SOURIAU MSH Series User manual

Connectors for Navy Applications

and Heavy Duty Industries

MSH/MPH SERIES

3

MSH/MPH series

Contents

• Introduction .................................................................................................................................................................................................................... 4

• Applications ................................................................................................................................................................................................................... 5

• Description ..................................................................................................................................................................................................................... 7

• Schematic ....................................................................................................................................................................................................................... 8

• Characteristics ............................................................................................................................................................................................................ 10

• Contacts ......................................................................................................................................................................................................................... 11

• Polarization keys ......................................................................................................................................................................................................... 15

• Cable codes ................................................................................................................................................................................................................. 15

• References ................................................................................................................................................................................................................... 16

• Contact layouts ........................................................................................................................................................................................................... 17

• Dimensions .................................................................................................................................................................................................................. 20

• Spare parts .................................................................................................................................................................................................................. 27

• Tools ............................................................................................................................................................................................................................... 28

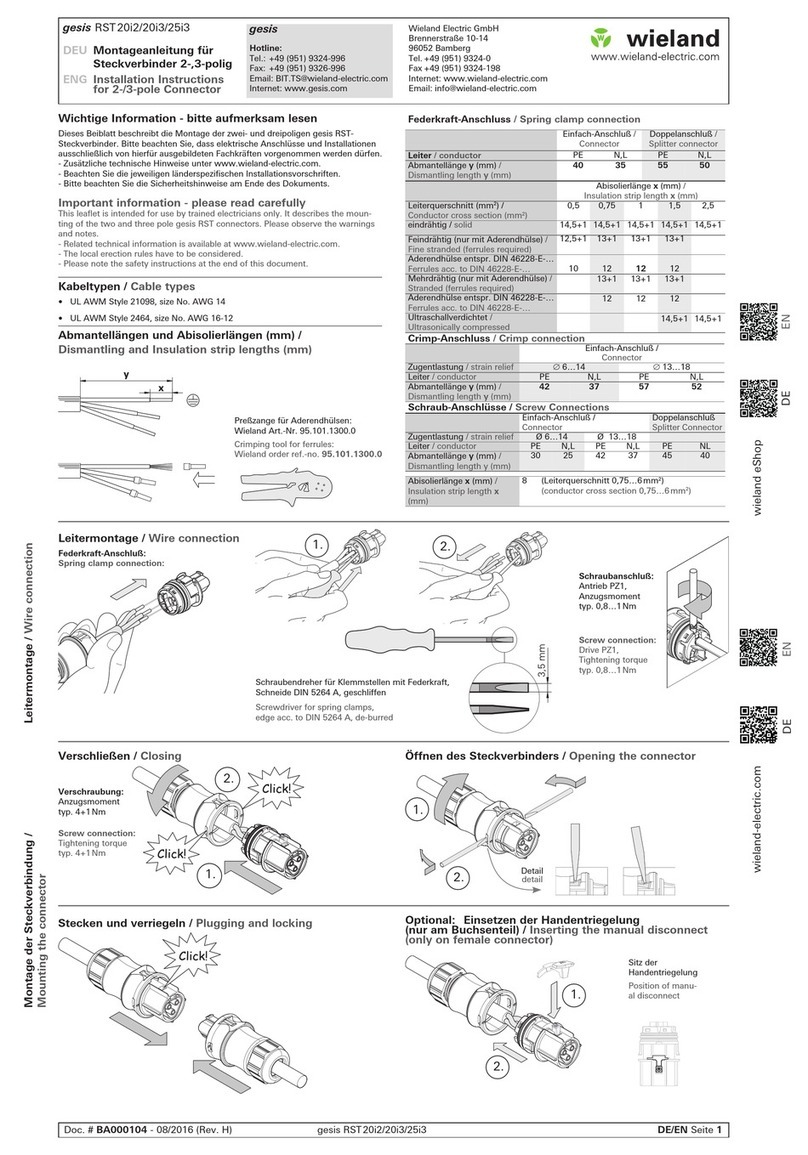

• Wiring instructions .................................................................................................................................................................................................... 32

• Recommended connectors .................................................................................................................................................................................. 34

4

MSH/MPH series

Introduction

MSH and MPH series cylindrical connectors comply with environmental tests of French standard NFC 93422 and satisfy

the requirements of marine specification 538c AGB/T.They are listed in GAM T1 and MAT 6840005.

• Two series are available:

These series are available with 8 shell sizes and large variety of layouts including signal, power and RF conntacts.

• New Cadmium Free plating available for MSH series:

- MSH Aluminium shells plated with Tin over nickel to be compliant with ROHS requirements.

Series Shell Remarks

MSH Treated aluminium alloy HALOGEN free

MPH Bronze HALOGEN free

5

MSH/MPH series

Applications

The highly robust design of MSH/MPH series makes them particularly suited for naval and heavy-duty industry applications.

• upper decks

• radars

• monitoring and power

supply racks

• platform

• armament systems

• platform

• gas or petrol

exploitation

• heavy plant

• power units

• inter-carriage

connections

• power supply racks

• trackside beacons

• power supply units

• cranes

• heavy plant

• tunneling machines

• concreting

• power supply units

• power supply units

• shelters

• communications

networks

• artillery

• radars

• steel industry

• shipbuilding

• petrochemicals

• power industry

• mining

Offshore industry

Navy

Ground-based

armament Rail transport

Heavy duty industry Construction industry

6

MSH/MPH series

Features Benefits

Mechanical

• Square threaded screw coupling • High vibration and shock withstanding.

(plug on receptacle). • Suitable for Harsh Environment application

• Conical coupling interface. (railways, mining, public works…).

• Special cone-design on backshell • Extreme resistance to pull out

for cable braid retention. or transverse forces on cable (80 kg).

• 5 key mechanical polarisation. • Reliable and safe mating.

• Scoop proof shells.

Environmental

• Oring sealing between plug and receptacle. • High performance sealing:

- permanent IP68,

• Packing seal on backshell to cable interface. - Permanent water immersion

up to 2 meters,

• Cable boot on backshell interface. - Compliance with main Marine

and Heavy Industries cable.

• Tin plated Aluminium • High corrosion resistance

or Marine bronze shells (salt spray, sea water, sand, dust,

hydrocarbons fluids…).

• RoHS compliant.

Electrical

• Dismountable crimp contacts. • Easy wiring.

• Growding ring on plug side. • EMI/RFI/protection.

Features and benefits

The very ruggedized design of MSH/MPH series brings the following benefits :

7

MSH/MPH series

Description

• Eight shell sizes, numbered 16-17-18-20-22-

24-26-28.

•Assembly and removal of push-on contacts

into the insulator via the rear of the shell.

• Assembly and removal of screw contacts via

the rear of the insulator.

• Leaktight sealing caps for plugs and

receptacles.

• Watertightness of shells and accessories via

O-ring seals (15 and 19).

• Seal with the cable via cable gland-type

elastomer seal (26).

• Cable held at 3 levels: cable clamp

(27 and 28), cable gland (25 and 26),

braid grip (21, 22, 23 and 24).

• Cable boot (29) for limiting the radius

of curvature of the cable on leaving the

connector.

1. E44-type receptacle body

2. Insulator collar

3. Rear insulator

4. Intermediate insulator

5. Contact retaining clips

6. Flat gasket for square flange receptacle,

and O-ring seal for nut fixing

7. End stop insulator

8. Male contact (ref.: M)

9. Male front insulator

10. Plugshell

11. Contact clips

12. Locking device

13. Female front insulator

14. Female contact (ref.: K)

15. Front plug O-ring seal

16. Grounding ring for MSH and MPH series

17. Rear friction washer

18. Connector coupling ring

19. Rear plug O-ring seal

20. Leaktight elbow backshell

21. Braid grip locking screw

22. Braid grip cone

23. Braid grip bush

24. Braid grip stop

25. Support washer

26. Gasket

27. Cable clamp with antirotation pins

28. Locking screw

29. Cable boot

8

MSH/MPH series

General configuration

For single or multi-contact signal, coaxial and power layouts with pins of less than 8 mm diameter.

To order accessory only : add Z suffix to the P/N. See glossary page 9.

9

MSH/MPH series

Single contact connectors configuration

Glossary

For single contact power layouts with pins between 10 mm and 25 mm in diameter.

To order accessory only : add Z suffix to the P/N.

Standard shell

Long shell

power single

contact

Series MSH MPH

Shell type

Plug FZ F1 FZ F1

Receptacle, front axial nut E2 E2

Receptacle, 4-screw fixing E44 E44

Receptacle, no accessory options, 4-screw fixing E43 E43

Receptacle, no accessory options, rear axial nut E0 E0

Bulkhead TRE -

Plug sealing cap BF BF

Plug sealing cap with eyelet lanyard BFC BFC

Receptacle sealing cap BE BE

Receptacle sealing cap with ring lanyard BEB(A) BEB(A)

Receptacle sealing cap with eyelet lanyard BEC BEC

(A) For E2-type receptacle.

Plug F5 F5

Receptacle, front axial nut E32 E32

Receptacle, 4-screw fixing (6) E33 E33

Plug sealing cap BF5 BF5

Plug sealing cap with lanyard BF5C BF5C

Accessories(1)

Leaktight straight backshell RD(3)

Leaktight elbow backshell(2) RL(3)

Non-leaktight cable clamp(2) SC(3)

Non-leaktight wire grip(2) SF(3)

Thread mask backshell RZT

10

MSH/MPH series

Mechanical

• Shells

- Series MSH: aluminum alloy.

- Protection:

- Tin plated on nickel underlayer;

Nickel: 10 µm

Tin: 35 µm.

- or cadmium plated bichromated-treated

on nickel under layer (standard)

- Series MPH: marine bronze.

• Seal and cable boot

- Elastomer.

• Flexible insulation, front and rear

- Silicone elastomer.

• Rigid insulation

- Polyoxy phenylene reinforced PPOm.

• Contacts

- Copper or copper alloy.

- Protection : gold plating on nickel

for contacts mx8.

- Silver on nickel for contacts > x8.

• Mechanical endurance

- 200 to 500 locking/unlocking cycles

(depending on size).

• Charge in cantilever: m800 N

• Cable pulling: m800 N

• Free fall: 2,5 m

- Trampling: m80 kg.

Electrical

• Withstand voltage:

At normal pressure

1500 V between contacts size 20,

2500 V for the other contacts.

• Insulation resistance:

- Cabled plug : M104Mh

- Cabled receptacle : M104Mh

- Coupled connectors : M5.103Mh

• Metallization Resistance:

On coupled connectors between

the receptacle plate and rear of plugshell : ≤

m 2.5 mh

Environmental

• Operating temperature:

-55°C to +125°C.

• Immersion resistance:

- 0.2 bars, serie MSH - 2 bars, serie MPH.

• Impact:

100 g - 11 ms - 2 impacts/direction/ axes.

• Vibrations:

- 0.35 mm during 1 h - sweep from 5 to 55 Hz

on the 3 axis.

• Salt spray:

- Series MSH: 6 x 48 h cycles.

- Series MPH: 20 x 48 h cycles.

• Humid heat: 56 days at 40°C.

• Resistance to liquids:

- Kerosene, JP4, 35A, 3515 - oronire

and skydrol 508/A.

• NBC Protection: Resistant to

decontaminating agents.

Characteristics

11

MSH/MPH series

Power crimp contacts

Crimp contacts

Type Size Part number Max. Contact Permissible cables Ø A Ø F

current A resistance m

h

Section mm2AWG gage contact barrel

Male 20 M-20-MS 7

m

2 0,38 to 0,93 22 to 18 1,6 1,35

Female K-20-MS

Male 16 M-16-MS 13

m

1,5 0,93 to 1,91 18 to 14 1,6 2,00

Female K-16-MS

Male 12 M-12-MS 20

m

1,2 1,91 t o3,18 14 to 12 2,4 2,55

Female K-12-MS

Reducing 20 MKMS-20-28 0,1 to 0,15 28 to 26 0,65

sleeves MKMS-20-24 0,21 to 0,38 24 to 22 0,95

16 MKMS-16-26 0,15 to 0,6 26 to 20 1,2

MKMS-12-22 0,1 to 0,38 28 to 22 0,9

12 MKMS-12-18 0,38 to 0,93 22 to 18 1,40

MKMS-12-16 0,6 to 1,34 20 to 16 1,70

Contacts

Max. Contact Permissible cables Ø A Ø F

Type Size Part number current A resistance m

h

Section mm2contact barrel

Flexible Extra flexible

Male 8M-8-MS 45

m

1 5,15 to 10 3,18 to 6 3,6 4,4

Female K-8-MS

Male 6M-6-MS 10 6 5

Female K-6-MS 75

m

0,8 4,6

Male 6E M-6E-MS 16 10 5,5

Female K-6E-MS

Male 25C M-25C-MS 25 16 7,7

Female K-25C-MS 120

m

0,5 6,7

Male 25CE M-25CE-MS 35 25 9

Female K-25CE-MS

Male 50MC M-MS-50MC 170

m

0,3 50 40 8 10,3

Female K-MS-50MC

Réducing 8 MK-MS-8-12 3,18 to 5,15 3,4

sleeve

Pin Socket Reducing sleeve

Pin Socket Reducing sleeve

12

MSH/MPH series

Power single crimp contact

Max. Contact Permissible cables Ø A Ø F L

Type Size Part number current A resistance m

h

Section mm2contact barrel Max

Flexible Extra flexible

Male 50C M-50C-MS 50 45 10,8 65

Female K-50C-MS 235 66

Male 50CE M-50CE-MS 60 50 11,8 65

Female K-50CE-MS

m

0,08 10 66

Male 70C M-70C-MS 70 60 12,5 65

Female K-70C-MS 291 66

Male 70CE M-70CE-MS 95 70 14,5 65

Female K-70CE-MS 66

Male 95C M-95C-MS 95 70 14,5 68

Female K-95C-MS 352

m

0,05 14 66

Male 95CE M-95CE-MS 120 95 17 68

Female K-95CE-MS 69

Male 185C M-185C-MS 185 150 20,5 70

Female K-185C-MS 535

m

0,03 18 71

Male 185CE M-185CE-MS 240 185 23 70

Female K-185CE-MS 71

Male 300C M-300C-MS 300 240 26 80

Female K-300C-MS 723

m

0,02 25 81

Male 300CE M-300CE-MS 350 300 28 80

Female K-300CE-MS 81

Contacts

Pin Socket

13

MSH/MPH series

Power solder contacts

Watertight coaxial contacts

Contacts

Pin Socket

Male Female

Type Size Part number Max. Contact Permissible cables Ø A Ø F

current A resistance m

h

Section mm2contact barrel

Male 6MC M-MS-6MC 27

m

1 5,94 Max. 2,8 3,4

Female K-MS-6MC

Male 10MC M-MS-10MC 45

m

1 10,5 Max. 3,6 5

Female K-MS-10MC

Male 16MC M-MS-16MC 65

m

0,8 15,82 Max. 4,6 6

Female K-MS-16MC

Male 25MC M-MS-25MC 90

m

0,8 24,62 Max. 5,7 7,8

Female K-MS-25MC

Male 35MC M-MS-35MC 120

m

0,5 34,67 Max. 6,7 9

Female K-MS-35MC

Withstand Part number of

Male Female voltage, Max Insulation Contact permissible cables

x

A

x

B

x

C

x

D

part number part number Sea level Current resistance resistance MIL NFC Marine max. max. max. max.

Vrms 50 Hz AM

h

M

h

C17 93.550 599a

TQL/TR

CM-50A-MSH CK-50A-MSH 50 2500 12 > 5000

m

3 / / 50MSB 1,9 7,6 8,6 11

CM-75A-MSH CK-75A-MSH 75 2700 5

m

4 / / 75MSB 1

Impedance

h

14

MSH/MPH series

Standard - watertight - coaxial contacts

Contacts

Withstand Part number of

Male Female voltage, Max Insulation Contact permissible cables

x

A

x

B

x

C

x

D

part number part number Sea level Current resistance resistance MIL NFC Marine max. max. max. max.

Vrms 50 Hz AM

h

M

h

C17 93.550 599a

TQL/TR

KX2(1)

CM-501-MS CK-501-MS RG58 KX15 50PPN 3,1 4,1 6,5

RG122

RG174 KX3 50RPN

CM-502-MS CK-502-MS 50 1200 4 > 5000

m

5 RG316 KX22 50RT 1,1 1,6 2,2 2,7

CM-507-MS CK-507-MS RG178 KX21 1,6 1,7 2,1

RG223

CM-508-MS CK-508-MS RG142 KX23 3,1 4,3 6,5

50PSB

RG59 KX6 75PPN

CM-751-MS CK-751-MS RG140 KX25 75PD 3,8 4,6 6,5

75 1500 2,5 > 5000

m

8 RG302 0,7

CM-752-MS CK-752-MS RG179 1,7 2,3 2,7

CM-758-MS CK-758-MS 75PSB 3,8 4,8 6,5

OBT-CM-MS OBT-CK-MS Sealing plug

Impedance

h

Miniature - non-watertight - coaxial contacts

Male Female

Withstand Part number of

Male Female voltage, Max Insulation Contact permissible cables

x

A

x

B

x

C

x

D

part number part number Sea level Current resistance resistance MIL NFC Marine max. max. max. max.

Vrms 50 Hz AM

h

M

h

C17 93.550 599a

TQL/TR

CM-511-MS(1) CK-511-MS(1) RG178 KX21 0,3 0,9 1,7 2

RG174 KX3 50RPN 0,5 1,6 2,2 2,8

CM-512-MS(1) CK-512-MS(1) RG316 KX22 50RT

50 600 2 > 5000

m

12 RG178 KX21

CM-521-MS(2) CK-521-MS(2) RG174 KX3 50RPN 0,5 1,6 2,2 2,8

RG316 KX22 50RT

Impedance

h

Male Female

(1) Withdrawn from spécification NFC93550; replaced by KX15.

(1) “RADIALL” crimp contacts. (2) “RAYCHEM” thermo-soldering contacts.

15

MSH/MPH series

Polarization keys

Cable code

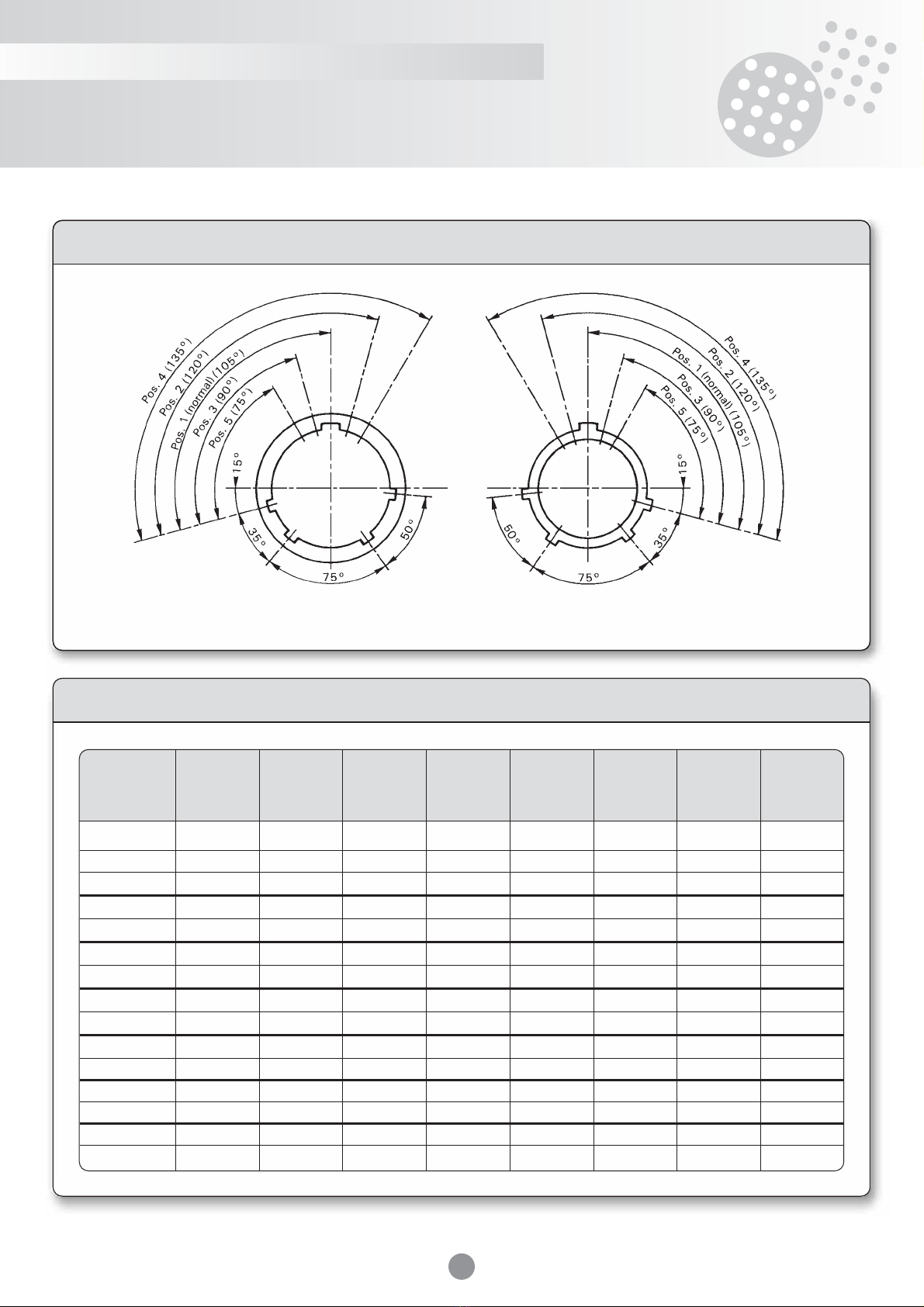

16 17 18 20 22 24 26 28

A0 22,2 to 23,1 29,2 to 30,2 34 to 35,4

A14,5 to 16 17,5 to 19 20,5 to 22,2 25,5 to 27 27,5 to 29,2 30,5 to 32 32,5 to 34 40,5 to 42

A1 13 to 14,5 17 to 17,5 19 to 20,5 24 to 25,5 26 to 27,5 29 to 30,5 31 to 32,5 39 to 40,5

B12 to 13 15 to 16 17,5 to 19 22,5 to 24 24,5 to 26 27,5 to 29 29,5 to 31 37,5 to 39

B1 11 to 12 14 to 15 16 to 17,5 21 to 22,5 23 to 24,5 26 to 27,5 28 to 29,5 36 to 37,5

C10 to 11 13 to 14 14,5 to 16 19,5 to 21 21,5 to 23 24,5 to 26 26,5 to 28 34,5 to 36

C1 9 to 10 12 to 13 13 to 14,5 18 to 19,5 20 to 21,5 23 to 24,5 25 to 26,5 33 to 34,5

D8 to 9 11 to 12 12 to 13 16,5 to 18 18,5 to 20 21,5 to 23 23,5 to 25 31,5 to 33

D1 7 to 8 10 to 11 11 to 12 15 to 16,5 17 to 18,5 20 to 21,5 22 to 23,5 30 to 31,5

E6 to 7 9 to 10 10 to 11 13,5 to 15 15,5 to 17 18,5 to 20 20,5 to 22 28,5 to 30

E1 5 to 6 8 to 9 9 to 10 12 to 13,5 14 to 15,5 17 to 18,5 19 to 20,5 27 to 28,5

F7 to 8 8 to 9 10,5 to 12 12,5 to 14 15,5 to 17 17,5 to 19 25,5 to 27

F1 6 to 7 7 to 8 9 to 10,5 11 to 12,5 14 to 15,5 16 to 17,5 24 to 25,5

G22,5 to 24

G1 21 to 22,5

Viewed from receptacle mating Viewed from plug mating

Shell size

Cable code

16

MSH/MPH series

37-20 RST A1 T P3 A

MSH

MPH

22MRLE2

References

Standard shell

Long shell

power single

contact

Series MSH MPH

Shell type

Plug FZ F1 FZ F1

Receptacle, front axial nut E2 E2

Receptacle, 4-screw fixing E44 E44

Receptacle, no accessory

options, 4-screw fixing E43 E43

Receptacle, no accessory

options, rear axial nut E0 E0

Bulkhead TRE -

Plug sealing cap BF BF

Plug sealing cap with

eyelet lanyard BFC BFC

Receptacle sealing cap BE BE

Receptacle sealing cap

with ring lanyard BEB(A) BEB(A)

Receptacle sealing cap

with eyelet lanyard BEC BEC

(A) For E2-type receptacle.

Plug F5 F5

Receptacle, front axial nut E32 E32

Receptacle, 4-screw fixing (6) E33 E33 (6)

Plug sealing cap BF5 BF5

Plug sealing cap with lanyard BF5C BF5C

Accessories(1)

Leaktight straight backshell RD(3)

Leaktight elbow backshell(2) RL(3)

Non-leaktight cable clamp(2) SC(3)

Non-leaktight wire grip(2) SF(3)

Thread mask backshell RZT

Insulation type(6)

Male M

Female K

Shell size

16-17-18-20-22-24-26-28 XX

Connector series

MSH connectors

MPH connectors Halogen free XXX

Contact layout(6)

Number/size of contact XX-XX

see § layout

Braid grip(1) (for RD and RL)

With braid grip RST

Without braid grip Y

With braid grip power

single contact PST

Cable code(1) (for RD, RL and SC)

A to E1 XX

see § cable codes

Cable boot(1)(for RD and RL)

With cable boot T

Without cable boot (no mention) -

Polarization key(6)

Normal P1

Other position P2-P3-P4-P5 PX

see § polarization key

Surface treatment

Tin plated(7) A

Cadmium-plated bichromate-treated -

Olive drab 014

(1) Leave a blank if the connector has no accessories - (2) Cannot be fitted to long single-contact power shell - (3) Add Z to the part number for accessory orders only -

(4) Do not use with contacts xA > 3,6 - (5) Leave a blank for accessories only or sealing caps - (6) Consult us for availability.

(7) New plating in compliance with ROHS legislation.

]

17

MSH/MPH series

17

Contact layouts (standard shell)

1

1#16 MC

3

3#16

3

3#20

7

7#20

16

3

3#6

3#6E

3

3#8

3#6 MC

3#10 MC

3

3#16 MC

27

27#20

20

3

3#12

7

7#16

12

12#20

17

Viewed from male connectors mating (The main polarization key is shown in the “normal” position).

1

1-C50A

1-C75A

3

3-C501(1)

3-C502

3-C507

3-C508 (50 h)

3-C751

3-C752

3-C758 (75 h)

3

3#6 MC

3#8

3#10 MC

12

12-C50(2)

Without contacts

12- C511

12 C512

12 C5

12

12#16

19

19#20

18

Legend

Grounding contacts

Note : Do not use insulators with contacts from Ø A > 3,6 in plugs fitted with an elbow backshell RL (z)

(1) See § Standard coaxial contacts - (2) See § Miniature coaxial contacts

Standard AGB/T 538 Non standard

18

MSH/MPH series

Contact layouts (standard shell)

Viewed from male connectors mating (The main polarization key is shown in the “normal” position).

Grounding contacts

Note : Do not use insulators with contacts from Ø A > 3,6 in plugs fitted with an elbow backshell RL (z)

(1) See § Standard coaxial contacts - (2) See § Miniature coaxial contacts

3

3#8

3#6 MC

3#10 MC

3

3#16 MC

3#6

3#6E

3

3#25 MC

4

4#10 MC

4#8

48

48#20

24

3

3#35 MC

3#25C

3#25CE

12

12-C501(1)

12-C502

12-C507

12-C508 (50

h

)

12- C751

12- C752

12-C758 (75

h

)

48

48-C50(2)

without contacts

48-C511

48-C512

61

61#20

26

2

2#25 MC

5

5#10 MC

5#8

7

7-C501(1)

7-C502

7-C507

7-C508 (50

h

)

7-C751

7-C752

7-C 758 (75

h

)

19

19#16

29

29-C50(2)

without contacts

29-C511

29-C512

37

37#20

22

Standard AGB/T 538 Non standard

19

MSH/MPH series

3

3#50 MC

85

85#20

28

Contact layouts (standard shell)

Viewed from male connectors mating (The main polarization key is shown in the “normal” position).

Grounding contacts

Note : Do not use insulators with contacts from Ø A > 3,6 in plugs fitted with an elbow backshell RL (z).

Note : Do not use elbow backshell RL(z) or cable-clamp SC (z) or wire-grip SF(z) with these layouts.

Power single contact layouts (long shell)

1

1#50C

1#50CE

1

1#70C

1#70CE

20

1

1#95C

1#95CE

22

1

1#185C

1#185CE

26

1

1#300C

1#300CE

28

Standard AGB/T 538 Non standard

20

MSH/MPH series

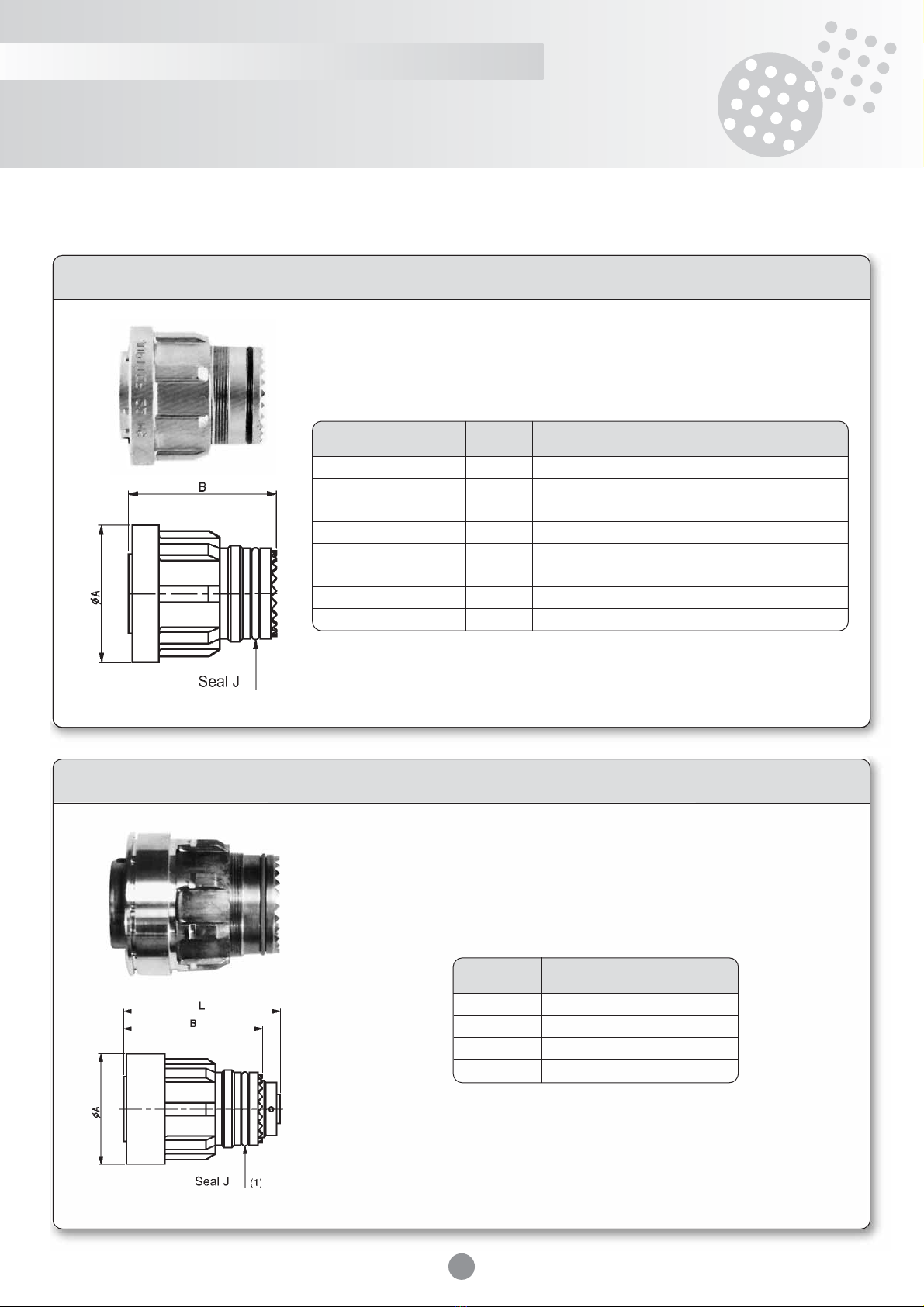

Standard plugs: FZ or F1

Dimensions

Shell size Ø A B “J” seal Internal seal (coupling)

16 35 53

x

1,78 x 18,77

x

1,78 x 17,17

17 39 53

x

1,78 x 21,95

x

1,78 x 20,35

18 43 53

x

1,78 x 26,70

x

1,78 x 25,12

20 48 53

x

1,78 x 29,87

x

1,78 x 28,30

22 52 53

x

1,78 x 33,05

x

1,78 x 31,47

24 56 53

x

1,78 x 34,65

x

1,78 x 34,65

26 59 53

x

1,80 x 37,40

x

1,80 x 37,40

28 74 53,5

x

1,78 x 50,52

x

1,78 x 50,52

Power single contact plug: F5

Size Ø A B L maxi

20 48 61 70

22 52 61 72

26 59 61 74

28 74 61,5 84

(1) See standard (plug)

This manual suits for next models

1

Table of contents

Other SOURIAU Cables And Connectors manuals