Southworth PalletPal 360 User manual

Owner’s Manual

PalletPal 360

Level Loader

April 2014

TM

Model # _______________________________

Serial # _______________________________

Placed in Service ________________________

Southworth Products Corp

P.O. Box 1380, Portland, Maine 04104-1380

Phone 800/743-1000 or 207/878-0700 Fax 207/797-4734

www.SouthworthProducts.com

2PALLETPAL 360 OWNER'S MANUAL

Please note: This manual was current at the time of printing. To ob-

tain the latest, most updated version, please contact Southworth’s

Customer Service Department or go to our website: www.South-

worthProducts.com, under the Parts & Service tab you will nd a

complete list of current owner’s manuals to print.

This manual covers all types of PalletPal 360 models including standard

nish steel and special nishes like epoxy or hot dipped galvanized.

The PalletPal 360° was introduced in June 2011, and if your unit

looks like this you have the correct PalletPal 360°owner's manual.

If your unit looks like the picture below you should NOT use this manual. Go

to www.SouthworthProducts.com and download the owner's manual for the

original PalletPal titled 'PalletPal (Spring) Manual'.

PALLETPAL 360 OWNER'S MANUAL 3

Contents

INTRODUCTION ........................................................................................Page 4

RESPONSIBILITY OF OWNERSAND USERS...................................................5

SAFETY .............................................................................................................. 6

Safety Label Compliance.........................................................................7

Installation Notes ................................................................................... 8

Operation Notes – Manual Use ............................................................. 8

Operation Notes – Use with Fork Lift or Stacker.................................... 9

SPECIFICATIONS ............................................................................................. 9

INSTALLATION INSTRUCTIONS .................................................................... 10

Unpacking the Unit .............................................................................. 10

Spring Selection Charts ........................................................................10

Installing the Optional Adjustable Feet ................................................. 11

Installing the Springs ...................................................................... 11-16

OPERATING INSTRUCTIONS ......................................................................... 17

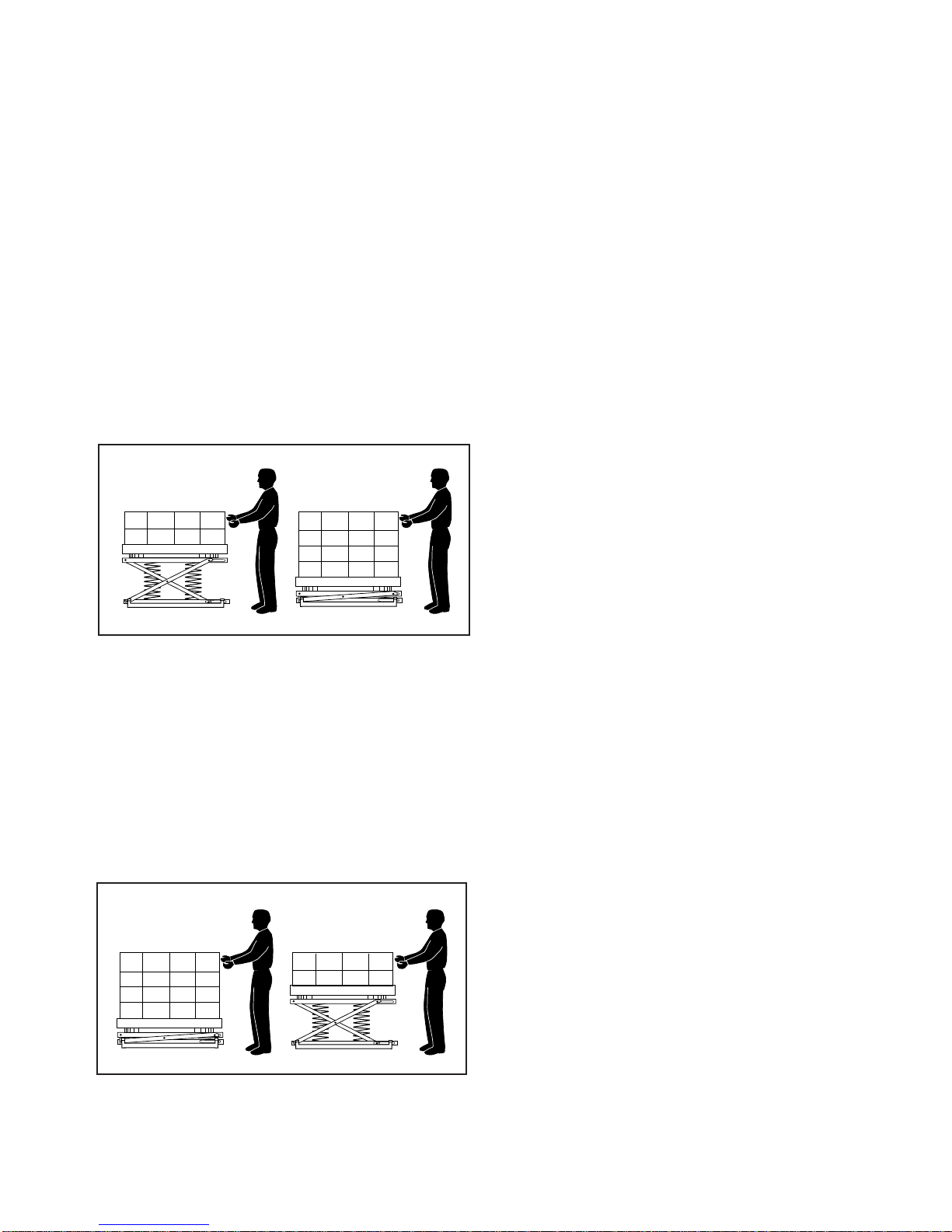

Loading Manually ................................................................................ 17

Removing Loads Manually .................................................................. 17

Operating Safety – Manual use ........................................................... 17

Loading with a Fork Lift ....................................................................... 17

Unloading with a Fork Lift .................................................................... 18

Moving the PalletPal............................................................................. 18

MAINTENANCE ............................................................................................... 18

Routine Periodic Maintenance...............................................................18

TROUBLESHOOTING ......................................................................................19

ORDERING REPLACEMENT PARTS .............................................................. 20

WARRANTY.................................................................................. Back of manual

List of Figures

Fig. 1 Safety Labels.................................................................................... 8

Fig. 2 Pinch Points ..................................................................................... 8

Fig. 3 Orange Spring Installed ................................................................... 8

Fig. 4-17 Step by Step Installation.......................................................... 12 - 16

Fig. 18 Spring Mounting Positions ............................................................. 16

Fig. 19 Loading Manually ........................................................................... 17

Fig. 20 Unloading Manually ....................................................................... 17

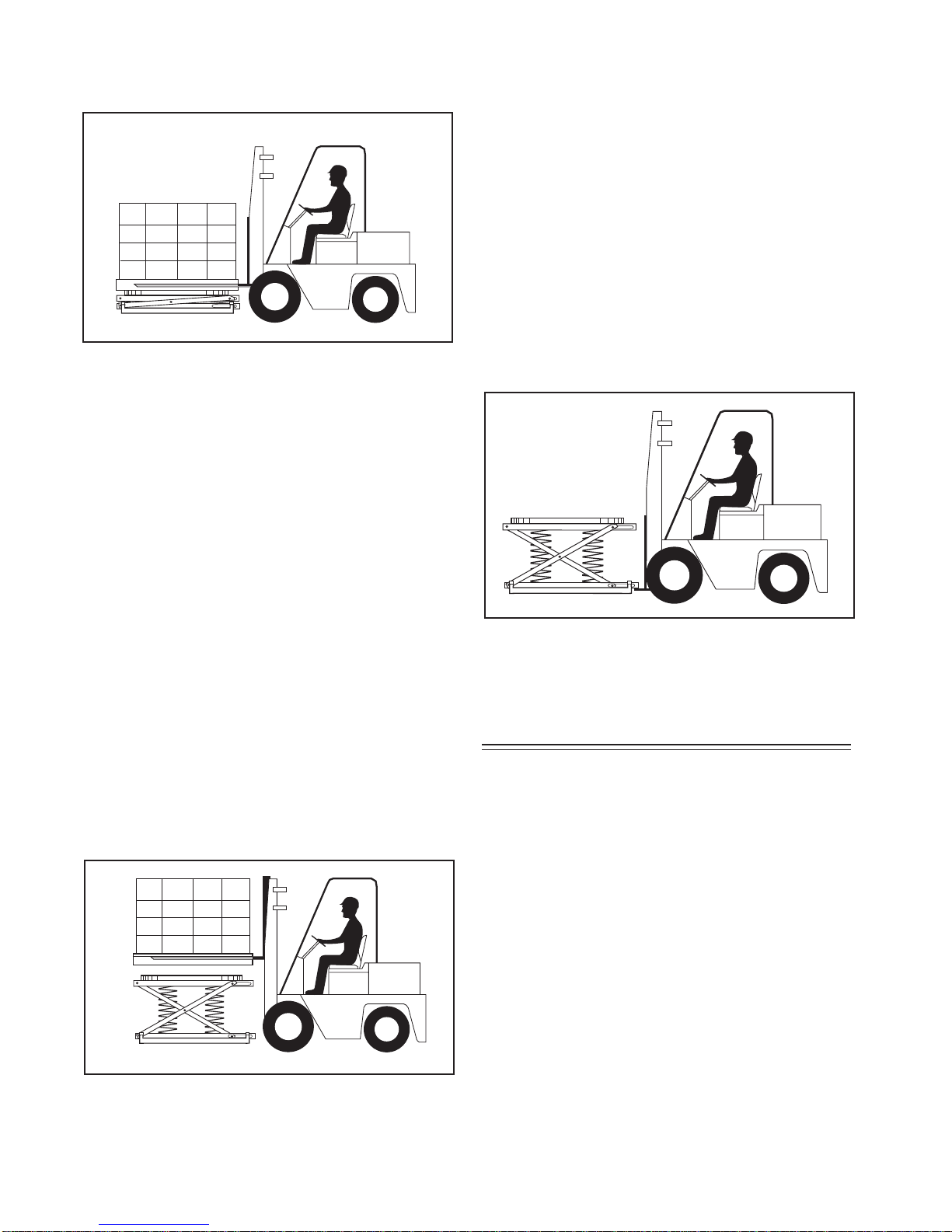

Fig. 21 Loading with a Fork Lift .................................................................. 18

Fig. 22 Unloading with a Fork Lift .............................................................. 18

Fig. 23 Moving the PalletPal ...................................................................... 18

4PALLETPAL 360 OWNER'S MANUAL

Introduction

The PalletPalTM Level Loader is a simple device which will automatically maintain a load at the ideal

height for manual loading and unloading. If a palletized load is placed on the unit, the unit gradually

rises as boxes or parts are removed. This automatically maintains the top of the load at the correct

working height.

The unit may also be used in another way. An empty pallet may be placed on the PalletPal. The unit

gradually lowers as boxes or parts are added. Again, this keeps the top of the load at the correct

height. Complete pallets may be loaded or unloaded using a fork lift.

Each PalletPal unit includes a steel or stainless steel scissor lift mechanism and at least one large

compression spring. The springs are chosen to match the weight and height of a fully loaded pallet.

Springs are available for a wide range of weight and height combinations. The PalletPal also includes

a shock absorber (optional on the stainless steel model). This eliminates any tendency for the load

to bounce on the springs.

This manual contains information to help you to learn about the safe and proper installation, use, and

upkeep of your PalletPal unit. Please be sure that this manual is available to anyone who uses or

services the PalletPal unit.

PalletPal units may be used in a wide variety of industrial settings. The instructions in this manual are

not necessarily all-inclusive, as Southworth cannot anticipate all conceivable or unique situations. In

the interest of safety, please read this whole manual carefully. Be familiar with the contents

of this manual before you install or use the PalletPal unit. If you are not sure of the proper

procedure to be followed, please call Southworth Products Corporation for more information.

Southworth’s product warranty is shown on the rear cover of this manual. This instruction manual

is not intended to be or to create any other warranty, express or implied, including any implied

warranty of merchantability or tness for a particular purpose, all of which are hereby expressly

excluded. As set forth more specically in the product warranty, Southworth’s obligation under that

warranty is limited to the repair or replacement of defective components, which shall be the buyer’s

sole remedy,and Southworth shall notbe liable for anyloss, injury,or damage to personsor property,

nor for any direct, indirect, or consequential damage of any kind resulting from the PalletPal unit.

PALLETPAL 360 OWNER'S MANUAL 5

Responsibility of Owners and Users

Inspection and Maintenance

The device shall be inspected and maintained in proper working order in accor-

dance with Southworth’s owner’s manual.

Removal from Service

Any device not in safe operating condition such as, but not limited to, excessive

leakage, missing rollers, pins, or fasteners, any bent or cracked structural mem-

bers, cut or frayed pneumatic lines, damaged or malfunctioning controls or safety

devices, etc. shall be removed from service until it is repaired to the original

manufacturer’s standards.

Deection

It is the responsibility of the user/purchaser to advise the manufacturer where

deection may be critical to the application.

Repairs

All repairs shall be made by qualied personnel in conformance with South-

worth’s instructions.

Operators

Only trained personnel and authorized personnel shall be permitted to operate

the positioner.

Before Operation

Before using the device, the operator shall have:

• Read and/or had explained, and understood, the manufacturer’s operating

instructions and safety rules.

• Inspected the device for proper operation and condition. Any suspect item

shall be carefully examined and a determination made by a qualied per-

son as to whether it constitutes a hazard. All items not in conformance

with Southworth’s specication shall be corrected before further use of the

equipment.

During Operation

The device shall only be used in accordance with this owner’s manual.

• Do not overload.

• Ensure that all safety devices are operational and in place.

Modications or Alterations

Modications or alterations to any Southworth industrial positioning equipment

shall be made only with written permission from Southworth.

6PALLETPAL 360 OWNER'S MANUAL

Safety

The PalletPal unit has been carefully designed to be as safe as possible for operators and service workers. If

you take a few common-sense precautions, you will be able to use the unit safely. However, the PalletPal is a

powerful unit with moving parts, and is capable of causing personal injury if proper precautions are not taken.

Therefore, throughout this manual, Southworth has identied certain hazards which may occur in the use and

servicing of the PalletPal unit, and provided appropriate instructions or precautions which should be taken to

avoid these hazards. In some cases, Southworth has also pointed out the consequences which may occur if

Southworth’s instructions or precautions are not followed. Southworth uses the following system of identifying

the severity of the hazards associated with its products:

DANGER! Immediate hazard which will result in severe personal injury or death.

WARNING! Hazard or unsafe practice which could result in severe personal injury or death.

CAUTION! Hazard or unsafe practice which could result in minor personal injury or property damage.

Please read and follow this instruction manual, including all safety instructions and precautions, carefully

and completely.

Figure 1 shows the safety labels on this unit. Please be sure that all of the labels are in place, and are visible to

the machine operators. Never paint over the labels. If any of the labels are missing, please contact Southworth

for replacements. The safety labels help to protect your workers.

Note: The shock absorber is optional on the stainless model. If the shock absorber is not present,

use a screw driver or a bolt as a maintenance device to hold the lift up. If the shock is with the lift,

use the pivot pin as a device to hold the lift up. See Fig. 8.

PALLETPAL 360 OWNER'S MANUAL 7

SAFETY LABEL COMPLIANCE

To aid in understanding the concept and the importance of the symbol and signal word, the following

has been excerpted from ANSI Z535.4.

4.10 Safety Alert Symbols

A symbol which indicates a potential personal injury hazard. It is composed of an equilateral

triangle surrounding an exclamation mark. The safety alert symbol shall not be used to alert

persons to property-damage-only accidents.

4.1 Signal Words

The meaning of different signal words as dened by ANSI Z535.6 and Z535.4 standards may be

provided in collateral materials. The following artwork may be used for this purpose.

For use with DANGER signal word

(Red Background)

For use with WARNING signal word

(Orange Background)

For use with CAUTION signal word

(Yellow Background)

DANGER indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a haz-

ardous situation which, if not avoided, could result in minor or

moderate injury.

NOTICE is used to address practices not related to personal

injury.

(Red Background)

(Orange Background)

(Yellow Background)

(Blue Background)

8PALLETPAL 360 OWNER'S MANUAL

WARNING!

After the springs are installed, if the

springs are not seated correctly, or the

twist-lock caps are not tightened, the parts

may pop loose when the unit is used. You

may be hurt, or the load may be damaged.

Operation Notes – Manual Use

WARNING!

Never operate the unit if anyone is sitting

or riding on the rotating ring.

WARNING!

Never operate the unit if the load is off-

center. The load may shift, and you may

be injured. This can also damage the unit.

WARNING!

As the unit moves, keep away from the

“pinch points” where metal parts meet.

See Fig. 2.

WARNING!

Keep the area around the unit clean. Do

not allow any dirt, debris, spilled oil, or

excess grease to collect. These materials

may cause you to slip while the unit is

operating, and you may be injured.

WARNING!

Stay clear of the rotating ring when it is

moving. As the pallet turns, a part of the

load may rotate around and hit you. Never

turn the load when anyone is standing

beside the unit.

Installation Notes

NOTICE

The unit must be installed on a rm, nearly-

level surface. The frame of the unit must

sit rmly on the oor, and the oor must

be level. If the frame is not supported

correctly, stresses may develop in the

frame. The unit may bind or not work

easily. The rotating ring may not rotate

correctly.

Fig. 1.

Safety Labels

A

SOUTHWORTH SMS

3055610 -

-

C

D

B

A

4321

D

C

Portland, Maine 04104-1380

A

B

32DWG NO

DWG. NO.

.5 DATE

1:4 -

5-4-11

60037572

LD LOC DIAG PPAL360

DIMENSIONS ARE IN

PROJECTION 063Z8

CAGE CODE MODEL

SCALE

DATE

WT

REFERENCE

4

REV

32

UNLESS OTHERWISE

C

SIZE SHEET 1 OF 1

SPECIFIED.

SHEET 1 OF 1

60037572

USE OF PROPRIETARY INFORMATION

INCHES

3RD ANGLE

1

DR

LIMITED TO WRITTEN AGREEMENT

CK

TITLE:

FRACTIONS 1/

.XXX .005

.XX .01

ANGLES: Southworth Products Corp.

P.O. Box 1380

- LBS

--05-04-11INITIAL RELEASEA

ECO #REVISED BYDATEDESCRIPTIONREV. REVISIONS

ITEM

NO. QTY. U/M DESCRIPTION PART NO.

3 2 EA SERIAL TAG

2 3 EA BK-LD DCL 1.00X9.00 SOUTHWORTH 5900191

1 2 EA BK-LD DCL 2.00X6.00 CATION, DO NOT LIFT 5900170

2X3 SERIAL TAG CENTERED

ON INNER LEG CROSS TUBE

POCKET EACH SIDE.

APART

CENTERED ON FORK

DECAL 5900170

DECAL 5900191 ON OUTSIDE

OF ANGLE RING EQUALLY

SPACED 120

2X3 SERIAL TAG ON UNDER SIDE OF

STRONGBACK THIS END.

BOM FOR REFERENCE ONLY

THIS DRAWING MUST BE AT REVISION: 'A'

PalletPal 360

PalletPal 360

Fig. 2. Pinch Points

PALLETPAL 360 OWNER'S MANUAL 9

WARNING!

Do not try to use this unit with damaged or

broken pallets. Broken pallets may have

boards or nails which hang down below

the main part of the pallet. As the pallet is

turned, these boards or nails may catch on

the frame of the unit. This can cause the

pallet to stop turning suddenly, causing

the load to shift.

You may be injured, and the unit may be

damaged. The boards or nails on the

bottom of the pallet should not extend

down more than 1/8 inch.

Operation Notes:

Use with Fork Lift or Stacker

You must take some special precautions when using a

fork lift or stacker with the unit:

When loading using a fork lift or stacker –

WARNING!

When adding a load to the unit, lower the

forks completely before removing the

fork lift. The pallet must be completely

supported by the PalletPal. If you do not

do this, the load may be dropped when

Specications

Load capacity.............................400 to 4500 lbs., depending on springs

Load size....................................50" wide x 50" long x 72" high (max.)

Length........................................45 1/4inches

Width (base frame) ....................36 3/4inches

Compressed height....................9 1/2inches

Extended height.........................27 3/4inches

Rotating ring, outside diameter..43 5/8inches

Rotating ring, inside diameter ....40 5/8inches

Adjustment for sloping oors......Can adjust for oor slope up to 1:25

using optional adjustable feet

Net weight..................................380 lbs., with (3) springs installed

you remove the fork lift. The unit or the

load may be damaged, or you may be hurt.

Figure 7 shows the correct way to load

using a fork lift.

When unloading using a fork lift or stacker –

WARNING!

When removing a load from the unit, lift the

load clear of the PalletPal before backing

out the fork lift. If you do not do this, the

top of the unit may jump up when you

remove the fork lift. The unit or the load

may be damaged, or you may be hurt.

Figure 8 shows the correct way to unload

using a fork lift.

When moving the PalletPal -

NOTICE

Do not move the PalletPal while it is loaded.

This will damage the base frame of the

unit. The pockets on the base frame are

designed to support an unloaded PalletPal,

they cannot support any extra weight.

10 PALLETPAL 360 OWNER'S MANUAL

Installation Instructions

Unpacking the PalletPal 360

1. Before you start to install the unit, check for local

codes and ordinances which may apply. It is your

responsibility to obtain any necessary permits.

2. Please read all of these instructions carefully. Be

sure to read and understand all of the warnings.

3. Inspecttheshipping palletcarefullyforany damage

which may have affected the unit. If you see signs of

damage, tell the trucker. Also make a note of this on

the shipping papers which you are asked to sign.

4. Choosethe placewhereyouwant tousetheunit. It

isvery importantthatthePalletPal besetup onasmooth

and at surface. Check the oor surface carefully and

make sure that it is free of all loose debris and dirt.

Usingoptionaladjustablefeet,theunitcancompensate

for a slightly sloping oor (1:25), but the surface must

be smooth and solid.

CAUTION!

The unit must be installed on a smooth at

surface. If the oor is not at, this can create

stresses in the frame of the unit. The unit may

not work properly, or parts of the unit may

wear more quickly than they should. You may

be hurt or the load may be damaged.

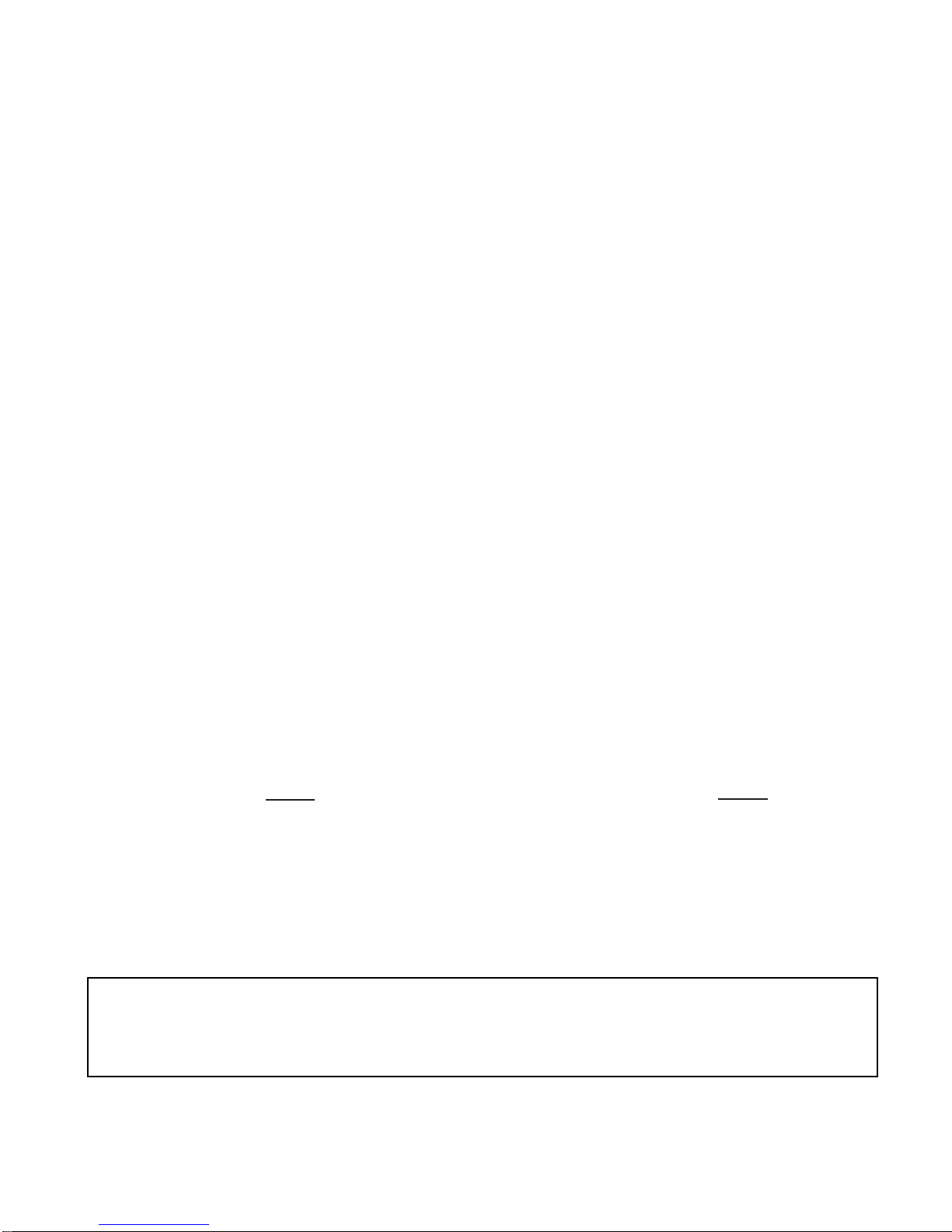

Table 1 - Spring selection chart

1 Caution: PalletPal springs are precisely calibrated and will work best within the load weight and height ranges selected. Selection

based on higher or lower than actual weight will result in restricted raising or lowering capability. Should pallet weight or height weight

requirements dramatically change, PalletPal can be adapted in the field at any time by simply changing the spring combination used.

PalletPal 360 Spring Selection Guide

In order to make sure your PalletPal

functions properly you must have the

proper spring configuration. This simple

chart below will allow you to pick the right

spring configuration for your application

based on the weight of your pallet load

and the height of your pallet load.

Weight of Fully Loaded Pallet (lbs.)

0-

400

400-

800

800-

1200

1200-

1600

1600-

2000

2000-

2400

2400-

2800

2800-

3200

3200-

3600

3600-

4000

4000-

4500

58-60” 0011112223 3

56-58” 0011122223 3

54-56” 0011122223 3

52-54” 0111122233 3

50-52” 0111122233 4

48-50” 0111122233 4

46-48” 0111122333 4

44-46” 0111223334 4

42-44” 0112223344 4

40-42” 0112233344 4

38-40” 0112233444 4

36-38” 0112234444 4

34-36” 1122334444 -

32-34” 112334444- -

30-32” 112334444- -

0Range 0 – White Spring (1 Spring)

1Range 1 – Orange Spring (1 Spring)

2Range 2 – Orange and Gray Springs (2 Springs)

3Range 3 – Orange and Purple Springs (2 Springs)

4Range 4 – Orange, Gray, and Purple Springs (3 Springs)

Height of Fully Loaded Pallet

800-743-1000 • SouthworthProducts.com

PalletPal comes complete with rotator ring, fork truck pockets in base

and selected range spring package. Adjustable feet are optional.

1. Fill in the weight of a fully loaded pallet here: ___________

(Do not guess. Get actual weight from prospect or have a pallet weighed)1

2. Fill in the height of a fully loaded pallet here: ___________

(Do not guess. Get actual height from prospect or measure a loaded pallet)1

3. Using the chart below, select the correct PalletPal range: ___________

PALLETPAL 360 OWNER'S MANUAL 11

Fig. 3 Orange Spring Installed

5. Position the PalletPal beside the point where the

unit will be set up.

6. Removethebanding which secures the unit tothe

pallet. Remove all packing material. Shift the unit to

the oor. Support the base as you do this.

7. Check to see that the frame of the unit is sitting

rmly on the oor. Try to move or rock the frame of

the unit. The base frame should be stable, and should

not move. Check to see that the base frame is level.

(If any part of the frame is more than 1/2" out of level in

relation to any other part, you must install the optional

adjustable feet to level the unit. See the instructions

below.)

8. Remove the springs and lay them out on the oor.

9. If you have any questions about the steps in the

installation process, please call Southworth Customer

Service at 1-800-743-1000.

Setting up and Installing the Springs

1. The PalletPal will always have at least one

spring. This spring has an orange mark, and is larger

in diameter than the others. This large orange spring

is always placed in the front of the unit. Figure 3 shows

the position of the rst spring.

The frame of the unit can handle loads of up to 4500

lbs. In order to adapt the unit for different pallet loads,

the springs are changed. The springs are chosen to

match the weight and height of a fully loaded pallet. A

unit may have one to three springs.

Each time the pallet weight or pallet height is changed,

the springs may also need to be changed. Table 1 on

page 10 show how the springs are selected.

Back

(Hinge End) Front

(Roller End)

Optional Adjustable Feet

Adjust each of the feet until the base frame of the PalletPal unit is level. All four of the feet must touch the

oor. Once the settings are correct, tighten the nuts against the mounting frame.

12 PALLETPAL 360 OWNER'S MANUAL

3. The shock absorber is attached to the

top frame of the unit with a pivot pin, and this

is held in place by a linch pin. The pivot pint

is used to hold the table frame in the raised

position. Take a look at the mechanism and

note the positions of the parts. Remove the

linch pin and remove the pivot pin. Lay the

free end of the shock absorber down.

2. The unit is shipped without springs

installed. The installation of the rst spring

(orange) requires two people. Lift off rotating

ring and both yellow bayonets. Set them aside,

they will be installed later.

Fig. 4

Fig. 5

4. With the help of an assis-

tant, lift the top frame until it hits

the upper latch stops.

Fig. 6

PALLETPAL 360 OWNER'S MANUAL 13

Fig. 7

5. While holding both latches up and lift the

top frame pass the latches until it is at its full,

uppermostposition. Have the assistant holdthe

weight and insert the pivot pin in the hole in the

baseframe.See Fig. 8. With the PalletPal in this

full upper most position the orange spring can

be installed.

Fig. 8

6. Insert either

end of the large

orangespring into

the lower pocket.

Be sure the bot-

tom spring coil

is positioned out-

sidethealignment

tab as shown.

Fig. 9

Alignment Tab

14 PALLETPAL 360 OWNER'S MANUAL

7. Grasp the spring by the second or

thirdcoildown from the top (do NOTgrasp

the top coil or rung) and push the spring

downandundertheedgeofthetopframe.

Fig. 10

8. While pushing down to

compress spring push it forward

into the pocket up under the top

frame. It will "snap" into position

when completely in the pocket.

Fig. 11

Fig. 12 Fig. 13

CORRECT

Fully inserted into pocket

INCORRECT

Spring NOT fully inserted into pocket

PALLETPAL 360 OWNER'S MANUAL 15

Fig. 14

9. Remove the shock absorber pivot pin. Push down on top frame until

latches engage. (Both latches will drop into place).

10. Reinstall the shock absorber pivot pin and linch pin.

Fig. 15

16 PALLETPAL 360 OWNER'S MANUAL

Fig. 16 Fig. 17

11. Install additional springs as needed

through the bayonet openings. Reinsert the

yellowbayonets and twisttolockthem in place.

12. Reinstall the rotator ring.

Before using the unit, do a safety check. Be sure that each of the spring bayonet

caps is in place and rotated to their locked position. Check the top and bottom of

each spring to be sure it is seated correctly. Check the linch pin at the top of the

shock absorber. These checks are very important.

The PalletPal 360 is now ready for use!

13. Figure 4 shows the position of additional springs if needed. Double-check to be sure you have the correct

springs. Refer to Table 1 on page 10 and see that you have the correct springs for your application.

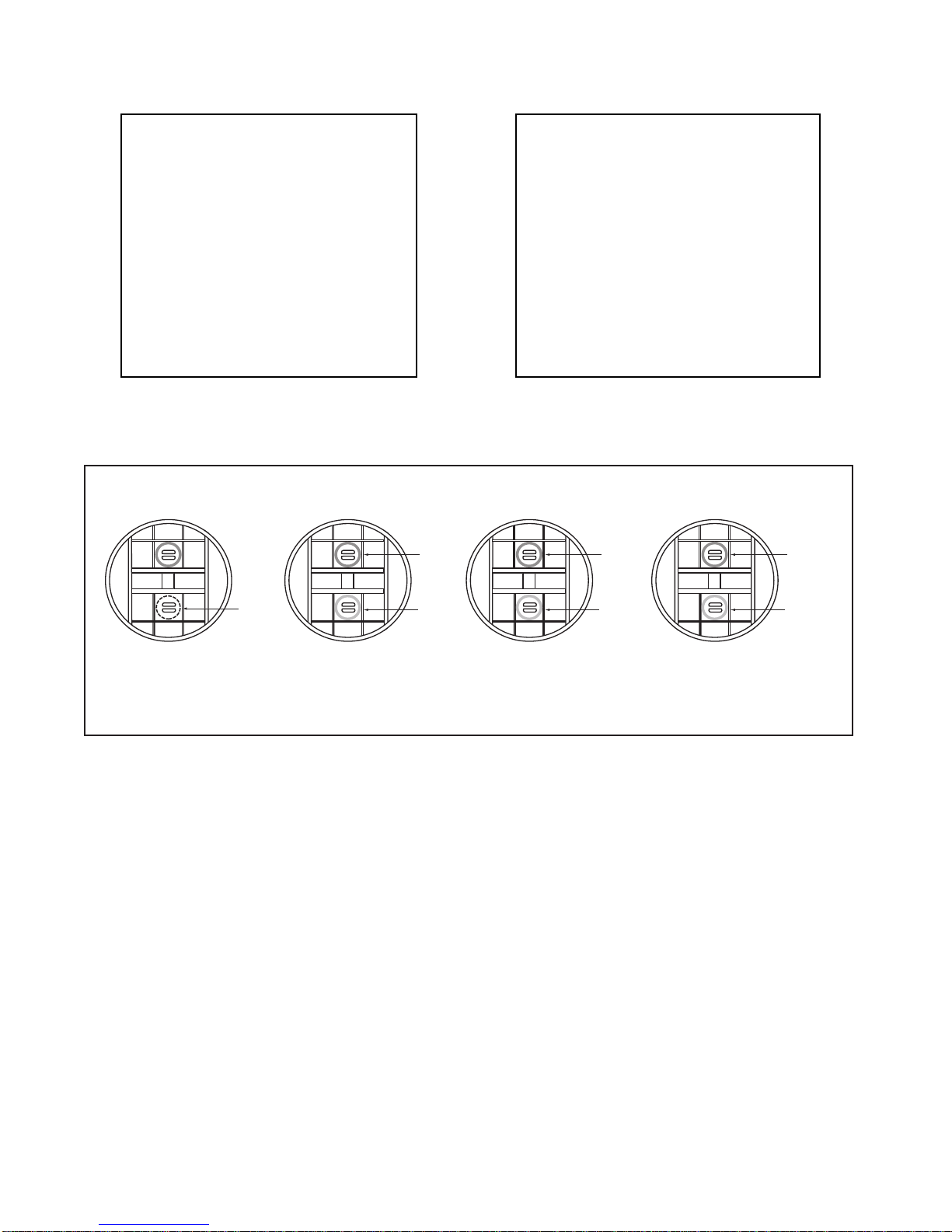

Fig. 18

Spring Mounting Positions

Orange

spring

Range #1

Rear

Front

Orange

spring

Grey

spring Purple

spring

Range #2

Rear

Front

Orange

spring

Range #3

Rear

Front

Purple

spring

Orange

and Grey

springs

Range #4

Rear

Front

Front= roller end of legs

Rear= hinge end of legs

PALLETPAL 360 OWNER'S MANUAL 17

Operating Instructions

Loading Manually

Addboxesor parts until the pallet isfull. Loadthe pallet

in layers. Use the rotating ring to position the pallet to

eliminate walking around. The unit will gradually lower

the pallet until it reaches the bottom. See Fig. 19.

Removing Loads Manually

Removeboxesorpartsuntil the pallet is empty. Unload

the pallet in layers. Use the rotating ring to position the

pallet to eliminate walking around. The unit will gradu-

ally raise the pallet. See Fig. 20.

Operating Safety - Manual Use

1. Do not use this unit with a load greater than the

rated load. This includes the weight of the payload and

the weight of the pallet. Table 1 on page 10 shows how

to be sure you have the correct spring combination for

your application.

2. Never push the load off of the side of the unit. If

you do this, the frame of the unit may jump upward.

3. Never use the unit when anyone is sitting or riding

on the rotating ring.

4. Do not try to use this unit with damaged or broken

pallets. Broken pallets may have boards or nails which

hang down below the main part of the pallet. As the

pallet is turned, these boards or nails may catch on the

frame. The pallet may stop turning suddenly and this

can cause the load to shift. You may be injured and

the unit may be damaged. If the boards or nails on the

bottom of the pallet extend down more than 1/8inch,

they will interfere with the turning action.

5. Stay clear of the rotating ring when it is moving.

As the pallet turns, a part of the load may rotate around

and hit you.

6. Keep the area around the unit clean. Do not allow

any dirt, debris, spilled oil, or excess grease to collect.

These materials may cause you to slip while the unit is

operating and you may be injured.

Loading with a Fork Lift

1. Place the load on the lift, then lower the fork lift.

Before removing the load, be sure the unit is carrying

the weight, not the fork lift. See Fig. 21.

• Lower the load until the springs on the PalletPal

are fully compressed.

• Be sure the forks on the lift are clear of the inside

of the pallet.

WARNING!

If you skip these steps, the load may drop

suddenly when you remove the fork lift.

You may be hurt or the unit or load may

be damaged.

WARNING!

Never drop the load on the rotating ring. If

you do this while the rotating ring is mov-

ing, the load may shift. You may be injured

or the unit may be damaged. If you drop

the load while the rotating ring is stopped,

the unit may be damaged.

Fig. 19

Loading Manually

Fig. 20

Unloading Manually

CAUTION!

Rotate the pallet load. Never place

your hands on the rotator ring. You

may be hurt.

18 PALLETPAL 360 OWNER'S MANUAL

Fig. 22

Unloading with a Fork Lift

Fig. 21

Loading with a Fork Lift

Fig. 23

Moving the Pallet Pal

2. Be sure the load is centered on the unit.

WARNING!

If the load is off-center, it may shift when

the rotating ring is turned. You may be hurt

or the unit or load may be damaged.

Unloading with a Fork Lift

1. Inserttheforks fully into the pallet, and lift thepallet

straight up and clear of the top of the unit. See Fig. 22.

• Raise the pallet until the springs on the PalletPal

are fully extended.

• Be sure the pallet clears the top of the rotating

ring before you move the fork lift.

WARNING!

If you skip these steps, the unit may jump

up suddenly when you remove the pallet.

You may be hurt or the unit or load may

be damaged.

Moving the Pallet Pal

NOTICE

Do not move the Pallet Pal while it is load-

ed. This will damage the base frame of the

unit. The pockets on the base frame are

designed to support an unloaded PalletPal,

but cannot support any extra weight.

1. Remove any load from the top of the Pallet Pal.

2. Insert the forks into the pockets in the base frame.

See Fig. 23.

Maintenance

Routine Periodic Maintenance

Every 90 days -

• Check for loose hardware and signs of excessive

wear. On the models where the shock absorber

is used, check for signs of leakage.

• Check to be sure that the unit is placed on a rm

level surface. If the optional feet are installed, be

sure that all four feet are touching the oor and

are locked in position.

PALLETPAL 360 OWNER'S MANUAL 19

Troubleshooting

Troubleshooting Check List

Problem Possible Cause Check This

The unit lowers too easily (too

early). The spring combination may be too

weak for the load. Check the spring ratings.

See Table 1 on page 10.

The unit does not lower

enough (too late). The spring combination may be too

strong for the load. Check the spring ratings.

See Table 1 on page 10.

The top of the unit rotates

away from you. The frame of the unit may not be level. Move the unit to a level sur-

face or install the optional

adjusting feet.

The top of the unit bounces. The shock absorber may be damaged. Check for leaks or dents.

Replace if damaged.

Excessive “rumble” when the

ring rotates Wear or lack of lubrication to bearings

under rotating ring. Remove turntable, lubricate

or replace bearings.

Wear or metal aking from un-

derside of rotating ring. Normal condition caused by work-hard-

ening of metal. No repair necessary. This

will stop once the rotator ring

wears in.

20 PALLETPAL 360 OWNER'S MANUAL

Ordering Replacement Parts

Southworth has carefully chosen the components in your unit to be the best available for the purpose.

Replacement parts should be identical to the original equipment. Southworth will not be responsible

for equipment failures resulting from the use of incorrect replacement parts or from unauthorized

modications to the unit.

Southworth can supply all replacement parts for your PalletPal. With your order, please include the

model number and the serial number of the unit. You can nd these numbers on the name plate. This

plate is located within the scissors mechanism.

To order replacement parts, please call the Parts Department at (207) 878-0700 or (800) 743-1000.

Parts are shipped subject to the following terms:

• FOB factory

• Returns only with the approval of our Parts Department.

• Payment net 30 days (except parts covered by warranty).

• Freight collect (except parts covered by warranty).

Parts replaced under warranty are on a “charge-credit” basis. We will invoice you when we ship the

replacement part, then credit you when you return the worn or damaged part, and we verify that it is

covered by our warranty. Labor is not covered under our warranty for Parts orders.

Parts Department

Southworth Products Corp.

P.O. Box 1380

Portland, Maine, 04104-1380

Telephone: (800)743-1000 or (207)878-0700

FAX: (207)797-4734

Other manuals for PalletPal 360

2

Table of contents

Popular Valve Positioner manuals by other brands

Samson

Samson 3730-4 Configuration manual

halstrup-walcher

halstrup-walcher PS 3 EIP Series instruction manual

Festo

Festo CMSX C-U-F1 Series Translation of the original instructions

Aventics

Aventics R434001244 Service information

Burkert

Burkert 8692 Supplement to operating instructions

Pepperl+Fuchs

Pepperl+Fuchs Profinet PCV50-F200-B17-V1D manual