3

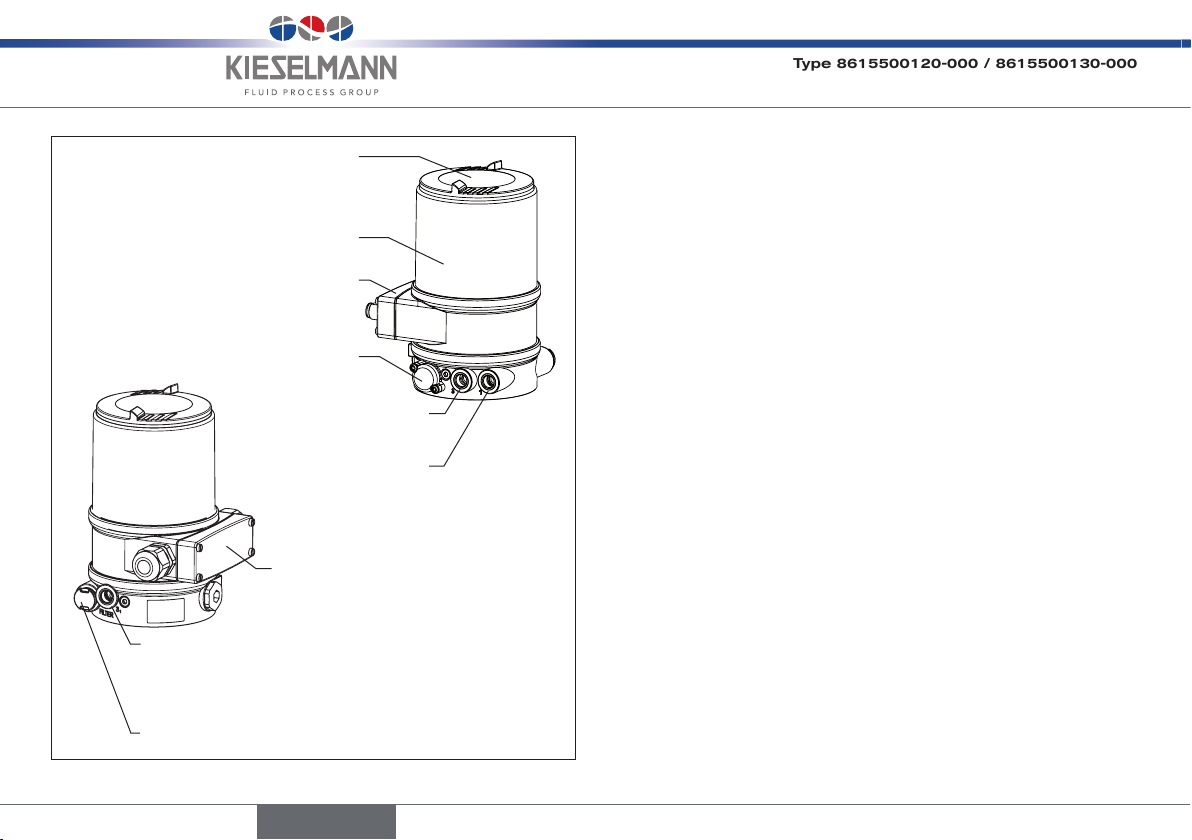

Type 8615500120-000 / 8615500130-000

1 QUICKSTART GUIDE .................................................................................4

1.1 Definition of the term 'Device' .................................................4

1.2 Symbols .......................................................................................4

2 AUTHORIZED USE ......................................................................................5

2.1 Restrictions .................................................................................5

3 BASIC SAFETY INSTRUCTIONS ..........................................................6

4 GENERAL INFORMATION ........................................................................7

4.1 Contact address ........................................................................7

4.2 Warranty ......................................................................................7

4.3 Information on the Internet ......................................................7

5 SYSTEM DESCRIPTION ............................................................................7

5.1 Functions ..................................................................................... 8

6 TECHNICAL DATA ........................................................................................9

6.1 Conformity ................................................................................... 9

6.2 Standards ....................................................................................9

6.3 Operating conditions ................................................................ 9

6.4 Rating plate ...............................................................................9

6.5 Mechanical data.........................................................................9

6.6 Pneumatic data ........................................................................10

6.7 Electrical data ...........................................................................10

7 OPERATION ..................................................................................................11

7.1 Description of the operating and display elements .........11

7.2 Function of the keys ................................................................... 12

8 OPERATING STATES ...............................................................................13

8.1 Changing the operating state ...............................................13

8.2 Displays in the AUTOMATIC operating state ...................... 14

8.3 Master code ..............................................................................15

9 OPERATING LEVELS ...............................................................................15

9.1 Switching between the operating levels ............................15

10 INSTALLATION ............................................................................................16

10.1 Installation of devices for the Ex area .................................16

10.2 Safety instructions ...................................................................16

10.3 Installation on stroke actuators ................................................... 16

10.4 Installation on rotary piston actuators ....................................... 17

10.5 Installation on rotary actuators from third party

manufacturers ................................................................................................ 17

10.6 Pneumatic connection ............................................................18

11 ELECTRICAL INSTALLATION ...............................................................19

11.1 Safety instructions ...................................................................19

11.2 Electrical installation with circular plug-in connector ......20

11.3 Electrical installation with cable gland ................................25

12 PROFIBUS DP / DEVICENET..............................................................26

12.1 Electrical installation ...............................................................26

13 START-UP ......................................................................................................29

13.1 Safety instructions ...................................................................29

13.2 Starting-up Type 8615500120-000 /

8615500130-000 ...............................................................................29

14 SAFETY END POSITIONS .................................................................... 31

15 ACCESSORIES ...........................................................................................32

16 TRANSPORT, STORAGE, DISPOSAL .............................................. 32

Contents

English