Sourcetronic ST600 Series User manual

SOURCETRONIC –Quality electronics for service, lab and production

ST600 Series Frequency Inverter

User Manual

Frequency Inverter ST600 Series High-Performance Multifunction VFD Preface

-i-

Preface

Thank you for choosing the ST600 series high-performance multifunction VFD.

The frequency inverter ST600 series VFD is a high-performance and multipurpose VFD aiming to

integrate the driving of synchronous motors and asynchronous motors, and torque control, speed

control with position control. It is armed with advanced vector control technology and the latest digital

processor dedicated to motor control, thus enhancing product reliability and adaptability to the

environment. The frequency inverter ST600 high-performance multifunction VFD adopts customized

and industrialized design to realize excellent control performance through optimized functions and

flexible applications.

To meet the basic needs of customers, VFDs of power range from 4 to 110 kW are developed for the

ST600 series. To meet diversified customer demands, the frequency inverter ST600 series high-

performance multifunction VFD provides abundant expansion cards including a programmable

expansion card, PG card, communication card and I/O expansion card to achieve various functions

as needed.

The programmable expansion card adopts mainstream development environment for customers to

carry out secondary development easily, fulfilling varied customized needs and reducing customer

cost.

The PG card supports a variety of encoders like incremental encoders and resolver-type encoders; in

addition, it also supports pulse reference and frequency-division output. The PG card adopts digital

filter technology to improve EMC performance and to realize stable transmission of the encoder signal

over a long distance. It is equipped with encoder offline detection function to contain the impact of

system faults.

The ST600 series high-performance multifunction VFD supports multiple kinds of popular

communication modes to realize complicated system solutions. It can be connected to the internet

with an optional wireless communication card, by which users can monitor the VFD state anywhere at

any time via mobile app.

The VFD uses high power density design. Some power ranges and models carry built-in DC reactor

and brake unit to save installation space. Through overall EMC design, it can satisfy the low noise and

low electromagnetic interference requirements to cope with challenging grid, temperature, humidity

and dust conditions, thus greatly improving product reliability.

This operation manual presents installation wiring, parameter setup, fault diagnosis and

troubleshooting, as well as precautions related to daily maintenance. Read through this manual

carefully before installation to ensure that the frequency inverter ST600 series high-performance

multifunction VFD is installed and operated in a proper manner to give full play to its excellent

performance and powerful functions.

Our company reserves the right to update the information of our products.

Frequency Inverter ST600 Series High-Performance Multifunction VFD Contents

-ii-

Contents

Preface..................................................................................................................................i

Contents..............................................................................................................................ii

1 Safety Precautions ...........................................................................................................1

1.1 What this chapter contains........................................................................................1

1.2 Safety definition........................................................................................................1

1.3 Warning symbols ......................................................................................................1

1.4 Safety guidelines ......................................................................................................2

1.4.1 Delivery and installation .................................................................................2

1.4.2 Commissioning and running ...........................................................................3

1.4.3 Maintenance and component replacement .....................................................4

1.4.4 Scrap treatment .............................................................................................4

2 Precautions for Quick Application...................................................................................5

2.1 What this chapter contains........................................................................................5

2.2 Unpack inspection ....................................................................................................5

2.3 Application confirmation............................................................................................5

2.4 Environment confirmation .........................................................................................5

2.5 Installation confirmation............................................................................................6

2.6 Basic commissioning ................................................................................................7

2.7 Safety standard related data.....................................................................................7

3 Product Overview.............................................................................................................8

3.1 What this chapter contains........................................................................................8

3.2 Basic principle ..........................................................................................................8

3.3 Product specification...............................................................................................10

3.4 Product nameplate .................................................................................................12

3.5 Product model ........................................................................................................12

3.6 Rated values ..........................................................................................................13

3.7 Structure diagram...................................................................................................15

4 Installation Guide...........................................................................................................17

4.1 What this chapter contains......................................................................................17

4.2 Mechanical installation............................................................................................17

4.2.1 Installation environment ...............................................................................17

4.2.2 Installation direction .....................................................................................18

4.2.3 Installation mode..........................................................................................19

4.2.4 Single-unit installation ..................................................................................20

4.2.5 Multiple-unit installation ................................................................................21

4.2.6 Vertical installation .......................................................................................22

4.2.7 Tilted installation...........................................................................................24

4.3 Standard wiring of main circuit ................................................................................26

4.3.1 Wiring diagram of main circuit ......................................................................26

4.3.2 Main circuit terminal diagram........................................................................28

4.3.3 Wiring process of the main circuit terminals ..................................................34

4.4 Standard wiring of control circuit .............................................................................35

4.4.1 Wiring diagram of basic control circuit ..........................................................35

4.4.2 Input/output signal connection diagram.........................................................37

4.5 Wiring protection.....................................................................................................38

4.5.1 Protect the VFD and input power cable in short-circuit..................................38

4.5.2 Protect the motor and motor cable in short circuit .........................................39

Frequency Inverter ST600 Series High-Performance Multifunction VFD Contents

-iii-

4.5.3 Protect motor and prevent thermal overload .................................................39

4.5.4 Bypass connection.......................................................................................39

5 Basic Operation Instructions.........................................................................................40

5.1 What this chapter contains......................................................................................40

5.2 Keypad introduction................................................................................................40

5.3 Keypad display .......................................................................................................43

5.3.1 Displaying stopped-state parameters............................................................43

5.3.2 Displaying running-state parameters ............................................................44

5.3.3 Displaying fault information ..........................................................................45

5.4 Operating the VFD through the keypad...................................................................45

5.4.1 Enter/exit menu............................................................................................45

5.4.2 Editing a parameter list.................................................................................49

5.4.3 Adding parameters to the parameter list displayed in stopped/running state..50

5.4.4 Adding parameters to the user defined parameter list ...................................51

5.4.5 Editing user defined parameters ...................................................................52

5.4.6 Editing parameters in parameter groups.......................................................52

5.4.7 Monitoring states..........................................................................................53

5.4.8 Autotuning motor parameters .......................................................................53

5.4.9 Backing up parameters ................................................................................54

5.4.10 System settings..........................................................................................54

5.4.11 Power-on setup wizard ...............................................................................55

5.5 Basic operation instruction......................................................................................56

5.5.1 What this section contains............................................................................56

5.5.2 Common commissioning procedures............................................................57

5.5.3 Vector control...............................................................................................60

5.5.4 SVPWM control mode..................................................................................64

5.5.5 Torque control ..............................................................................................72

5.5.6 Motor parameter...........................................................................................76

5.5.7 Start/stop control..........................................................................................81

5.5.8 Frequency setup ..........................................................................................87

5.5.9 Analog input .................................................................................................91

5.5.10 Analog output .............................................................................................93

5.5.11 Digital input ................................................................................................97

5.5.12 Digital output ............................................................................................105

5.5.13 Simple PLC..............................................................................................109

5.5.14 Multi-step speed running .......................................................................... 112

5.5.15 PID control ............................................................................................... 114

5.5.16 Run at wobbling frequency ....................................................................... 119

5.5.17 Local encoder input..................................................................................120

5.5.18 Commissioning procedures for closed-loop control, position control and

spindle positioning ..............................................................................................121

5.5.19 Fault handling ..........................................................................................126

5.5.20 Tension control solutions ..........................................................................130

6 Function parameter list................................................................................................134

6.1 What this chapter contains....................................................................................134

6.2 Function parameter list .........................................................................................134

P00––Basic functions .........................................................................................135

P01––Start/stop control.......................................................................................138

P02––Parameters of motor 1 ..............................................................................143

Frequency Inverter ST600 Series High-Performance Multifunction VFD Contents

-iv-

P03––Vector control of motor 1...........................................................................147

P04––V/F control................................................................................................152

P05––Input terminals ..........................................................................................158

P06––Output terminals .......................................................................................165

P07––HMI ..........................................................................................................169

P08––Enhanced functions ..................................................................................174

P09––PID control................................................................................................181

P10––Simple PLC and multi-step speed control..................................................185

P11––Protection parameters...............................................................................188

P12––Parameters of motor 2 ..............................................................................194

P13––Control parameters of synchronous motor.................................................197

P14––Serial communication function ..................................................................198

P15––Functions of communication expansion card 1 ..........................................202

P16––Functions of communication expansion card 2 ..........................................204

P17––State-check functions................................................................................209

P18––Closed-loop control state check ................................................................213

P19––Expansion card state check ......................................................................215

P20––Encoder of motor 1 ...................................................................................217

P21––Position control.........................................................................................220

P22––Spindle positioning....................................................................................225

P23––Vector control of motor 2...........................................................................227

P24––Encoder of motor 2 ...................................................................................229

P25––Expansion I/O card input functions............................................................232

P26––Output functions of expansion I/O card......................................................234

P27––Programmable expansion card functions...................................................237

P28––Master/slave control functions...................................................................240

P90––Tension control in speed mode..................................................................243

P91––Tension control in torque mode .................................................................246

P92––Tension optimization .................................................................................249

P93––Tension control status viewing...................................................................250

7 Troubleshooting...........................................................................................................253

7.1 What this chapter contains....................................................................................253

7.2 Indications of alarms and faults.............................................................................253

7.3 Fault reset ............................................................................................................253

7.4 Fault history..........................................................................................................253

7.5 VFD faults and solutions.......................................................................................253

7.5.1 Details of faults and solutions.....................................................................253

7.5.2 Other state .................................................................................................260

7.6 Analysis on common faults ...................................................................................261

7.6.1 Motor fails to work......................................................................................261

7.6.2 Motor vibrates ............................................................................................262

7.6.3 Overvoltage ...............................................................................................263

7.6.4 Undervoltage..............................................................................................263

7.6.5 Unusual heating of motor ...........................................................................264

7.6.6 VFD overheating ........................................................................................265

7.6.7 Motor stalls during ACC..............................................................................266

7.6.8 Overcurrent................................................................................................267

7.7 Countermeasures on common interference...........................................................268

7.7.1 Interference on meter switches and sensors...............................................268

Frequency Inverter ST600 Series High-Performance Multifunction VFD Contents

-v-

7.7.2 Interference on communication ..................................................................269

7.7.3 Failure to stop and indicator shimmering due to motor cable coupling.........270

7.7.4 Leakage current and interference on RCD..................................................270

7.7.5 Live device chassis ....................................................................................271

8 Maintenance and hardware fault diagnosis ................................................................272

8.1 What this chapter contains....................................................................................272

8.2 Periodical inspection.............................................................................................272

8.3 Cooling fan...........................................................................................................274

8.4 Capacitor..............................................................................................................276

8.4.1 Capacitor reforming....................................................................................276

8.4.2 Electrolytic capacitor replacement ..............................................................277

8.5 Power cable .........................................................................................................277

9 Communication protocol .............................................................................................278

9.1 What this chapter contains....................................................................................278

9.2 Modbus protocol introduction................................................................................278

9.3 Application of Modbus...........................................................................................278

9.3.1 RS485........................................................................................................278

9.3.2 RTU mode .................................................................................................281

9.4 RTU command code and communication data ......................................................284

9.4.1 Command code: 03H, reading N words ......................................................284

9.4.2 Command code: 06H, writing a word..........................................................286

9.4.3 Command code: 10H, continuous writing....................................................287

9.4.4 Data address definition...............................................................................288

9.4.5 Fieldbus scale............................................................................................291

9.4.6 Error message response ............................................................................292

9.4.7 Read/Write operation example ...................................................................294

9.5 Common communication faults.............................................................................299

Appendix A Expansion cards..........................................................................................300

A.1 Model definition....................................................................................................300

A.2 Dimensions and installation..................................................................................308

A.3 Wiring ..................................................................................................................312

A.4 I/O expansion card function description ................................................................313

A.4.1 IO expansion card 1 (SIO501-00)...............................................................313

A.4.2 IO expansion card 2 (SIO502-00)...............................................................315

A.5 Programmable expansion card (SPC502-00) function description.........................317

A.6 Communication card ............................................................................................320

A.6.1 Bluetooth communication card (STX501) and WIFI communication card

(STX502)............................................................................................................320

A.6.2 PROFIBUS-DP communication card (STX503) ..........................................322

A.6.3 CAN multi-protocol communication card (STX505).....................................324

A.6.4 PROFINET communication card (STX509) ................................................325

A.6.5 Ethernet/IP communication card (STX510) and Modbus TCP communication

card (STX515) ....................................................................................................327

A.7 PG expansion card function description................................................................329

A.7.1 Sin/Cos PG card (SPG502)........................................................................329

A.7.2 Resolver PG card (SPG504-00).................................................................332

A.7.3 Multi-function incremental PG card (SPG505-12).......................................334

A.7.4 24V incremental PG card (SPG505-24)......................................................337

A.8 IoT cards..............................................................................................................340

Frequency Inverter ST600 Series High-Performance Multifunction VFD Contents

-vi-

A.8.1 4G card (SIC502-2-CN, SIC502-2-EU, SIC502-2-LA).................................340

Appendix B Technical data.............................................................................................341

B.1 What this chapter contains ...................................................................................341

B.2 Derated application ..............................................................................................341

B.2.1 Capacity ....................................................................................................341

B.2.2 Derating.....................................................................................................341

B.3 Grid specifications................................................................................................342

B.4 Motor connection data..........................................................................................342

B.4.1 EMC compatibility and motor cable length..................................................343

B.5 Application standards ...........................................................................................343

B.5.1 CE marking................................................................................................343

B.5.2 EMC compliance declaration......................................................................343

B.6 EMC regulations...................................................................................................344

B.6.1 VFD category C2 .......................................................................................344

B.6.2 VFD category C3 .......................................................................................345

Appendix C Dimension drawings...................................................................................347

C.1 What this chapter contains...................................................................................347

C.2 VFD structure.......................................................................................................347

C.3 Dimensions of VFDs ............................................................................................348

C.3.1 Wall-mounting dimensions.........................................................................348

C.3.2 Flange mounting dimensions .....................................................................353

Appendix D Optional peripheral accessories ................................................................357

D.1 What this chapter contains...................................................................................357

D.2 Wiring of peripheral accessories...........................................................................357

D.3 Power supply .......................................................................................................358

D.4 Cables .................................................................................................................358

D.4.1 Power cables.............................................................................................358

D.4.2 Control cables ...........................................................................................359

D.4.3 Cable arrangement....................................................................................362

D.4.4 Insulation inspection ..................................................................................362

D.5 Breaker and electromagnetic contactor ................................................................363

D.6 Reactors ..............................................................................................................364

D.7 Filters...................................................................................................................366

D.7.1 Filter model description..............................................................................368

D.8 Brake system.......................................................................................................370

D.8.1 Brake component selection........................................................................370

D.8.2 Brake resistor cable selection ....................................................................373

D.8.3 Brake resistor installation...........................................................................373

Appendix E STO function description............................................................................375

E.1 STO function logic table .......................................................................................375

E.2 STO channel delay description.............................................................................376

E.3 STO function installation checklist ........................................................................376

Appendix F Acronyms and abbreviations ......................................................................377

Appendix G Energy efficiency data................................................................................379

Appendix H Further information.....................................................................................382

H.1 Product and service queries .................................................................................382

H.2 Feedback on Sourcetronic VFD manuals .............................................................382

H.3 Documents on the Internet ...................................................................................382

Frequency Inverter ST600 Series High-Performance Multifunction VFD Safety Precautions

-1-

1 Safety Precautions

1.1 What this chapter contains

Read this manual carefully and follow all safety precautions before moving, installing, operating and

servicing the VFD. If these safety precautions are ignored, physical injury or death may occur, or there

may be damage to the equipment.

If any physical injury, death or damage to the equipment occur due to neglect of the safety precautions

in the manual, our company will not be responsible for any damages and we are not legally bound in

any manner.

1.2 Safety definition

Danger: Serious physical injury or even death may occur if these requirements are not followed.

Warning: Physical injury or damage to the equipment may occur if these requirements are not

followed.

Note: Procedures taken to ensure proper operation.

Qualified electricians: People working on the device should take part in professional electrical and

safety training, receive the certification and be familiar with all steps and requirements of installing,

commissioning, operating and maintaining the device to prevent any emergencies.

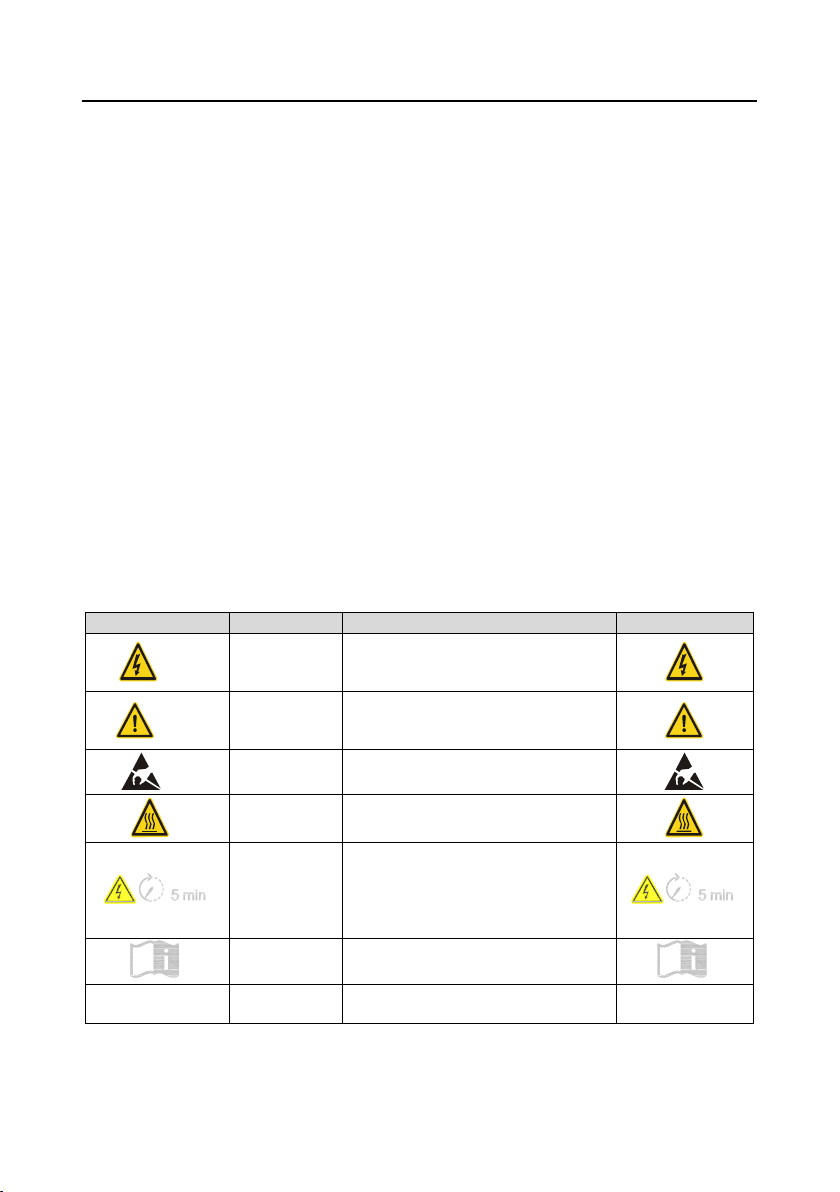

1.3 Warning symbols

Warnings caution you about conditions which can result in serious injury or death and/or damage to

the equipment, and advice on how to avoid said danger. The following warning symbols are used in

this manual:

Symbols

Name

Instruction

Abbreviation

Danger

Danger

Serious physical injury or even death

may occur if these requirements are not

followed.

Warning

Warning

Physical injury or damage to the

equipment may occur if these

requirements are not followed.

Forbid

Electrostatic

discharge

Damage to the PCBA board may occur if

these requirements are not followed.

Hot

Hot sides

The base of the VFD may become hot.

Do not touch.

Electric shock

As high voltage still presents in the bus

capacitor after power-off, wait at least five

minutes (or 15 min / 25 min, depending

on the warning symbols on the machine)

after power-off to prevent electric shock.

Read manual

Read the operation manual before

operating the equipment.

Note

Note

Procedures taken to ensure proper

operation.

Note

Frequency Inverter ST600 Series High-Performance Multifunction VFD Safety Precautions

-2-

1.4 Safety guidelines

⚫Only trained and qualified electricians are allowed to carry out related operations.

⚫Do not perform wiring, inspection or component replacement when a power supply is

connected. Ensure all the input power supplies are disconnected before wiring and

inspection, and wait for at least the time designated on the VFD or until the DC bus

voltage is less than 36V. The minimum waiting time is listed in the table below.

VFD model

Minimum waiting time

400V

1R5G3–110G3

5 min

400V

132G3–315G3

15 min

400V

355G3 and above

25 min

⚫Do not refit the VFD unless authorized; otherwise fire, electric shock or other injuries

may occur.

⚫The base of the radiator may become hot while running. Do not touch to avoid injury.

⚫The electrical parts and components inside the VFD are electrostatic. Take measures

to prevent electrostatic discharge during related operation.

1.4.1 Delivery and installation

⚫Install the VFD on fire-retardant material and keep the VFD away from combustible

materials.

⚫Connect the optional brake parts (brake resistors, brake units or feedback units)

according to the wiring diagram.

⚫Do not operate on a damaged or incomplete VFD.

⚫Do not touch the VFD with wet items or body parts; otherwise electric shock may occur.

Note:

⚫Select appropriate tools for delivery and installation to ensure safe and proper running of the VFD

and to avoid physical injury or death. To ensure physical safety, the installation staff should take

mechanical protective measures, such as wearing exposure shoes and working uniforms.

⚫Be sure to avoid physical shock or vibration during delivery and installation.

⚫Do not carry the VFD by its front cover only, as the cover may fall off.

⚫Installation site should be away from children and public places.

⚫The VFD should be used in proper environment (see section 4.2.1 "Installation environment" for

details).

⚫Prevent the screws, cables and other conductive parts from falling into the VFD.

⚫As leakage current of the VFD during running may exceed 3.5mA, ground properly and ensure

the grounding resistance is less than 10Ω. The conductivity of PE grounding conductor is the

same as that of the phase conductor. For models higher than 30 kW, the cross sectional area of

the PE grounding conductor can be slightly less than the recommended area.

⚫R, S and T are the power input terminals, and U, V and W are output motor terminals. Connect

Frequency Inverter ST600 Series High-Performance Multifunction VFD Safety Precautions

-3-

the input power cables and motor cables properly; otherwise damage to the VFD may occur.

1.4.2 Commissioning and running

⚫Disconnect all power sources applied to the VFD before terminal wiring, and wait for at

least the time designated on the VFD after disconnecting the power sources.

⚫High voltage presents inside the VFD while running. Do not carry out any operation on

the VFD while it is running except for keypad setup. It must be noted that the control

terminal of EV1000 inverter is an ELV (Extra Low Voltage) circuit, which cannot be

connected directly to the accessible terminals of other devices if no protective isolation

measure is taken. For instance, the RS485 terminal of the inverter can be connected to

RS232 interface of the PC only after a converter with protective isolation is connected

between them.

⚫The VFD may start up by itself when P01.21 (restart after power cut) is set to 1. Do not

get close to the VFD and motor.

⚫The VFD cannot be used as an "emergency-stop device".

⚫The VFD cannot act as an emergency brake for the motor; it is a must to install a

mechanical brake device.

⚫During driving permanent magnet synchronous motor, besides above-mentioned items,

the following work must be done before installation and maintenance.

1. Disconnect all input power sources including main power and control power.

2. Ensure that the permanent-magnet synchronous motor has been stopped, and that

the voltage on output end of the VFD is lower than 36V.

3. After the permanent-magnet synchronous motor is stopped, wait for at least the time

designated on the VFD, and ensure the voltage between "+" and "-" is lower than

36V.

4. During operation, it is a must to ensure the permanent-magnet synchronous motor

cannot run again by the action of external load; it is recommended to install an

effective external brake device or disconnect the direct electrical connection between

permanent-magnet synchronous motor and the VFD.

Note:

⚫Do not switch on or switch off input power sources of the VFD frequently.

⚫For VFDs that have been stored for a long time, set the capacitance and carry out inspection and

pilot run on the VFD before use.

⚫Close the front cover before running; otherwise electric shock may occur.

Frequency Inverter ST600 Series High-Performance Multifunction VFD Safety Precautions

-4-

1.4.3 Maintenance and component replacement

⚫Only well-trained and qualified professionals are allowed to perform maintenance,

inspection, and component replacement on the VFD.

⚫Disconnect all the power sources applied to the VFD before terminal wiring, and wait

for at least the time designated on the VFD after disconnecting the power sources.

⚫Take measures to prevent screws, cables and other conductive matters from falling into

the VFD during maintenance and component replacement.

Note:

⚫Use a proper torque to tighten the screws.

⚫Keep the VFD and its parts and components away from combustible materials during

maintenance and component replacement.

⚫Do not carry out insulation voltage-endurance test on the VFD, or measure the control circuits of

the VFD with megameter.

⚫Take proper anti-static measures on the VFD and its internal parts during maintenance and

component replacement.

1.4.4 Scrap treatment

The heavy metals inside the VFD should be treated as industrial effluent.

When its life cycle ends, the product should enter the recycling system. Dispose of it

separately at an appropriate collection point instead of placing it in the normal waste stream.

Frequency Inverter ST600 Series High-Performance Multifunction VFD Precautions for Quick

Application

-5-

2 Precautions for Quick Application

2.1 What this chapter contains

This chapter introduces the basic principles required during installation commissioning. Users can

ensure quick installation commissioning by following these principles.

2.2 Unpack inspection

Check as follows after receiving products.

1. Check whether the packing box is damaged or dampened. If yes, contact local sellers or Sourcetronic

offices.

2. Check the model identifier on the exterior surface of the packing box is consistent with the purchased

model. If not, contact local sellers or Sourcetronic offices.

3. Check whether the interior surface of the packing box is improper, for example wet, or whether the

enclosure of the VFD is damaged or cracked. If yes, contact local sellers or Sourcetronic offices.

4. Check whether the nameplate of the VFD is consistent with the model identifier on the exterior surface

of the packing box. If not, contact local sellers or Sourcetronic offices.

5. Check whether the accessories (including user's manual, control keypad and expansion card units)

inside the packing box are complete. If not, contact local sellers or Sourcetronic offices.

2.3 Application confirmation

Check the following items before operating the VFD:

1. Verify the load mechanical type to be driven by the VFD, and check whether overload occurred to

the VFD during actual application, or whether the VFD power class needs to be enlarged.

2. Check whether the actual running current of load motor is less than rated VFD current.

3. Check whether the control precision required by the actual load is the same as the control precision

provided by the VFD.

4. Check whether the grid voltage is consistent with the rated VFD voltage.

5. Check whether the functions required need an optional expansion card to be available.

2.4 Environment confirmation

Check the following items before use:

1. Check whether the ambient temperature of the VFD during actual application exceeds 40°C, if yes,

derate 1% for every additional 1°C. In addition, do not use the VFD when the ambient temperature

exceeds 50°C.

Note: For a cabinet-type VFD, its ambient temperature is the air temperature inside the cabinet.

Frequency Inverter ST600 Series High-Performance Multifunction VFD Precautions for Quick

Application

-6-

2. Check whether ambient temperature of the VFD during actual application is below -10°C, if yes,

install a heating facility.

Note: For a cabinet-type VFD, its ambient temperature is the air temperature inside the cabinet.

3. Check whether the altitude of the application site exceeds 1000m. When the installation site altitude

exceeds 1000m, derate 1% for every increase of 100m; when the installation site altitude exceeds

3000m, consult the local Sourcetronic seller or office.

4. Check whether the humidity of the application site exceeds 90%, if yes, check whether condensation

occurred, if condensation does exist, take additional protective measures.

5. Check whether there is direct sunlight or the possibility of animal intrusion at the application site, if

yes, take additional protective measures.

6. Check whether there is dust, explosive or combustible gases at the application site, if yes, take

additional protective measures.

2.5 Installation confirmation

After the VFD is installed properly, check the installation condition of the VFD.

1. Check whether the input power cable and current-carrying capacity of the motor cable fulfill actual

load requirements.

2. Check whether peripheral accessories (including input reactors, input filters, output reactors, output

filters, DC reactors, brake units and brake resistors) of the VFD are all of the correct type and installed

properly; check whether the installation cables fulfill the requirements on current-carrying capacity.

3. Check whether the VFD is installed on fire-retardant materials; check whether the hot parts (reactors,

brake resistors, etc.) are kept away from combustible materials.

4. Check whether all the control cables are routed separately from power cables based on EMC

requirement.

5. Check whether all the grounding systems are grounded properly according to VFD requirements.

6. Check whether installation spacing of the VFD complies with the requirements in the operation

manual.

7. Check whether installation mode of the VFD complies with the requirements in the operation manual.

Vertical installation should be adopted whenever possible.

8. Check whether external connecting terminals of the VFD are firm and tight enough, and whether the

moment is up to the requirement.

9. Check whether there are redundant screws, cables or other conductive objects inside the VFD, if

yes, take them out.

Frequency Inverter ST600 Series High-Performance Multifunction VFD Precautions for Quick

Application

-7-

2.6 Basic commissioning

Carry out basic commissioning according to the following procedures before operating on the VFD.

1. Select motor type, set motor parameters and select VFD control mode according to actual motor

parameters.

2. If autotuning is needed: if possible, disconnect the motor load to carry out dynamic parameter

autotuning; if the load cannot be disconnected, perform static autotuning.

3. Adjust the acceleration and deceleration time based on actual working conditions of the load.

4. Jogging to carry out device commissioning. Check whether the motor running direction is consistent

with the direction required; if not, it is recommended to change the motor running direction by

exchanging the motor wiring of any two phases.

5. Set all the control parameters, and carry out actual operation.

2.7 Safety standard related data

IEC/EN 61508 (Class A system)

ISO 13849**

SIL

PFH

HFT

SFF

λdu

λdd

PTI*

PL

CCF

DC

Category

2

8.73x10-10

1

71.23%

1.79x10-9

0

1 year

d

57

60%

3

* PTI: Proof test interval

** Depends on the classification defined on the EN ISO 13849-1.

Frequency Inverter ST600 Series High-Performance Multifunction VFD Product Overview

-8-

3 Product Overview

3.1 What this chapter contains

This chapter mainly introduces the operation principles, product features, layouts, nameplates and

model instructions.

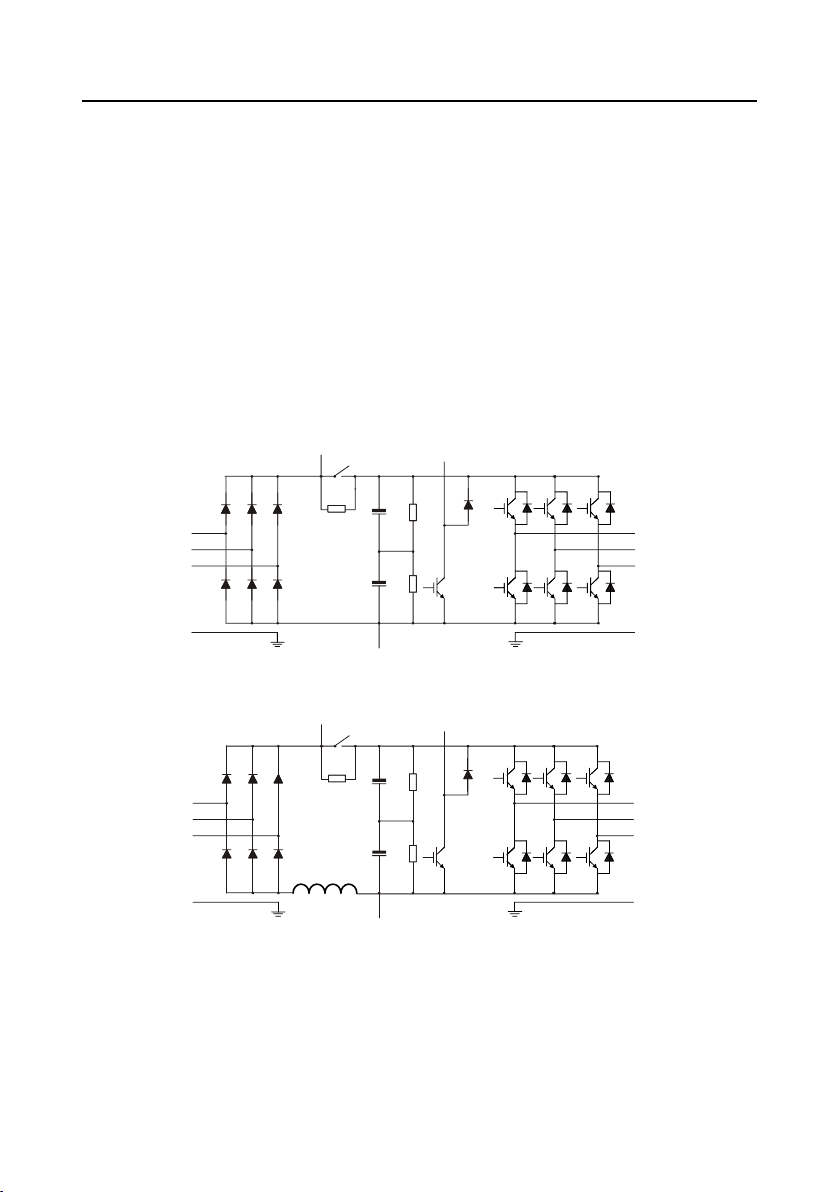

3.2 Basic principle

The frequency inverter ST600 high-performance multifunction VFD is used to control asynchronous

AC induction motor and permanent-magnet synchronous motor. The figure below shows the main

circuit diagram of the VFD. The rectifier converts 3PH AC voltage into DC voltage, and the capacitor

bank of intermediate circuit stabilizes the DC voltage. The inverter converts DC voltage into the AC

voltage used by AC motor. When the circuit voltage exceeds the maximum limit value, external brake

resistor will be connected to intermediate DC circuit to consume the feedback energy.

Figure 3-1 Main circuit diagram for standard and SP model VFDs 015G3 and below

R

S

T

U

V

W

(+)

(-)

PE PE

PB

Figure 3-2 Main circuit diagram for standard model VFDs 018G3–037G3

R

S

T

U

V

W

(+)

(-)

PE PE

PB

Frequency Inverter ST600 Series High-Performance Multifunction VFD Product Overview

-9-

Figure 3-3 Main circuit diagram for standard model VFDs 045G3–110G3

R

S

T

U

V

W

(+)

(-)

PE PE

Figure 3-4 Main circuit diagram for standard model VFDs 132G3 and above

R

S

T

U

V

W

(+)

(-)

DC reactor

P1

PE PE

Figure 3-5 Main circuit diagram for SP model VFDs 018G3–110G3

R

S

T

U

V

W

(+)

(-)

PE PE

PB

Note:

1. Standard model VFDs 132G3 and higher can be connected to external DC reactors. Before

connection, take off the copper bar between P1 and (+). Standard model VFDs 045G3 and higher

can be connected to external braking units. DC reactors and braking units are optional parts.

2. Standard model VFDs 018G3–110G3 are equipped with built-in DC reactors.

Frequency Inverter ST600 Series High-Performance Multifunction VFD Product Overview

-10-

3. Built-in brake units are included in the SP model VFDs and standard model VFDs 037G3 and below.

The models that carry built-in brake units can also be connected to external brake resistors. The

brake resistors are optional parts.

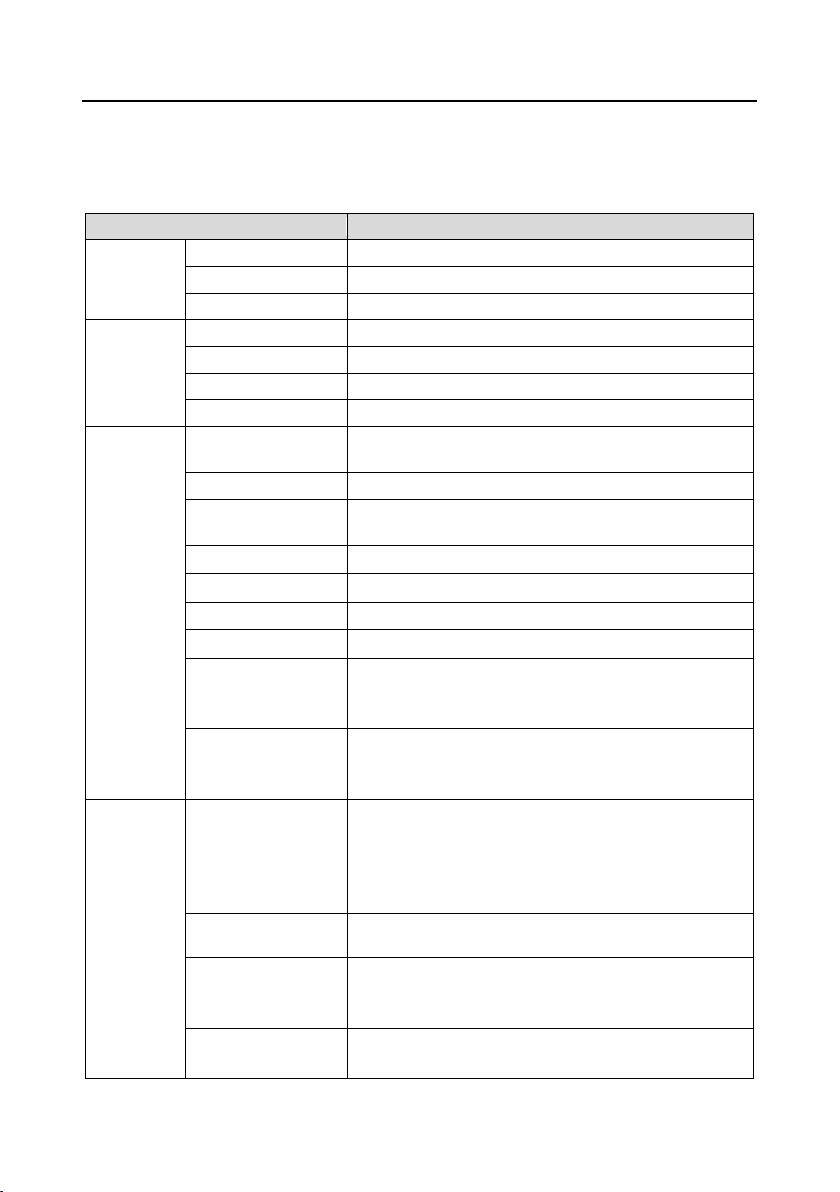

3.3 Product specification

Function description

Specification

Power input

Input voltage (V)

-4 model: 3PH 380V (-15%)–440V (+10%)

Input current (A)

Refer to section 3.6 Rated values.

Input frequency (Hz)

50Hz or 60Hz, allowable range: 47–63Hz

Power output

Output voltage (V)

0–input voltage

Output current (A)

Refer to section 3.6 Rated values.

Output power (kW)

Refer to section 3.6 Rated values.

Output frequency (Hz)

0–400Hz

Technical

control

performance

Control mode

Space voltage vector control, sensorless vector control (SVC),

and feedback vector control (FVC)

Motor type

Asynchronous motor, permanent-magnet synchronous motor

Speed regulation ratio

Asynchronous motor 1: 200 (SVC); Synchronous motor 1: 20

(SVC), 1:1000 (FVC)

Speed control precision

±0.2% (SVC), ±0.02% (FVC)

Speed fluctuation

± 0.3% (SVC)

Torque response

<20ms SVC) , <10ms (FVC)

Torque control precision

10% (SVC) , 5% (FVC)

Starting torque

Asynchronous motor: 0.25Hz/150% (SVC)

Synchronous motor: 2.5 Hz/150% (SVC)

0Hz/200% (FVC)

Overload capacity

150% of rated current: 1min;

180% of rated current: 10s;

200% of rated current: 1s;

Running

control

performance

Frequency setup mode

Digital, analog, pulse frequency, multi-step speed running,

simple PLC, PID, Modbus communication, PROFIBUS

communication, etc;

Realizes switch-over between the set combination and the set

channel

Automatic voltage

regulation function

Keeps the output voltage constant when grid voltage changes

Fault protection function

Provides over 30 kinds of fault protection functions, such as

overcurrent, overvoltage, undervoltage, over-temperature,

phase loss and overload, etc.

Speed tracking restart

function

Realize impact-free starting of the motor in rotating

Frequency Inverter ST600 Series High-Performance Multifunction VFD Product Overview

-11-

Retension at transient

voltage drop

Keeps running with regenerative energy when the grid

transiently drops.

Motor switchover

Supports two groups of motor parameters to control motor

switchover.

Peripheral

interface

Terminal analog input

resolution

No more than 20mV

Terminal digital input

resolution

No more than 2ms

Analog input

2 inputs, AI1: 0–10V/0–20mA; AI2: -10–10V

Analog output

1 output, AO1: 0–10V /0–20mA

Digital input

Four regular inputs; max. frequency: 1kHz; internal impedance:

3.3kΩ

Two high-speed inputs; max. frequency: 50kHz; supports

quadrature encoder input; with speed measurement function

Digital output

One high-speed pulse output; max. frequency: 50kHz

One Y terminal open collector output

Relay output

Two programmable relay outputs

RO1A NO, RO1B NC, RO1C common port

RO2A NO, RO2B NC, RO2C common port

Contact capacity: 3A/AC250V, 1A/DC30V

Extension interface

Three extension interfaces: SLOT1, SLOT2, SLOT3

Expandable PG card, programmable expansion card,

communication card, I/O card, etc

Others

Installation mode

Support wall-mounting and flange-mounting

Operation ambient

temperature

-10–50°C

Ingress protection

rating

IP20; IP55

Cooling mode

Forced-air cooling

Brake unit

Built-in brake units are included in all SP model VFDs.

EMC filter

Conducted emissions of all models meet the requirements of C3

in the IEC/EN 61800-3 standard. The -AS models offers the 30m

motor cable, meeting the C3 requirements.

External filter is optional: Conducted emission can meet the

requirements of C2 in the IEC/EN 61800-3 standard.

Note: It is required to observe the EMC compliance required by

the appendix of the manual. The motor and motor cables shall

be selected based on technical requirements specified in the

appendix of the manual.

STO certification level

Meet the SIL2 level

Frequency Inverter ST600 Series High-Performance Multifunction VFD Product Overview

-12-

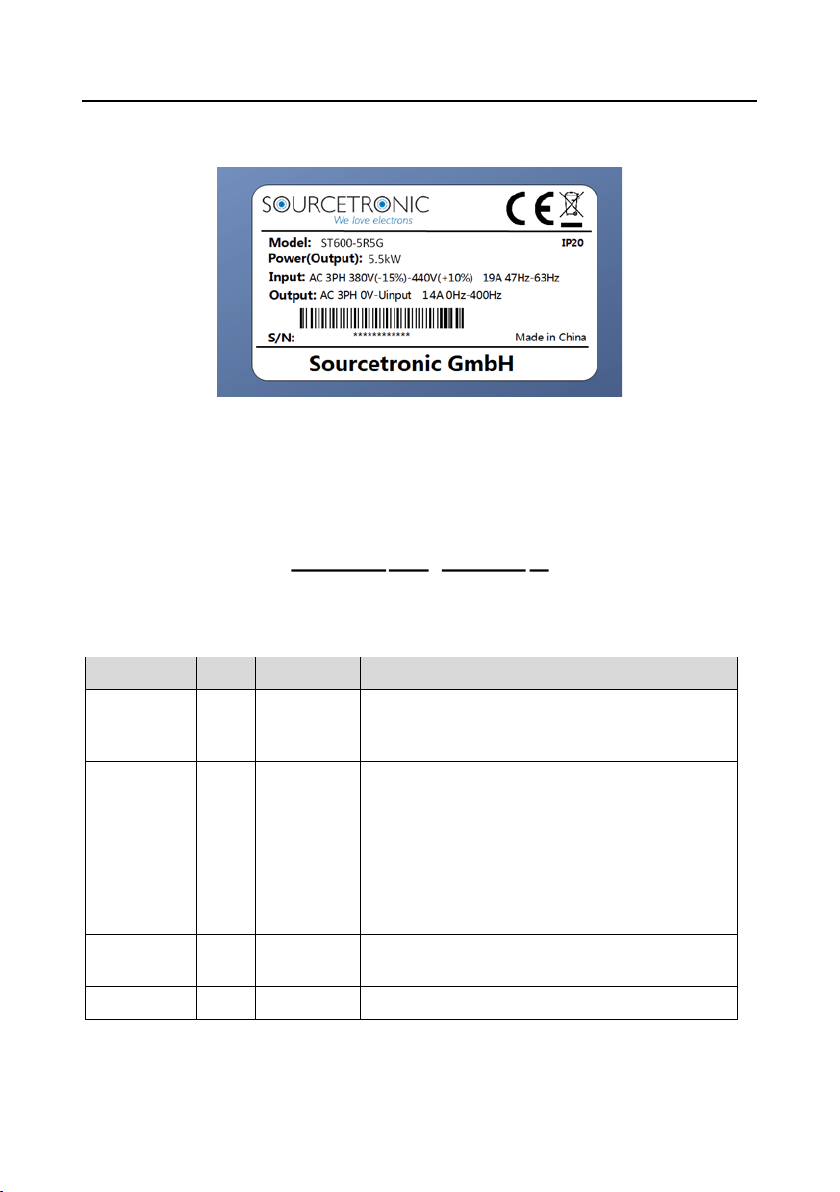

3.4 Product nameplate

Figure 3-6 Product nameplate

Note: This is an example of the nameplate of standard frequency inverter ST600 products. The

UKCA/CE/IP20/IP55 markings on the top right will be marked according to actual product model and

certification conditions.

3.5 Product model

Figure 3-7 Product model

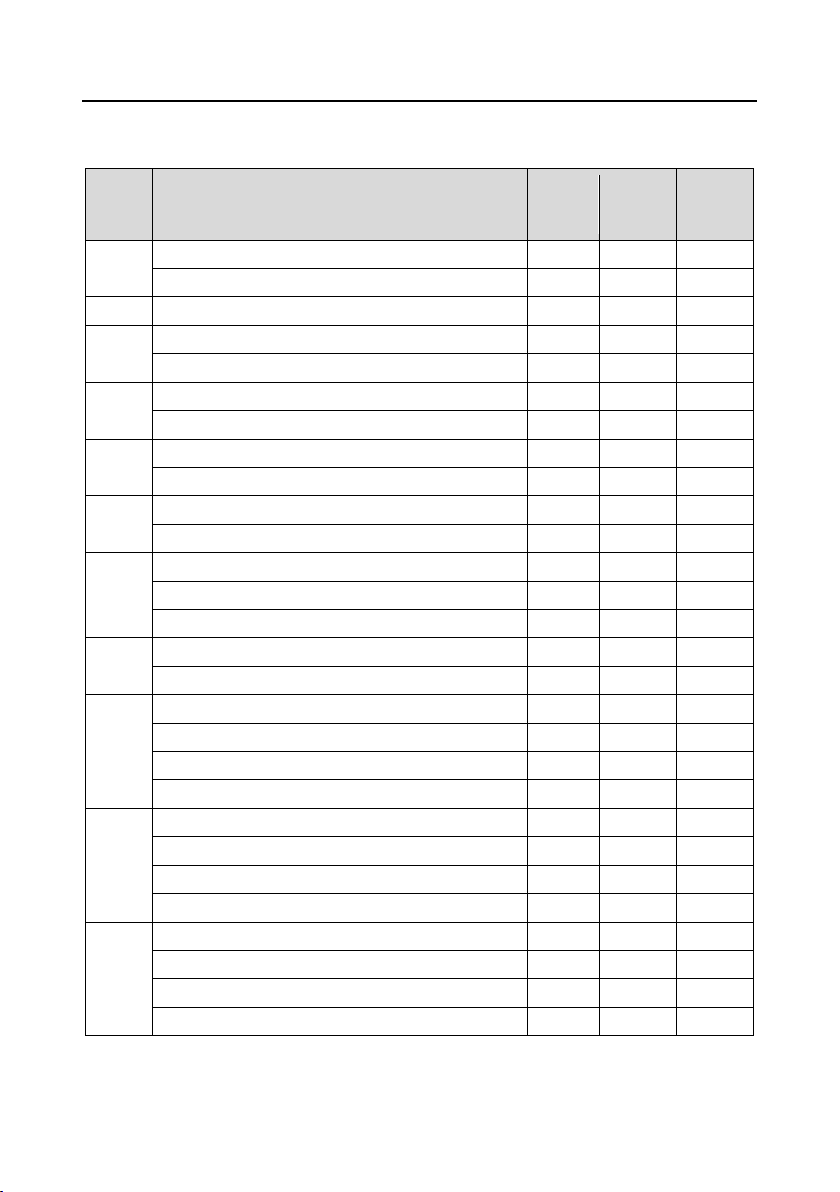

Table 3-1 Description of product models

Field

Sign

Description

Example

Product

category

①

Abbreviation

of product

series

ST600: frequency inverter ST600 high-performance multi-

function VFD

IP rating

②

Ingress

protection

rating

None: IP20 ingress protection rating (No protection

against dust nor water)

SP: IP55 ingress protection rating (It is impossible to

completely prevent dust from entering, but the amount of

dust from entering will not cause damage to the

equipment. It will not cause damage when the product

under normal installation state is immersed in water from

each direction).

Rated power

③

Power range

+ load type

5R5: 5.5kW

G: Constant torque load

Voltage level

④

Voltage level

3: AC 3PH 380V (-15%)–440V (+10%)

S T600SP 5R 5G 3-

① ② ③ ④

Frequency Inverter ST600 Series High-Performance Multifunction VFD Product Overview

-13-

3.6 Rated values

Table 3-2 Rated values of standard models

Frame

code

Product model

Output

power

(kW)

Input

current

(A)

Output

current

(A)

1

ST600-1R5G3

1.5

5.0

3.7

ST600-2R2G3

2.2

5.8

5

2

ST600-004G3

4

13.5

9.5

3

ST600-5R5G3

5.5

19.5

14

ST600-7R5G3

7.5

25

18.5

4

ST600-011G3

11

32

25

ST600-015G3

15

40

32

5

ST600-018G3

18.5

45

38

ST600-022G3

22

51

45

6

ST600-030G3

30

64

60

ST600-037G3

37

80

75

7

ST600-045G3

45

98

92

ST600-055G3

55

128

115

ST600-075G3

75

139

150

8

ST600-090G3

90

168

180

ST600-110G3

110

201

215

9

ST600-132G3

132

265

260

ST600-160G3

160

310

305

ST600-185G3

185

345

340

ST600-200G3

200

385

380

10

ST600-220G3

220

430

425

ST600-250G3

250

460

480

ST600-280G3

280

500

530

ST600-315G3

315

580

600

11

ST600-355G3

355

625

650

ST600-400G3

400

715

720

ST600-450G3

450

840

820

ST600-500G3

500

890

860

Other manuals for ST600 Series

1

This manual suits for next models

40

Table of contents

Other Sourcetronic Inverter manuals

Popular Inverter manuals by other brands

Zlpower

Zlpower IG500-12-C user manual

Samlex Europe

Samlex Europe SWI 3000-12 owner's manual

Carrier

Carrier ASPAS1CCA007 Specifications

Xantrex

Xantrex XPower 1500 owner's guide

Sandi Electric

Sandi Electric SDP-30KW User and installation manual

SolaX Power

SolaX Power X-Hybrid SK-BMU Quick installation guide