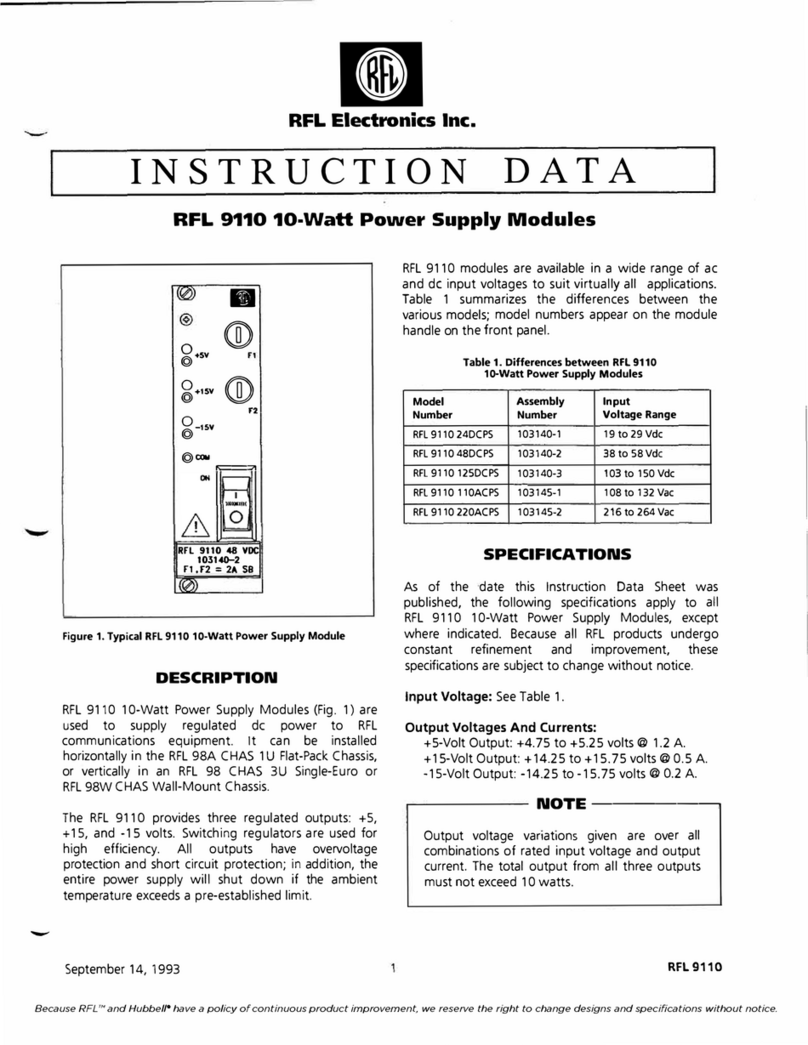

3. Leds

Add D5, D9, D14.

Bend the leads at 7mm from the body taking care of the anode position

(the longest lead).

Warning : it is easy to bend the leads in the wrong direction !

older the LED so it rests on the board. tart by soldering one lead,

adjust the position, then solder the second lead.

4. Test pins

older the 4 test pins TP1 to TP4.

Copyright ©2008 ound kulptor

7.00 mm

Anode : long lead

www.soundskulptor.com

Document revision 1.1 – Last modification : 21/04/08

P L1 Assembly guide

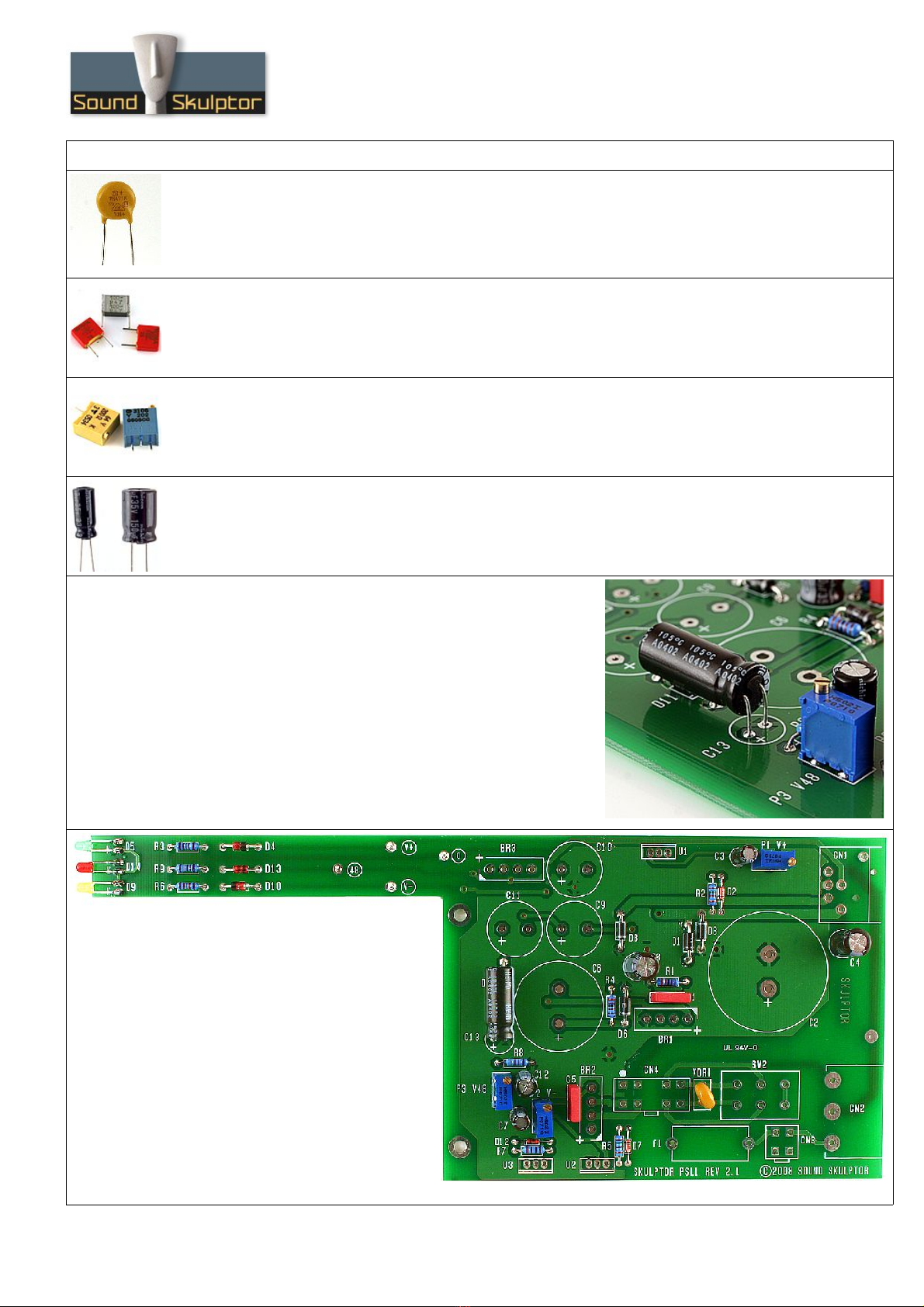

5. VDR1

Add the VDR1 varistor.

6. Film capacitors

Add C1 and C5.

7. Trimmer potentiometers

Add P1, P2, P3. older one pin, check verticality then solder the other pins.

8. mall electrolytic capacitors

Add C3, C4, C7, C8, C12.

older one lead first, adjust verticality then solder the second lead.

Warning : The +lead must go into the +hole. Do not reverse (they may explode !)

9. C13

Add C13 but lay it down horizontally on the board, as shown

on the photograph. This is because it is high and will be in the

way when we will be screwing the regulator heatsinks, later

on.

Copyright ©2008 ound kulptor

www.soundskulptor.com

Document revision 1.1 – Last modification : 21/04/08

P L1 Assembly guide

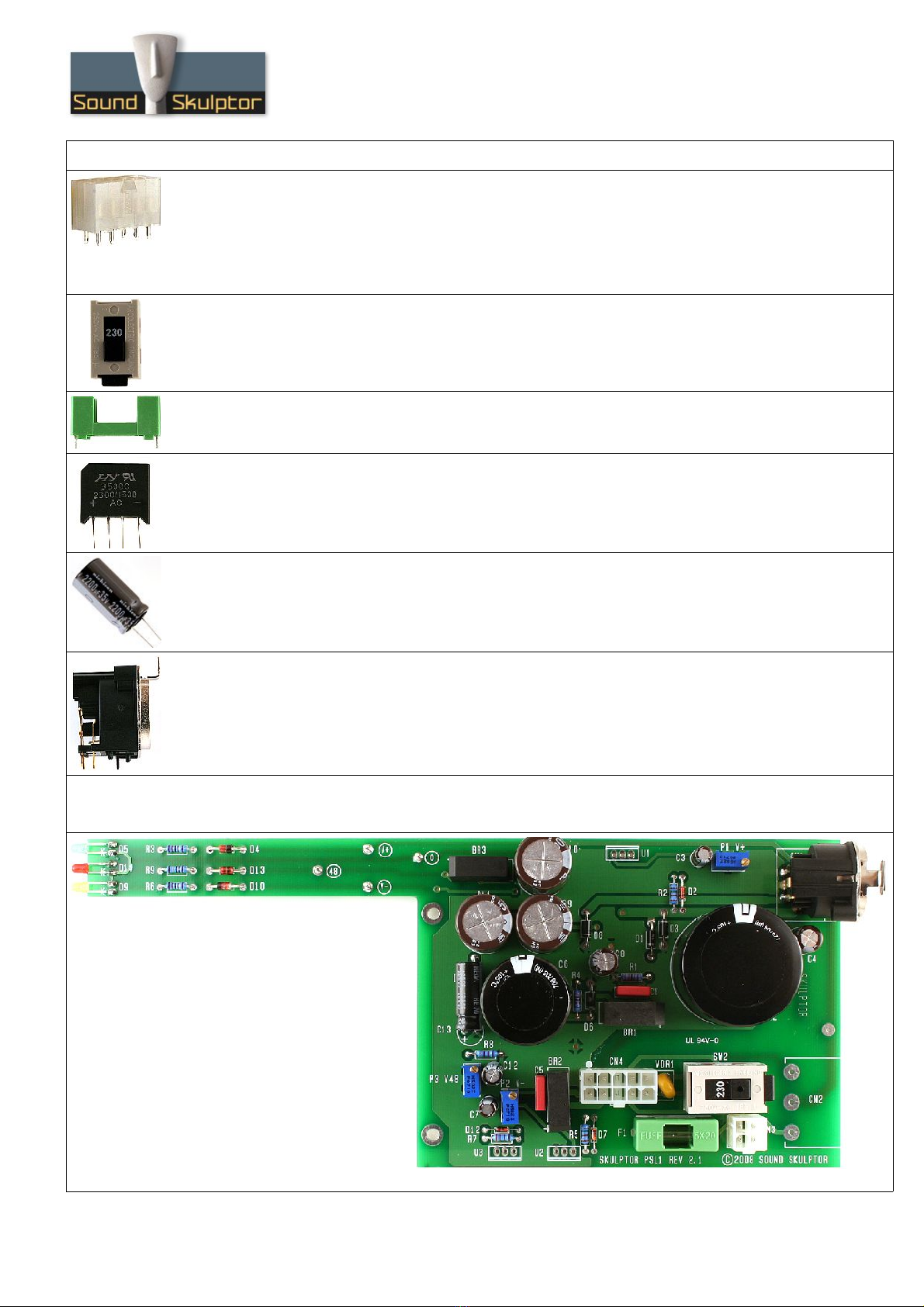

10. Connectors

Add CN3, CN4.

After soldering, cut the pins flush. The pins are not very long but they carry mains voltage and the

clearance distance between them and the case must be respected.

Warning : Make sure to position the connector in the right direction which is identified by the latching pin

on the PCB.

11. 115/230V elector switch

Add W2.

12. Fuse holder

Add the fuse holder.

13. Bridge rectifiers

Add BR1, BR2, BR3.

Warning : Make sure to respect the direction of the bridge rectifiers, It is marked by + and - signs.

14. Medium size electrolytics

Add C9, C10, C11.

15. XLR ocket

Add CN1. The position of the socket is critical for a good backplate matching. It must sit flat on the

PCB. Press firmly the socket on the PCB and solder one of the centre pins. Check position then solder

the other pins.

16. Large Electrolytics

Add C2, C6

Copyright ©2008 ound kulptor

www.soundskulptor.com

Document revision 1.1 – Last modification : 21/04/08

P L1 Assembly guide

17. Board inspection

Brush the solder side of the board with a hard tooth brush to remove any remaining solder bits.

Make a full visual check. Any missing component on the board ? Any remaining component in the box ?

When everything is correct move forward with the case assembly.

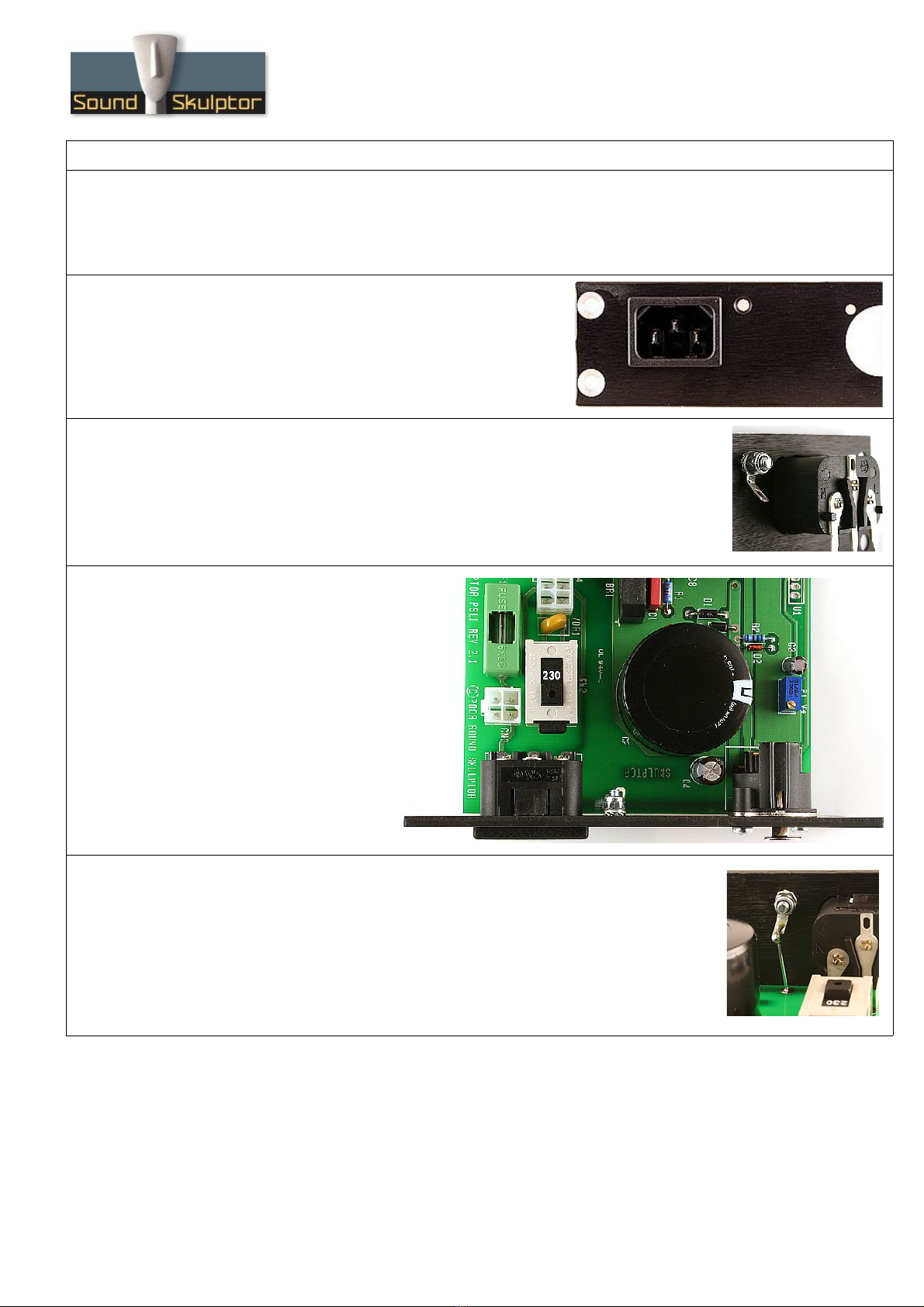

18. IEC connector assembly

nap the IEC connector into the back plate.

19. Case connection

Insert an M3x10 screw into the backplate. Add a shakeproof washer, a solder

tag and finally a self locking nut. Tighten together.

20. Backplate mounting

Put the backplate in place, by

inserting the IEC connector pins

into the PCB and by fitting the

XLR in the plate cutout. ecure

the XLR with two 2.9x9.5 self

taping screws.

older the IEC connector pins

after checking that the PCB if

perfectly parallel to the backplate

long side.

21. Earth connection

Use the 0,9mm tined wire to make the connection between the solder tag and

the PCB

Copyright ©2008 ound kulptor

www.soundskulptor.com

Document revision 1.1 – Last modification : 21/04/08

P L1 Assembly guide

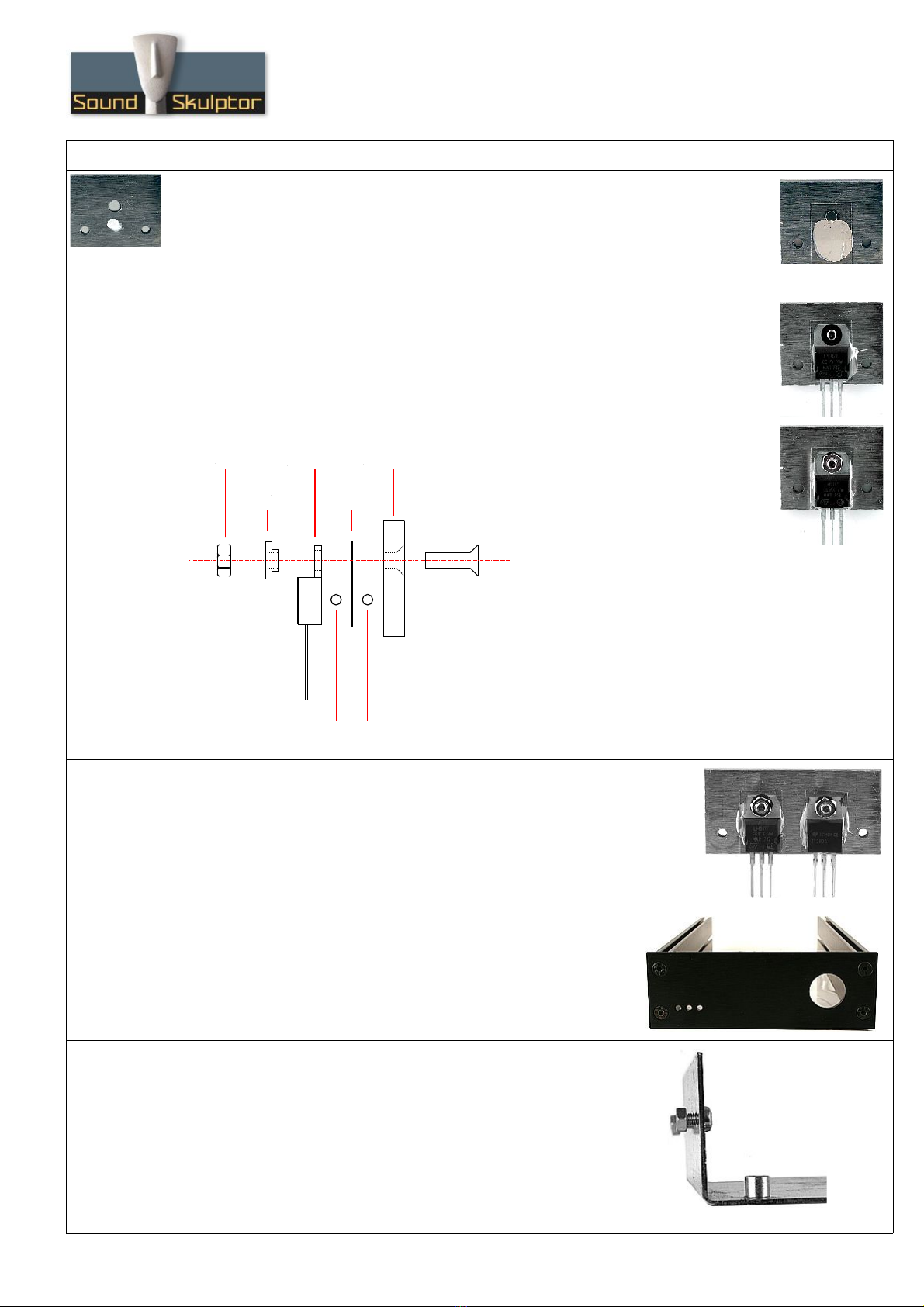

22. ingle heatsink assembly

Place a drop of thermal compound on the heatsink front face, the volume of a grain of

rice. The back face can be identified by the countersunk hole.

Next place the mica insulator.

Place a second drop of thermal compound on the mica insulator.

Insert the M3x10 countersunk screw from the back, the LM317 regulator and the

Insulating shoulder washer.

Place the M3 nut and tighten all together.

Use your digital multimeter in the Ohm position to check that there is no connection

between the heatsink and the center pin of the regulator.

23. Dual heatsink assembly

Repeat the same operations for the two regulators of the dual heatsink.

LM317 on the left,

TL783 on the right.

24. Case assembly

Assemble the front plate and the two sides of the case with four

black M4 countersunk srews.

The internal face of the sides is the one with a single groove.

25. Transformer plate assembly

Place two M3x6 pan head screws with two nuts on the transformer plate

and slide it into the right side of the case.

Copyright ©2008 ound kulptor

M3x10 screw

Heatsink

Thermal compound

Mica

insulator

Regulator

houlder

washer

Nut

www.soundskulptor.com

Document revision 1.1 – Last modification : 21/04/08

P L1 Assembly guide

26. Regulator heatsinks assembly

Place two M3x10 pan head screws with two nuts on the regulator heatsinks. Insert the regulator pins

into the PCB. Do not solder yet.

27. Top and bottom cover fixing nuts

Add 2 nuts in the top and bottom grooves of both sides of the case (for a total of 8 nuts). They will be

used to attach top and bottom covers.

28. PCB insertion

Insert the PCB into position by sliding the heatsink screws into the case grooves. Make sure the LEDs fit

into the front plat holes.

29. Back plate assembly

Attach the back plate with four M4 countersunk srews.

30. PCB fixing

Attach the PCB to the transformer plate with 2 M3x6 pan head screws.

31. Transformer plate fixing

Tighten firmly the 2 transformer plate fixing

screws.

Copyright ©2008 ound kulptor

www.soundskulptor.com

Document revision 1.1 – Last modification : 21/04/08

P L1 Assembly guide

32. Heatsinks fixing

Tighten the 2 fixing screws of both heatsinks.

older the 3 regulators. Cut the pins flush.

33. witch wiring

The power switch must be soldered to the 2 wires of the pre-assembled connector CN3.

Insert two 15mm pieces of heatshrink tube on the wires. older the wires to the power

switch. hrink the tubes on the switch pins with a heat gun.

34. witch fixing

Insert the switch into the front plate and plug in the connector.

35. Transformer fixing

Attach the transformer. The nut should be

tightened to prevent any transformer movement

but without crushing the windings.

Plug in the transformer connector.

Copyright ©2008 ound kulptor

Transformer plate

oft washer

oft washer

Transformer

Mounting disc

Nut

www.soundskulptor.com

Document revision 1.1 – Last modification : 21/04/08

P L1 Assembly guide

36. etup

Follow the instructions of the P L1 etup Guide.

37. Closing the case

With the help of the bottom cover, position the fixing nuts in front of the holes.

Place the mylar insulating sheet on the bottom of the PCB.

Place the bottom cover and secure it with 4 black screws.

Place the top cover and secure it with 4 black screws.

tick the four self adhesive rubber feet on the bottom of the case.

38. Congratulations, you're done !

Copyright ©2008 ound kulptor

Table of contents