Voltij

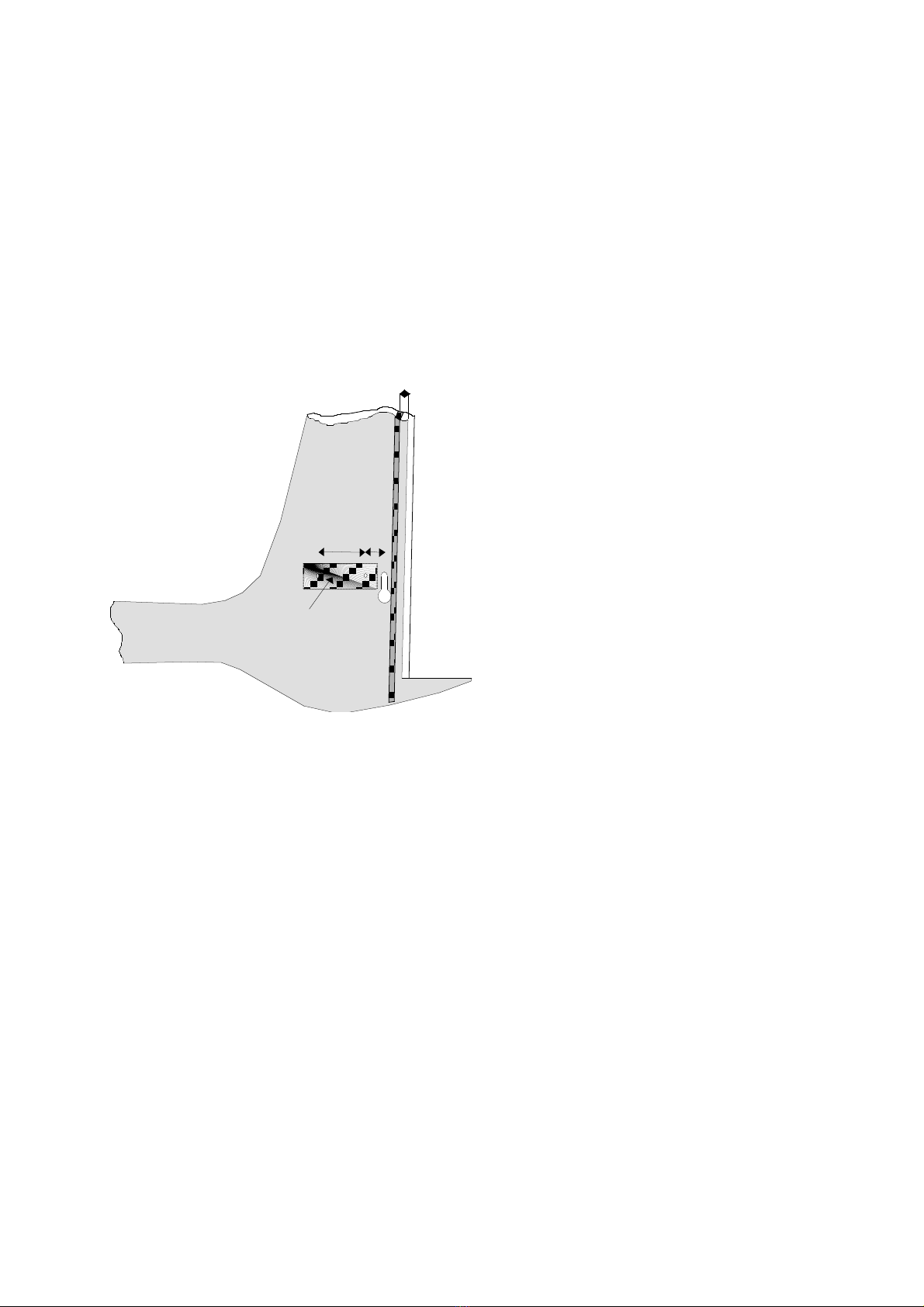

Voltij is a sailplane any fibre revolutionary intended for the stunt-flying sailplane. It has a

symmetrical profile especially calculated for the use of the elevators and a piloting 4 axes. This

profile enables him to be as powerful invertedas at the place. By using the elevators, it sands

easily what makes it possible to quickly gain altitude to carry out a program of stunt-flying. The

mixing depth towards elevators also enables him to take load factors raised without starting, which

allows a tonic stunt-flying. It is necessary at the time construction to bring it a care very particular

to the commands for are without play to have the precision necessary in stunt-flying. The control

surfaces will have to be produced semi-tight as indicated in this note. Painting is painting of an

acrylic type which does not like solvent. It is necessary to avoid alcohol and other white spirit. Best

it is the soapy water. For the Scotch tape traces WD40 cleans good. The duration of construction

is 15 to 20 hours.

Caractéristiques Techniques

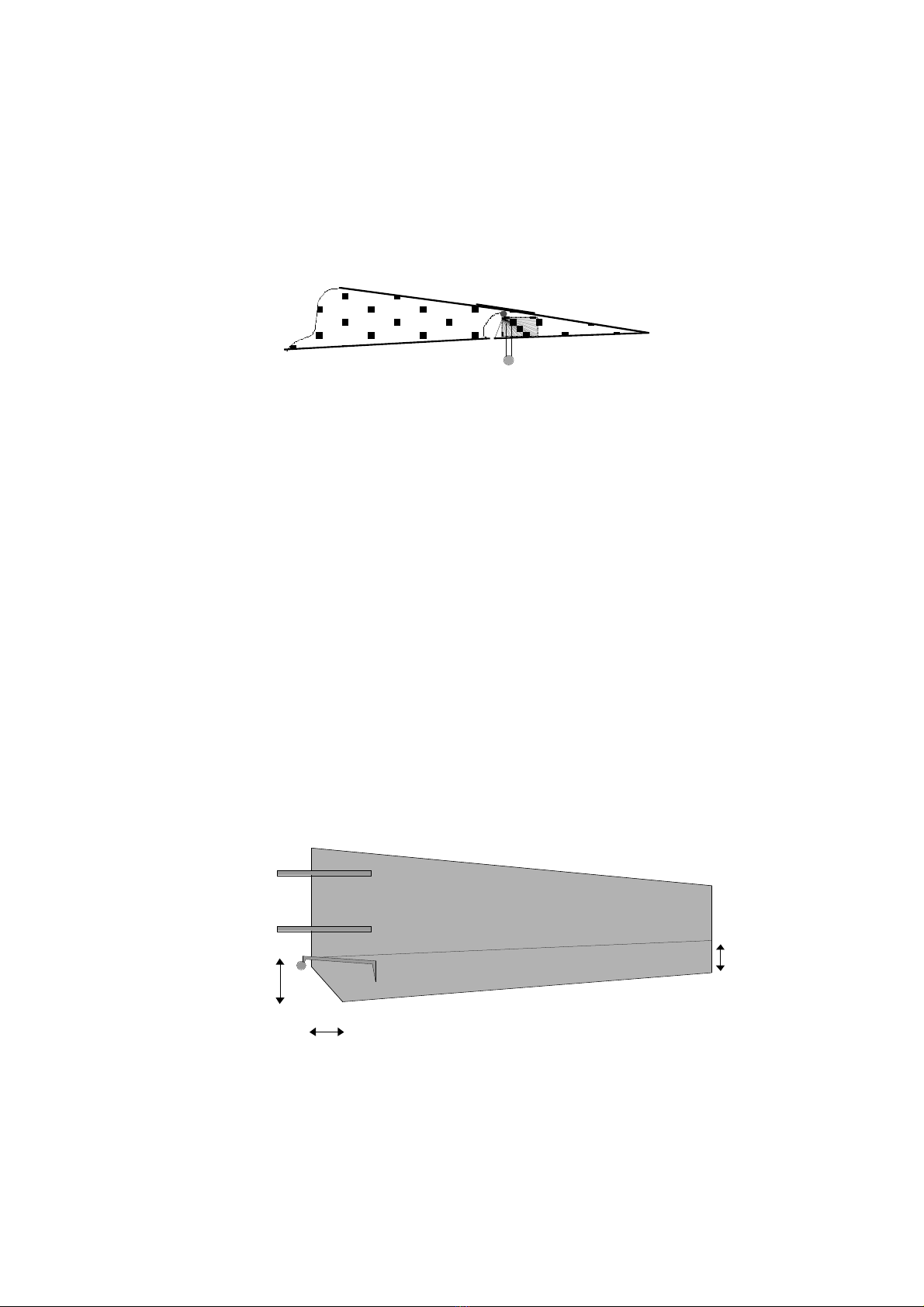

Span: 2020 mm

Cords : 250, 110 mm

Surface : 36 dm2

Profil : MG 05 à 9%

Length :1250 mm

Weight : 1600 g

Ballast : 200g

Charge alaire : 44, 50 g/dm_

Radio: 4 servo de taille standard et de bonne qualité

1 accu 4 ou 5 éléments 1400mA

1. Liste des Accessoires

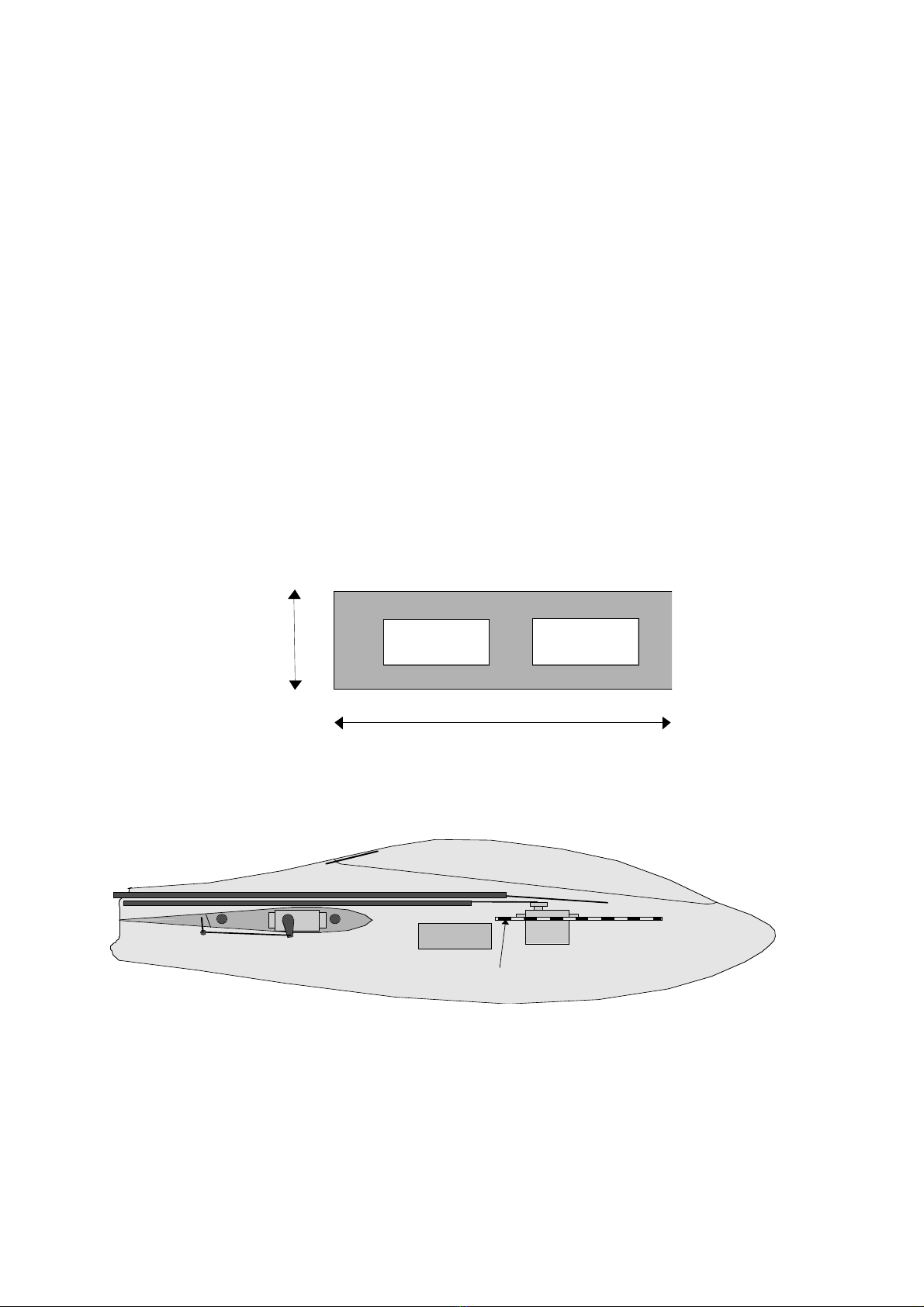

1 platine servo en CTP aviation de 20/10 d’environ 150mm x 42mm

4 chapes à mâchoire coté servos

2 chapes à boules coté ailerons

1 chapes à mâchoire coté dérive

1 chapes à mâchoire coté stab (option stab pendulaire)

2 chapes à boules coté stab (option stab à volets)

6 ou 7 tiges filetées M2 pour les commandes d’aileron, et les tringles

2 tubes de carbone diamètre 6mm pour les tringles de dérive et de stab (chez Décathlon)

2 renforts en CTP 20/10 de 10x10 pour recevoir les guignols d’ailerons

2 renforts en bois dur de 15x15x5mm pour le renvoi de stab ou un bloc de 50x16x15mm pour le stab à

volets

16 petites vis à bois pour la fixation des servos dans le fuselage

Balsa 30x20x4mm pour le raidisseur de dérive

2 cordes à piano de 2mm x 80 mm pour la fixation de la verrière

1 rouleau de scotch charnière

1 tube de colle silicone pour les charnières

2 cordes à piano de 2mm x 100mm pour les clés de stab (fournis)

2 tubes laiton de diamètre intérieur de 2mm x 17mm pour les fourreaux de stab (fournis)

2 clés d’aile Carbone de diamètre 8mm x 250mm( fournis)

En option : 2 clés d’aile acier de diamètre 8mm x 250mm