the socket. If you have your finger on the switch

whilst carrying the tool or you connect the tool to

the power supply whilst it is switched on, this

could cause accidents.

Remove all adjusting tools or wrenches

before you switch on the tool. Any tool or

wrench in a rotating part of the tool could cause

injuries.

Do not overestimate your capabilities. Make

sure you have a sure footing and keep your

balance at all times. This will enable you to

control the tool better in unexpected situations.

Wear suitable clothes. Never wear loose

fitting clothes or jewelry. Keep hair, clothing

and gloves away from moving parts. Long

hair, loose clothing or jewelry can be caught by

moving parts.

Do not overload your tool. Use the correct electric

tool for the job in hand. Operate the device only

within the specified output range. Use a suitable

tool which is appropriate for the task: Never use

low-powered machines for heavy duty work. Do

not use electric power tools to perform work for

which they are not intended.

WARNING: Only use the accessories

recommended in these instructions. The use of

other accessories could result in injuries being

caused.

Prevent the running chainsaw from coming

into contact with the ground or wire fences,

and do not use it to cut undergrowth or

trimmed timber.

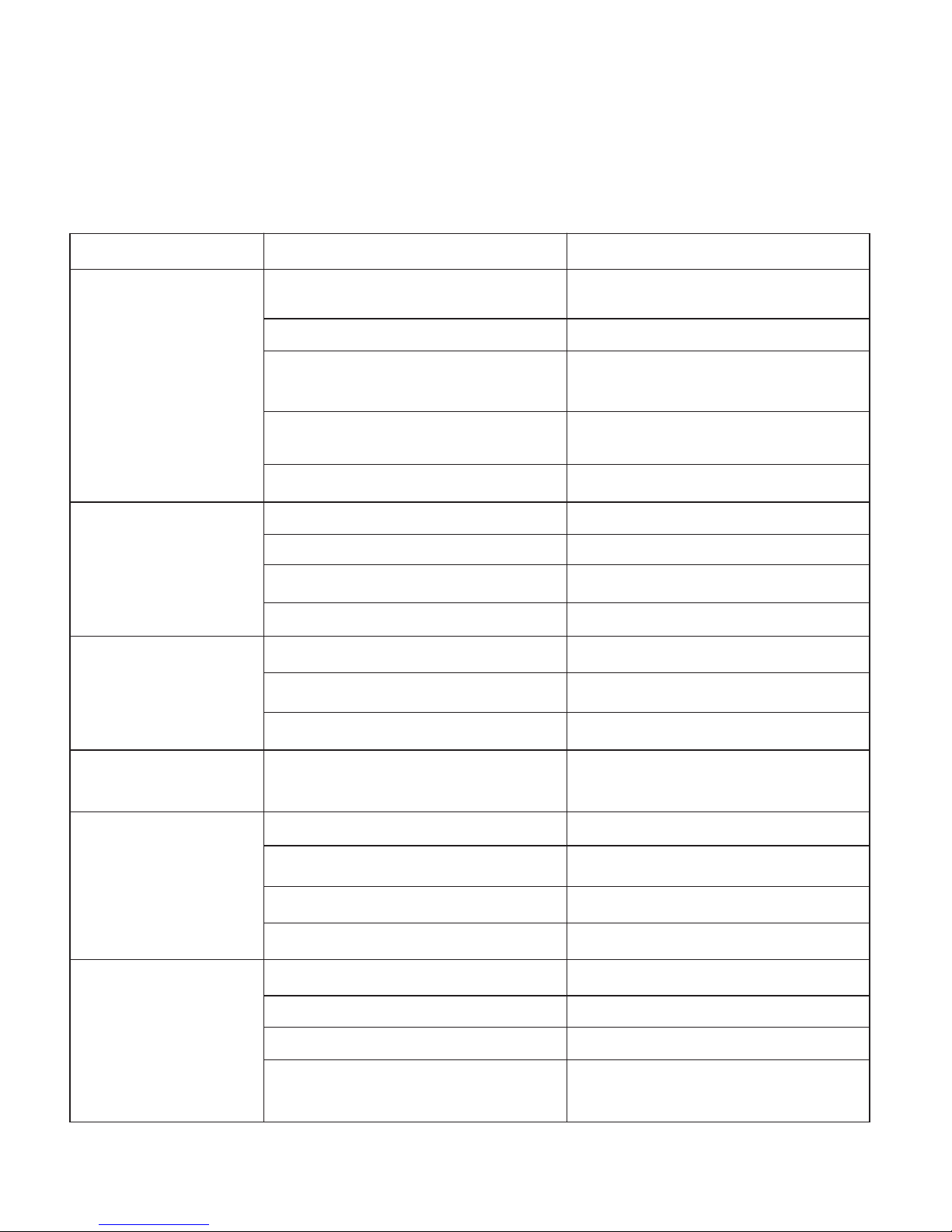

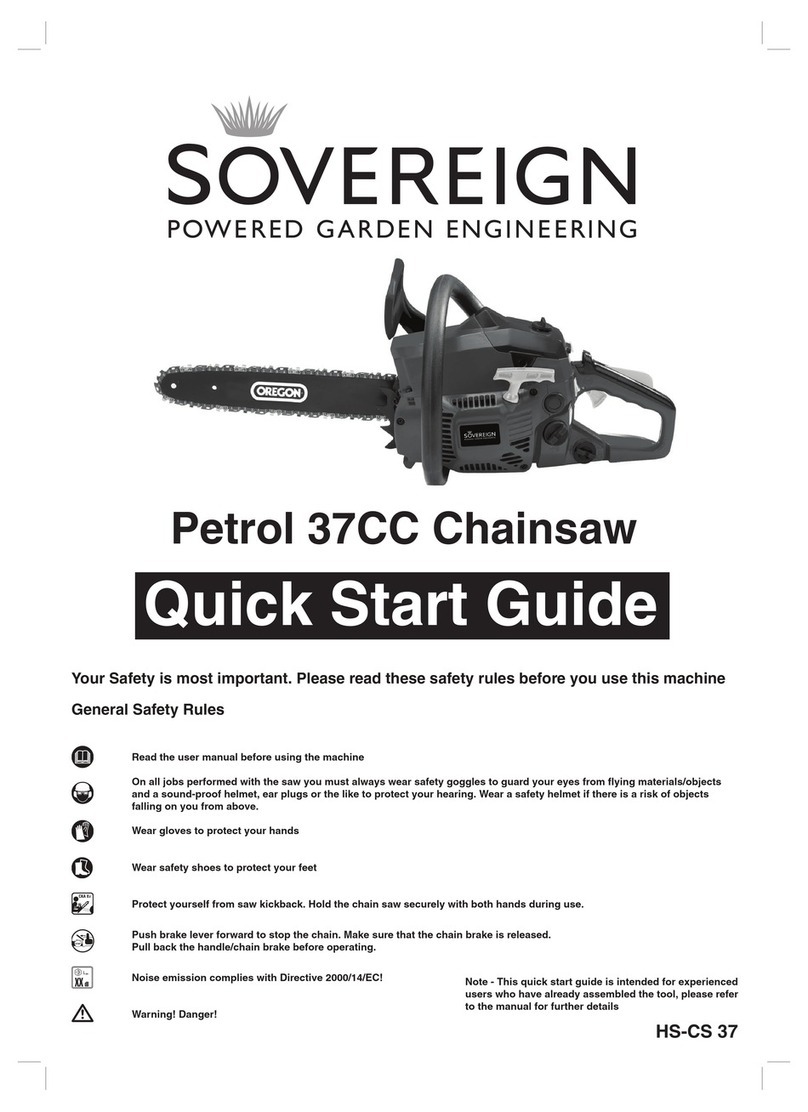

First-time users should be given a practical

demonstration of how to use the chainsaw by

an experienced chainsaw operator, who

should also explain the necessary protection

equipment and help them to practice cutting

a round piece of wood on a sawhorse or

sawing trestle to start with.

Take care of your electric power tools. Keep

the cutting tools sharp and clean to enable

you to work better and more safely. Check

the power cable of the electric tool on a

regular basis and have it replaced by an

authorized specialist if it is damaged. Check

your extension cables regularly and replace

them if damaged.

Check the electric power tool for damage.

Each time before re-using the electric tool,

carefully check that the safety devices or any

parts showing signs of slight damage are working

properly and as intended. Check that moving

parts are in good working order and do not jam,

and that no parts are damaged. All parts must be

correctly assembled and meet all the conditions

required to ensure that the electric power tool

works correctly. Unless stated otherwise in the

operating instructions, any damaged safety

devices and parts must be properly repaired or

replaced by an authorized service center.

Damaged switches must be replaced by a

customer service workshop. To prevent danger,

damaged power cables must be replaced by the

manufacturer or the customer service

representative of the manufacturer.

Service

Make sure that your tool is only repaired by

qualified personnel using only genuine spare

parts. This will ensure that your tool remains safe

to use.

Special safety instructions for

chainsaws

Always disconnect the mains plug before

performing any maintenance work, when the

chainsaw is not in use and before changing

any tools.

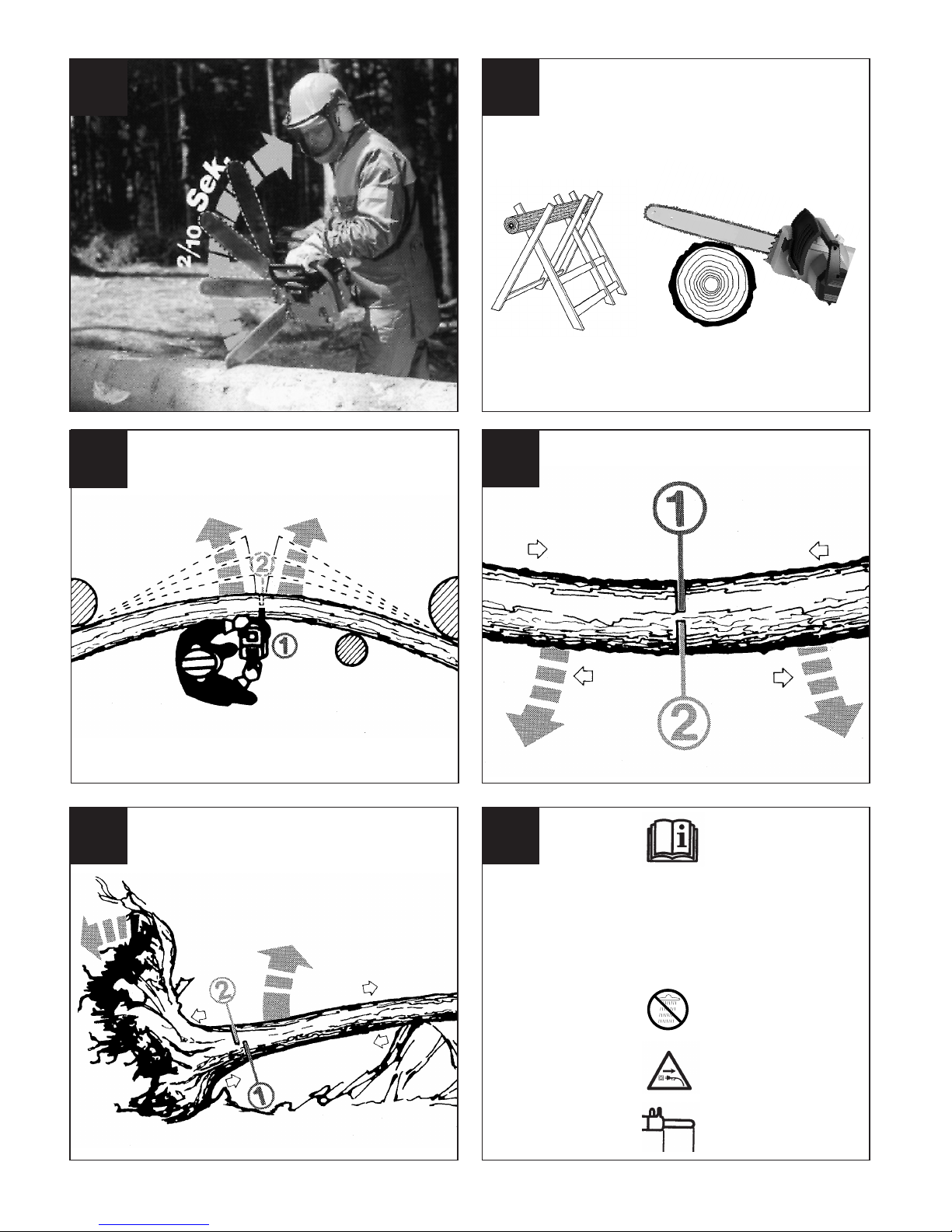

When the chainsaw is running make sure

that you keep all parts of your body away

from the chainsaw. Before starting up the

chainsaw make sure that it is not touching

anything. When you are working with a

chainsaw, a single moment of carelessness is all

it takes to catch up clothing or parts of your body

in the chainsaw.

Do not use the chainsaw while up a tree

unless you are specially trained to do this.

Otherwise you risk injuring yourself if you use the

chainsaw inappropriately whilst up a tree.

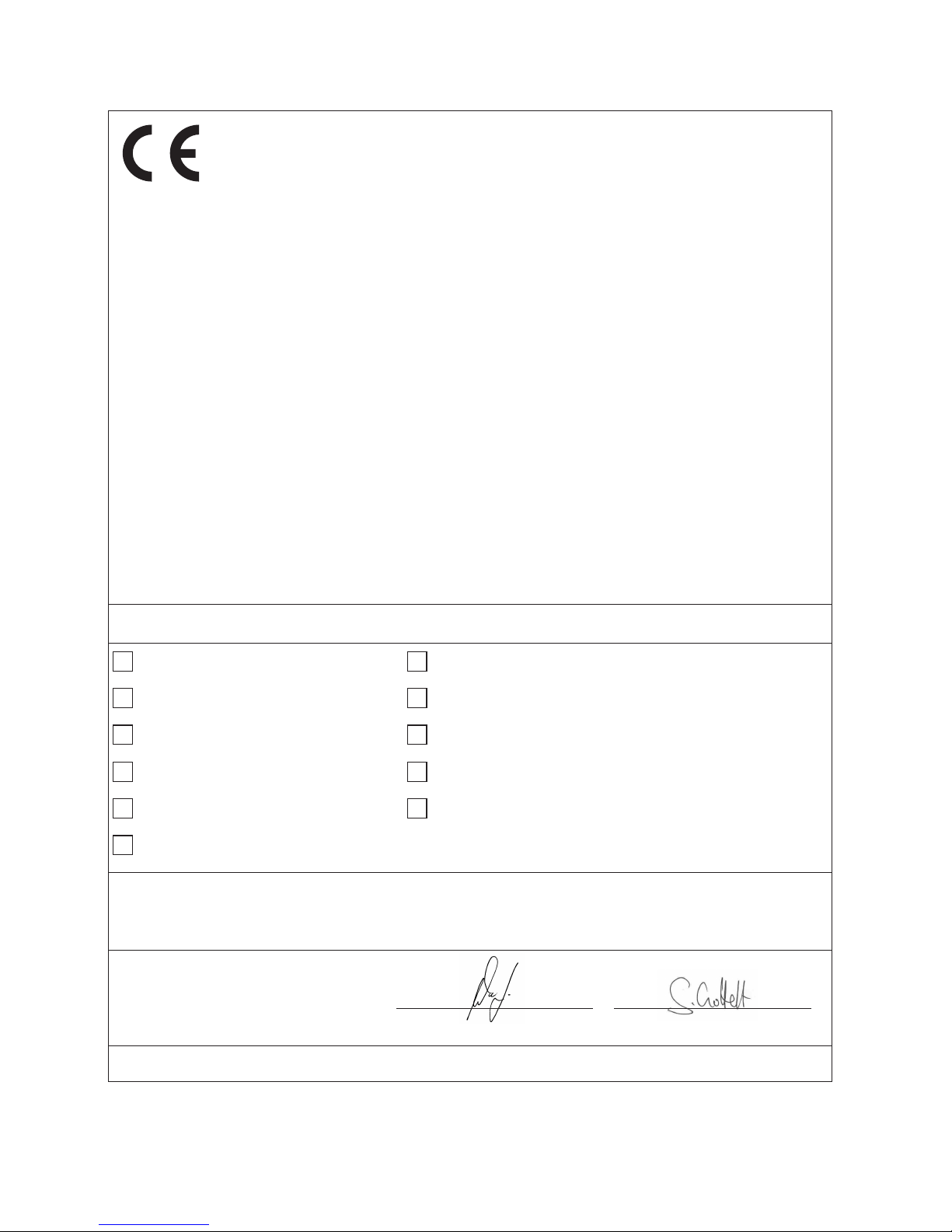

When cutting through a branch which is

under tension, take into account how it will

spring back once the cut has been made.

Once the tension in the wood fibers is released

the cut branch could hit the operator and/or seize

control of the chainsaw.

Carry the chainsaw by the front handle with

the chain stationary and the guide rail facing

backwards. Always fit the protective cover

when transporting the chainsaw or putting it

into storage. Careful handling of the chainsaw

reduces the likelihood of accidental contact with

the saw chain while it is running.

Follow the instructions for lubrication, chain

tension and replacement of accessories. A

chain which is not properly tensioned or

lubricated can break or increase the risk of

kickback.

Keep the handles dry, clean and free from oil

10