7. Cleaning, maintenance, storage, transport

and ordering of spare parts

7.1 Cleaning

• Keep all safety devices, air vents and the motor housing

free of dirt and dust as far as possible. Wipe the equipment

with a clean cloth or using compressed air at low pressure.

(Ensure to blow it in a safe direction).

• We recommend that you clean the device immediately

each time you have finished using it.

• Clean the equipment regularly with a moist cloth and

some soft soap. Do not use cleaning agents or solvents;

these could attack the plastic parts of the equipment.

Ensure that no water can seep into the device.

7.2. Maintenance

Always switch off the machine and pull out the spark boot

plug before carrying out any maintenance work.

7.2.1 Replacing the line spool / cutting line

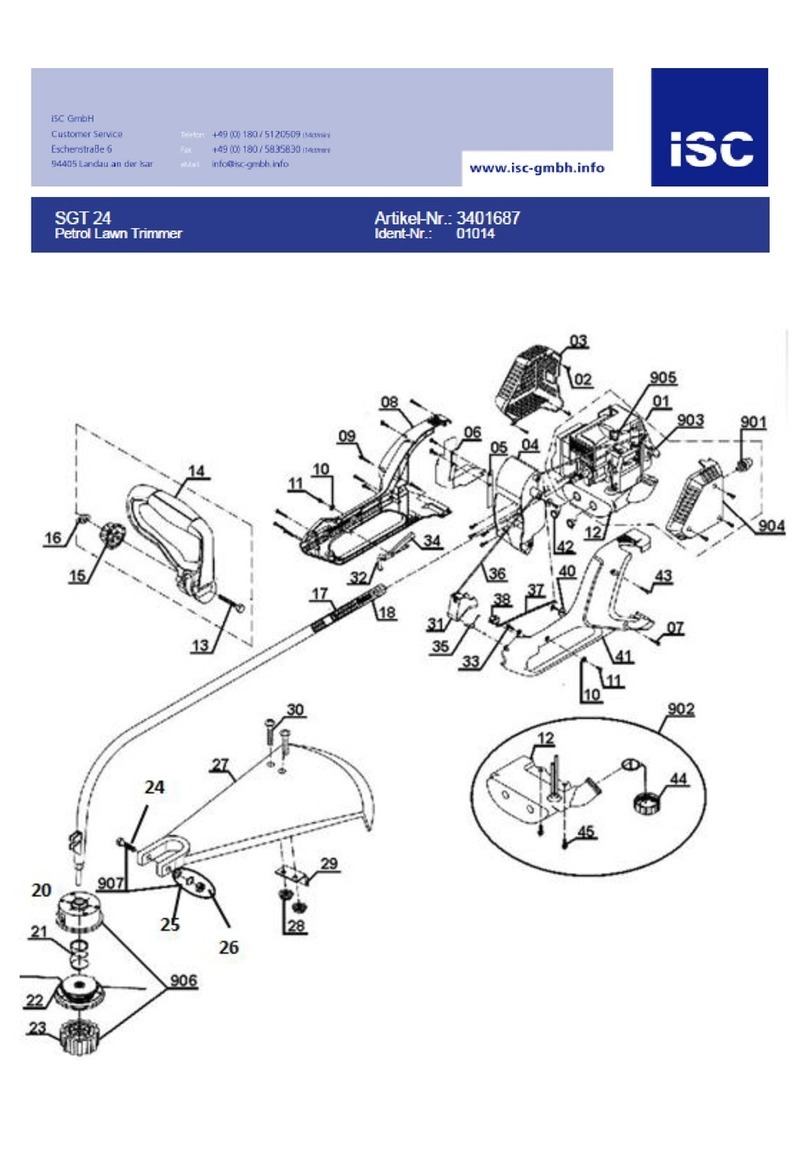

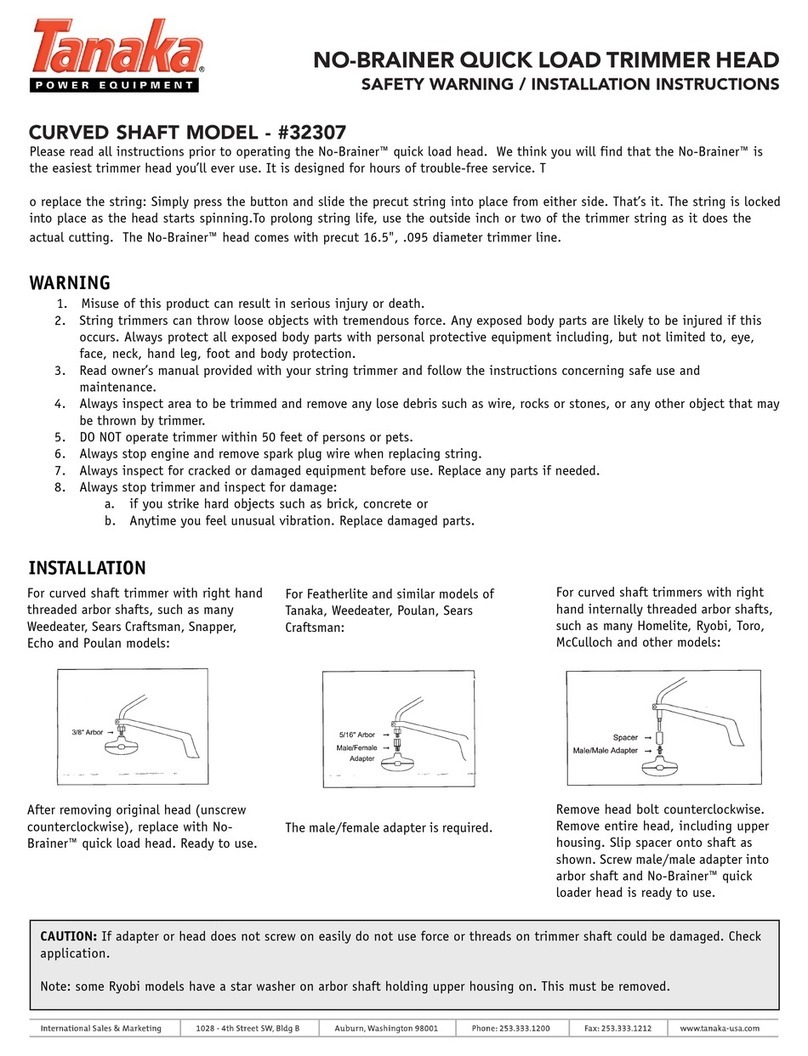

1. Unscrew the retainer screw knob (Fig. N1/Item G) in a

counter-clockwise direction and remove (Fig. N1/N2). If

you fail to do this by hand, use the key (Fig. C/Item 21).

2. Remove the spool (Fig. N3/Item H) and the spring (Fig.

N3/Item I) from the spindle (Fig. N3/Item J).

The following steps only have to be carried out if only the

line and not the entire spindle requires replacing:

• Remove the remaining cutting line from the spool.

• Hold the two halves of a new cutting line together in the

middle and place the loop in one of the slots on the spool

divider (Fig. N4).

• Wind the line with tension in a clockwise direction as

shown in the illustration (Fig. N5), with the two halves

being separated by the spool divider. Wind up all of the

line down to the last 15cm of each end.

3. Fasten each of the ends of the line in a slot (Fig. N6/

Item L) on the opposite side of the spool.

4. Fit the spring (Fig. N3/Item I). on the inside of the spool

and thread each of the ends of the line through one of the

eyelets in the spool holder (Fig. N3/Item K).

5. Insert the spool in the spool holder. Make sure that the

spring slides over the spindle and does not get stuck.

6. Press the spool into the spool holder with your hand

and use your other hand to fasten the retainer screw knob

tightly (Fig. N7).

7. Give each end of the line a strong tug to pull the line out

of the slots.

8. Cut off all excess line to reduce it to approx. 13 cm.

This will reduce the load on the engine when starting up

and warming up.

7.2.2 Maintenance of the air filter (Fig. J1-J2)

Soiled air filters reduce the engine output by preventing the

air reaching the carburettor.

Regular checks are therefore essential. The air filter

should be checked after every 25 hours of use and

cleaned if necessary. If the air contains a lot of dust, the air

filter should be checked more frequently.

1. Remove the air filter cover (Fig.J1-J2)

2. Remove the filter element.

3. Clean the filter element by tapping it or blowing it.

4. Assemble in reverse order.

Please note: Never clean the air filter with petrol or

inflammable solvents. Clean the air filter with compressed

air or by tapping it.

7.2.3 Maintenance of the spark plug (Fig. K1-K2)

Spark plug gap = 0,6 mm. Tighten the spark plug with a

torque of 12-15 Nm.

Check the spark plug for dirt and grime after 50 hours

of operation and if necessary clean it with a copper wire

brush. Thereafter service the spark plug after every 50

hours of operation.

1. Pull off the spark plug boot (Fig. K1) by twisting.

2. Remove the spark plug (Fig. K2) with the supplied spark

plug wrench.

3. Assemble in reverse order.

7.2.4 Grinding the safety guard blade

The Safety Guard blade (Fig. L/Item F) can become

blunt over time. When you notice this, undo the two screws

holding the Safety Guard blade to the safety Guard. Clamp

the blade in a vise. Sharpen the blade with a flat file and

make sure that the angle of the cutting edge is not altered

in the process. File in one direction only.

7.2.5 Carburettor settings

Important. Settings on the carburettor may only be made

by authorized by an authorised petrol repair agent. The

air filter cover must be removed before any work on the

carburettor, as shown in Figures J-J2.

Setting the throttle cable:

If the maximum speed of the machine falls over time and

you have ruled out all the other causes listed in section 9

Troubleshooting, it may be necessary to adjust the throttle

cable.

First of all check whether the carburettor opens fully when

the throttle lever is pressed fully. This is the case if the

carburettor slide (Fig. O1/Item 1) rests against the stop

(Fig. O1/Item 2) when the throttle is fully open. Figure 16

shows the correct setting. If the carburettor slide does not

touch the stop, it must be adjusted.

The following work is required to adjust the throttle cable:

• Undo the lock nut (Fig. O2/Item 3) a few turns.

• Undo the adjusting screw (Fig. O2/Item 4) until the

carburettor slide rests against the stop when the throttle is

fully open, as shown in Figure O1.

• Retighten the lock nut.

Setting the idling speed:

Important. Set the idling speed when the machine is

warm.

If the engine stalls when the throttle is not pressed and

you have ruled out all the other causes listed in section 9

Troubleshooting, the idling speed must be adjusted. To do

this turn the idling speed screw (Fig. O2/Item 5) clockwise

until the machine runs smoothly at idling speed.

If the idling speed is so fast that the cutting tool turns

as well, it has to be reduced by turning the idling speed

screw counter-clockwise (Fig. O2/ Item 5) for as long as is

required for the cutting tool to stop turning as well.

Helpline No. UK 0151 649 1500 / IRE 189 094 6244